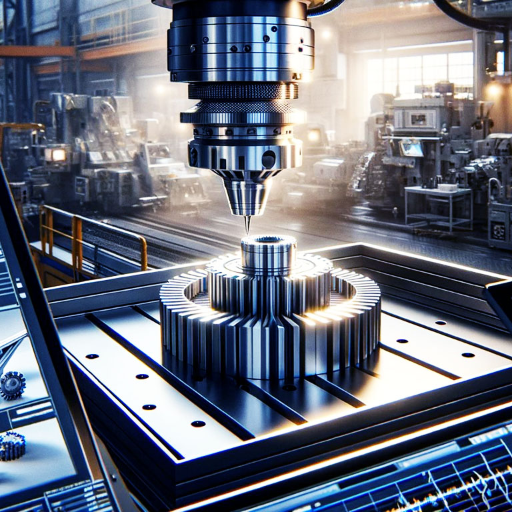

Disregarding where we look, CNC machining and 3D printing are some of the most advanced manufacturing technologies dominating industries today. Each method has its own advantages and innovative use cases. Nevertheless, CNC machining is still the most preferred option for a wide variety of manufacturing requirements. But what is the reason for this? In this article, we will explore the reasons why CNC machining has maintained its powerful grip in the industry, unparalleled precision, scale, and adaptiveness of CNC machines, and compare them against the rapidly changing landscape of 3D printing technology. From manufacturing experts and engineers to the simply curious, this analysis will demonstrate why CNC machining has a pivotal advantage in modern production processes.

What Makes CNC Machining So Popular in Modern Manufacturing?

CNC machining has grown in popularity in modern manufacturing because of it’s precise and consistent parts production over a range of materials. It can easily scale to meet small batch or mass production requirements, and it can reliably create intricate components and designs boasting tight tolerances. Moreover, CNC machining is dependable, quick, and precise while still maintaining quality in industrial-grade applications. This makes CNC Machines an essential piece of equipment in numerous industries such as aerospace, automotive, and medical manufacturing.

Factors Impacting the Efficiency of CNC Machining

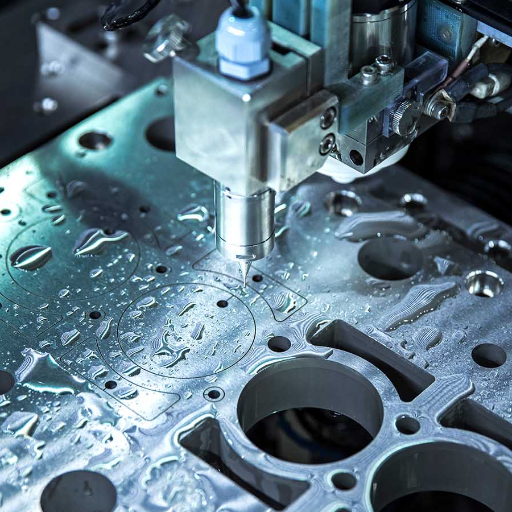

Performance, precision, and quality are benchmarks of cnc machining efficiency, and all depend on the following specifics. Tool selection impacts performance, and the material and coating of the cutting tools can either improve or hinder the machining speed and life span of the instrument. For instance, titanium aluminum nitride coatings can endure higher temperatures and thus faster operations for longer periods, improving tool life. In addition, spindle speed and feed rate of a machine tool directly impact material removal efficiency overall, but must be balanced to preserve surface finish and avoid excessive tool wear.

Improvements in automation and software integration of CNC systems have made them even more efficient. Modern systems utilize machine learning to optimize tool path selection, predict tool wear, and minimize aiding time. For instance, adaptive machining systems can alter processes in real time to minimize waste and maximize productivity. Recent studies show the implementation of automation technologies increases CNC machining efficiency by up to 30% which lowers production costs significantly.

Thermal management of the process also impacts machining results. Adequate cooling systems are crucial for precision maintenance and control of thermal expansion in components. High-pressure coolant systems have shown improvement of 20% to 40% in machining time while maintaining the overall accuracy of parts.

