Cutting-edge manufacturing demands precision, efficiency, and innovation, and few tools embody these qualities as powerfully as fiber lasers and CNC machines. Both technologies have revolutionized industries ranging from automotive to aerospace and beyond, shaping the way materials are processed and final products are crafted. But how do these two giants of modern manufacturing compare? What are their respective strengths, limitations, and ideal applications? This article dives into the dynamic world of fiber lasers and CNC machines, providing an in-depth exploration to help you understand their differences and make informed decisions. Whether you’re a seasoned industry professional or simply curious about advanced manufacturing technologies, this guide will equip you with the knowledge needed to stay ahead in today’s rapidly evolving technological landscape.

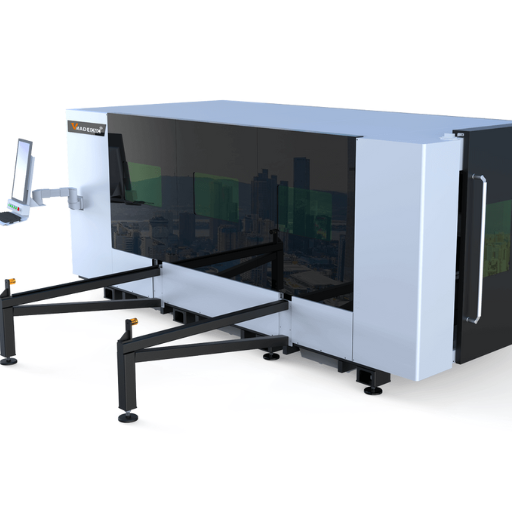

What is the difference between CNC and Fiber Laser?

The CNC (Computer Numerical Control) machines and fiber lasers are two different tools used in manufacturing. In particular, each tool specializes in fulfilling different purposes, thus they operate on mechanically different principles.

CNC Machines: The CNC is a versatile machine which cuts metal, wood or plastic, mills, drills, and even shapes these materials into desired objects. The programmable computers governing the CNC machines use stepby instructions to control the actions of the cutting instruments. Therefore, they carve very detailed and repeatable designs into the workpieces. Due to the wide range of machining practices performed, these machines are best suited to all-in-one projects.

Fiber Lasers: The Fiber lasers are machines that use a concentrated beam of light to cut, engrave, or etch materials with extreme precision. Strength is offered by fiber lasers making them better to use when working with metals and some plastics. Fiber lasers spend less time than conventional lasers and they also reduce material waste making them a more practical option overall. These machines are best suited for the manufacture or marking of intricate designs, smooth edges, fine details.

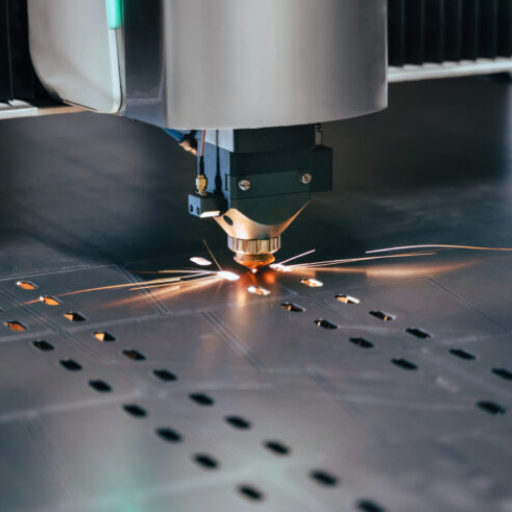

How does a laser cutter work?

A laser cutter operates by focusing a high-powered laser beam onto a specific point of a material to cut, engrave, or mark it with extreme precision. The process begins with a guided laser source—typically CO2 or fiber lasers—that emits a beam at a specific wavelength. This concentrated beam is directed through a lens and directed by mirrors to achieve pinpoint accuracy.

