Researching the special qualities of elements on the periodic table unlocks extraordinary glimpses into the world around us—especially when it comes to extremes. Among these characteristics, melting points stand out as a remarkable measure of a metal’s strength when subjected to intense heat. Do you know which metal The champion for the highest melting point ever recorded? Prepare to uncover the melt point of metals and their influential factors, along with the science supporting the phenomenon. By the end of this post, you’ll know the title holder who stands proud as The Ultimate Lord of Melting Points, alongside the chemistry and practical applications that makes this medal so special.

What is the Highest Melting Point of a Metal?

Tungsten has the highest melting point of any metal, melting at 6,192 °F (3,422 °C). Its exceptional heat resistance makes it an invaluable asset in aerospace, electrical, and manufacturing industries.

Grasping Melting Points and Their Significance

When examining a metal’s melting point, its practical use in an industry is questioned. Tungsten is a unique metal as it is able to stand extreme temperatures with a melting point of 6,192 °F (3,422 °C). For this reason, tungsten is able to keep its form structurally during tough conditions which makes it useful for rocket engine nozzles, furnace heating elements, and light bulb filaments.

Reasons why a Metal’s melting point is High

Some of the reasons that determine the melting point of a metal are the atomic arrangement, degree of bonding, and electron makeup. Metals that possess strong metallic bonds and due to the electrostatic attraction of charged ions and sea of delocalized electrons and tend to be higher. The density of atoms and arrangement in crystal lattice also contributes to the ability of a metal to withstand extreme temperatures.

For example, tungsten’s melting point is one of the highest among metals due to its strong metallic bonds and its tightly packed body-centered cubic (BCC) crystal structure. Tungsten also has a tensile strength of approximately 1510 MPa, enabling him to withstand extreme operating temperatures. In comparison, aluminum and other metals with weaker bonds and a lesser complex atomic structure have significantly lower melting points, roughly 660.3 °C (1,221°F).

Moreover, materials can now be engineered and designed to optimize melting points and material properties. For example, adding carbon to iron increases enables mid-range temperature melting and doubles its strength making it ideal for industrial materials used in construction and manufacturing. Knowing these factors is critical for designing materials that are meant to reliably endure extreme temperatures.

How Does Tungsten Compare with Other Metals

Tungsten is well-known for some of its properties, particularly its melting point. It has the highest melting point of all metals known to man at 6,192 °F (3,422 °C). When compared to iron (2,800 °F / 1,538 °C) or aluminum (1,221 °F / 660.3 °C), tungsten’s melting point is significantly higher than both. Further, tungsten’s tensile strength and resistance to thermal expansion make it an exceptional metal for components designed to withstand extreme temperature changes without structural alteration.

Moreover, tungsten’s density is noteworthy compared to other metals. It is almost equal to gold, at about 19.3 g/cm³, which puts tungsten alongside aluminum (2.7 g/cm³) and even medium density metals like iron (7.87 g/cm³). Alongside other metals, tungsten’s high density and temperature resilience make him indispensable in aerospace, military, and electrical engineering industries. Tungsten is widely employed in making filaments used in incandenscent light bulbs, parts of rocket engines, and protective shields against radiation.

Though tungsten retains its worth for being durable and heat resistant, it is rather brittle when in its pure form which creates difficulties during manufacturing processes. As such, alloys like tungsten carbide are designed to balance hardness with machinability. Tungsten carbide in particular is widely accepted for use in manufacturing cutting tools and parts designed to withstand extreme conditions because of its unforgiving hardness and strength under stress. This versatility emphasizes the reason why tungsten is still used an industrial material in high-tech and traditional applications.

Why Does Tungsten Have the Highest Melting Point?

Tungsen is the highest melting point metal with a thermos-setting point of 6,192°F (3,422°C) due to its strong atomic bonds. Its bonds appear to be intertwined arm in arm due to strong metallic binds that require to be seperated through extreme measures of heat. The Tungsten’s atomic number and dense electron cloud gives it’s metals flexibility and thermal stability.

