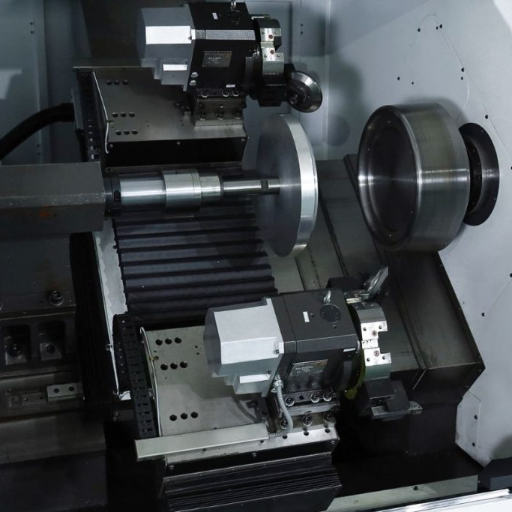

Numerous modifications continue to take place in the CNC machining domain, each one enhancing precision, efficiency, and automation levels. One important development is The ATC CNC Router which is powered with an Automatic Tool Changer (ATC) system. By automating the multi-step processes these machines perform, manual work is minimized while productivity and precision are greatly improved. In this article, we will unravel what exactly an ATC CNC router is and how it functions. From technology to features, benefits, and applications, we will cover all aspects to help you understand the impact it has in the manufacturing world. Whether you are a professional machinist or a beginner trying to learn something new, this thorough investigation will help you gain the expertise needed to fully utilize ATC CNC routers. So, let us begin the learning journey about this astonishing system.

What is the difference between an ATC CNC router and a standard CNC router?

As compared to regular CNC router, an ATC CNC router’s main differentiating feature is its ability to perform automatic tool changes. While CNC routers have manual tool changes, an ATC CNC router has a system that can automatically change tools per instructions in the program. This significantly reduces downtime, enhances efficiency, and make it possible to complete more complex and precise projects without requiring constant manual attention.

Important qualities which set ATC CNC machine capabilities apart from the others

- Automatic Tool Changes: The removal of manual work in for tool changing enhances operational efficiency and quickens the time required for production.

- Precision and Versatility: The router enables the performance of complex designs and accommodates use of different materials because of the different tools available.

- Time Efficiency: Smooth work processes are ensured because repetitive tasks are automated reducing delays.

- Boosted Productivity: Offers dependable performance for detailed or large-scale projects.

Improved Efficiency by Automatic Tool Changer Systems

In manufacturing, productivity and downtime are crucial for growth cycles. These processes need optimization and automatic tool changer systems (ATC) improve both of these. As stated, these systems are able to achieve tool changes in 1 to 2 seconds depending on the tools and machines involved. This high functionality allows production cycles to be uninterrupted. Continuous production is important when dealing with high consumer demand or trying to ramp up operations in an industry.

Recent advancement has integrated ATC systems with modern CNC machines for the robust automation of tool exchange interfaces, facilitating smoother and more accurate tool transitions. ATC users faced as much as 30% reduction in idle time according to recent surveys from the industry. This lessens the need for manual intervention, further increasing productivity alongside decreasing costs.

These systems are highly beneficial in operations that require multiple machining such as drilling, milling, and carving into several diverse materials. Advanced sensors, combined with IoT monitoring enable tools to predict required maintenance, reducing unplanned downtimes, prolonging machine life, and enhancing systems further making them increasingly intelligent. ATC systems also improve safety in workplaces where they impact operator tools directly due to less manual handling reducing chances workplace injuries.

Pricing Differences of ATC CNC Routers and Ordinary CNC Routers

In deciding between purchasing an Automatic Tool Changer(ATC) CNC router or an ordinary CNC router, cost is particularly a great concern. ATC CNC routers have a higher cost of purchase with prices starting from $15,000 to $50,000, based on the brand, size, and specifications. In contrast, ordinary CNC routers are more affordable, priced between $5,000 and $20,000 for advanced models.