When the laser hits the material, it delivers intense heat that causes the material to melt, burn, or vaporize, creating a clean cut or mark. Advanced systems often utilize computer numerical control (CNC) for automated and highly detailed designs. Laser cutters are capable of working on a variety of materials, including metals, plastics, wood, paper, and textiles. Modern fiber laser cutters, for instance, can achieve cutting speeds up to 140 meters per minute depending on material thickness, with cutting tolerances as tight as ±0.1 mm.

Additionally, laser cutting technology has evolved to incorporate features like adaptive optics and real-time monitoring to ensure consistent quality. For example, many industrial laser cutters now offer power outputs up to 12 kW, enabling them to handle thicker materials while maintaining precision. Beyond its speed and accuracy, laser cutting is highly efficient, with minimal material waste compared to traditional cutting methods, making it a preferred choice across industries like manufacturing, automotive, and aerospace.

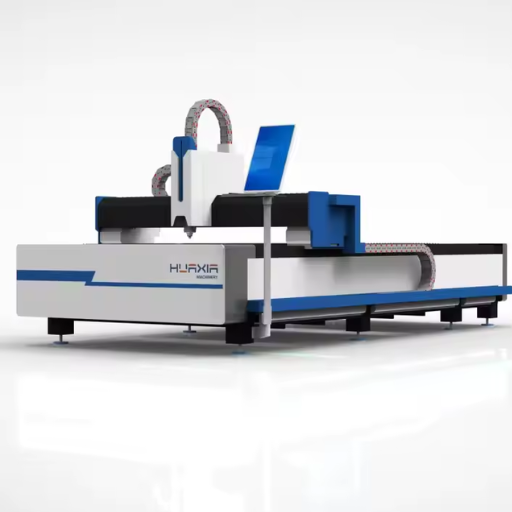

What is a CNC machine?

A CNC (Computer Numerical Control) machine is an advanced manufacturing tool designed to perform a wide range of tasks like cutting, drilling, milling, and shaping materials with incredible accuracy and efficiency. Controlled by pre-programmed computer software, CNC machines interpret detailed design instructions to automate production processes, reducing the need for manual intervention. This not only enhances precision but also ensures consistency across numerous production cycles.

Modern CNC machines vary widely in size and application, from small desktop models suitable for hobbyists to large industrial-grade systems used in high-volume production. For instance, CNC milling machines are commonly utilized to create intricate metal components, while CNC routers are ideal for working with wood, plastic, or composite materials. Industrial CNC machines today boast accuracy levels as high as ±0.001 inches, enabling manufacturers to meet stringent tolerances in sectors like aerospace and medical device production.

The global CNC machine market is steadily expanding, with its value estimated to reach $117 billion by 2030, driven by increasing demand for automation and precision in manufacturing processes. Thanks to their versatility, CNC machines are used in industries ranging from automotive and electronics to construction, showcasing their ability to adapt to different needs while maintaining unmatched reliability and efficiency.

Comparing laser cutting and CNC cutting methods

When comparing laser cutting and CNC cutting, several factors come into play, including precision, material compatibility, speed, cost-efficiency, and application suitability.

- Precision and Tolerances

Laser cutting is renowned for its exceptional precision, capable of achieving tolerances as tight as ±0.001 inches. This makes it an ideal choice for intricate designs and highly detailed components often used in industries like electronics or medical manufacturing. CNC cutting, while also precise, typically operates with tolerances around ±0.005 inches, depending on the specific machine and process. This makes CNC cutting more suitable for thicker and less detailed parts where ultra-high precision is less critical.

- Material Compatibility

Laser cutting excels with materials like thin metals (steel, aluminum, titanium), plastics, and even wood or acrylics. However, it struggles with reflective materials like certain aluminum alloys unless specialized equipment is used. CNC cutting, by contrast, has the advantage when working with a wider range of material thicknesses and types, including metals, wood, plastics, and composite materials, often up to several inches thick.

