Laser technology has become an essential asset in modern manufacturing and design because of its precision and versatility. Have you ever encountered the terms “laser engraving” and “laser marking”? If yes, then you might be wondering what sets the two apart. Although both methods employ sophisticated laser systems, they have different functions and specialize in different uses. This guide aims to explain both processes so you have a better idea of how they work, where they are utilized, and which version would be most suitable for your project. In case this is your field of work, or if this is something you wish to learn, the information in the following articles will help you understand the topic better so you can make the right choices. Without further ado, let us find out the important differences between engraving and marking.

What Are the Key Differences Between Laser Marking and Laser Engraving?

Laser marking and engraving are distinct processes that differ by reason and how deeply they impact the target material. When using a laser to mark a material, the laser does not physically remove any material. Instead, it changes the color of the surface marking. This is excellent for situations where little change is needed to be made. Such cases include but are not limited to: logos, barcodes, and numbers.

Engraving is another different case, where a portion of the material is removed to achieve a deeper design. This is ideal for cases where strong markings are needed such as detailed artwork and personal items.

Factors Affecting Laser Marking and Engraving Quality

In the case marking and engraving, certain elements affect the efficiency and quality of the final product. These factors include the kind of material, operational speed, wavelength, focal length, and the precision of the laser system in question. For instance, some metals, such as stainless steel and aluminum, are commonly used with industrial-grade lasers because of their strength. Softer materials such as plastic or wood, on the other hand, need lower settings to avoid burning and warping.

A laser’s speed and frequency are directly proportional to how well the text and artwork created would be in terms of contrast and resolution. For faster production cycles, higher speeds are often employed, although this may engrave less detail or shallower depth. Moreover, a laser’s wavelength is also vital as it needs to be equal to the absorption rate of the material for optimal results. Metals, for example, are best suited for fiber lasers, while CO2 lasers are non-metallics like glass and other organic materials.

With more recent developments, the use of MOPA (Master Oscillator Power Amplifier) lasers has greatly improved a mark’s precision, allowing high-contrast marking on reflective materials gold and silver. Evidence suggests that businesses adopting this technology have seen an efficiency improvement of nearly 25% in performing serializations and decorative designs.

Taking care of the cooling systems of the machines also needs attention. Overheating can harm the performance and decrease the rate at which the pieces of equipment would be used in terms of efficiency. Maintained and clean calibrations enable the equipment to achieve the highest standards, going as far as dealing with magnitudes of precision. This makes the machinery invaluable in fields such as manufacturing and even medical devices where i’d readily fitted with rigorous as no tolerance standards.

How Power Affects the Efficiency of Laser Marking

Marking precision and efficiency of different materials is highly dependent on the laser power used. Faster marking is achieved with higher laser power, as the greater energy can more quickly break through a surface. This is especially critical for metals or plastics, where deep and clear markings must be readable and indelible.

As new developments unfold, it is becoming clearer that the density of the material and the expected output quality dictate the optimal laser power settings. For metals, such as stainless steel, deeper engravings necessitate higher power settings. Soft materials, like wood or acrylic, require lower power settings to minimize burning or damaging the material’s surface. Industry statistics suggest that sharpening the calibration of power settings optimally increases marking speed by 15–20%, lowering production time without impacting quality.

Furthermore, achieving high-resolution markings with fine details requires balancing power and pulse frequency. Detailing with high power presents a risk of overheating, which diminishes definition and distorts the material. In contrast, too little power leads to incomplete markings. Optimizing these parameters has become easier for laser marking system companies due to advancements in fiber lasers combined with software-controlled power adjustments, ensuring consistent outcomes in large production runs.

Prezise understanding and application of laser power not only improves efficiency and productivity, but also increases the service lifetime and maintenance of the systems. This reduces potential wear and tear associated with the energy output settings.

Factors Affecting The Results of the Raised Marks and the Deep Engravings

Primary constituents of raised marks or deep engravings include the power of the laser, the speed of marking, and the materials to be worked on. Both higher laser power and slower marking speeds tend to give deeper engravings due to the increased energy within the material. On the other hand, faster speeds with lower power tend to favor raised marks as the material removal is surface level.

Recent studies suggest that the effectiveness of laser marking differs significantly with each substrate used, furthermore, metals like steel or aluminum show remarkable variance in depth changes with increased power. Some industrial-grade lasers reach remarkable depths of 500 microns. Conversely, polymers, softer materials may only demonstrate surface changes that improve visibility without significant penetration.