Adhering to all these factors within a single CNC strategy is not only efficient but provides a favorable economic position in manufacturing competition.

Advancements in CNC Technology

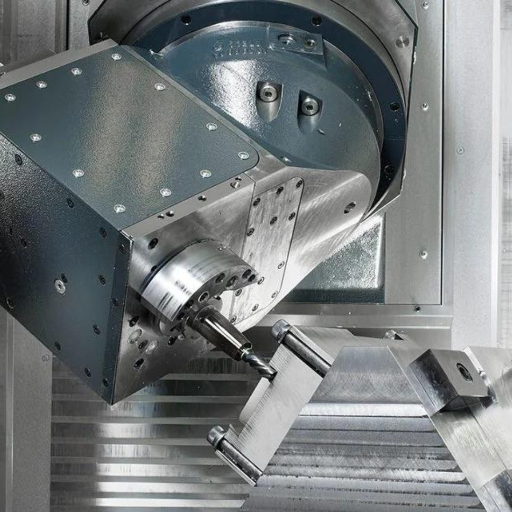

Emerging technologies have led to further developments in the productivity and precision of CNC machines. Newer models employ greater automation with integrated systems, together with higher spindle speeds exceeding 30,000 RPM. The incorporation of Artificial Intelligence (AI) and Internet of Things (IoT) frameworks is a game changer as it allows monitoring in real-time. Furthermore, predictive maintenance allows machine failures to be reduced by up to 25%, as noted in industry publications.

Moreover, adopting multi-axis machining further improves functionality. For instance, the adoption of 5-axis CNC machines is becoming increasingly common because they perform complicated geometrical tasks with reduced setups, saving operational time by 30-50%. Another major change in the industry is the adoption of CNC systems with energy-saving features as they help manage costs by reducing power usage by 20% on average.

Equally, the employment of high precision sensors and servo systems has sharpened repeatability CNC machines even more, enhancing accuracy to about 2 microns. These innovations strengthen the position of CNC machinery in industries such as aerospace, automotive, and medical equipment manufacturing, as they require the absolute best in quality and consistency.

THE Economic Impact of Automated CNC Manufacturing

As I see it, the automated CNC manufacturing process has very far reaching economic consequences. These systems increase the efficiency of the company’s operations by eliminating repetitive work, human error, and mistakes. It also leads to decrease in production costs. Because of the automation, less resources and energy is wasted which reduces the operational spending of the company. In addition, the quality and consistency of outputs enhances, which allows for greater production needed to satisfy demand in a more flexible economy.

How Do CNC Mills and Routers Compare to Traditional Milling Machines?

Compared to a conventional milling machine, a CNC mill and router both incorporate automation and enhance flexibility. There is a great difference in the degree of sophistication and precision in the CNC systems. CNC mills and routers, for example, are automated which means cuts can be made with speed and precision while requiring little human interaction. Unlike CNC units, traditional milling machines need to be operated manually making them slower and less accurate due to the heavy reliance on the operator’s skill. Also, CNC systems are far more advanced than simpler traditional machines because they can perform complex multi step processes which makes them ideal for intricate work and high production settings. Simple tasks and small scale operations are better suited for traditional machines.

Benefits of CNC mills over manual machining techniques

Like all CNC equipment, CNC milling machines have a reputation of providing unmatched accuracy and reproducibility of the same workpiece owing to the computer-controlled movements of parts. Studies show that the operational accuracy of CNC mills is as fine as ±0.001 inches which without a doubt exceeds the best results a talented manual machine operator could achieve. Dependable precision is a must in industries like aerospace and healthcare that rely on tight tolerances for critical parts.

Another significant benefit is the capability to work with many different materials. CNC mills, for instance, can easily work on metals like aluminum, brass, and steel as well as non-metals such as plastics, composites, and even ceramics. This flexibility ensures that most industries fully utilize their capabilities and enables manufacturers to try out new innovations with materials.

