In today’s fast-paced industrial landscape, precision, efficiency, and versatility are key factors driving innovation in manufacturing and product identification processes. Enter UV laser marking machines—a groundbreaking technology redefining how businesses imprint critical information on materials. These state-of-the-art machines stand out for their unparalleled ability to create high-quality, permanent marks on a diverse array of surfaces without causing damage or compromising durability.

This guide takes a closer look at the many advantages of UV laser marking machines, from their exceptional marking precision to their ability to handle complex applications in industries such as electronics, medical devices, and automotive manufacturing. Whether you’re exploring these machines for your business or simply curious about their capabilities, this article is here to illuminate how UV laser marking is setting new standards in quality and flexibility.

What is UV Laser Marking and How Does it Work?

UV laser marking is a process that uses ultraviolet light to create precise, high-contrast markings on a variety of materials. It operates by directing a focused UV laser beam onto the surface, which alters the material at a microscopic level through a process called photochemical reaction. This reaction makes the marks permanent without causing thermal damage to the surrounding areas, ensuring exceptional clarity and detail. UV laser marking is especially favored for applications requiring fine, intricate markings on sensitive or delicate materials like plastics, glass, or medical-grade components. This method’s precision and versatility make it an ideal solution for industries demanding high-quality results.

Understanding the UV Laser Marking Process

UV laser marking operates by utilizing a focused ultraviolet laser beam to create marks on materials without high heat. The process involves the absorption of UV light by the material, triggering a photochemical reaction that alters its surface characteristics. This results in clear, precise, and durable markings. Ideal for heat-sensitive materials, UV laser marking is widely used in industries such as electronics, medical devices, and plastics due to its ability to deliver high-quality results with minimal risk of damage.

How Does UV Laser Technology Differ from Other Lasers?

UV laser technology stands out from other laser types due to its shorter wavelength, typically around 355 nanometers, which allows for high precision and minimal heat-affected zones. This shorter wavelength is part of the ultraviolet spectrum, enabling UV lasers to achieve “cold marking.” Unlike traditional lasers like fiber or CO2 lasers, which rely on thermal energy to process materials, UV lasers induce photochemical reactions. This key difference makes UV laser technology ideal for marking heat-sensitive materials like plastics, glass, and silicon wafers, as it prevents warping or damage.

Additionally, UV lasers excel in creating finer markings, down to micrometer-level precision, which is critical for industries requiring high-quality outcomes, such as microelectronics and medical devices. According to industrial research data, UV lasers can achieve writing speeds exceeding 250 characters per second, demonstrating both efficiency and accuracy. Furthermore, their ability to work on a wide range of materials, including those that are transparent or reflective, significantly broadens their application compared to other laser technologies. These features make UV laser technology a superior choice for industries dependent on intricate, damage-free surface processing.

Why Choose UV Lasers for Marking Applications?

UV lasers are an exceptional choice for marking applications due to their unmatched precision, versatility, and ability to process sensitive materials without causing damage. One of their key benefits is the ability to create high-contrast, permanent marks on an extensive range of materials, including metals, plastics, ceramics, and glass, making them ideal for industries such as electronics, automotive, and medical device manufacturing.

Operating at a wavelength of 355 nm, UV lasers achieve a “cold processing” effect, ensuring minimal heat-affected zones and preventing damage or deformation to the substrate material. This property is particularly crucial for applications requiring fine, accurate marks, such as QR codes, barcodes, or serial numbers, where readability and durability are paramount.

Statistically, UV lasers deliver an outstanding beam quality (M² < 1.2), which facilitates precise marking even on micro-scale components. Furthermore, advancements in UV laser technology have led to higher energy efficiencies, with certain modern systems capable of operating at up to 20 kHz repetition rates, optimizing both quality and speed. This efficiency not only reduces operational costs but also enhances productivity.

Combined with their eco-friendly nature—due to less energy consumption and the reduction of harmful byproducts—UV lasers are increasingly becoming the preferred solution for high-tech, high-precision marking requirements across diverse industries. Their adaptability and cutting-edge performance ensure they remain at the forefront of laser marking technologies.

What are the Key Applications of UV Laser Marking Machines?

UV laser marking machines are widely used across industries due to their precision and versatility. Key applications include:

- Electronics Industry: Used to mark circuit boards, microchips, and other sensitive components without causing damage due to their low heat impact.

- Medical Devices: Ideal for marking medical equipment, surgical tools, and implants with sterilization-resistant markings.

- Plastic Products: Commonly used to engrave logos, serial numbers, and patterns on polymers without surface deformation.