The increased functionality and efficiency of ATC CNC routers accounts for the higher costs. Because of the ATC system, operators do not incur any labor time as the machines does tool-switching for them on complex projects, which lessens manual work. This alone accounts for about 25-35% savings of labor costs in high-production scenarios. Additionally, companies that utilize ATC CNC routers report an overall productivity improvement of 30-50% as tool change associated downtimes are reduced.

Nonetheless, for smaller operations with less complex needs, standard CNC routers would still be sufficient. These types of routers offer a lower price, making them a good choice for hobbyists or less advanced businesses who do not need feature rich designs. It should be added that the ordinary CNC routers do have lower maintenance expenses because, unlike automated tool changers, requirements additional systems that need periodic maintenance.

In the end, the decision between the two types of machines depends on the production volume, level of detail, and anticipated profits for the investment over time. While ATC CNC routers are excellent in professional or industrial settings that have greater demands, budget users focused on less sophisticated jobs will find ordinary CNC routers to be a practical answer.

How does an automatic tool changer system work on CNC machines?

With the use of an Automatic Tool Changer (ATC), the process of switching tools for machining within CNC machines is automated. It utilizes a tool magazine or carousel which stores multiple tools. During a step of the programmed process, the CNC machine retrieves the correct tool, removes the tool from the spindle, and places the new one onto the spindle. This auto replacing guarantees effortless execution and precision with minimal downtime.

Factors affecting ATC’s Efficiency in Modern Machining

The most crucial factors with respect of ATC efficiency are tool capacity, tool-change time, and advanced sensor systems. Modern ATCs allow for quick changes of tools which shrink total cycle time. For example, many cutting-edge systems are capable of performing tool changes in under 2 seconds as long as the machines are capable of supporting high volume manufacturing.

Furthermore, ATC systems now include advanced sensors and software that monitor tool wear and alignment with great precision. Industry studies indicate that the addition of predictive maintenance algorithms and real-time monitoring to ATCs can reduce unplanned outages by 20% and increase the life of cutting tools by 15%. These features maintain operational efficiency while also ensuring that ATCs are cost-effective in the long run.

Moreover, these tools have broadened the application range of ATC systems because of advancements in robotics, such as robotic-assisted tool loading for error reduction, precision engineering for tool positioning, and automation that improves reliability and flexibility. These innovations make ATCs vital to efficient production processes in aerospace, automotive, and manufacturing.

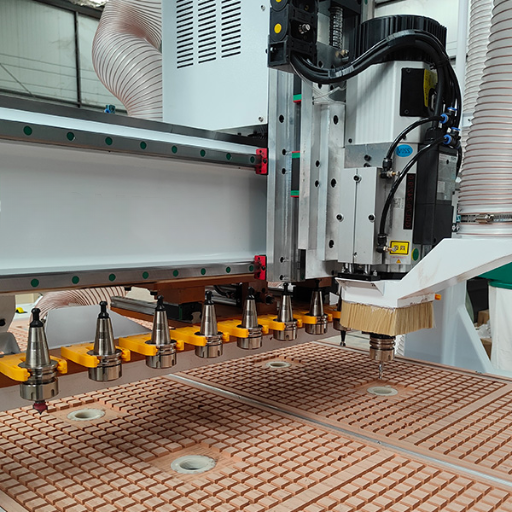

Types of Automatic Tool Magazines: Linear Tool vs Disc Tool Magazine

A linear tool magazine is a type of automatic tool changer design used for tool storage and retrieval during machining operations. Tools arranged in a straight row are retrieved in the order of use and loaded into the spindle for efficient and straightforward tool changes. This arrangement works well for processes that do not require complex setups. Such designs are generally favored in smaller CNC machines or when floor space is a constraint. Linear tool magazines are known for their simplicity and cost-effectiveness. Most systems can hold between 10 to 40 tools, depending on the size and capacity of the machine, and the streamlined structure of the linear tool magazine helps reduce the overall footprint of the machine.