Alongside this, AI-powered applications and more intricate optimization methods are assisting in setting up configurations in advance across industries for improved consistency. Practical industrial case studies show that optimizing the laser parameters has achieved an improvement of marking accuracy by 25% while also reducing the average processing times by 18%. This not only guarantees the production clarity of components, but also smooth operational processes which is vital in high demand industries like Aerospace, Automobiles, and Medical and Surgical Instruments.

Whether it is a decorative feature or a functional mark, achieving these results requires adjusting the parameters to the appropriate values for laser marking applications. The efforts made to enhance these processes illustrate the importance of the application of technology in automated precision manufacturing systems.

How Does the Laser Engraving Process Work?

Laser engravers utilize a focused beam of light to etch or vaporize directly on a surfaced material to engrave it. The laser burns away the material’s surface to carefully mark the surface as needed. A computer controls the engraving which makes it possible to accurately inscribe designs, words, or shapes on numerous surfaces like metal, glass, plastic, or wood. The process is relatively quick and is often used to make markings and engravings for various purposes and looks.

Things that Affect the Effectiveness of Laser Engraving

There are many things that affect the efficiency and accuracy of engravings the most include choosing laser power, beam focus, material type, and marking speed. Laser power is the most important thing that controls the energy output and how deeply a material is engraved. The depth also depends on the material. Softer materials like wood and plastic require lower power settings while more rigid materials like metal need a higher setting.

Another decisive contributor to achieving clean and precise results is beam focus. Focused laser beams Intensely concentrated energy on smaller areas to sharpen and detail engrave. Misaligned focus would be the opposite, marking blurry, uneven etchings. Moreover, the focus of the engraver and the material used as the subject of engraving has direct connection; materials respond variably to heat and light absorption. A reflective material like aluminum, for example, might need coating or pretreatment to make them suitable for engraving.

Advancement in laser technology further customizes the engraving process, enabling things like pulse frequency and even the wavelength of the laser to be tailored to specific needs. Research and testing have shown that added control results in faster marking speeds with fewer mistakes, improving productivity substantially.

The Relation of Laser Power and the Depth of Engraving

Power of the laser greatly affects the depth of engraving done onto a material. With greater power comes higher energy output, allowing the laser to burn deeper into the material. In industry scenarios, for instance, a 50W laser will usually handle engraving to 2mm on stainless steel while a 100W does it to 5mm on optimum conditions.

The material type, focus settings, and engraving speed also impact how efficiently the laser power translates to depth. For harder materials like titanium or hardened steel, significantly greater depths require higher power settings and slower speeds, whereas softer materials like wood or acrylic respond to moderate settings.

Recent research suggests that some parameters, if set properly, precision and unwanted surface defects can be improved. An example would be tuning the frequency and spot size alongside the power settings; this would create precise engravings at a consistent depth. Striking the right balance would cater to achieving quality results regardless of whether it is done for decoration or industrial marking.

Suitable Materials for Laser Engraving

In my experience, laser engraving is effective on most materials. Organics like wood, leather, and paper perform exceptionally well since they respond readily to the heat of the laser. Among plastics, acrylic and other types of synthetics are popular choices because they provide clean and precise engravings. Metals, including stainless steel, aluminum, and brass, also work with some higher power settings or other specialized treatments done to them. Glass and ceramics can be highly decorative, although they are more prone to cracking and require deft hands. All in all, laser engraving remains an excellent addition to any industrial or creative endeavor because of its versatility.

What Is the Laser Marking Process and How Does It Differ?

Permanent markings on the surface of materials can be made with a marked difference differentiating laser engraving and laser marking. This process of laser marking does not remove any material, it modifies the surface properties. This method is most commonly used for branding, barcodes, and serial numbers.

Understanding Laser Marking Annealing, Ablation and Color change

Annealing is described as a technique that permanently changes the color of softer metals without physically changing the structure due to laser marking.

Ablation changes the pigmented layer by exposing the material beneath it for a distinct visually captivating marking. This allows for logos and words to be defined more distinctly, especially with coated and painted materials.

Plastic surfaces can be engraved with text and logos using color change marking where the pigment of the material changes due to laser heating the surface of the material.