- Automotive Parts: Utilized for marking engine components, dashboards, and safety labels with high durability.

- Luxury Goods: Ensures accurate marking on watches, jewelry, and glass for clear branding and customization.

These applications highlight the machine’s ability to deliver high-quality results on delicate and varied materials.

Marking on a Variety of Materials: From Metal to Plastic

Laser marking technologies have evolved to provide versatile solutions for a wide range of materials, combining precision, speed, and durability. For metals like stainless steel, titanium, and aluminum, laser marking ensures excellent contrast and wear resistance, crucial for applications in aerospace, medical devices, and serialized components. The process can achieve highly detailed markings without compromising material integrity, with markings remaining legible even under extreme environments like high temperatures or chemical exposure.

When it comes to plastics, laser marking adapts seamlessly to the varying properties of materials such as ABS, polycarbonate, and acrylic. For instance, CO2 lasers are commonly used for marking logos or barcodes on packaging plastics, boasting efficiency and permanency. Additionally, advanced fiber lasers are capable of creating high-resolution markings on engineering plastics used in electronics or automotive parts. Statistical data indicates that industries relying on laser marking for precision and productivity have witnessed increased reliability, with typical repetition accuracies as fine as ±0.1 mm.

The flexibility of modern laser systems also allows for intricate customization, ensuring that businesses stay adaptable in competitive markets. This broad capability makes laser marking an indispensable tool across diverse industries dealing with metal, plastic, and everything in between.

Exploring Industrial Use Cases for UV Laser Marking

UV laser marking has emerged as a vital technology in various industries due to its precision, versatility, and ability to work on delicate materials without causing thermal damage. Industries such as electronics, healthcare, and aerospace have benefitted greatly from the application of UV laser marking, as it enables the creation of highly detailed, permanent marks that are resistant to wear and corrosion.

Electronics Industry

The electronics industry frequently relies on UV laser marking for marking printed circuit boards (PCBs), cables, and components. The ultraviolet wavelength offers unparalleled precision, making it ideal for intricate designs and small text on sensitive surfaces. With increased demand for miniaturized, high-tech devices, manufacturers prioritize UV laser marking for its non-invasive process that safeguards component integrity. For instance, microchip labeling requires markings that are clear yet cause no damage to the delicate circuits, a key deliverable by UV lasers.

Healthcare Sector

In the healthcare sector, UV laser marking plays a crucial role in ensuring traceability and compliance with stringent industry regulations. Medical devices and surgical tools often require clear, tamper-proof markings such as serial numbers, barcodes, or logos. UV lasers’ ability to etch onto a variety of materials like stainless steel, titanium, and certain polymers ensures that the markings remain legible even after rigorous sterilization processes. Recent advancements have shown that UV laser marking can enhance efficiency in the production of medical devices, with some systems achieving speeds of over 1,000 characters per second while maintaining precision.

Aerospace Applications

The aerospace industry depends on UV laser systems for marking components that must endure extreme conditions. Aircraft parts made from lightweight alloys and composites, such as turbine blades or fuselage components, require markings that offer durability under high temperatures and stress. UV laser marking ensures that crucial information like serial numbers and manufacturing details remain intact for maintenance and safety compliance over time. Research has also indicated that UV laser marking reduces the risk of structural weaknesses in materials compared to other methods.

Consumer Goods Production

With the growing demand for personalized and secure products, the consumer goods industry leverages UV laser marking for diverse applications. From engraving unique serial numbers on luxury watches to placing QR codes on packaging for anti-counterfeiting, this technology provides high precision and aesthetic appeal. Recent studies suggest that implementing UV laser systems in production lines can lead to a 30-50% enhancement in output rates, and the customization possibilities continue to expand with technological advancements.

The potential of UV laser marking continues to redefine production standards across industries, combining speed, accuracy, and adaptability in ways traditional methods cannot achieve.

Comparing UV Laser Marking with Traditional Methods

UV laser marking stands out as a game-changer when compared to traditional marking methods due to its unmatched precision and versatility. While conventional methods, such as engraving and chemical etching, often involve physical contact or the use of consumables, UV laser marking offers a non-contact solution that significantly reduces wear and operational costs. This results in lower maintenance requirements and longer equipment lifespans.

Traditional methods also pose limitations in terms of material compatibility. For instance, mechanical engraving may not yield optimal results on delicate or heat-sensitive surfaces such as plastics or thin metals. UV lasers, on the other hand, operate with short wavelengths that minimize heat impact, making them ideal for such materials. This capability enhances production quality and reduces the likelihood of damage.

