A metal’s melting point reveals a lot of information regarding the metal, including its properties, applications, and behavior in different situations. Of all the metals which are used in industries and in crafts, copper is exceptionally important due to its thermal and electrical properties. What is it about copper that makes its melting point so significant and what does it tell us on this multipurpose metal? In this article, we will look into the science that explains the copper melting point, its significance in industrial activities, and how it increases our understanding of its many uses. A student or a professional in the area of materials science or just someone interested in the world of metals will find this blog useful in understanding copper and its importance in practical life.

What is the Melting Point of Copper?

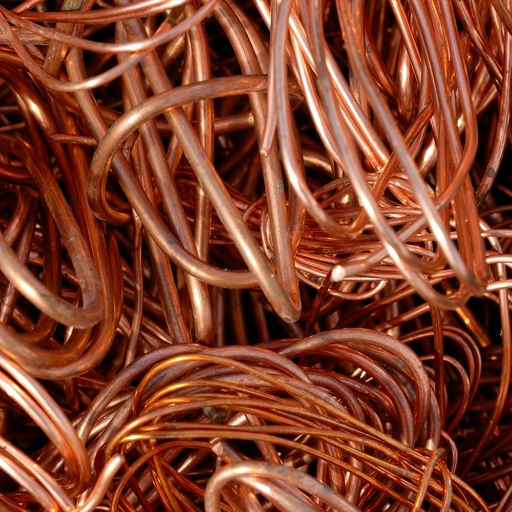

Copper is a metal that can be used for electric wires, plumbing, and heat exchangers because they withstand both heat and corrosion. They also have a melt temperature of 1,085 °C.

How Does Pure Copper Differ in Melting Temperature From Copper Alloys?

As discussed above, pure copper can withstand temperatures of 1,985 °F. However, if other metals are introduced into the copper alloy, the melting temperature changes. For instance, brass, an alloy of copper and zinc, has a melt temperature of around 900 °C. Another example of bronze, which consists tins and copper, melts between 910 °C and 980 °C.

Changes occur when the secondary metals added modify the freezing structure of the material, as well as the bonds of the secondary metals, thus increasing or lowering the materials melting temperature. Because of this fine-tuned melting temperature, copper alloy could be used for many industrial purposes ranging from making machine parts to casting parts into sculptures. As an example, brass is a lot easier to work with because of its softness and ability to resist corrosion. Bronze is also used extensively in marine hardware and in tools because of its strength and resistance to wear. Knowing these properties is important when deciding which material to use in certain mechanical high temperature applications.

What Determines the Melting Point of Copper?

Copper melting point is about 1984 degrees Fahrenheit or 1085 degrees Celsius. This value could change along several lines especially when combined with other metals. When alloying copper with zinc, tin, or aluminum, the materials specific composition could change the alloys melting point. A good example would be brass which is a copper zinc alloy. It is known to have a lower melting point which ranges from 1650 to 1720 degrees Fahrenheit (900 to 940 degrees Celsius) While bronze which is a copper tin alloy melts in a range of 1742- (950-1000 degrees Celsius). There are specific ratios of copper to the other metals which determine the chemical properties and the melting point of these alloys.

The inclusion of impurities and oxygen can also change copper’s physical properties. Compared to industrial-grade copper which contains some impurities, high-purity copper is more precise and stable in terms of melting point, while industrial grade copper’s impurities may lower the melting range.

As for external parameters, they can also melt copper, albeit with lesser effect at a copper’s melting point 1,085°C (1,984°F). These include atmospheric pressure. Such knowledge is useful for industries like metallurgy and manufacturing, where detailed management over the design temperature during melting and the subsequent cast addition greatly impacts the end product’s quality.

What are the industrial applications for the melting point of copper?

For most industrial uses, knowing the melting point of copper, which is around 1,085°C (1,984°F), is necessary. It is important for the processes of smelting, making alloys and manufacturing wires for electricity. Knowing when to apply force or work on the copper without damaging its physical structure due to melting requires precision understanding of the melting point.

Copper is widely used in construction and electronics because it is thermally and electrically conductive. For instance, when manufacturing copper alloys like bronze or brass, temperature control is needed to ensure proper element blending for ideal material properties. Also, in welding and soldering, copper’s melting point controls the joints’ seam temperatures that guarantee strong and durable bonds.

An example of these recent developments includes precision inductive and digital thermometers, which help industries keep better track of melting processes. This precision helps reduce energy consumption, material waste, and improve product quality. Knowing copper’s melting point alongside these new technologies show how critical information can greatly bolster industrial efficacy and cut down on resource expenditure.