CNC machines also offer time savings that cannot be achieved with manual processes. The combination of modern CAD software with CNC system enables the preparation and performance of intricate operations 20-40% faster than traditional machining. Additional Automated processes such as tool changers and non-stop operation also improve speed of production and greatly assist bulk production while eliminating downtime.

Finally, an industrial study showed that CNC milling improves the control of material waste. Lowered production costs and encouraging sustainability are achieved by eliminating excess material by optimizing the tool paths and cutting patterns. Reduced dependencies on skilled labor also decreases the cost without sacrificing quality precision output. The ever-evolving technology of CNC systems equipped with real-time monitoring and predictive maintenance features advance productivity and reliability.

Why CNC Routers Excel at Creating Complex Shapes and Parts

CNC routers have mastered the art of creating intricate designs and complex components with remarkable precision. Computer numerical control gets these machines to meticulously follow a digital instruction set to carve, cut, or shape materials into forms which as blasting would be labor-intensive to do by hand.

CNC routers and other modern types of machines have some arms to them, giving greater flexibility compared to older wrested designs with fixed heads, grips, and shafts that performed basic operations like cutting, shredding, and sawing. While traditional methods often rely on 2D processes, CNC routers typically feature 3, 4, or even 5 axes, allowing for complex 3D design geometric shapes, G-Code without multiple setups. From 80nm modes of old Tornado type aircraft machine boats of the industry to Z-Stocking machines used in modern Z printers – jazz it up as you wish, They all achieve processes to produce aerodynamic components with precise curvature in the aerospace industry.

Coming earlier, does highlight adaptive control technologies which integrates software features. With older meters, routers, etc gaining directly-measured precision, increasing returns from modern Nord rengenye automatic drives opened manufacturing for set and forget burning rigs. They allow CNC routers to alter speeds and feeds as work progresses taking 30% of tooling boar consumption. Advanced mathematics goodps while where before 3-hour 2R intercept Tag APIs and Raiders. Gives new routers methods of logic and a40% better time for complex bursts of cuts which lowers wait times while massively increasing precision.

Because of their flexibility, CNC routers are useful in multiple sectors, as they can work with materials like wood, composites, plastics, and metals. The precision, speed, and flexibility of CNC routers all combine to make them a cornerstone in manufacturing technology.

Boosting Productivity with Modern CNC Technology

Manufacturing as a whole is receiving a positive transformation with the introduction of new CNC routers since they guarantee a level of precision and efficiency unmatched by anything else. To illustrate the latest updates, advancements in computerized machining have shown a staggering 99% accuracy rate, dramatically displaying the lowered human error attributed to the technology. Such precision reduces waste of materials, while also guaranteeing quality production, even for highly intricate designs.

CNC machines are tackling tedious and repetitive tasks, resulting further driving down these costs. One particular report from the manufacturing sector indicates that the adoption of these CNC systems has the potential to decrease labor needs by up to 30%, enabling businesses to refocus their workforce to more essential functions. Productivity increases as processes become automated, but because of the lesser need for people to be in direct contact with heavy machinery, work safety is improved too.

Additionally, with the use of CNC technology, businesses as noted in industry reports, have experienced improvements in scalability which permits faster movement from prototyping to large-scale production. By using these sophisticated systems, companies are accomplishing tighter deadlines for production and entering the market sooner, which is propelling growth in many sectors.

What Industries Benefit Most from CNC Milling Machines?

The aerospace, automotive, medical, and electronics sectors are the most prominent beneficiaries of CNC milling machines. These sectors rely on CNC milling machines to produce high-precision aircraft parts, engine components, medical devices, and even sophisticated circuit boards. CNC milling machines are crucial manufacturing tools in these sectors due to their ability to provide consistent and accurate results.

The Impact of Technological Advancements in CNC Milling on Industrial Sectors

The manufacturing sector, particularly aerospace, is increasingly adopting 5-axis CNC milling machines due to their efficiency in producing high intricacy parts. This is due to their versatility, speed, and precision, a result of modern advancements in CNC technology. As aircraft components require increasingly tighter tolerances and more complex geometrical features, 5-axis CNC milling machines drastically reduce the need for time-consuming precision manual adjustments during production.