Efficiency is another area where UV laser systems excel. Studies indicate that UV lasers can operate at speeds up to 3-5 times faster than some traditional marking methods, contributing to a substantial increase in productivity. Additionally, they provide much finer detail, consistently producing marks with resolutions as high as micrometers. This precision is particularly valuable in industries requiring intricate designs, such as electronics or medical device manufacturing.

Another critical factor is environmental impact. Many traditional processes involve the use of harsh chemicals or consumables, leading to waste generation and potential environmental harm. UV laser marking is an eco-friendly alternative as it eliminates the need for consumables, contributing to greener production processes.

Cost efficiency over time is yet another advantage. Although the initial investment for UV laser systems can be higher, the long-term savings in operational costs, coupled with enhanced production capabilities, often result in a better return on investment. For companies seeking to modernize and streamline their workflows, UV laser marking provides a future-proof solution that outperforms traditional methods in nearly every metric.

What are the Advantages of Using UV Laser Marking Machines?

- Precise Marking: UV laser marking machines provide unmatched precision, allowing for detailed and high-quality marks on a variety of materials without causing damage.

- Versatile Material Compatibility: These machines are suitable for marking a wide range of materials, including plastics, glass, ceramics, and metals, making them adaptable to various industries.

- Non-Contact Process: The non-contact nature of UV laser marking ensures minimal wear-and-tear on the material being marked, preserving its structural integrity.

- Environmentally Friendly: UV laser systems operate without the use of harmful chemicals, providing a clean and eco-friendly marking solution.

- Durable and Permanent Marks: The marks produced are resistant to fading, rubbing, or environmental degradation, ensuring long-lasting results.

Benefits of UV Laser Marking: Minimal Heat and Precise Marking

UV laser marking stands out due to its exceptional ability to work with minimal heat, making it a superior choice for delicate and heat-sensitive materials. This unique feature significantly reduces the risk of thermal damage, preserving the structural integrity and aesthetics of the material being processed. For instance, in the electronics industry, UV lasers are widely used for marking printed circuit boards (PCBs) and microchips, as they leave precise and high-quality markings without compromising the functionality of tiny components.

Furthermore, the precision offered by UV laser marking is unmatched, with spot sizes reaching as small as 10 micrometers. This level of accuracy is particularly beneficial in industries like medical device manufacturing, where compliance with strict regulations often requires the application of tiny, yet perfectly legible, text or symbols on instruments and tools. According to industry-leading studies, this precision improves productivity by reducing errors and minimizing material wastage.

The combination of minimal heat and high precision also makes UV laser marking a valuable asset in luxury goods manufacturing. It enables detailed engraving on delicate surfaces such as glass, ceramics, or fine metals, ensuring that each product is marked with clarity and sharpness. The versatility and adaptability of UV laser technology continue to push boundaries across various industries, highlighting its critical role in modern manufacturing.

How UV Lasers Prevent Heat Damage on Sensitive Materials

UV lasers excel in applications involving delicate materials due to their unique ability to process without causing heat damage. This capability stems from their operation at shorter wavelengths, typically around 355 nanometers (nm), enabling a phenomenon known as “cold marking” or “cold processing.” Unlike longer wavelength lasers, UV lasers focus energy within the photoablation process, where material bonds are broken at a molecular level without introducing significant thermal energy to the surrounding areas.

One significant advantage of UV lasers is their minimal heat-affected zone (HAZ). For example, when marking thin glass or high-precision electronics, traditional laser technologies can create micro-cracks or warping caused by excessive heat. UV lasers, however, operate with exceptional precision, ensuring that only the targeted area is marked, with no changes to the structural integrity of the material.

Recent industry data demonstrates that UV lasers are widely appreciated in fields like semiconductor manufacturing and medical device production, where sensitive materials such as silicon wafers and bio-compatible plastics must retain their properties post-marking. Studies highlight that UV laser processing reduces thermal impact by over 50% compared to standard infrared lasers, making it the preferred choice for ensuring durability and accuracy.

Furthermore, UV lasers are highly versatile, ideal for high-definition marking on a broad range of materials, including ceramics, polymers, and thin metals. This adaptability not only prevents heat-related damage but also maintains the aesthetic and functional integrity of these materials, making UV lasers a crucial tool in industries requiring meticulous craftsmanship.

Understanding the High Absorption Rate of UV Lasers

The high absorption rate of UV lasers lies in their ability to interact effectively with a wide variety of materials due to their shorter wavelengths, typically in the range of 355 nm. This shorter wavelength allows UV lasers to focus on small areas with pinpoint precision, ensuring minimal thermal impact on the surrounding material. This characteristic makes them indispensable for delicate applications such as micro-marking, semiconductor processing, and medical device manufacturing.