Unlike disc tool magazines, which focus on ease of access, these are designed for greater storage capacity and faster tool changes. These tools are stored on a circular disc, which facilitates rotation for tool access. Disc magazines are best suited for more sophisticated and larger machines that simultaneously require several tools for more intricate machining processes. Depending on the specific model, disc tool magazines can support more than 20 and up to over a hundred tools, exhibiting an exceptional versatility in meeting intricate industrial needs. Moreover, they often incorporate sophisticated servomechanisms which permit such rapid tool indexing speeds that tools can be changed in as little as one or two seconds, which drastically increases operational effectiveness.

When It Comes to Tool Holder Systems and Their Compatibility with ATC CNC Routers

In the case of the tool holder systems and their compatibility, I always make sure that the selected system is appropriate for the CNC router, including the machines setup and operations performed in it. All the tool holder elements are designed with the spindle, and precise and rigid clamping, which work as predetermined lock-in points, ensure high performance is achieved. They must also ensure proper taper type and pull stud Holes along with collet sizes so that they integrate properly with the automatic tool changers. These steps enable better control of machining precision while maintaining streamlined tool changes which improves system productivity.

What are the advantages of using an ATC CNC router for production?

- Efficiency: With automatic tool options, there is less downtime and faster production speed, which allows operations to be performed in a faster pace.

- Precision: Minimal errors and high-quality results are ultimately obtained as a result of accurate and consistent tool alignment.

- Versatility: A more complex and multiphased step gets done in just one setting, which is made possible by switching different tools.

- Productivity: The occurrence of human error and time wastage is significantly reduced due to less manual action being taken.

How Tool Changers Affect Manpower Requirements and Processing Time

The implementation of Automatic Tool Changers (ATC) is to increase effectiveness by optimizing work being done in machines. A manual tool change will always waste time that should not be spent on changing over, and ATC systems take care of the tool transitioning already. ATCs physically cut down the tool change timing from several minutes to seconds, as explained in studies. Implementation of ATC implements a range of 30-50 % productivity increase in different manufacturing processes.

There is also an impact on skilled machinists who will nowadays no longer be needed, which cutting down costs for labor expenses. A proportion of 20 to 25 % is what ATC enabled CNC routers range to cut down manpower request due to the removing of manual adjustments and setups added in the recent manufacturing trend studies.

These technologies save costs by more than 15% in certain applications by ensuring accurate tool alignment and selection, which minimizes errors, reduces material wastage, and saves resources. The features mentioned earlier make ATCs necessary in industries with high output and are precision-centric, including aerospace, automotive, and furniture production.

Increased Material Effective Compatibility and Efficiency

The efficiency of multi-material projects is unmatched as Automatic Tool Changers (ATCs) integrate effortlessly with modern CNC machines, allowing for the processing of various materials, including lightweight plastics and hardened steel. Latest developments indicate that ATCs can reduce tool change times to 1-2 seconds. This is a major improvement considering manual changes can take several minutes, especially in projects that require a lot of tool changes. Productivity is drastically improved with this change.

Furthermore, ATCs have been designed with adaptive control technology, allowing for smarter sensor integration. For example, certain sensors can monitor tools for wear and, if needed, tools can be changed out or some adjustments made to keep accuracy through automation. Studies suggest operational costs and downtime can be significantly reduced, and high precision projects can be shifted seamlessly as these intelligent features extend tooling lifespans by up to 30%. This is applicable in almost all industries, making ATCs invaluable.

After all, the application of ATCs is broadening to include hybrids with both additive and subtractive manufacturing processes. ATCs simplify the intricate processes required for geometry fabrication and production by seamlessly switching between deposition and cutting tools held in the spindle without the need for operators. This feature reduces lead time by as much as 40 percent. Such attributes position ATCs as pivotal elements of advanced manufacturing systems.