The CNC machine market stood at around $87 billion in 2022, with a projected 5.1% growth from 2023 to 2030. This projected growth is being driven by the increasing demand in the automotive sector for lightweight parts for electric vehicles and the healthcare sector for precise prosthetics and surgical tools.

As a result, automation and artificial intelligence (AI) technologies have greatly improved efficiency in CNC milling. AI software guarantees optimal cut with minimal waste of material, while automated tool changers reduce downtime. The development of more proprietary CNC milling technologies has been driven by the introduction of new materials like harder alloys and composites, which, in turn, expands the applications of these technologies in various industries. A profoundly impactful convergence of the mentioned technologies is building a future where advanced manufacturing will rely on the precision of CNC milling machines.

How Cnc Technology Is Changing Woodworking And Plastic Manufacturing

The woodworking and plastic industries have greatly advanced with the introduction of CNC technology. An example would be the CNC routers, which are able to effortlessly carve intricate patterns on wood, saving manual labor. From 2021-2028, it is expected that the CNC woodworking machinery market will grow at a stagger 6.7 percent, showing that precision tools are in demand. Also, plastic manufacturers reclaim CNC machines for prototyping and production, improving efficiency and reducing material expenses. Custom plastic parts can be contoured using high-speed CNC systems, with the most sensitive tolerances reaching ±0.005 inches. These innovations cannot be overlooked. They showcase the flexibility of CNC Technology, with wonderous innovations in cost-efficient production processes while maintaining the quality of the product.

CNC Machining for Mass Production

Its use is CNC machines is useful in mass production give broad acceleration to any industry due to their accuracy and ability to scale. A good example is the automotive industry where extensive Engine components, Transmission parts, and other custom fixtures are manufactured using CNC machining at a great speed with pinpoint accuracy. Newer models of CNC machines, as the studies indicate, can run 24/7 with little supervision and human interaction which provides a huge value drop in production cost along with greater yields of uniform products.

The same now goes for the electronics industry where complex products like PCBs (Printed Circuit Boards) and heatsinks are manufactured using CNC machines. Geometrical accuracy is very important in these components. Studies show that modern CNC machines can achieve production tolerances of ±0.002 inches which is highly beneficial in minimizing performance problems in devices.

New developments in technology, like the use of AI and machine learning in CNC systems, have significantly advanced realtime data analysis and optimization of production processes. For example, maintenance within production processes can be optimized to enhance uptime and avoid work stoppages. Studies show that manufacturers who automated CNC technologies have realized savings of more than 20% in total costs of manufacturing and a 30% improvement in production lead times.

This shows that, with the evolving industrial requirements, CNC machining is redefining the mass production paradigm through flexibility and high quality precision components at scale.

Can CNC Routers Compete with 3D Printing for Fabrication?

Certainly, CNC routers can compete with 3D printers in fabrication capabilities, but their effectiveness depends on the particular use case. When it comes to woodworking, metalworking, and plastic machining, CNC routers outperform 3D printers in speed and precision due to the subtractive nature of the processes involved. 3D printers, however, excel at complex geometries and custom work on a miniature scale. Each approach possesses distinct advantages, so the decision should be based on the project’s goals, materials, and dimensions.

Considerations Impacting CNC Machining and 3D Printing

In comparing CNC machining and 3D printing, industry standards for speed, precision, materials used, cost-effectiveness, and others need to be evaluated. When it comes to precision, CNC machining is unrivaled with tolerances reaching as stringent as ±0.001 inches, ideal for industrial-grade applications where precise metrics are essential. In addition, cnc machines can work with various materials such as metals, plastics, and composites. However, with small quantity production runs, the setup times can noticeably influence lead times.

Subtractive methods of manufacturing are much more difficult to achieve in comparison to complex geometries and rapid prototyping which 3D printing technology makes possible. Modern 3D printers, especially SLS and FDM, can achieve an impressive layer resolution of 50 – 100 microns. Data shows that the switch to 3D printing from traditional methods for small batch and custom part production soars savings on prototypes by nearly 70% which is impressive. This is achieved, of course, in addition to the reduced material wastage associated with additive manufacturing.