- Cutting Speed

For thin materials, laser cutting outpaces CNC cutting in terms of speed, particularly for intricate designs. Lasers operate quickly, using the concentrated energy beam to cut through materials with minimal resistance. CNC machines, though slightly slower, remain consistent over thicker materials, where laser power may become less efficient. For example, in processing steel, laser cutting can handle sheets up to 15mm thick at high speed, whereas CNC routers can cut steel up to 38mm but at a slower rate.

- Cost and Maintenance

Laser cutting has higher initial setup and equipment costs due to the complexity of the laser systems. However, it may offer savings in long-term operational efficiency for high-precision needs. CNC cutting, while often more affordable to acquire, can incur higher costs for tool wear and maintenance, particularly when machining harder materials. Operational costs also vary based on energy consumption, with laser cutters generally using more power for their high-intensity beams.

- Applications and Industry Usage

Laser cutting thrives in applications requiring intricate designs, such as decorative panels, electronic enclosures, and signage. CNC cutting is better suited for structural components, furniture manufacturing, and prototyping where durability and versatility are essential.

- Environmental Impact

Laser cutting generally produces less waste material compared to CNC cutting, which often leaves more noticeable chip and scrap byproducts. However, the higher energy consumption of laser cutting may offset some of its environmental efficiency, depending on the energy source used.

Both cutting methods have their strengths and limitations, and the choice largely depends on project-specific requirements, such as material type, required precision, and production volume. Combining these methods within a manufacturing workflow ensures flexibility and maximizes efficiency for diverse production needs.

How does a fiber laser cutting machine operate?

A fiber laser cutting machine operates by directing a high-intensity laser beam through optical fibers to focus the energy onto a specific point on the material’s surface. The focused heat melts, vaporizes, or burns through the material. Assisted by pressurized gases, such as oxygen or nitrogen, the molten material is blown away, creating clean and precise cuts. This process is highly efficient and is particularly effective for cutting metals, offering exceptional speed, accuracy, and minimal material waste.

Principles of laser cutting technology

Modern laser cutting technology has evolved significantly, leveraging advanced systems to provide unparalleled precision and efficiency. With cutting accuracy often reaching tolerances within ±0.003 inches, this technology is highly favored for applications in industries like aerospace, automotive, and medical manufacturing, where exact specifications are critical. Laser cutting systems can achieve speeds of up to 1,000 inches per minute, making them incredibly effective for high-volume production.

Furthermore, the integration of innovative features such as fiber lasers has enhanced energy efficiency. Fiber laser machines use approximately 70% less energy compared to CO2 lasers, reducing operating costs and environmental impact. They also offer the ability to cut a wide range of materials, from stainless steel and aluminum to non-metallic substances like plastics and ceramics, with consistent edge quality and minimal thermal distortion.

Additionally, advancements in automation have streamlined the process further. Features like automated material handling, real-time monitoring, and adaptive software allow machine operators to optimize performance and minimize downtime. These innovations not only increase productivity but also improve safety by reducing the need for manual intervention. Such developments underscore the continuous evolution of laser cutting technology and its growing importance in modern manufacturing practices.

Advantages of fiber lasers over co2 lasers

- Higher Energy Efficiency

Fiber lasers are significantly more energy-efficient compared to CO2 lasers. They convert a greater portion of input energy into laser light, with efficiency rates often exceeding 30%, whereas CO2 lasers typically operate at around 10-20% efficiency. This reduction in energy consumption translates to lower operational costs.

- Better Beam Quality

Fiber lasers provide a smaller, more precise beam diameter, offering superior beam quality. This allows for finer cuts and greater detail, making them ideal for intricate designs and applications requiring high precision.

- Lower Maintenance Requirements

Unlike CO2 lasers, fiber lasers have a more compact and robust design with fewer moving parts. They do not rely on mirrors or optics that require frequent alignment or cleaning, resulting in reduced maintenance time and costs.

- Faster Cutting Speeds

Fiber lasers can achieve faster cutting speeds, especially on thin and reflective materials like stainless steel, aluminum, and brass. For instance, on materials less than 6mm thick, cutting speeds can be up to three times faster than CO2 lasers.