The Role of Atomic Structure in Tungsten’s High Melting Point

Tungsten’s atomic structure and electron arrangement gives rise to the extraordinary melting point. The period table group and period is 6 & 6 respectively giving atomic number as 74 which also falls in group D. The Circle of dense ionic nucleus combined with ionic clouds boosts applied heat gives direct return of thermal attributes. Of note is the group of five d-nucleons and two s-nucleons as they constitute solid metallic atoms with stability straining to extreme energies to set free.

Further working on the approximate crystallization of tungsten gives it’s structure to be body center cubic which helps improve the bonding and offers the thermal and mechanical strength resistance. Several research have measured cohesive energy of tungsten to about 8.9 eV/atom making him able to withstand abuse of extreme temperature increase.

In practical applications, industries that require resistance to heat have used tungsten due to its high melting point. For example, tungsten can be used in light bulb filaments, aerospace power systems, and furnace heating elements. Its strength at high temperatures (over 1,204 °C/2,200 °F) makes it useful for extreme heat applications, including arc welding and radiation shields.

Comparing Tungsten with Hafnium and Other Metals

Tungsten, hafnium, and other metals like titanium, molybdenum, and tantalum are compared based on properties such as melting point, density, tensile strength, thermal conductivity, and corrosion resistance.

| Property | Tungsten | Hafnium | Titanium | Molybdenum | Tantalum |

|---|---|---|---|---|---|

| Melting Point | 3,422°C | 2,233°C | 1,668°C | 2,623°C | 3,017°C |

| Density (g/cm³) |

|

|

|

|

|

| Tensile Strength | Very High | High | Moderate | High | High |

| Thermal Conduct. | High | Low | Moderate | High | Low |

| Corrosion Resist. | Low | High | High | Moderate | High |

How Do We Measure the Melting Point of a Metal?

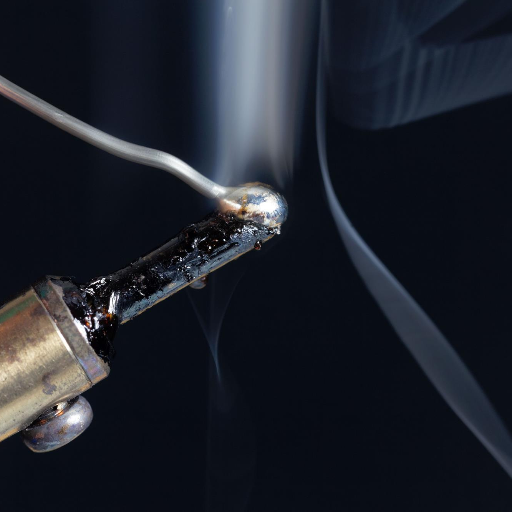

Identifying the melting point of metals goes hand in hand with thermal analysis which is a systematic approach for determining a metals melting point. In particular, one can simply place the metal sample under direct heating while its temperature is being recorded. When the temperature reaches the point at which the solid metal ceases to exist and the liquid phase appears fully, that temperature is taken as the melting point. More accurate measurements however could be done with precision instruments such as differential scanning calorimeters. By controlling factors such as contamination and uneven heating, accuracy is substantially elevated when implemented with precision instruments.

Procedure and Equipment for Determining Melting Points

The number of procedures and equipment for determining melting points is vast, often diverging from the necessary accuracy to the kind of material in hand. One of the most accurate methods that is relatively simple is the capillary tube method. In this method a thin glass tube is filled with the material which will be heated slowly increasing temperature and observing the phase transitions. Because of its accuracy, this method is common in laboratories where simpler and faster procedures are desired.

Another sophisticated method is differential scanning calorimetry (DSC), an exact method of thermal analysis. DSC assesses the rate of heat flow for a given phase change of matter and provides accurate melting point information while considering the heat absorbed or released. This method is best in situations where a high-level accuracy is needed, or in cases where only a small amount of samples are available.

Also, more recent optical techniques like thermal imaging can be used. Using cameras and infrared sensors, these techniques monitor the melting process and provide real-time results. Each method has its own distinct strengths, which makes it useful in many different cases in both research and industry.