How Does Copper’s Melting Point Compare to Other Metals?

Unlike some other metals used in industries, the melting points of copper is relatively low. With a melting temperature of 6,192°F (3,422°C), tungsten is one of the few metals which can withstand considerably higher temperatures than copper, which melts at 1,984°F (1,085°C). Copper is much easier to melt and shape for different uses—like in tools—and tends to have less heat-resistance than numerous metals, although some, like aluminum, are easier to work with as they melt at a lower temperature than 1,221°F (660°C) and iron which melts at 2,800°F (1,538°C).

Comparison of Conductivity with Iron and Aluminum

Copper alloys with aluminum as well as iron fall short when compared to copper’s remarkable thermal and electric conductivity. Expanding at a rate of 59.6 x 10⁶ S/m, copper is one of the best electrical conductors, although more abundant and cheaper aluminum pales in comparison at 37.7 x 10⁶ S/m. Iron is used often these days for structural and industrial applications but due to its low electrical conductivity (10 x 10⁶ S/m), proves to be a less efficient choice for electrical work.

With a thermal conductivity value of approximately 401 W/m·K, copper once again outperforms other materials. Aluminum follows with approximately 235 W/m·K, while iron lags with a mere 80 W/m·K. This makes copper perfect for radiators or heat exchangers where peak efficiency is a necessity.

Copper showcases its weaknesses when looking at mechanical strength, where both iron and aluminum outperform it. A tensile strength measurement for pure copper shows a value of 210 MPa, while aluminum stretches between 70 and 700 MPa, and iron surpasses 350 MPa depending on carbon content and treatment. These disparities demonstrate copper’s unparalleled suitability for specific applications demanding intensive advanced thermal and electric conductivity, while the other two metals are better for structural jobs and machines.

Understanding different melting points in metal alloys

Metal alloys exhibit varying melting points based on their composition, typically ranging from 90°C (Field’s metal) to over 3,400°C (tungsten carbide).

| Alloy | Melting Point (°C) | Key Component | Strength | Usage |

|---|---|---|---|---|

| Field’s metal | 90 | Bismuth | Low | Precision |

| Lead-tin | 183–215 | Tin | Moderate | Soldering |

| Aluminum | 660 | Aluminum | Light | Aerospace |

| Brass | 900–940 | Copper | Durable | Instruments |

| Bronze | 950–1,050 | Copper/Tin | Hard | Artwork |

| Iron | 1,200–1,535 | Carbon/Iron | Strong | Tools |

| Steel | 1,370–1,510 | Iron/Carbon | Very Strong | Structures |

| Tungsten Carbide | >3,400 | Tungsten | Extreme | Cutting |

Which metal has the lowest melting point?

Of the metals, bismuth has the lowest melting point of 90°C (194°F). This property makes bismuth suitable for certain applications requiring low-temperature melting, such as in fire-detection systems and safety devices, as well as for precision casting. Often bismuth is alloyed with other metals to form low melting point alloys like Wood’s metal or Rose’s metal which are used in specialized industrial processes.

For comparison, common metals like aluminum and copper have much higher melting points of 660°C (1,220°F) and 1,085°C (1,985°F) respectively. The versatility of bismuth in tailored low-heat uses stand out especially with the stark difference between its properties and those of other metals.

Furthermore, bismuth is unique as it is non-toxic and can replace lead in numerous applications where lead was used, making them more eco-friendly. His low melting point coupled with his non-toxic nature makes him indispensable for new technologies and industrial innovations.

Practical Applications of Copper’s High Melting Point

Because copper has a high melting point, it is ideal for applications requiring significant exposure to heat and for electrical wiring, industrial machinery, heat exchangers, and engine parts. It’s important that these parts are durable and reliable in harsh environments.

Why Copper’s High Melting Point Makes It Ideal For Welding

Copper’s high melting point of 1,085°C (1,984°F) helps maintain structural integrity during welding processes, making it an excellent choice for those applications. Because of copper’s low tensile strength, copper conducts heat very well, which helps to prevent local overheating that can lead to deformation or weak joints.

Welding heat does not weaken copper’s bond with other metals, thus making it ideal for various alloys. These properties make copper useful in the construction, automotive, and aerospace industries. Also, electrical engineers prefer copper for welded components because it can conduct electricity and withstand elevated temperatures without loss of efficiency.