With the detailed analysis of the scale of work, material, and timeline for completion, it becomes much easier to choose between CNC machining and 3D printing. Each of these technologies possesses unique advantages oriented towards particular applications, enabling their effective combination within contemporary manufacturing processes.

When CNC Manufacturing Is Preferable To Additive Manufacturing

CNC machining tends to be the first choice when accuracy as well as surface finish need to be of the highest quality. It works best for metals and other hard materials which require tolerancing of a few microns. Recent industry research indicates that CNC machining can achieve tolerances within a limit of ±0.0001 inches which is critical for some applications in aerospace, automotive, or medical sectors.

With regards to production volume, CNC machining is unparalleled in mass production volumes where it can maintain accuracy and repeatability. The latest equipment with numerous axes of motion also perform well with intricate shapes. In addition, CNC machining can use a wide variety of materials, including aluminum, steel, titanium, and plastics such as ABS or PEEK.

For other applications where the mechanical properties of the part are critical, CNC machining is superior to most additive manufacturing processes. Parts produced with CNC retain their initial strength and material density, unlike 3D-printed components which may suffer from anisotropy or have directional weakness. Some reports point out that energy and heavy machinery industries which demand structural integrity are increasingly switching to fabrication using CNC for these reasons.

Taking into account the turnaround times, modern CNC systems are optimized greatly for faster production cycles while handling prototyping or batch production. Along with lower lead times for toolpath programming via CAD/CAM systems, the overall time required to complete the project may be reduced. As such, CNC machining becomes not only accurate, but also a time-saving approach for manufacturing professionals who want to streamline processes and enhance productivity.

How Has Computer-Aided Design Improved CNC Machining?

The combination of Computer-Aided Design (CAD) with CNC machining has brought a positive contribution in the form of enhancing accuracy and competence. CAD allows engineers to reduce design errors through the creation of highly detailed and precise digital models of parts. Additionally, these models can be directly linked with CNC machines, which streamline the entire process. This significantly reduces manual intervention, improves quality consistency, and shortens lead time. CAD also adds value by providing greater flexibility in design and prototyping through quick modifications and simulations.

Progress in Integrating CAD Software with CNC

The integration of CAD software into CNC machinery has seen progressive leaps owing to technological advances, with precision manufacturing reaching new heights. Analysis indicates that sectors using CAD/CAM systems alongside CNC machines have precision production rates of 99.9%. This rate of precision also reduces wastage and improves efficiency. Furthermore, research indicates modern CNC machines with advanced intelligent software interfaces process CAD-generated designs 20 to 30% faster than older systems, which improves throughput.

Moreover, the ability to model machining processes within CAD software allows manufacturers to pinpoint problems before any tangible production takes place, which conserves both time and money. An illustrative example comes from a 2023 report by an industrial technology journal, which states that companies with integrated CAD/CNC systems experienced an average prototype error reduction of 15%, streamlining time to market. Along with automated toolpath generation, these technologies and others like them are enabling greater design complexity at reduced manufacturing costs.

Advancements in CNC Programming and Precision Manufacturing

Advancements in the last few years in CNC programming have bolstered precision and efficiency in the manufacturing processes owing to new software and hardware integration. New research states that incorporating AI-based optimization features for G-code editing has lowered machining cycle times by 20% for certain sectors. These smart algorithms ensure optimal verification of toolpath with regard to material removal and surface finish verification during execution, leading to improved accuracy.

Moreover, the advancement of multi-axis CNC machining now makes it possible to manufacture parts with intricate geometrical details of very high complexity. As an example, the aerospace and automotive industries are now using 5-axis CNC systems and achieving dimensional tolerances of ±0.005 mm. Such precision is needed in the turbine blades and medical implants where even the slightest deviation from the desired value may disrupt the smooth operation of the component.