Why Precision and Efficiency are Vital for Laser Marking

Today, marking with a laser is one of the necessities in many industrial processes due to the efficiency and adaptability it offers. One of the critical attributes of laser marking technology is the high-speed marking capability which does not compromise on quality. The automobile and electronics industries, as well as the pharmaceutical sector, use laser marking for purposes such as branding and tracking products on their production lines.

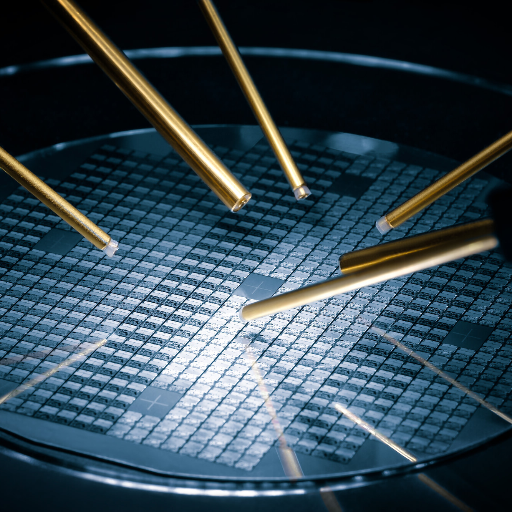

Fiber laser systems have been among the more recent additions which have drastically improved speed and accuracy of marking. For example, modern fiber laser systems are capable of marking stainless steel and aluminum at well over 1000 characters a second. This speed is helpful in sustaining a manufacturer’s production needs without the risk of quality control issues. In mark engraving, these speeds are essential for real-time engraving required in production, for example, the addition of QR codes or batch information on the packaging.

Based on industry report data, the worldwide demand for laser marking machines is projected to accelerate at a compound annual growth rate (CAGR) of 8% during the period of 2023 to 2030 due to their increasing applications in product identification as well as anti-counterfeiting initiatives. Downtime in companies is now being further minimized due to new innovations like advanced beam control and automated integration with the production lines, which in turn improves operational efficiency.

With these new advancements, modern manufacturing needs are continuously being met, making laser marking crucial for quality assurance, traceability, and upholding brand integrity, which is why it has become a valuable asset.

Surface Changes in Aesthetic Appeal with Laser Marking Vs Material Loss with Engraving

Laser engraving and laser marking are two distinct processes that are sometimes hard to tell apart in industrial contexts. With laser marking, surface changes are the primary means of modification as the laser beam makes features such as color markings, oxide markings, or even annealing without removing material. This method is popular for branding products and inserting bar codes for tracking, serial numbers, or user identification on items that need meticulous identification because they cannot bear surface marking. Laser engraving, as the name suggests, goes deeper into the material to remove material and create a permanent mark which is also textural such that it can withstand all conditions which is suitable for tough uses.

The most recent developments in lasers show how accurately these methods are carried out. The fiber lasers with higher wavelengths are quite good at surface enhancement processing on stainless steel, while CO2 lasers work best for engraving organic materials such as wood and leather. It has also been reported by industry experts that laser marking with advanced beams, in their latest versions, is capable of reaching up to seven meters in speed per second which makes laser marking efficient in repetitive manufacturing tasks. In addition, laser-based methods when compared to the conventional mechanical methods tend to result in less cut, reliable, and cost efficient wear in industrial workflows.

As studies have shown, laser marking improves the environmentally friendly capabilities of processes as it helps with waste reduction. Marking, unlike engraving, is a cleaner process as no materials are intended to be damaged and thus can support eco-friendly objectives for the manufacturing sector. The decision to mark or engrave relies on the potential application and material but both stand as essential innovations for industrial and product design.

What About Laser Etching and How Does It Compare?

Laser etching changes the surface of a substance to produce a raised etch. It is a faster process than engraving, but is more shallow. As such, there is often a need to restrain the amount of material that is changed.

Factors Impacting Efficiency of Laser Etching

Increased or decreased power and intensity of a laser will directly influence the sharpness and precision of the etched marks. Other critical parameters include laser speed and frequency. Using lower speed increases precision while higher speed reduces the definition of mark, especially on tougher materials like metal. If the speed is adjusted to a lower rate, the etching of softer materials can be made easier and quicker.

In addition, modern technology has shifted attention to the absorption rates of the materials within the etcher. Glass, coated metals, and plastics are materials that have varying level of energy absorption. For example: metals with a high thermal conductivity would not be able to be etched into without sufficient energy being put in.