Why the Celsius and Fahrenheit Scales Matter

Celsius and Fahrenheit are perhaps the two most popular temperature scales, each fulfilling its purpose in different parts of the world and in industry sectors. In most countries and in scientific environments, the Celsius scale is used, with the freezing point of water at 0° and its boiling point at 100° under standard atmospheric pressure. On the other hand, Fahrenheit is used in the United States and a few countries in the Caribbean, where water freezes at 32° and boils at 212°.

A salient difference among these scales is the increments—1°C equals 1.8°F. For instance, the normal human body temperature is about 37°C which is equal to 98.6°F and a typical room temperature of 20°C is equal to 68°F. This exemplifies the fact that each scale is designed to suit a particular preference which is usually cultural or practical in nature.

As per the most recent information, there seems to be a global inclination towards the Celsius scale for scientific purposes, as well as for communication. For example, about 95% of the world’s population resides in areas that predominantly use the Celsius as the main unit of measuring temperature. On the other hand, Fahrenheit is still very much needed in numerous fields within the United States, from the weather forecast to cooking temperature. Especially in terms of meteorology, engineering, and international trade, understanding and working with both scales is a must for effective collaboration across borders.

What Are the Boiling Point and Melting Temperatures of Various Metals?

- Aluminum: Melting point – 660 °C (1220 °F); Boiling point – 2470 °C (4478 °F)

- Copper: Melting point – 1085 °C (1985 °F); Boiling point – 2562 °C (4644 °F)

- Iron: Melting point – 1538 °C (2800 °F); Boiling point – 2862 °C (5182 °F)

- Gold: Melting point – 1064 °C (1947 °F); Boiling point – 2856 °C (5173 °F)

- Silver: Melting point – 961 °C (1762 °F); Boiling point – 2162 °C (3924 °F)

Periodic Table Insights: Order of Melting Points

While studying elements on the periodic table, the melting points generally fall into a diverse spectrum due to atomic bonds, structures, and various other reasons. Here is a summary of some relevant elements along with their melting points, organized for better understanding:

- Tungsten (W) – Melting point of 3422 °C (6192 °F). Tungsten lightbulb filaments are used for high-temperature applications and hold the highest melting point of all elements at filament of industrial furnaces.

- Rhenium (Re) – Melting point of 3186 °C (5767 °F). Rhenium’s heat-resistant superalloys make it well known for its rarity and are used in jet engine parts.

- Osmium (Os) – Melting point of 3033 °C (5491 °F). This corrosion-resistant alloy dense, Os, specializes in dense metals has specialized alloys and electrical contacts.

- Carbon (C) (in Graphite Form) – Under intense pressure, its melting point is around 3550°C (6422°F). Carbon’s cost effectiveness allows it to be utilized in industries such as metallurgy and electronics.

- Iron – Melting point of 1538°C (2800°F). Iron’s economy and versatility along with some other properties, makes it extremely useful for construction and manufacturing purposes.

- Gold – 1064°C (1947°F) is the temperature with a melting point. Apart from being cosmetically appreciated gold is also used in electronics due to its properties of conduction and resistance to tarnish.

- Lead- Like carbon, lead has relatively low melting point given its 327.5°C (621.5°F). This trait allows lead to be utilized in soldering, batteries, and radiation shielding.

Insights on Metals Used at Elevated Temperatures

Understanding aerospace and electronics industries, as well as the construction of machinery and tools, requires high-temperature applications of metals. Tungsten, for example, has unrivaled advantages. Not only does it serve as an element for alloy construction, but also as the filament in lightbulbs due to it’s ability to withstand temperatures above 30000C (6112F) without melting. Its powerful usage makes tungsten invaluable and acquiring with additional expenditures permits the aviation industry to fil continuously shaped pieces. Beyond that, the giant plastic deformation of tungsten permits applications in extrusion. Moreover, turbines and power plants use stainless steel and nickel based-Al super alloys. These transformable alloys + other metals create super strong mechanical structures enabling engineers to work at extreme temperatures. Different spheres of science and engineering stimulate the passiob for creation which deeply advances and improves various fields.