When UV lasers interact with materials, the photons in the laser beam carry more energy, enabling stronger absorption, even by materials with low reflectivity like glass and certain plastics. For instance, studies show that materials such as fused silica and ceramics exhibit absorption rates above 90% with UV lasers, allowing for smoother and more efficient processing. Additionally, polymers such as polycarbonate and polyethylene can readily absorb UV wavelengths, which facilitates precision cutting and marking without deformation or discoloration.

This high absorption capability also helps reduce or eliminate the risk of damage caused by heat. Unlike other laser types, UV lasers process materials primarily through a mechanism known as “cold ablation,” where material bonds are disrupted and vaporized without transferring excessive heat to adjacent areas. This ensures superior edge quality and improved safety for materials prone to distortion, such as thin films or sensitive components.

Overall, the efficiency and precision offered by UV lasers, paired with their unparalleled absorption rates, set them apart as a leading technology for intricate and high-resolution applications across multiple industries.

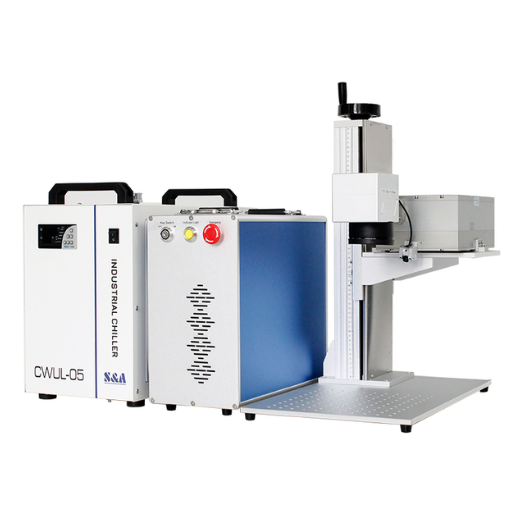

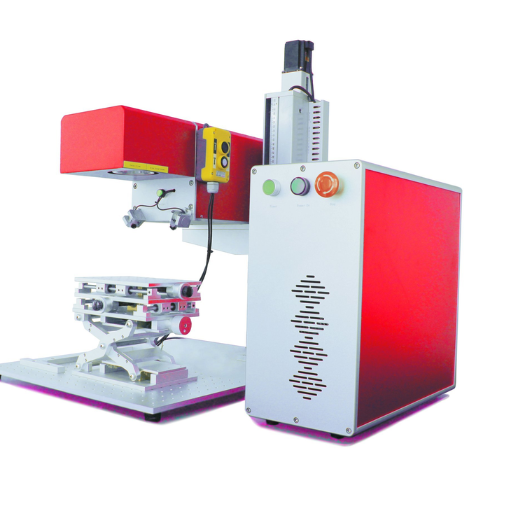

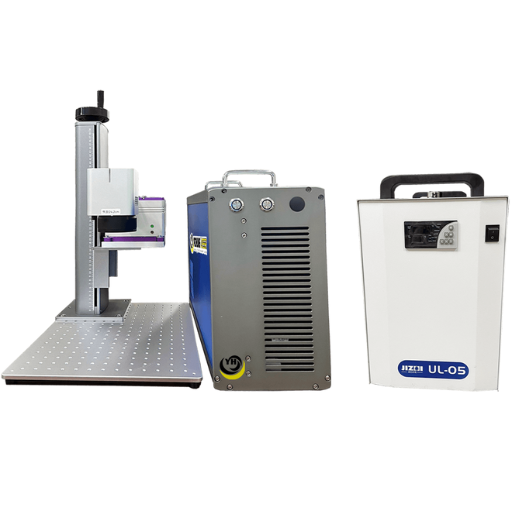

How to Choose the Right UV Laser Marking Machine?

When choosing the best-suited UV laser marking machine, start by determining the application requirements which include the nature of the material, marking accuracy, and marking speed. Make sure the machine’s parameters, such as wavelength and power, align with the materials intended for processing. Analyze the software that comes with the system in terms of user-friendliness and modification capabilities. Consider other features such as the presence of performance enhancing and longevity influencing cooling systems. Lastly, evaluate the brand’s standing in the market, their after-sales services, and the duration of the warranty to ensure sustained trust and support.