- Ability to Cut Reflective Materials

Fiber lasers excel at cutting highly reflective materials without the risk of back reflections damaging the laser, a common issue with CO2 lasers. This makes them better suited for industries working with copper, brass, or gold.

- Longer Lifespan

The life expectancy of fiber lasers is significantly longer, often exceeding 100,000 hours, compared to CO2 laser systems. This durability reduces the need for frequent replacements, adding to cost efficiency over time.

- Compact Design

Fiber lasers have a more compact build, requiring less physical space for installation. This space-saving design is ideal for modern manufacturing environments where floor space is often at a premium.

- Lower Operating Costs

With high energy efficiency, low maintenance requirements, and reduced consumable parts, fiber lasers offer lower long-term operating costs compared to CO2 lasers.

- No Gas Requirements

CO2 lasers require expensive laser gases for operation, such as CO2, helium, and nitrogen. On the other hand, fiber lasers are solid-state systems and do not require laser gases, eliminating this additional cost and complexity.

- Environmentally Friendly

Fiber lasers consume less power and do not require gases, making them a more environmentally friendly option. Their energy efficiency contributes to reducing the overall carbon footprint of manufacturing operations.

Applications of fiber laser systems

Fiber laser systems have become indispensable in a variety of industries due to their versatility, precision, and efficiency. Below are some key applications:

- Cutting and Welding

Fiber lasers are widely used in cutting and welding applications, particularly in the automotive, aerospace, and construction industries. Their high power and precision enable the cutting and joining of metals such as stainless steel, aluminum, and titanium with exceptional accuracy. For example, fiber laser cutting can achieve cutting speeds up to eight times faster than traditional methods for thin materials, significantly boosting productivity.

- Marking and Engraving

Industries including electronics, jewelry, and medical devices rely on fiber lasers for high-precision marking and engraving. Fiber lasers provide permanent and highly detailed marks on materials like metals, plastics, and ceramics. This is particularly critical in traceability, where barcodes, serial numbers, or QR codes need to be accurately and durably etched on products. Compared to CO2 lasers, fiber lasers can process harder materials more effectively.

- 3D Printing and Additive Manufacturing

The role of fiber lasers in additive manufacturing is growing rapidly. They are integral to laser-based metal 3D printing processes, where a high-powered laser precisely melts powdered metal layer by layer to create complex parts. This technology is revolutionizing industries like aerospace and healthcare, enabling lightweight, custom designs and faster production cycles. Some systems achieve up to 99.5% material density, rivaling traditionally manufactured equivalents.

- Surface Cleaning and Treatment

A notable application of fiber laser technology is in laser cleaning, which is used to remove rust, paint, or contaminants from metallic surfaces without causing damage. This process is increasingly adopted in industries such as shipbuilding and automotive restoration due to its environmental benefits, as it eliminates the need for chemicals or abrasive media.

- Electronics Manufacturing

Fiber lasers provide unparalleled precision for tasks like PCB micro-cutting and drilling, which are vital in producing electronic components. Thanks to their short wavelength and small focal spot, fiber lasers can achieve micron-level precision required for modern miniaturized devices. They are also heavily used in glass and transparent material processing in smartphones and tablets.

- Medical Applications

The medical field uses fiber lasers for tasks ranging from cutting surgical tools to engraving medical devices. Additionally, their precision and reliability make them suitable for delicate procedures, such as hair removal, skin treatments, or eye surgeries like LASIK.

These applications highlight the transformative impact of fiber laser systems across diverse sectors, combining precision, cost-efficiency, and environmental benefits to meet modern industrial and technological demands. The flexibility and efficiency of fiber lasers continue to drive innovation across manufacturing and beyond.

What are the benefits of using a CNC cutter?

CNC cutters offer several key benefits:

- Precision and Accuracy – CNC cutters are highly accurate, ensuring consistent and precise cuts, even on complex designs.

- Efficiency – They streamline production by reducing manual labor and significantly speeding up the cutting process.