With ATC Systems: Enhancement in Efficiency and Accuracy

With regard to automatic tool changers in particular, the phenomenon of increased efficiency in addition to reduced costs of ATC systems capacity control has brought about a newfound significance to modern manufacturing facilities. Studies show that some of the most sophisticated ATC systems can achieve a minute change of tools to be accomplished in a matter of a few seconds. Moreover, a high speed rotary ATC can perform tool switching in 1.2-1.5 seconds which reduces the waiting time of tools during operations.

Moreover, the new generation of ATCs features intelligent sensors, IoT, and other predictive maintenance technologies which enable real-time monitoring of the tool’s condition. 25 percent of unanticipated downtime can be eliminated by such systems, as predictive analytics tend to and overcome challenges from tools before production standards are affected due to inadequate tooling.

In CNC machining, ATCs improve precision by minimizing human error and ensuring tools are consistently in the correct position. This advancement alone can achieve 20% less material waste, lowering operational costs while maintaining high-quality finishes. Overemphasis on broader and smaller production cycles showcases the indispensable benefits ATCs provide in both scenarios.

When should you invest in an ATC CNC router machine?

Purchasing an ATC CNC router machine makes sense when your production entails high precision and frequent tool changes. An ATC router can help if you’re working on sophisticated, deadline-driven projects and suffering from stalling production cycles due to repetitive manual tool changes. Moreover, if your focus is on curtailing operational cost and material waste, the ATC machine offers considerable advantages, thus proving it’s worth for businesses, both small and large scale.

Considerations Regarding Production Volume When Implementing ATC Systems

Production volume is one of the factors that must be considered when implementing an Automatic Tool Changer (ATC) system. Businesses that demand high productivity are able to take advantage of the ATC’s workflow enhancement and downtime reduction capabilities. As per the most recent reports, automated machining systems like ATC routers are reported to provide efficiency improvements of as much as 30-50%, depending on the task complexity and the number of tools needed to be changed.

For instance, the aerospace and automotive industries considering the productivity boosts following ATC implementation, report increased productivity improvement relative to the precision machining of diverse materials. ATC system functionality data shows that companies with ATC equipment often realize ROI in 18 to 24 months as reduced downtime and increased throughput more than offset the initial investment.

Moreover, medium scale operators stand to gain from adopting ATC systems if there are frequent changes to the production tools within their workflow. Leverage of this technology allows manufacturers to control output consistency while increasing operations more effectively. Because of their precision, ATC systems are effective for any organization looking to increased production volume, flexibility, and reduced operational costs while still maintaining high standards.

Woodworking Tasks That Gain The Most From Automatic Tool Changers

Automatic tool changers (ATC) bring greater benefits with industries such as furniture making, cabinetry, or flooring that use a multitude of tools throughout the manufacturing process. In these industries, ATCs can bring significant value. For example, in furniture production, there is a need to interchange tools for cutting, drilling, and shaping different components of a piece. Empirical evidence suggests that implementing ATC systems in business and production processes enables a decrease of up to 25% in production time which means meeting higher manufacturing demand with lower employed skilled labor.

Another sector benefiting from ATC technology is Cabinetmaking. Multi-tool setups now make it easy to achieve advanced precision for complex designs and intricate detailing like decorative carvings or dovetail joints. Automatic tool changers used in CNC machines have proven to boost company productivity, with some reporting as much as 30% more throughput, according to a report from IndustryWeek.

Besides, flooring manufacturers seem to want quick changes in tools for edge trimming, groove cutting, and surface finishing. The addition of ATC (Automatic Tool Changer) systems appears to have lowered operational delays, further enhancing efficiency. As per fresh market reports, firms with ATC machinery have claimed ROI (Return on Investment) in 18 to 24 months due to increased productivity and minimized waste.