Reports from industries reveal that fiber lasers are becoming more popular due to their effectiveness and adaptability across diverse materials, with particular tasks boasting up to 25% greater efficiency when compared to traditional CO2 lasers. Further, some modern systems have started incorporating smart optimization algorithms that can automatically modify parameters like frequency and speed for best results with lowest operator input. Productivity along with results quality in laser etching processes is improved with the integration of these technologies.

Difference Between Laser Etching, Engraving and Marking

The fundamentals distinguishing laser etching, engraving, and marking rests in change of depth and the method used in alteration of material (structure) in any one of the processes. In the case of laser etching, it is the surface melted while a raised mark is formed which means it’s shallow-cut and usually does not exceed 0.001 inches (25 micrometers). This method is applicable where processing speed, contrast, and surface integrity matters. A good example is anodized aluminum branding.

Laser engraving is a different story in which it is more cut out and deeper not only to etch a mark but achieve one that is highly durable and lasting. In fact, the marking is so durable that it can wear over time. In engraving, for example serial numbers there may be an estimate during the process duration of it reaching 0.02 inches (0.5mm) which is typical for industrial use and applications that require harsh conditions.

In comparison to engraving or etching, marking with a laser involves less intense laser energy and changes the outer material surface color without physically removing any materials. It is used widely for the creation of barcodes, logos, and regulatory information marks that need to be sharply contrasted on metals and plastics. For instance, fiber laser systems often achieve high-definition markings on titanium and stainless steel.

Factors Influencing Laser Etching and Marking Results

An underlying list of essential features impact the effectiveness and accuracy of laser etching and marking processes such as speed, frequency, type of material, focus of the laser beam. Combine high-speed settings with optimal frequency, and you get efficient processes. For smaller marks, weeping and frequency pairing can increase processing speed by as much as 30 percent while maintaining accuracy and contrast balance.

Even though material type takes the front seat in playing a vital role, as different lasers are designed to work with particular materials, in this case, CO2 lasers with organic materials (wood and leather) and fiber lasers with metals and plastics), advanced systems now provide pre-configured settings to enhance optimization based on material properties.

Moreover, sharpening focus improves quality. To achieve uniform and fine details, modern laser systems employ auto-focus opportunistic technology with a tolerance of 1/1000 of an inch. Overlapping these features with modern cooling technologies helps eliminate overheating, achieving clean and precise results in many applications.

Factors Impacting the Efficiency of Laser Etching and Engraving

The efficiency and quality of the laser etching and engraving processes are determined by a number of important factors. One very prominent factor is the type of material used. Metals, plastics, and ceramics for instance have different reactions to laser intensity and wavelength, which affects how deep, how fast, and how clearly the marking will be made. Taking stainless steel as an example, it highly resists marking and therefore requires high power settings, while softer materials such as wood or acrylic tend to etch faster at low power settings.

Another important consideration is the speed of marking. Modern laser systems strike a balance between speed and accuracy, achieving industrial grade applications at some 7,000 mm/s marking speed, or even more for finer materials and less intricate designs. Higher speeds greatly reduce the time taken for some high volume operations, making lasers more effective time wise for industries like manufacturing and aerospace.

Effective cooling solutions are a must for the reliable functioning of laser marking systems therfore ensuring effective thermal management. Marking systems need to have a well integrated thermal management system as they need to be able to perform for long intervals of time without accuracy in instrustional marking. This is especially important when working with materials that are sensitive to heat since overheating them could result in distortion or even complete destruction of the intended output.

Software integration improves functionality and changes the perception of value addition. Leading laser systems in the market now come with equipped graphic designing software which allows dynamic edits, support for vectorized inputs, pattern engraving as well as complex arrangements among many other features. Some systems even incorporate advanced AI to predict certain maintenance parameters such as system wear which leads to prolonged system life with minimal upkeep. With continued advancements in technology, the market for laser etching and engraving is persistently expanding, relentlessly demanding precise and efficient work done.

Which Industries Use Laser Marking and Engraving?

- Manufacturing: Used for part identification, serial numbers and barcodes.

- Electronics: Engraving of circuit boards and marking components.

- Jewellery: Engraving bespoke designs and personalising items.

- Medical: Marking surgical instruments and implants for traceability.

- Automotive: VIN numbers are engraved, and various engine parts are marked.

- Aerospace: Marking of key parts require permanent and exact positioning.