New industry analysis suggests that there is a global market for wel copper applications that is in the range of dozens of billions globally. It is predicted that supply and demand in the Electrical and Electronics industry alone will surpass $60 billion by the year 2030. This can be attributed to the fact that copper performs much better than other metals over high-temperature operations as complex manufacturing processes ensures strong and consistent welds.

The Role of Copper in High Temperature Applications

Because of its extreme oxidation resistance, thermal and electric current conductively, copper is a preferred material for high temperatures applications. It also possesses a very high melting point of 1.083m which is 1981 degrees farenheit and maintains industrial strength under harsh conditions. This makes copper a choice to industrial processes.

The most notable segments that impacted the recent soaring price of copper on a global level have been the production of electric vehicles and investment into renewable energy. Starting from 2021, Global Data estimates the CAGR at 4.1% uptil 2026. Bolstering the country’s economy promises further extending the scope of welding applications especially through product diversification. There is also growing demand for copper alloys for use in the manufacture of heat exchangers, boiler tanks and other electrical appliances that expect efficiency and durability in steam high temperature working environment.

Additionally, the electrical and electronics industry continues to be a primary driver of copper demand. Copper is critical in making semiconductors, electric motors, and in power distribution systems, which are expected to grow continuously. The International Copper Association’s report estimates that the standalone electric vehicle market will require over 4.5 million metric tons of copper by 2030, suggesting a quadrupling in demand. This dramatic increase reinforces copper’s essential role in supporting sustainable technologies while excelling in high-temperature environments.

The Science Behind Metal Melting Points

How much energy a metal needs to change from solid to liquid depends on the melting point and the strength of bond holding its atoms in solid state. These links between metals atoms are interatomic forces which can differ based on electron arrangement, atomic structure, or word impurities. As an instance, tungsten’s metals have bigger melting points thanks to their tight atomic structure and strong intermetallic bonds. While lead with much tighter melting point due to weaker interatomic forces. These elements are important in aerospace engineering, mechanical manufacturing, or scientific material innovations.

What determines a metal’s melting point?

Every metal has a different intrinsic and extrinsic factors relating to atomic structure all signifying less energy would be needed to melt certain metals. For the bonds within the substance, lack of energy within the substance is referred to as thermal energy, and is needed depends on the degree of bonds. Owing a high atomic mass would result in tightly packed lattices granting a stronf bonds supporting a metals ability to withstand temperature increase without melting.

For example, tungsten is one of the few elements with an exceptionally high melting point of 3,422 °C (6,192 °F). Its remarkable structure, which consists of a body-centered cubic lattice, leads to strong atomic bonding and accounts for tungsten’s dense interatomic bonds. In contrast, lead and other metals with a more relaxed atomic arrangement, such as lead, have much weaker interatomic forces. This results in a significantly lower melting point of 327.5 °C (621.5 °F).

Recently, advancements in experimental analysis and the computations of material science have enabled researchers to predict and even manipulate melting points. A 2023 study shows that researchers successfully calculated melting points for a number of alloys and studied how trace elements such as chromium or carbon could significantly affect them. This drives new possibilities to invent tailored materials for extreme environment conditions, especially in aerospace or high-temperature industrial furnaces.

In summary, while metals inherently possess certain qualities that influence their melting points, other environmental factors such as pressure, temperature, or the introduction compounds may change them further. Grasping these essentials is important when crafting materials that are meant to match operational environments.

Effects of Impurities on Melting Point Temperatures

The role of impurities is quite important when it comes to the melting points of substances. The addition of some impurities to a pure substance tends to change the orderly arrangement of the lattice of the material. Such change can either increase or decrease the melting point depending on the type of impurity and how it interacts with the base substance. Take metals for example, common impurities such as carbon, sulfur, or silicon can have a very large effect on the melting temperature.

Recent studies also provide examples that prove these effects. A noted example is pure iron which has a melting point of 1,538°C (2,800°F). The presence of Carbon lowers this temperature significantly as we see in steel alloys which active between 1,370°C to 1,515°C (2,498°F to 2,759°F) depending on the carbon content. The same applies to semiconductors such as silicon where even the smallest impurities can change the melting point, something critical for the manufacture of electronic components.

The reaction can also be shown in other non-metals. Take for example the lowering of the freezing point of ice when salt is added. This principle is very useful when de-icing roads during winter. The lowering freezing point of ice is a perfect example of how the presence of impurities modify the temperature of phase change in a material.