- Versatility – CNC cutters can work with a variety of materials, including wood, metal, plastic, and composites.

- Cost-Effectiveness – They reduce material waste by optimizing cutting patterns and enhance overall productivity.

- Repeatability – CNC technology ensures consistent results across multiple projects, ideal for mass production.

- Ease of Use – Once programmed, CNC cutters require minimal supervision, making them user-friendly and reliable.

These advantages make CNC cutters indispensable for industries seeking high-quality and efficient manufacturing solutions.

Key features of CNC machines

- Precision and Accuracy

CNC machines operate with exceptional precision, often achieving tolerances within ±0.001 inches. This level of accuracy ensures the production of high-quality components, critical in industries such as aerospace and medical device manufacturing.

- Automation

Once programmed, CNC machines perform operations autonomously, reducing the need for manual labor. This feature not only saves time but also significantly lowers the risk of human errors in manufacturing processes.

- Versatility

CNC machines can handle a wide variety of materials, including metals, plastics, wood, and composites. Additionally, they are versatile enough to perform multiple operations such as drilling, milling, turning, and cutting within a single setup.

- High-Speed Operations

Modern CNC machines are equipped with high-speed spindles and advanced drive systems, allowing them to complete tasks much faster than traditional machining methods. This increases productivity and shortens production cycles.

- Consistency

With programmed instructions, CNC machines replicate designs with perfect consistency, making them ideal for mass production where uniformity is essential.

- Complex Geometries

CNC machines can handle intricate designs and produce components with complex geometrical shapes that are difficult or impossible to achieve manually.

- Real-Time Monitoring

Advanced CNC systems come equipped with sensors and software that allow real-time monitoring and feedback, ensuring the machining process remains efficient and error-free.

- Scalability

CNC technology supports scalability, as the same program can be reused countless times, enabling seamless production from small batches to larger manufacturing runs.

- Tool Management Systems

Many CNC machines are integrated with automated tool changers, which allow for smooth transitions between different machining operations in a single program.

- Integration with CAD/CAM Software

CNC machines leverage CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) software to streamline the designing and programming process, reducing lead times and improving workflow.

These key features demonstrate why CNC machines are a vital asset in modern manufacturing, offering unparalleled efficiency, precision, and flexibility.

Industries that rely on CNC cutting

- Aerospace Industry

The aerospace industry relies heavily on CNC cutting to meet its demanding standards for precision and reliability. Components like turbine blades, structural parts, and aircraft engines are machined to exact specifications to ensure safety and performance. According to recent industry estimates, the global aerospace CNC machining market continues to grow due to advancements in manufacturing technology and increasing demand for air travel.

- Automotive Industry

CNC machines play a crucial role in manufacturing automotive components such as engine blocks, gears, and transmission parts. The capability to produce complex and precise designs makes CNC cutting an essential process for both internal components and external features. The automotive machining market is projected to reach significant growth, driven by electrification trends and evolving vehicle designs.

- Medical Industry

Precision is paramount in the medical field, where CNC machined tools and components are used to create surgical instruments, orthopedic implants, and custom prosthetics. The increased demand for minimally invasive procedures and advanced medical devices further underscores the importance of CNC cutting in achieving the necessary accuracy and quality demanded by healthcare providers.

- Electronics Industry

With the rapid advance of technology, the electronics industry requires highly intricate and miniaturized components such as connectors, semiconductors, and microelectromechanical systems (MEMS). CNC cutting is vital in producing these components with precision, aiding in the development of smaller, more powerful devices.

- Construction and Architecture

The construction industry benefits from CNC cutting for producing custom metal, wood, and composite materials for architectural designs, furniture, and support structures. The ability to create intricate and large-scale components efficiently has made CNC machines popular in modern construction projects.

These industries exemplify the widespread use of CNC cutting technology, which continues to expand as innovations in machinery and software further enhance capabilities, enabling manufacturers to meet evolving market demands with exceptional precision and efficiency.