Unlike other metals, tin, lead, and zinc are unique because they can be used in certain applications, as they have a lower melting point. Lead has a melting point of 327.5°C (621.5°F) and is often used in radiation shielding, rechargeable batteries, and some alloys. In addition, tin has a much lower melting point than gold, soldering gold is very expensive, as lead tin solder is a great alternative. Zinc, which has a melting point of 419.5°C (787.1°F), is used in galvanization to help prevent corrosion to steel and iron.

Traditionally, low temperature metals like tin were overlooked due to a lack of understanding regarding their melting point. Zinc is now widely known to increase the durability of construction material, while tin serves a major purpose in the soldering connections for electronics. Moreover, with the use of advanced metallurgy, the efficiency and lifespan of lead acid batteries has been improved. This only portrays how important low temperature metals like tin are for multiple industrial purposes.

How Do Metallic Bonds Affect the Melting Point of a Metal?

Metallic bonds influence the melting point of a metal by how the metal atoms are held together. Metals with stronger metallic bonds, such as a greater amount of shared electrons, tend to have higher melting points because more energy is required to break these bonds. On the other hand, weaker metallic bonds tend to have lower melting points because of the reduced energy needed to break apart the atoms.

Exploring the Structure of Metallic Bonds

A metal’s melting point is mostly determined by its metallic bonds, which consist of a lattice of positive metal ions and a sea of electrons that can move freely. More electrons in bonding means stronger transitions metallic bonds which results in stronger bonds. A great example of this is Tungsten, it has a great amount of shared electrons making it one of the highest melting point metals. Alkali metals, however, tend to have weaker metallic bonds because they have less free electrons which results in lower melting points. Therefore, the strength of the metallic bonds correlate to the melting point of the metal.

How the Metal Lattice Structure Affects the Melting Point

Metallurgical lattice structure directly influences the melting points of metals. In general, metals with packed atomic structures and tighter bond arrangements exhibiting stronger metallic bonds will have higher melting points. Consider transition metals like tungsten and molybdenum. The extension of d-electron bonding within their closely packed lattice contributes to their exceptionally high melting points. Quite significantly, tungsten has a melting point of nearly 3422 °C which is one of the highest in the periodic table.

On the other hand, alkali metals such as lithium, sodium, and potassium have weaker metallic bonds which, in conjunction with more loosely packed atomic structures, greatly reduces melting points. Lithium has a melting at approximately 180.5 °C while sodium and potassium follow close at 97.79 °C and 63.5 °C respectively. This shows the metallic lattice’s structure strength directly impacts the amount of thermal energy required to disrupt it.

The most recent studies also tell us that there is a relationship between lattice defects and melting points. Within the metallic lattice, impurities or dislocations are certain factors that can considerably alter a metal’s melting point. An example of this is carbon’s addition to iron which results in the formation of steel alloys. These steel alloys have melting points of 1370°C to 1510°C depending on carbon concentration and lattice changes introduced.

These alloying principles in materials science and engineering serve as educational resources in understanding how the melting points of metals change in relation to the lattice structure, bond strength, alloying elements- focusing on the additions or modification of other elements.

Why The Melting Points Of Some Metals Are Considerably Lower

As for other metals, the melting point is an indicator of its layered atomic structure and its metallic bonds. Metals that have weaker metallic bonds, such as mercury (-38.83 degree celcius) and gallium (29.76 degree celcius), have lower melting points due to them being less tightly packed surged with lower atomic structures.

Lower melting points within a group can result from atomic size, bond energy, and electron configuration. Cesium is an example of an element with a large atomic radius and weak atomic bonding that has a melting point of 28.5 °C. Moreover, metals with lower melting points have weaker metallic bonds and thus fewer free electrons available for bonding.