Woodworking companies are now able to craft custom orders as well as cater to large-scale production needs all thanks to the flexibility afforded by ATC technology which is critical for staying ahead of the competitiveness in the enduring markets.

ROI Analysis of Upgrading With ATC Technology

Incorporating skirts into your projects, to your specialty designs, or to pre-designed templates is as easy as it gets. Installing the ATC (Automatic Tool Changer) technology for woodworks will significantly enhance business operations and foster profitability in the long run. Although specific calculations aren’t available, the project estimates suggest that companies utilizing the ATC technology have achieved a 30-50% surge in production compared to industries without Automatic Tool Changer functions. For example, ATC systems facilitate the speedy changes of tools which aid in decreasing downtime by about 40%. This provides more operational hours for production than adjustments.

Also, analyzing the waste involved shows that ATC-enabled machinery cuts waste by as much as 25% due to its cutting accuracy. Industries note that this level of accuracy not only reduces errors, but also guarantees consistent quality, which is critical for customer satisfaction and minimizing rework costs. From a financial perspective, companies report an average ROI within 18-24 months because of decreased costs associated with labor, resource allocation, and the quick turn-around on large orders. The addition of ATC technology is more than an enhancement; it is an investment in scalability, efficiency, and sustained competitiveness in a rapidly transforming marketplace.

What maintenance is required for ATC CNC router systems?

- Purging the machine of dust and debris on a daily basis.

- Lubricating parts that move in accordance with manufacturer’s instructions.

- Cleaning tool holders and collets, and blades as appropriate.

- Tightening loose connections and bolts where necessary.

- Replacing or upgrading software and drivers when needed for effective performance and compatibility.

Maintenance Requirements for Servo Motor and Tool Magazine

To assure reliability and efficiency of an ATC CNC router system, easy blades accessibility should be integrated. Routine care of both the servo motor and tool magazine is fundamental for the effective operation of the router system and ensuring its productivity and performance. It is necessary to conduct regular cleaning of the tool magazine to avoid eventual losses resulting from the forgone tool changes. In preventing the tools and workpiece from damage as a result of misalignment, examination of the grapplers and alignment parts require attention. General maintenance of moving parts for rotary devices entails applying oil or grease at intervals prescribed by the maker.

For servo motors, keeping an eye on temperature and vibration levels can assist in troubleshooting issues allegedly causing problems. Most components that generate excessive heat or vibration are likely to have issues with bearings or alignment of the motor. Also, checking the power supply connections can aid in maintaining steady performance. Reports suggest that servo motors are frequently not maintained which tends to cause up to 30 percent losses in machine efficiency, increasing machine downtimes and significantly raising expenditure in production systems. Businesses can rely on system preventive maintenance of these components to enhance dependability and lower operational halts.

Automatic tool changer common problems

Fuelled and incomplete transfer of servo motors entail incorrect tool alignment, inadequate lubrication, and sensor damages. Alignment of either of the tool aids serves can be extremely taxing and can result in machine errors and breakdowns. Worn off parts may prove to create more spare parts with little aid provided to increase their shelf life. Supply problem supply sensor malfunctions may slow issues on stepper motor activity resulting in operation delays. With timely inspections and routine maintenance, almost all these problems can be avoided allowing smooth operations.

Best Practices for Maintaining Your ATC Spindle and Tool Holders

When it comes to ATC spindle and tool holders, it is important to always remember that there needs to be regular maintenance as well as operational best practices. An industry study shows that 30% of the lifespan of these components can be added if regular cleaning and lubrication is done. Furthermore, the bearings must not be misaligned during installation and use, as this also increases the chances of unneeded friction which can lead to wear and tear.

Also as important is controlling the temperature; overheating can result in spindle bearing degradation, as well as failure. Thermal damage in particular is believed to be reduced by 40% if the working environment’s controlling cooling system is properly monitored. Furthermore, ensuring that the tools are balanced is important; unbalanced tools have the ability to create vibrations from the tool holders and spindle fatigue leading to imbalance.