Factors to Consider When Selecting a UV Laser Marker

- Material Compatibility

UV laser markers excel in marking a wide range of materials, including plastics, glass, ceramics, and metals. To ensure optimal results, evaluate how well the laser can interact with the specific materials you plan to mark, as certain surfaces may require unique parameters to achieve the desired outcome.

- Marking Precision and Quality

High precision is a hallmark of UV lasers due to their short wavelength (typically 355 nm), which enables fine, detailed marking without causing thermal damage. Look for data on marking resolution and spot size to determine if the machine can meet your detailed engraving needs.

- Power Output

Consider the power output of the laser, typically ranging from 3W to 15W for most UV laser applications. A lower power output is ideal for delicate materials like glass or plastics, while higher power may be necessary for more robust or thicker materials.

- Marking Speed

Marking speed is a key factor, especially for high-volume production. Compare the machine’s speed in terms of characters per second or scan speed (e.g., mm/s) to align with your productivity requirements without compromising quality.

- Cooling Mechanism

UV lasers frequently require cooling systems, either air-cooled or water-cooled, to maintain operational stability and prevent overheating. Evaluate the efficiency and maintenance needs of the cooling mechanism as it can directly affect both performance and longevity.

- Software Integration and Ease of Use

Ensure the machine is equipped with user-friendly software and supports various formats like DXF, AI, or PLT for seamless integration into your existing workflow. Look for additional features such as editable templates or advanced scripting for customized applications.

- Durability and Lifetime

The longevity of the laser source is critical for ensuring cost-efficiency. Check the rated lifetime, typically measured in hours (e.g., 20,000 to 30,000 hours), to estimate how long the equipment will remain productive under regular use.

- Safety Features

UV lasers operate within a short wavelength range, making them potent yet potentially hazardous. Ensure proper safety measures such as protective coverings, interlock systems, and compliance with regulations like FDA or CE standards to safeguard the operator.

- Size and Portability

Depending on your workspace, the physical dimensions of the machine should be measured carefully. For smaller workspaces, compact models are ideal, while larger industrial-grade options may align better for large-scale production needs.

- Cost of Ownership

Beyond the initial purchase cost, account for operational costs such as energy consumption, maintenance, and replacement parts. For reference, UV lasers often have lower energy consumption compared to other types of industrial lasers, adding to their cost-effectiveness over time.

By thoroughly analyzing these factors and reviewing technical specifications, you can confidently select a UV laser marker tailored to your application demands, ensuring efficiency, precision, and value in the long term.

Understanding the Importance of Wavelength and Laser Power

The wavelength and power of a UV laser play crucial roles in determining its suitability for different applications. UV lasers typically operate at wavelengths around 355 nm, which falls within the ultraviolet spectrum. This shorter wavelength allows the laser to achieve higher precision by delivering energy to a significantly smaller focal spot. This characteristic is especially valuable for applications requiring intricate details, such as micro-marking on sensitive materials including glass, plastics, and ceramics.

Laser power, on the other hand, directly influences the depth and speed of marking or engraving. Higher power translates to greater energy output, enabling deeper engravings or faster material processing. However, low power might be preferred for delicate applications to avoid damage or excessive heat generation. For instance, UV lasers with 3W power are often favored for sensitive tasks like marking pharmaceutical packaging, while higher-power models like 5W or 10W versions are better suited for industrial-grade applications such as circuit board processing or automotive part marking.

Data also suggests that by optimizing both wavelength and power, manufacturers can achieve greater efficiency and reduced material waste. UV lasers, thanks to their short wavelength, exhibit minimal thermal impact on materials. This property ensures clean, high-contrast marks without distortion, even on heat-sensitive surfaces. Furthermore, selecting the correct combination of these variables can enhance operational reliability and extend equipment lifespan by minimizing wear and unnecessary stress on the laser system.

By understanding the interplay of these factors, you can make informed decisions to meet precision requirements, improve workflow performance, and maximize overall output quality.

Evaluating UV Laser Engraving vs. Fiber Laser Engraving

When comparing UV laser engraving with fiber laser engraving, it is essential to consider their respective capabilities, materials compatibility, and application environments to select the most suitable technology.

UV Laser Engraving operates at a shorter wavelength (typically 355 nm), which enables a process known as “cold marking.” This process minimizes heat-affected zones, making UV lasers ideal for working with heat-sensitive materials such as plastics, glass, and certain ceramics. UV lasers excel in precision, allowing for clean, high-contrast markings without surface damage. For instance, industries like pharmaceuticals and electronics rely heavily on UV lasers for micro-marking and compliance-sensitive applications due to their ability to deliver exceptional accuracy. However, UV laser systems are generally more expensive to deploy and maintain compared to their fiber counterparts.