Comparing CNC milling and laser cutting

CNC milling and laser cutting are two distinct methods widely used in manufacturing, each offering unique advantages suited to specific applications. CNC milling is a subtractive process that uses rotary cutters to remove material from a workpiece. It excels in creating precise, three-dimensional components from various materials, including metals, plastics, and wood. One key advantage of CNC milling is its ability to handle thicker and denser materials, making it ideal for industries requiring durable and complex parts, such as aerospace and automotive. CNC milling typically achieves tolerances within ±0.005 inches, which allows for exceptional accuracy.

On the other hand, laser cutting utilizes a high-powered laser beam to cut or engrave materials. This method is renowned for its speed, precision, and ability to produce intricate designs. Laser cutting is particularly useful for thinner materials like steel sheets, acrylic, or leather, and provides a smooth, clean edge finish without the need for secondary processing. Modern laser cutters can achieve tolerances as fine as ±0.001 inches, making them suitable for highly detailed work. Additionally, laser-cutting machines are often energy-efficient, reducing operating costs compared to some traditional methods.

When comparing the two, the choice between CNC milling and laser cutting largely depends on the material, design complexity, and intended use of the finished product. CNC milling is better suited for projects requiring structural durability and depth, while laser cutting excels in speed and intricate surface-level designs. With advancements in both technologies, manufacturers now frequently combine these methods to maximize efficiency and versatility, tailoring production processes to meet diverse industry requirements.

When should you choose laser cutting over CNC cutting?

You should choose laser cutting over CNC cutting when precision and intricate designs are critical. Laser cutting is ideal for projects that involve detailed patterns, smooth edges, or thin materials like acrylic, fabric, or paper. Additionally, it is a faster and more cost-effective method for high-volume production of smaller components or decorative elements, especially when working with non-metallic materials.

Material considerations for laser cutting

When selecting materials for laser cutting, it’s essential to consider their compatibility with laser technology, as not all materials deliver optimal results. Materials like acrylic, plywood, MDF, and paper are excellent candidates due to their ease of cutting and ability to produce clean edges. Acrylic, for example, is widely used because it melts rather than burns, creating a polished edge that requires no additional finishing. Thickness is also a key factor; standard laser cutters typically handle materials up to 0.5 inches for non-metals, ensuring precision without distortion.

Metals, such as stainless steel or aluminum, are also suitable but require a higher-powered laser. Careful attention must be given to the material’s reflective properties, as reflective surfaces can interfere with the laser beam. For instance, stainless steel is highly reflective and often requires a special coating or a fiber laser to achieve effective results. Heat-sensitive materials like PVC or polycarbonate should be avoided as they release hazardous fumes when cut with a laser.

Additionally, moisture content in materials like wood or MDF should be minimized. High moisture can lead to inconsistent cuts and a charred appearance. Always ensure that materials are flat and free of contaminants, as dirt or adhesives can hinder the laser’s accuracy. For enhanced results in production settings, consider pre-testing the material to optimize the cutting speed, power settings, and frequency for the specific laser cutter being used.

Precision and speed: laser vs CNC

When comparing lasers and CNC machines, both have unique strengths that cater to different needs in precision and speed. Laser cutters excel in achieving extreme precision, often cutting with tolerances as tight as ±0.003 inches. This level of accuracy makes them ideal for intricate designs and detailed engraving tasks. Additionally, laser cutters operate faster in scenarios involving thinner materials such as acrylic, fabric, or thin wood sheets, as there is no physical contact with the material—reducing the need for tool changes or adjustments, thereby increasing efficiency.

On the other hand, CNC machines are highly versatile and are often favored for heavier materials such as metals and dense woods. While their precision is slightly less refined compared to lasers, usually within ±0.005 inches, CNC machines can handle deeper cuts and a broader variety of materials. They also perform well in speed when working on three-dimensional cuts or milling tasks, which require removing significant material volumes.