Replacing and upgrading components that require higher quality materials is vital and must be prioritized as well. Research shows that when using advanced grade tool holders made of hardened steels or alloys, lifetime increases by up to 50%. Additionally making use of various new diagnostic tools such as vibration analysis equipment allows for early detection of any warning signs related to component wear that would otherwise lead to expensive downtimes.

In the end, following a proactive maintenance plan and using cutting-edge technologies can greatly improve the lifespan of your equipment while also reducing downtime and increasing productivity.

Reference sources

- Study: Mechanisms of a 3-axis CNC Machine Design and Experiment3

- Objective: To design and evaluate a 3-axis CNC machine for engraving and cutting applications.

- Methodology: The study utilized Fusion 360 and PROTEUS software for design and simulation. The machine was tested on various materials, including wood, to assess its precision and functionality.

- Key Findings:

- The 3-axis CNC machine demonstrated high precision in engraving and cutting tasks, making it suitable for a wide range of applications.

- The study highlighted the importance of robust design and powerful motors for handling different materials.

- The machine’s adaptability to various tasks underscores the versatility of 3-axis CNC systems, one of the most common types of CNC machines.

- Study: Virtual Instrumentation-Based Data Collection and Analysis for CNC Machining Process4

- Objective: To develop a virtual instrumentation system for monitoring and analyzing CNC machining processes.

- Methodology: The study employed LabVIEW and MATLAB software to collect and process data from CNC machines, focusing on improving operational efficiency.

- Key Findings:

- The system provided real-time insights into CNC machining operations, enhancing process control and optimization.

- The study emphasized the role of data-driven approaches in modern CNC machining, applicable across various machine types, including lathes, mills, and routers.

- This research supports the integration of advanced monitoring systems in CNC machines to improve performance and reliability.

- Top ATC CNC Router Manufacturer And Supplier In China

Frequently Asked Questions (FAQs)

Q: What is the main difference between ATC and CNC machines?

A: The primary discrepancy lies in the function of the tool change. ATC (Automatic Tool Changer), which is a type of tool changing apparatus, is a feature that may be implemented in a CNC (Computer Numerical Control) machine. A standard CNC router uses a handheld tool changer, but an ATC CNC router can automate tool changes during the operation. This process is managed by the control system of the machine, which eliminates the need to stop work for tool changes, thus greatly improving work efficiency. Advances in CNC technology have made ATC systems more affordable and widespread, enabling quick completion of multifaceted projects that require numerous tools.

Q: What is the operation of the Automatic Tool Change (ATC) function on CNC routers?

A: The ATC function on a CNC router works with a preset control system. As the router performs its work on the spindle, it regularly and periodically stops to pick up new tools from a tool magazine. The automatic tool change process is overseen by a controller that executes according to a programmed tool path. Changes in tool position are usually done by the use of tapered tool holders which gives better alignment as well as firm connection. All tools can be changed within a few seconds and therefore the machine can change tools with little pause to the work in progress.

Q: Why would someone pick an ATC CNC router over a standard CNC router?

A: An individual prefers an ATC CNC router to a standard CNC router primarily because of increased productivity and versatility. The automatic tool-changing feature in ATC routers saves the time that would have been spent changing tools manually. This is especially useful in complicated projects that involve multi-tool processes. For businesses that deal with various work pieces, an ATC system enables the machine to switch from cutting, drilling, to engraving with relative ease. Although ATC machines come with a higher upfront price, they lower labor expenses and boost output. These machines work best in environments where efficiency is crucial because they are designed for increased productivity.

Q: Which work pieces gain productivity with an ATC CNC router?