Role of Laser Power and Marking Speed in Industrial Applications

Laser power plays a substantial role in the effectiveness, quality and precision of engraving and marking in industrial processes. The mark or engraving speed is determined by the laser power. Increased laser power enables quicker marking workflows, further increasing a manufacturer’s production throughput. For example, higher endurance marks stainless steel and aluminum faster and clearer. On the other hand, softer plastics and coated materials require lower power to preserve optimal conditions.

Marking efficiency of up to 7 meters per second has become possible due to improvements made in laser technologies, as indicated in recent industry research. This benefit in speed is advantageous to aerospace industries and automotive industries to achieve high output for large volume production and serialization of units.

Moreover, adjusting the laser power for optimal efficiency in traceability applications guarantees adherence to international mark and quality standards. Engravings such as numbers, barcodes, and QR codes are required to be permanently etched and readable even, enduring high temperatures, abrasion, or chemical exposure. Because of this, every industry calibrates their laser systems to an optimal fine setting which increases speed, depth, and clarity while minimizing resource consumption and process e, increasing efficiency.

Uses of Laser Technology for Personalization and Decoration

Because lasers are accurate, multifunctional tools that can work on a large variety of materials, they have changed the personalization and decorative fields entirely. Laser cut intricate patterns of wood, acrylic, glass, metal and even jewelry with so much accuracy. New advancements in technology revealed that ultra-fast laser systems are now capable of achieving micrometer level detailing meaning even more complex designs possible which were impossible through traditional means.

As an illustration, market research indicates an increasing interest in purchasing custom laser engraving services for items like phone cases, watches, or even wedding gifts. These segments are estimated to contribute to an average annual market growth of about 7.5% CAGR in the laser engraving sector as reported by market experts. Furthermore, CO2 lasers have a strong position in this segment because of their engraving efficiency on organic materials like bamboo and leather. At the same time, fiber lasers engraving metals with unmatched speed and precision.

Equally important is that modern laser systems integrate contemporary software applications, including AI-based design, which helps small business and large corporations to optimize workflows while enhancing creative possibilities. Be it designing unique jewelry pieces or engraving corporate logos on giveaways, lasers enable unprecedented flexibility and creativity in customization and decorative personal touches.

Reference sources

- Study: An Overview Study on Laser Technology and Applications in the Mechanical and Machine Manufacturing Industry1

- Objective: To provide an overview of laser technology and its applications, including engraving and marking.

- Key Insights:

- Laser engraving involves creating grooves on the material surface by raising its temperature above the melting point, leading to material removal. It is widely used for intricate designs and high-quality finishes.

- Laser marking, on the other hand, alters the material’s surface properties without removing material, often through discoloration or oxidation.

- The study highlights the precision and efficiency of both methods, emphasizing their suitability for different industrial applications.

- Study: Influence of Laser Marking Parameters on Data Matrix Code Quality on Polybutylene Terephthalate/Glass Fiber Composite Surface2

- Objective: To analyze the effects of laser marking parameters on the quality of data matrix codes.

- Key Insights:

- Laser engraving is described as a technique that creates deeper grooves compared to marking, which primarily focuses on surface-level changes.

- The study emphasizes the importance of selecting appropriate laser parameters (e.g., power, speed) to achieve desired results, whether for engraving or marking.

- It also notes that engraving typically requires higher energy density to achieve material removal, while marking relies on surface interactions like oxidation or carbonization.

- Top Laser Marking Machine Manufacturer And Supplier In China

Frequently Asked Questions (FAQs)

Q: What is the key distinction between laser etching and laser engraving?

A: The key distinction between laser etching and laser engraving lies in the depth of the marks left on the surface. With laser etching, a shallow mark (typically 0.001” or less) is made by melting the surface of the material, which expands and leaves a raised mark. With engraving, greater amounts of material are removed to create deeper marks, which can range from 0.001” to over 0.005.” Engraving physically vaporizes the material out creating a cavity while etching just changes the surface. This difference means engraving is the more permanent option, whereas etching, which is faster and easier, is more durable.

Q: For my project, when would I need laser etching vs laser engraving?

A: You will need laser etching when rapid marking is required with bare minimum disruption to material, such as in electronics, thin materials, or delicate parts. Laser etching is most appropriate for barcodes, serial numbers, and logos when speed is a concern. You will need laser engraving when the priorities are durability and depth, such as for industrial components subject to wear or for decorative pieces that demand unambiguous traceability. Your choice depends heavily on the material used, how permanent the mark should be, and how fast the production needs to be.