Efficiency also depends on project specifics. For instance, laser machines generally process 2D cuts faster, while CNC machines might outperform on complex 3D surfaces. An essential factor to consider is material thickness, as lasers struggle with thickness beyond certain thresholds (e.g., ¾ inch for wood), whereas CNC machines can tackle much heavier sections with ease. For choosing between the two technologies, the decision often hinges on the material type, design complexity, and production volume.

Cost implications of cutting vs laser

When evaluating the cost implications of cutting methods like CNC machining versus laser cutting, several factors come into play, including equipment costs, operational expenses, and efficiency. Laser cutting machines typically have higher initial purchase prices, often ranging from $8,000 to over $100,000 depending on power and precision levels. However, they are more efficient for high-speed cutting of thinner materials, which can reduce long-term labor costs in mass production scenarios.

On the other hand, CNC machines, with costs that typically range from $2,000 to $150,000 based on complexity and size, are often more versatile with material thicknesses and require less post-processing in some cases, which could lead to savings for intricate 3D projects. However, CNC machining may have higher tooling wear-and-tear costs over time, particularly when used on harder materials, which adds to operational expenses.

Energy consumption is another critical factor in cost analysis. Laser cutting machines generally consume more electricity due to the high energy demands of the laser, influencing long-term utility expenses. CNC machines might have lower energy requirements comparatively but may require frequent maintenance cycles, which increases downtime expenses.

Finally, production volume plays a significant role in determining overall cost efficiency. For high-volume, precise cuts on thinner materials, laser cutting is often more cost-effective as it minimizes waste and maximizes productivity. Conversely, for projects requiring robust, multi-dimensional machining, CNC machines can prove more economical by accommodating diverse designs without the need for supplemental tools.

Ultimately, the choice between cutting technologies should balance the up-front investment with operational costs, material limitations, and the specific requirements of the project at hand.

How to decide between laser and CNC for your project?

When deciding between laser and CNC for your project, consider the following key factors:

- Material Type – Laser cutting works well for thin materials like wood, acrylic, and metal sheets, while CNC is better suited for thicker materials, harder metals, and three-dimensional machining.

- Complexity of Design – Use laser cutting for intricate, detailed designs, as it provides precision without contact. For deeper cuts or multi-dimensional designs, CNC is the better choice.

- Budget and Scale – Laser cutting is cost-effective for smaller projects or precise cuts, while CNC machines are better for large-scale projects requiring versatility.

- Speed and Efficiency – For fast processing, laser cutting is ideal. For tasks requiring extensive shaping, CNC offers efficiency in handling diverse operations.

Evaluate these factors based on your project’s needs to make an informed decision.

Evaluating your cutting method needs

To determine the best cutting method for my project, I would assess the materials I am working with, the level of precision required, the budget I have, and the scale of the operation. If I need precision for smaller tasks, I would lean towards laser cutting, but for more complex shapes or larger projects, CNC might be the better option.

Understanding the difference between CNC cutting and laser cutting

Each project has different use cases that make CNC cutting or laser cutting preferable. When it comes to versatility for multi material projects, CNC cutting is unmatched. It can cleanly cut wood, metal, or plastic and is perfect for complex, multi-dimensional shapes. Laser cutting on the other hand is exceptionally precise and is best for detailed work on thinner materials. Paper, acrylic, and fabric all benefit from laser cutting’s ability to provide clean edges, but is better for smaller scale projects. For myself, I make my decision from the complexity, material type, and the intricacies required for the project.

Choosing the right cutting tool for your materials

When deciding on the right cutting tool, I focus on three key factors: the material I’m working with, the complexity of the design, and the level of precision required. For intricate designs on thinner materials, I would go with laser cutting due to its accuracy and clean edges. However, for thicker or multi-dimensional materials, I’d choose a CNC machine for its versatility and ability to handle complex shapes.

Reference Sources

-

Feasibility of Fiber Laser-CNC Milling Cooperative Machining Technique (2022)1:

- Key Findings: This study introduced a hybrid machining technique combining fiber laser and CNC milling for slotting thick CFRP (Carbon Fiber Reinforced Polymer) laminates. The fiber laser provided high efficiency and material removal rates, while CNC milling ensured superior surface quality. The hybrid approach minimized thermal damage and improved machining precision.