A: Work pieces that are multifaceted and have several distinct operations requiring different tools are best suited for an ATC CNC router. The best examples include complex sign engraving, advanced furniture parts, intricate woodworking and precise metal parts. Products that need rough cutting as well as fine detailing are also ideal candidates since the machine can change from a roughing cutter to a finer finishing tool automatically. Moreover, work pieces with intricate designs that require many different sizes and shapes of engraving tools are highly suited to the ATC. Manufacturers that make parts with added value in terms of drilling, routing and surface finishing done in one set up will benefit from maximum efficiency gains through the ATC.

Q: In what way does an independent tool magazine enhance CNC router capabilities?

A: An independent tool magazine enhances CNC router capabilities by providing storage and access during operation for multiple tools. In this manner, the machine can perform automatic tool changes without any operator intervention, which minimizes the turnaround time between tasks. Each CNC system has a different design, and the tool magazine can be adapted to each design. Smaller machines can have a capacity of 4-8 tools, while larger machines can have 20 or more. This configuration allows more complex operations to be performed in a single setup, increases productivity, and allows for pre-programmed unattended operation during repetitive tasks. Tool management and servicing can be done independently of the workstation because the magazine is independent.

Q: What is there to think about before purchasing a CNC router with ATC function?

A: There are a number of factors to look at when buying a CNC Router with ATC functionality. First, consider the production requirements—the pieces of work you will be processing as well as the tool change frequency. Second, check if the tool magazine capacity is sufficient. Third, check the controller and software compatibility. Fourth, look into the space requirements since ATC CNC routers typically need more space than standard machines. Lastly, consider the return on investment—though ATC machines have high initial costs, they save large amounts of labor time and improve productivity. Consider also the reliability of the tool change mechanism, the level of support, and the availability of spare parts.

Q: In what ways does an ATC CNC router enhance work efficiency over manual tool change work?

A: The time-consuming procedure of manual tool changes is completely eliminated by an ATC CNC router, which greatly increases work efficiency. If a CNC operator wishes to change a cutter manually, he/she has to stop the machine, remove the current tool, clean the collet, put in the new tool, set tool length, then re-start the program. This takes several minutes for each change. An ATC system, on the other hand, can perform a tool change in seconds. For cutworks that require several tools, this saves several hours of production time. Also, automated tool changes mean less human error in tool placement, and better work piece quality due to consistent tool position and increment placement during changes improving workflow automation.

Q: What types of cutters are compatible with ATC CNC routers?

A: ATC CNC routers have the operational capacity to use a broad range of cutters, provided that these cutters are compatible with the machine’s tool holders. Some popular types are end mills, ball nose cutters, V-bit engraving tools, drills, and specialized profile cutters. It is standard practice for most ATC systems to utilize tapered tool holders, such as ISO, HSK, or BT, which aids in effortless and accurate tool positioning. The tool magazine can house various sizes and types of cutters from small bits, like 1/8\” engraving bits, to larger tools such as 1\” roughing cutters. It is crucial to pay attention to the weight and balance of the selected tools, and to prepare them with the correct tool holder for automatic exchanges to streamline the ATC system’s functionality.

Q: In what ways has the innovation of CNC technology enhanced ATC systems over the years?

A: Over the years, the innovation of CNC technology has greatly enhanced ATC systems in numerous respects. Faster and more accurate control systems today provide tool changes with added precision and error detection. Modern software also aids in the optimization of tool paths. CAD interfaces are now much more user-friendly, allowing for simple programming of complex multi-tool actions. Moreover, modern mechanization advancements have made the construction of tools more dependable, enabling automated tool changes to occur thousands of times without breakdowns. There has been technological advancement in many other fields such as smaller and less expensive ATC systems that enable use in non-industrial and educational settings. More sophisticated integration with CAD/CAM software enables straightforward programming of multifaceted projects needing several different tools. All of these changes have rendered ATC CNC routers more affordable, increasing their efficiency and ability to perform sophisticated engraving and cutting tasks.