Q: What are the most common industries that make use of the laser etching and engraving services?

A: All industries make use of laser etching and engraving for different purposes. Medical device manufacturers apply these processes for permanent identification and traceability. The aerospace and automobile industries utilize a laser marking system for part identification and direct part marking. Electronics manufacturers use laser etching in marking of components as it does not cause damage. The industrial manufacturing sector uses laser processes for quality control while the consumer’s products uses laser etching and engraving for branding and product decoration.

Q: In what way does a laser marker differ from an engraving machine and what advantages does it have?

A: A number of factors set a laser marker apart from the traditional method of engraving. Laser markers are non-contact tools and do not touch the material at all, eliminating tool wear and distortion of the material. Furthermore, they offer uniformity and precision digitally over thousands of marks which is not achievable with engraving that uses physical tools as they wear down. Laser marking systems can process a wider variety of materials without needing specialized tools as other marked engraver lines do. Along with this, laser markers tend to run faster, allow for complicated layouts to be controlled, and require less mechanical clamping than traditional engraving.

Q: What other processes of laser marking exist besides etching and engraving?

A: Various processes of laser marking exist apart from laser etching and laser engraving. These include: laser ablation, which decuts coatings and reveals underlayers that possess a different color; laser annealing, which uses heat to change the color of the material without removing significant amounts; coloration such as laser coloration or laser dark marking where the color change occurs due to chemical reactions instead of removal; laser foaming where bubbles are produced beneath transparent substances; and carving laser mark carbonization on organic materials which darken the marks. Each such method has particular uses based on the substance as well as the look or functionality attribute intended in direct part marking procedures.

Q: How much deeper can laser engraving be as compared to laser etching?

A: In comparison to laser etching, laser engraving can reach greater depths. Laser etching typically leaves a mark with a maximum engraving depth of 0.001 inch (0.025 millimeters) or less; in contrast, laser engraving can leave deeper marks ranging from 0.001 inch to 0.020 inch (0.025 mm to 0.5 mm) or greater depending on material and laser power used. Some materials may require multiple passes, where the laser is pulsed repeatedly over the same spot to achieve deep marking. Etching is surface marking only, which means it cannot go beyond the top layer of a material because it does not take away material; it applies heat to expand the top layer.

Q: What are the benefits of laser marking over other engraving methods?

A: The advantages are endless. Laser marking processes provide exceptional accuracy and uniformity, even when dealing with intricate designs. When marking materials, they do not come in contact with them, so there is no marking, and no material deformation. There is a wide variety of adaptable materials that are altered with minimal effort, and no additional equipment is required. Marks made with lasers cannot be removed or modified, making it possible to track such items permanently and the markings provide good contrast and protective environment condition markings. Traceability marking systems is done faster with lasers than with mechanical systems, and, unlike those, laser machines guarantee precise repeatable marking. Moreover, laser marking does not use any chemicals, giving an eco-friendly impression. In addition to these, laser marking applies automated machine readable codes for robotic work and can switch between various marking methods but still use one machine.

Q: How do I know the difference between the different laser processes while selecting a piece of equipment?

A: When choosing equipment, pay attention to some of the key aspects to understand the difference between laser processes. First, define your marking requirements: the depth, contrast, and permanence of the mark. Then evaluate your materials: different metals, plastics, or organic materials will respond differently to different types of lasers. Primary consideration should also be given to volume and speed: production cycle time and volume may vary between laser processes. Samples also need to be marked using the equipment to verify quality. Power requirements depend on the laser, as some processes need higher power. Lastly, total cost of ownership should include consumables, maintenance, and energy. Speaking with specialists and seeing different processes demonstrated on your materials often works best.

Q: Why is traceability important when considering laser etching vs laser engraving?

A: Laser marking and engraving involves unique identification and record keeping, which necessitates active business surveillance. In regards to record keeping, traceability is very important in case of an issue arising with the ever needed identification. Laser engraving creates deep marks which can withstand harsh environments thus protecting traceability within industrial surroundings. For components that require going through various processes like engraving, painting, or going through harsh environments, engraved marks remain legible longer. While some laser etching may look desirable for aesthetic purposes, it has less practical value since the lettering is cut into a shallow depth and can become unreadable over time. When laser engraved markings are necessary for identification throughout the entire product lifecycle, it is important to consider that deep engraving is usually the best option.