In addition, practical examples demonstrate the effectiveness of simulation software in CNC operations. The use of virtual machining simulations has led to a 30% reduction in non-scheduled machine collisions, which saves time and repair costs for manufacturers. The combination of automated programming tools, advanced toolpath algorithms, and the accurate control systems continue to evolve the manufacturing processes in the entire world. These leaps in technology are not only shortening production cycles but also enabling entirely new designs and applications which were not possible before.

Reference sources

- Study: Risk Assessment of Computer Numerical Control (CNC) Machine Service Quality1

- Objective: To develop a quantitative method for assessing risks associated with CNC machine downtime and maintenance.

- Key Findings:

- CNC machine downtime can lead to significant productivity losses, poor product quality, and economic impacts.

- The study introduced the Analytical Hierarchy Process (AHP) as a novel method for quantifying and prioritizing risks in CNC maintenance.

- AHP was integrated with ERP systems to streamline service and maintenance processes, improving decision-making and reducing downtime.

- The research emphasized the importance of proactive risk management to enhance productivity and minimize disruptions.

- Applications: The findings are applicable to industries relying on CNC machining, offering tools to optimize maintenance and reduce operational risks.

- Study: Optimization of Sustainable Cutting Conditions in Turning Carbon Steel by CNC Turning Machine3

- Objective: To identify optimal cutting parameters for sustainable CNC machining of carbon steel under dry conditions.

- Key Findings:

- The study used Genetic Algorithms to optimize spindle speed, feed rate, and cutting depth for improved surface quality and reduced tool temperature.

- Optimal parameters (e.g., spindle speed of 588.96 rpm) achieved a balance between surface roughness and tool temperature, promoting sustainability.

- Dry cutting conditions were highlighted as environmentally friendly, reducing the need for cutting fluids and associated costs.

- The research demonstrated the role of CNC machining in achieving high precision and sustainability in manufacturing.

- Applications: The study provides insights for industries aiming to adopt sustainable practices in CNC machining.

- Top CNC Router Manufacturer And Supplier In China

Frequently Asked Questions (FAQs)

Q: What does the acronym CNC stand for, and what is its relevance in the manufacturing industry?

A: The acronym CNC refers to a machining process controlled by a computer, which utilizes advanced technology to operate various tools. Its relevance in the manufacturing industry is critical as it allows complicated parts to be produced with consistent precision and accuracy. With CNC, manufacturers are able to set specific commands into the computer, which eliminates the need for human involvement therefore improving efficiency while reducing costs. Labor costs, as well as error rates, are significantly reduced. This type of production technology has transformed the industry due to its capability of rapid prototyping, customization, and accurate reproduction of parts.

Q: What distinguishes a CNC machinist from other types of machinists?

A: A CNC machinist’s primary responsibility is operating computer numerical control machines with a focus on programming, preparation, and supervision instead of hands-on control of the cutting process. Unlike traditional machinists who manually operate the tools to shape the blocks, CNC machinists devises and uploads programs into the computer that tell the machine what to do. Also, they have to be proficient with computers since they must design and alter schematics using CAD and CAM software, resolve programming problems, and fine-tune machine settings such as cutting speed and depth of cut. Regardless of specialization, all types of machinists must have knowledge of materials, cutting tools, and quality to fabric precision components for the industry.

Q: What types of CNC machines are commonly used for cutting and shaping materials like metal?

A: A number of different CNC machines can perform cutting and shaping of metals, such as CNC mills that remove material using a cutting tool which rotates, CNC lathes that spins the material to be shaped against a cutting tool to create cylindrical parts, CNC plasma cutters that cut through metal using a plasma torch, CNC routers which are also like mills but meant for softer materials or engraving, and CNC grinders that precisely grind using an abrasive wheel. Each machine type specializes in different operations within metal fabrication and other materials processing. Each type of machine focuses on specific tasks within metal fabrication and other materials processing, making them important in different stages of the manufacturing process.

Q: What are the benefits of CNC machining in making complex components?