Fiber Laser Engraving, on the other hand, uses a longer wavelength, typically around 1064 nm, and is known for its robust functionality and high efficiency in engraving metals and certain plastics. Fiber lasers stand out in their ability to achieve deep, permanent markings, making them invaluable in industries such as automotive, aerospace, and manufacturing, where durability is critical. Fiber laser systems also tend to have a longer lifespan, lower operational costs, and higher energy efficiency, making them a cost-effective choice for large-scale or industrial operations.

From a performance perspective, UV lasers shine in applications requiring micro-detailing and non-damaging markings, especially for materials like polycarbonate or quartz. Fiber lasers, in comparison, are unmatched when it comes to high-speed engraving and creating durable, deep markings on metals, such as stainless steel or aluminum. For example, studies have shown that fiber lasers can mark metals up to 2x faster than UV lasers while maintaining excellent quality.

Cost Considerations are also a deciding factor. Fiber laser systems usually have a lower initial purchase price and require less maintenance, leading to a lower total cost of ownership over time. UV laser systems may involve higher initial and operational costs but are essential for delicate applications that demand high precision and minimal thermal impact.

What are the Differences Between UV Lasers and Other Laser Types?

UV lasers differ from other laser types primarily in their wavelength, precision, and application capabilities. UV lasers operate at a shorter wavelength (typically around 355 nm), which allows for higher precision and minimal heat impact during processing. This makes them ideal for delicate materials, such as glass, ceramics, or certain polymers, where thermal damage must be avoided.

By contrast, other laser types, like fiber lasers or CO2 lasers, have longer wavelengths and are better suited for engraving or cutting thicker and more robust materials, such as metals or wood. While fiber lasers excel in speed and power efficiency, and CO2 lasers are versatile in material compatibility, UV lasers stand out for their ability to achieve fine details without compromising the material’s integrity.

Ultimately, UV lasers are favored for applications requiring intricate detail and high-precision results, while other laser types are better suited for heavy-duty or large-scale tasks.

UV Lasers vs. Fiber Lasers: Key Differences

While comparing UV lasers with fiber lasers, I would certainly mention their unique advantages. UV lasers are unmatched when it comes to detail and intricate work, such as marking on glass, plastics, and ceramics without inducing thermal damage. In contrast, Fiber lasers are more efficient and powerful making them better for cutting or engraving of metals and other hard materials. Ultimately, the decision depends on the application and materials used.

How Do CO2 Lasers Compare to UV Laser Machines?

When comparing CO2 lasers to UV laser machines, I’d emphasize their distinct characteristics and applications. CO2 lasers are highly effective for cutting, engraving, and marking non-metallic materials like wood, acrylic, leather, and glass due to their longer wavelength and high power. Conversely, UV lasers, with their shorter wavelength, excel in precision and are particularly suited for delicate tasks, such as marking plastics, ceramics, and glass, without causing thermal damage. The choice between the two really depends on the type of material and the level of precision required for the application.

When to Use UV Light for Marking and Engraving?

UV light is best used for marking and engraving when precision is paramount, especially on delicate materials like plastics, ceramics, or glass. I rely on UV lasers when the process demands high accuracy without the risk of thermal damage, making them ideal for intricate designs or sensitive applications. They are particularly effective in industries such as electronics, medical devices, and jewelry, where detail and care are crucial.

What are the Future Trends in UV Laser Marking Technology?

The future of UV laser marking technology is focused on enhancing efficiency, precision, and versatility. Advancements are expected in beam quality and power output, enabling faster marking speeds and greater adaptability for various materials. Innovations in automation and software integration will improve productivity by allowing seamless operation in manufacturing systems. Additionally, there is growing interest in environmentally friendly solutions, leading to the development of more energy-efficient lasers and sustainable practices. These trends will shape UV laser marking into an increasingly reliable and versatile tool across industries.