From the perspective of engineering design and application, knowing the relationship that exists between impurities and the melting point of a given material is critical. Scientists and engineers apply this knowledge to design materials for an aircraft as well as for construction and electronics, changing the conditions will cause the material to react optimally.

In what way do alloys change the melting point of metals?

Alloys are formed by two or more metals combined together or a metal and non-metal. Increasing the desired property is the main goal. Alloying as a rule changes raising the melting point of a material in comparison with its components, which is very opposite. This is possible because different atoms are added, which makes the collective copper monocrystal structure of a pure metal easier to break with heat.

As an example, pure aluminum has a melting point of 660 C (1220 F). Further, common aluminum alloys like 6061 aluminum have lower melting ranges between approximately 555 C (1031F) – 635 C (1175 F) depending on alloying elements and their proportions. The same case applies to pure gold which melts at 1064 C (1947 F). however gold alloys with metals like silver or copper resulting in various gold karatages 14K or 10K gold would mean lower melting points because of more ingredients.

Further, detailed data states that in steels, adding elements like carbon, chromium, or nickel greatly changes the melting behavior. The same goes for pure iron with a melting point of roughly 1538 C (2800 F). Adding carbon in makes the steel reduces the melting range to 1370 C (2500 F) and 1510 C (2750 F) depending on specific carbon amount. Nickel based superalloys are also used in aerospace industry and specially designed to have distinct melting points and mechanical features to hold up under extreme temperatures where jet engines operate above 1000 C (1832 F).

These differences are important for the study of material science, as they pertain to engineering functions that require specific ranges of melting. Alloying metals to tailor their melting features has developed countless new technologies in such sections as aerospace, automotive, construction, and others. For further novel applications, innovative research in materials science strengthens our grasp of these interrelations.

Frequently Asked Questions about Copper and Its Properties

What are the primary properties of copper?

Copper possesses remarkable characteristics such as a high degree of electrical and thermal conductivity, resistance to corrosion, good ductility, and malleability. It exhibits antimicrobial traits too, which aids in the field of medicine and sanitation.

Why is copper used in electrical wiring?

For efficient and durable electrical wiring, copper is deemed ideal due to its electrical conductivity, ductility, and fairly lower cost in comparison to other metals.

How does alloying affect copper’s properties?

Copper loses some of its conductivity when alloyed with other metals like tin or zinc, but the trade off adds strength, durability and wear resistance. Because of this, copper alloys can be customized for different industrial uses.

What is the melting point of copper?

The melting point for pure copper is about 1,984 °F (1,085 °C), which makes it useful in a wide range of applications that involve high temperatures.

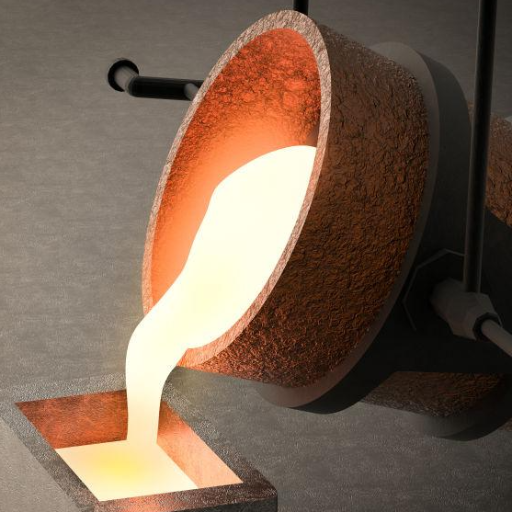

How to melt copper safely and efficiently?

To melt copper safely and efficiently, a furnace or high-temperature torch designed for copper or similar metals should be used. Proper heat-resistant gloves, goggles and protective clothing should be worn to ensure safety. Because copper requires a high temperature of 1,984 °F (1,085 °C) to melt, only devices rated for that temperature should be used. Make sure to work in an area with good ventilation to avoid fumes.

Are high temperatures acceptable for copper alloy usage?

As far as I know, some copper alloys such as beryllium copper or nickel copper have been proven to be thermally stable and resistant to deformation even under intense heat. However, these alloys respond to heat differently based on the alloy constituents and application needs.

What is the melting temperature of pure copper in Celsius and Fahrenheit?

The melting temperature of pure copper is 1,085 degrees celsius whereas 1,984 degrees fahrenheit. This higher melting point is useful in applications which need a lot of strength and resistance to thermal and mechanical effects. Since copper is also electrically conductive, this makes it more useful in electrical wirings and heat exchangers. It is also helpful to consider specific compositions of materials when dealing with high temperatures as some factors like alloying may change the melting point.