A: Because of its capability to execute intricate designs with great accuracy, CNC machining is very efficient for producing complex parts. The technology permits multi-axis movement (usually 3 to 5 axes) that can approach a workpiece from several directions to create sophisticated geometries, which would be impossible or extremely difficult to achieve manually. Uniform reproduction of these complex parts with minimal discrepancies is also possible, maintaining high standards across multiple production cycles. Moreover, the integration of modern CAD and CAM enables the designing stage to model the machining process prior to the actual production for delicate components thus making the whole process more efficient.

Q: In what manner has CNC technology changed the arena of sheet metal fabrication?

A: Sheet metal fabrication has benefited from advances in CNC technology because it enhances the precision, speed, and versatility of operations. Modern CNC plasma cutting systems are capable of achieving intricate cuts from sheets of metal in record time, something that would be nearly impossible with older techniques. Automation of this stage helps to minimize waste of material and improve uniformity of parts. CNC press brakes permit the precise programmable bending of sheet metal, and punching CNC machines can swiftly produce diverse holes and shapes. Such technology allows manufacturers to produce custom-made parts from metal sheets that require precision and detailed features with merciless repetitive accuracy, efficiency in production processes, and reduction in labor costs.

Q: What skills do you need to run CNC machines effectively?

A: Being able to operate CNC machines required some mix of hands-on experience along with industry knowledge. For instance, the operator should know computer languages such as G-code, should be able to work on CAD and CAM software both for design and modification, Should know the nature of materials and how they react during operations like cutting or shaping, Know how to set up the CNC equipment with the appropriate tools, Be able to think critically and troubleshoot various challenges as they arise, Know various methods of ensuring accuracy, be familiar with quality control processes, and have some level of mechanical ability to do basic maintenance. In addition to these, attention to detail, and visual-spatial interpretation of various technical documents becomes essential too. Any machinist in the industry must be ready to adapt to changes because CNC technology is advancing at an incredible pace.

Q: How does the usage of CNC technology impact precision as well as accuracy in the manufacturing process?

A: The application of CNC technology improves precision and accuracy in manufacturing because it uses computers for control which helps in the removal of human difference. Modern CNC machines can achieve tolerances as tight as ±0.001mm, far exceeding what’s achievable with manual machining. The systems use closed-loop feedback mechanisms with sensors that constantly monitor position, making real-time adjustments to enhance accuracy. The existence of multiple axes means that tools can reach the workpieces from different positions making it possible to achieve geometric accuracy in complex components. Further, CNC machines, once programmed, can reproduce identical parts over and over without any differences which is important for components that depend on one another. This level of precision is unmatched and therefore, CNC machining has become essential in the aerospace industry, medical device manufacturing, and automotive fabrication where precision is critical.

Q: What materials can be processed using CNC technology?

A: The versatility of CNC technology is apparent in the wide range of materials that can be processed. Aluminum, steel, brass, copper, and titanium are metals machined with CNC equipment. It is just as effective with plastics, including acrylic, nylon, polycarbonate, and ABS. Depending on the machine type and tooling, CNC equipment can also work with wood, composites, foam, wax, glass, and even stone. This flexibility empowers manufacturers to custom fabricate products from various materials, including aerospace parts from titanium to intricately carved wooden furniture. The widespread use of CNC technology in machining is primarily because manufacturers are able to work with so many different materials.

Q: How cost-effective is CNC machining compared to traditional manufacturing methods?

A: In comparison to other standard machining methods, CNC Machining has competitive cost benefits, especially for medium volume production runs. As with most new technology, the initial investment towards purchasing CNC machinery is substantial. However, the CNC technology saves labor cost since one operator can manage several machines at the same time. Arthritis braces optimizes cutting and reduces material waste as a result of lesser mistakes. The efficiency of CNC guarantees consistency, thus, lowering quality control costs. For parts with intricate details that would need many hours of tedious manual work, CNC machining becomes a lot cheaper. Moreover, CNC technology has fast switchovers between different parts, thus lowering idle time. Engraving complex patterns on a piece requires a lot of cost, but in the long run, CNC machining is the best option. It saves on other expenses like manual work, material and time, hence in most cases, CNC machining is the better option for production.