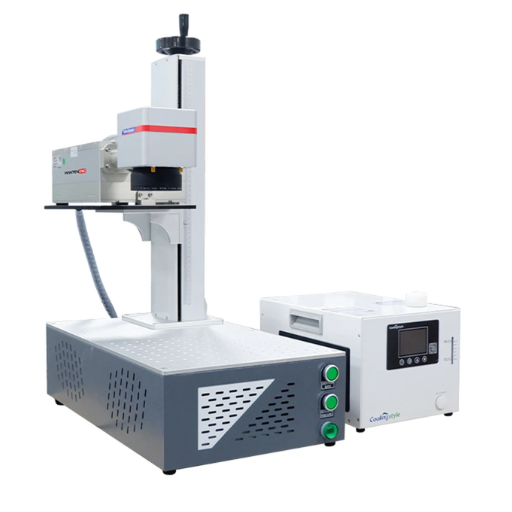

Innovations in UV Laser Systems and 3-Axis Control

Recent developments in UV laser systems and 3-axis control have revolutionized precision and efficiency in industrial applications. UV lasers are increasingly valued for their exceptional ability to create high-definition marks without causing thermal distortion, making them indispensable for delicate materials such as plastics, glass, and thin metals. Coupled with advancements in 3-axis dynamic focusing technology, these systems now offer superior adaptability, enabling marking on complex 3D surfaces with unparalleled accuracy.

One notable innovation is the integration of intelligent motion control algorithms in 3-axis systems. These algorithms streamline operations by optimizing the focal point during marking, ensuring consistent quality even on irregular or curved surfaces. This capability has reduced error margins and significantly enhanced production speeds across industries such as electronics, aerospace, and medical devices.

Data also highlights the remarkable efficiency improvements achieved through UV laser system enhancements. For example, compared to traditional laser marking methods, advanced UV lasers operate at higher speeds while consuming less power—reducing overall energy requirements by up to 30%. Additionally, the precision provided by 3-axis control mechanisms allows for a higher yield of defect-free products, helping manufacturers save on material waste and rework costs.

These strides in UV laser systems and 3-axis control reflect rapid technological progress that continues to redefine manufacturing standards. With further research and development, these systems are expected to drive even greater accuracy, sustainability, and versatility, cementing their role as a critical component in future industrial processes.

The Role of UV Lasers in High-Precision Marking Solutions

UV lasers have become indispensable in high-precision marking solutions, offering unmatched accuracy and efficiency for delicate and intricate applications. These lasers operate at shorter wavelengths, typically around 355 nm, which allows for extremely fine marking with minimal thermal impact. This makes them particularly suitable for industries like electronics, medical devices, and aerospace, where precision is critical and material integrity must be preserved.

One of the key advantages of UV laser systems is their ability to mark a wide range of materials, including plastics, glass, ceramics, and metals, without causing damage or deformation. For example, in the electronics industry, UV lasers are used to etch intricate designs onto printed circuit boards (PCBs) and microchips, ensuring traceability and compliance with strict regulations. Additionally, in the medical field, they enable permanent, high-contrast markings on surgical instruments or implants, crucial for sterility and identification.

Recent data highlights the growing adoption of UV lasers in manufacturing due to their efficiency and environmental benefits. With a projected compound annual growth rate (CAGR) of approximately 8.5% in the laser marking market over the next five years, manufacturers are increasingly turning to UV lasers to improve product quality while reducing waste and energy consumption. This trend aligns with the global shift toward more sustainable and precise manufacturing processes.

Furthermore, advancements in UV laser technology, such as enhanced beam steering and energy control, have enabled more detailed and complex patterns, catering to the increasing demands of modern industries. The ability to deliver high-resolution, non-contact, and chemically resistant markings reinforces UV lasers’ role as an essential tool for industries requiring precision and reliability.

Exploring the Expanding Range of Materials for UV Laser Marking

UV laser marking technology has significantly evolved, unlocking the potential to mark an expanding range of materials with precision and durability. One of the critical advantages of UV lasers lies in their cold marking process, which prevents material damage by minimizing heat effects. This makes UV lasers particularly suitable for sensitive materials such as plastics, glass, ceramics, and metals.

For instance, in the plastics industry, UV lasers are widely used for marking polycarbonate (PC), polyethylene terephthalate (PET), and acrylics. These materials benefit from high-contrast and permanent markings without the risk of melting or discoloration, crucial for medical devices, automotive components, and consumer electronics. Recent advancements show that UV lasers can even mark transparent and translucent plastics effectively, expanding their application range in packaging and labeling.

The use of UV lasers in glass processing is equally impressive. Industries leveraging UV lasers for engraving decorative patterns, serial numbers, or data matrix codes highlight the technology’s ability to create precise, intricate marks without weakening the structural integrity of glass. This is particularly valuable in sectors such as pharmaceuticals and luxury goods, where tamper-proof and aesthetically pleasing markings are essential.

Metals, including aluminum, stainless steel, and titanium, can also be marked using UV lasers, primarily when coated or anodized. These marks are highly resistant to wear and corrosion, making them a reliable solution for aerospace, defense, and industrial manufacturing. The cold marking process reduces oxidation risks, ensuring that functionality and appearance remain uncompromised.