Reference sources

- Numerical Analysis of the Influence of Evaporation of the High- and Low-Melting-Point Anode Materials on Parameters of a Microarc Discharge

- Authors: A. Saifutdinov et al.

- Journal: Plasma Physics Reports

- Publication Date: October 1, 2023

- Citation Token: (Saifutdinov et al., 2023, pp. 1187–1198)

- Summary: This study investigates the effects of evaporation from high- and low-melting-point anode materials, including copper, on the parameters of microarc discharges. The research highlights how the melting point influences the discharge characteristics and the stability of the arc.

- Methodology: The authors employed numerical simulations to analyze the evaporation processes and their impact on discharge parameters, providing insights into the thermal behavior of copper under high-energy conditions.

- Investigation of the Melting Point Depression of Copper Nanoparticles

- Authors: L. Somlyai-Sipos et al.

- Journal: IOP Conference Series: Materials Science and Engineering

- Publication Date: August 26, 2020

- Citation Token: (Somlyai-Sipos et al., 2020)

- Summary: This paper explores the melting point depression observed in copper nanoparticles compared to bulk copper. The findings indicate that the melting temperature of copper nanoparticles is significantly lower than that of the bulk material, which has implications for their applications in nanotechnology.

- Methodology: The researchers synthesized copper nanoparticles using a solvothermal method and characterized them using X-ray diffraction (XRD) and Scanning Electron Microscopy (SEM). They analyzed the thermal behavior of the nanoparticles through Differential Scanning Calorimetry (DSC).

- Thermodynamic Temperature Measurements from the Triple Point of Water up to the Melting Point of Gallium

- Authors: J. Widiatmo et al.

- Journal: International Journal of Thermophysics

- Publication Date: February 21, 2020

- Citation Token: (Widiatmo et al., 2020, pp. 1–27)

- Summary: While this study primarily focuses on gallium, it provides context for understanding melting points in general, including copper. The research discusses the methodologies for measuring thermodynamic temperatures, which can be applied to various materials, including metals like copper.

- Methodology: The authors conducted a series of thermodynamic measurements and calibrations to establish accurate temperature references from the triple point of water to the melting point of gallium, which can be extrapolated to other materials.

Frequently Asked Questions (FAQs)

Q: What is the melting point of copper?

A: The melting point of copper is 1984 °F ( 1085 °C ). In industries that deal with copper wire and other products, knowing the melting point of metals such as copper is very important.

Q: How does the melting point of copper compare to other metals?

A: It is copper’s melting temperature that assists in placing it between aluminum, which melts at 1212 °F (660.3 °C), and steel, which contains higher melting point metals depending on its composition.

Q: Why is knowing the melting point of copper important in manufacturing?

A: Knowing the temperature for processing copper, and molding it into products like wire and various alloys, makes the task easier if one understands the needed copper melting temperature.

Q: What is the melting point of brass, an alloy of copper?

A: Brass, which is an alloy of copper and zinc, has a melting range from about 1700 to 1800 °F (930 to 1000 °C) depending on its specific composition. This information regarding the melting ranges of copper alloys is important to metal fabricators.

Q: What is the role of copper’s melting point in using it as molten metal?

A: The copper’s melting point is relatively high as compared to other metals. This is beneficial to a certain extent in manufactring processes that require metals to stay in liquid state at high temperatures.

Q: Which manufacturing metals have different melting points?

A: Suprisingly, some of the most commonly used metals in manufacturing include copper, aluminum, steel, and brass. It can be noted that thier melting point and accuracy varies greatly changing the way these metals are processed and utilized.

Q: Why is copper preferred in high temperature uses?

A: Its melting point advantages copper for electronics that need to bear high temperatures.

Q: Are there metals that have higher tantalum than copper?

A: Certainly alloys like tungsten and steel do come under the category of having a higher melting point than copper. To put it an example, tungsten has one of the highest melting points among common metals which aids its usage in high temperature applications.

Q: How does the processing of metals differ with various metals and their melting points ?

A: Metals have different melting points and that affects how metals change through processing. Metals like copper have a specific temperature range at which they can remain solid or become molten, which impacts their usability in manufacturing.

Q: What importance does copper in its molten form hold during fabrication of metals ?

A: In fabrication of metals, molten copper fulfills an essential role as it aids in the casting, shaping, and joining of metal components. To achieve accurate and strong parts, components are required to be casted at high temperatures and copper’s capability of being molten is beneficial.