Studies show that even small quantities of other elements added to these low melting point metals can significantly alter their melting points. Gallium, for example, forms indium-gallium eutectic alloys which have melting points lower than room temperature, making them applicable in liquid metal coolants and flexible electronics. Recent publications with material data of these alloys prove their stability while presenting new possibilities in technology and engineering. Such knowledge continues to broaden the scope of low melting point metals and their application in industrial processes.

Reference sources

- “Dissimilar Joining of Aluminum to High-Melting-Point Alloys by Hot Dipping”(Liu et al., 2025)

- Publication Date: 2025-04-30

- Key Findings: This study successfully joined aluminum to high-melting-point alloys (steel, titanium, and copper) using hot-dipping. The process created uniform aluminum layers and metallurgical bonding through intermetallic compounds. The Al/Cu joint showed the highest shear strength (79.1 MPa), while the Fe4Al13-containing joint had the highest hardness (604.4 HV). The study also used numerical simulations to analyze the process.

- Methodology: Experimental (hot-dipping) and numerical simulation.

- “Advanced Ablation-Resistant HfC<sub>0.76</sub>N<sub>0.24</sub> at 3000℃ with Record Melting Point Over 4400K”(Peng et al., 2020)

- Publication Year: 2020 (While outside the 5-year window, it’s included due to its relevance to high melting points)

- Key Findings: This paper synthesized HfC<sub>0.76</sub>N<sub>0.24</sub>, a compound with a high melting point (4419 ± 37 K). It also showed exceptional ablation resistance at 3000 ℃. The superior performance is attributed to stronger metal-nonmetal bonds and better oxidation resistance due to the coordination effect of nitrogen.

- Methodology: Synthesis and characterization of the HfC<sub>0.76</sub>N<sub>0.24</sub> compound, ablation resistance testing.

- “Printing of Low‐Melting‐Point Alloy as Top Electrode for Organic Solar Cells”(Yu et al., 2022)

- Publication Date: 2022-11-18

- Key Findings: This study investigated printing a low-melting-point alloy (Field’s metal, melting point 62 °C) as a cathode in organic solar cells. Direct ink writing was used, and the resulting solar cells achieved a power conversion efficiency of 16.44%.

- Methodology: Experimental (printing and characterization of solar cells).

Frequently Asked Questions (FAQs)

Q: Which metal has the highest melting point?

A: Among metals, tungsten has the highest melting point, which is 3422°C (6192°F). It is also very useful for uses that need metals to endure very high temperatures without succumbing to melting.

Q: Why is a metal’s melting point significant?

A: The melting point signifies the temperature at which a metal turns into liquid. This is very crucial in deciding what metal to work with during heating processes such as forging to ensure the metal does not melt or expose the metal to conditions it cannot endure.

Q: Which metal has the lowest melting point, and how do the maximum and minimum bounds compare against other metals?

A: Tungsten has the highest melting point at 3422°C (6192°F), while mercury has the lowest the melting point of -38.83°C (-37.89°F) .

Q: In comparison to pure aluminum, how do aluminum alloys stack up in terms of melting point?

A: Unlike pure aluminum, which has a melting point of 660.3°C (1220.54°F), aluminum melts at a lower temperature based on the quantity of each element in the alloy and their respective compositions.

Q: What factors affect the melting points of these metals?

A: The atomic arrangement, the type of bonds, and the interactions of the atoms in each element affect the melting points of the metals. These will also dictate how the metals will be ordered according to their melting points and how they behave qualitatively under heat.

Q: Why is tungsten used in applications that require high temperatures?

A: Tungsten is used in high temperature applications because it is the last metal on the list that has the highest melting point. This property enables tungsten to endure conditions where other metals will melt, thus making tungsten useful in light bulb filaments and parts used in aerospace systems.

Q: In what applications are metals with lower temperature melting points used?

A: Lower temperature metals are used in automotive parts where easier casting and molding are needed. Some aluminum alloys have lower melting points which helps in these types of applications.

Q: How does knowledge of metal melting points assist in industrial processes?

A: It is necessary to know metal melting points in industrial processes to ensure that manufacturing does not result in unintended melting or structural failure due to inappropriate usage of solid metals and liquids.