With the ongoing demand for green and sustainable solutions, research continues to expand UV laser marking applications, incorporating materials that are eco-friendly, recyclable, or biodegradable. This innovation aligns with industry trends toward eco-conscious manufacturing while maintaining the precision UV lasers are celebrated for.

This expanding range demonstrates the versatility and adaptability of UV laser technology, solidifying its position as a leading solution in industries requiring impeccable accuracy and performance across diverse materials.

Reference Sources

-

Progress of Medical Lasers: Fundamentals and Applications1:

- Focus: This study reviews the use of lasers, including UV lasers, in medical applications such as dermatology, ophthalmology, and cancer therapy.

- Key Findings: UV lasers (200-400 nm) are highlighted for their precision in non-invasive procedures. They are used in photodynamic therapy (PDT) and photothermal therapy (PTT) for targeted treatments, leveraging their ability to interact with photosensitizers and nanoparticles.

- Methodology: The study combines theoretical analysis and experimental data to explore laser-tissue interactions, emphasizing the importance of wavelength and energy parameters.

-

Review: 40 Years of Laser-Marking Industrial Applications2:

- Focus: This review traces the evolution of laser marking technologies over four decades, including UV laser applications.

- Key Findings: UV lasers have become integral in marking diverse materials, from electronics to food packaging, due to their precision and adaptability. The study also discusses advancements in beam delivery systems and future trends.

- Methodology: A historical and technical review of laser technologies, supported by case studies and industrial applications.

-

New Ultraviolet Lasers for Material Processing in Industrial Applications3:

- Focus: This article examines the role of UV lasers in industrial material processing.

- Key Findings: UV lasers, particularly excimer lasers, are praised for their ability to create fine microstructures with minimal thermal impact. Recent advancements in diode-pumped, frequency-multiplied Nd:YAG lasers have improved reliability and cost-effectiveness, expanding their industrial use.

- Methodology: The study reviews technological advancements and their impact on industrial applications, emphasizing the benefits of short-wavelength outputs.

- Top UV Laser Marking Machine Manufacturer and Supplier in China

Frequently Asked Questions (FAQs)

Q: What are the primary advantages of using a UV laser marking machine?

A: UV laser marking machines offer high contrast and damage-free marking, making them ideal for applications that require precision. They are known as “cold marking” devices because they minimize thermal stress, allowing for distortion-free marking on sensitive materials.

Q: Why should I choose UV laser marking over traditional marking methods?

A: Choosing UV laser marking over traditional marking methods offers several benefits, including the ability to mark a wide range of materials without causing damage. This method provides high-precision engraving and is suitable for applications where clarity and permanency are crucial.

Q: How does a UV laser engraver differ from a fiber laser engraver?

A: A UV laser engraver uses a 355 nm laser through two crystals to achieve focused laser marking, making it suitable for materials that require non-contact, distortion-free marking. In contrast, a fiber laser engraver is more suited for metal marking and more robust materials, where precision and speed are essential.

Q: What types of materials can be marked using a UV laser engraver?

A: UV lasers can mark a variety of materials, including plastics, glass, ceramics, and metals. Their ability to perform high contrast and damage-free marking makes them ideal for products that require precise and clean engravings.

Q: What is the marking method used by UV laser marking machines?

A: UV laser marking machines use a focused laser beam to engrave or etch materials. This method is known for its high precision and ability to produce detailed markings without damaging the substrate, making it a preferred choice for sensitive applications.

Q: Are there any specific industries where UV laser marking and engraving is particularly useful?

A: Yes, UV laser marking and engraving are particularly useful in industries such as electronics, medical devices, and packaging, where high-quality, precise, and permanent markings are essential for safety and compliance.

Q: What is a 3-axis UV laser engraver, and how does it enhance marking and processing?

A: A 3-axis UV laser engraver allows for flexible marking and processing by adjusting the laser’s focal point in three dimensions. This capability ensures consistent marking quality on curved or uneven surfaces, enhancing the versatility and efficiency of the laser engraving machine.

Q: How do UV laser engravers contribute to high contrast and damage-free marking?

A: UV laser engravers contribute to high contrast and damage-free marking by utilizing a “cold marking” process that reduces thermal impact. This technique ensures that the marked materials retain their integrity and appearance without any surface distortion.

Q: Can UV lasers be used in conjunction with other laser types, such as a laser etching machine?

A: Yes, UV lasers can be used alongside other laser types, such as a laser etching machine, to provide a comprehensive marking solution. This combination allows for flexibility in marking techniques, accommodating various material properties and application requirements.