- Methodology: The research analyzed surface morphology and thermal damage using experimental trials on 10mm thick CFRP plates. It evaluated the effects of machining parameters on surface quality and material removal mechanisms.

-

A Technical and Commercial Comparison of Fiber Laser and CO2 Laser Cutting (2012)2:

- Key Findings: While this study primarily compared fiber and CO2 lasers, it highlighted the advantages of fiber lasers in cutting thin sheet metals with high precision and speed. It also noted the versatility of CO2 lasers for broader applications, which could be relevant when comparing CNC machines and fiber lasers.

- Methodology: The study compared cutting speeds, costs, and maintenance requirements, providing insights into the operational differences between laser technologies.

- Top Fiber Laser Marking Machine Supplier and Manufacturers in China

Frequently Asked Questions (FAQs)

Q: What are the primary differences between laser cutting machines and CNC machines?

A: The main differences between laser cutting machines and CNC machines lie in their cutting mechanisms. Laser cutting machines use a focused laser beam to melt, burn, or vaporize the material, providing precision and speed. In contrast, CNC machines use physical cutting tools to remove material, which can be more effective for thicker or denser materials.

Q: What are the advantages of using a laser for cutting materials?

A: Advantages of laser cutting include high precision, the ability to cut intricate shapes, a clean finish with minimal post-processing, and efficiency in cutting thin materials. Laser cutting uses a laser source that is ideal for detailed work and offers faster production times compared to some traditional methods.

Q: How does the cost of laser solutions compare to CNC cutting machines?

A: The cost of laser solutions can be higher than CNC cutting machines due to the advanced technology and maintenance required for the laser source. However, lasers can offer cost savings in production time and material waste, making them a worthwhile investment for specific applications.

Q: Can CNC and laser cutters be used for the same materials?

A: CNC and laser cutters can both be used for various materials such as wood, plastics, and metals. However, the choice between them depends on the material thickness and desired finish. CNC machines excel in processing thicker materials, while laser cutters are more suitable for cutting thin and delicate materials with precision.

Q: What are the differences between laser cutting and CNC cutting tools?

A: Laser cutting uses a concentrated light beam to cut materials, making it suitable for fine details and thin materials. CNC cutting involves physical tools that carve or mill the material, offering versatility and strength for thicker materials. The choice depends on the project requirements and material properties.

Q: What are the advantages of CNC cutting over laser cutting?

A: The advantages of CNC cutting include its ability to handle thicker and denser materials, versatility in cutting various shapes, and the use of diverse cutting tools. CNC machines can work with a wide range of materials, making them suitable for heavy-duty applications.

Q: Is using a CNC router slower than laser cutting?

A: Yes, using a CNC router can be slower than laser cutting, especially for intricate designs and thin materials. Laser cutting is generally faster due to its focused laser beam, which can quickly melt or vaporize materials without physical contact.

Q: What factors should be considered when choosing between CNC and laser cutting?

A: When choosing between CNC and laser cutting, consider the material type and thickness, desired precision, production speed, and budget. CNC machines are better for thicker materials, while laser solutions offer precision and speed for thinner materials. Evaluate the specific needs and goals of your project to make an informed decision.

Q: How do CO2 and fiber lasers differ in their application for cutting?

A: CO2 lasers are typically used for cutting non-metal materials like wood, acrylic, and glass, while fiber lasers are better suited for cutting metals due to their shorter wavelength, which allows for finer and faster cuts. Choosing the right type of laser depends on the material and application requirements.

Q: What are the benefits of using CNC machines and laser cutters together?

A: Using CNC machines and laser cutters together can offer comprehensive solutions for complex projects. CNC machines provide the strength to handle heavier materials, while laser cutters offer precision for detailed work. This combination allows businesses to optimize production, enhance flexibility, and improve overall product quality.