Laser beam welding is changing the way industries work on precision joining techniques. This advanced technology has been in great demand as it gives better precision, faster working rates, and stronger bonding than regular welding processes. Then what makes this welding technique so special and why should it be on your priority list for the next job? This guide will tell you about the basic principles behind LBW, its advantages, and the industries gaining from it. It will go on to present a deeper understanding of how laser beam welding is currently affecting fabrication technology, whether you are an engineer, manufacturer, or just curious about some other advanced technologies.

Introduction to laser beam welding

Laser beam welding is a high-precision joining technique that relies on a laser beam to melt and join materials. It is unique in that it creates strong and highly accurate welds, particularly when applied to delicate or complex designs. Other distinct features include high welding speed, minimum heat distortion, and applicability to a great variety of materials, such as metals and alloys. Various automotive, aerospace, and electronic industries employ laser beam welding as an interface between fabrication and reliability, efficiency, and engineering specifications.

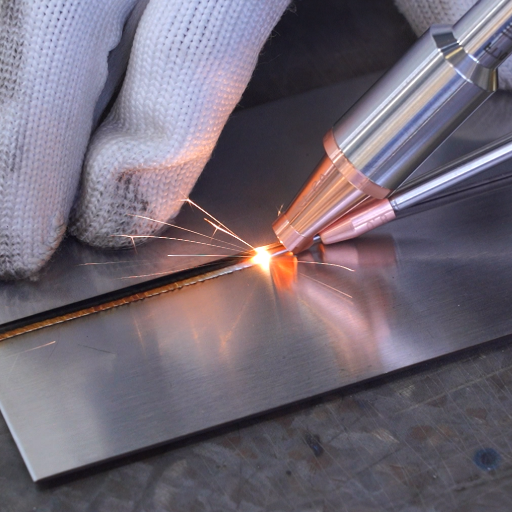

What is Laser Welding?

Laser welding or Laser beam Welding is an advanced joining method wherein a laser beam is focused onto a joint to melt and fuse materials at the interface. This technique is marked by the highest precision and fastest speed, suitable for even complex and high-strength applications. The laser beam provides a very localized heat source, so heat distortion is kept to the minimum with deep weld penetration.

Because of its versatility, this technology continues to conquer several industries. Laser welding, for instance, can be used to weld stainless steel, aluminum, titanium, or even dissimilar metals. According to a market analysis by ResearchandMarkets.com in 2023, the global laser welding market is expected to grow at a Compound Annual Growth Rate (CAGR) of 7.8% between 2022 and 2028. The growth is attributed to rising demand for efficient, automated welding technologies in sectors such as automotive, aerospace, and medical devices.

Laser welding is fast and super-efficient. High-power laser systems can weld at up to 10 meters per minute while maintaining very precise and clean welds-the best situation possible. This significantly reduces production time and cost. Also, there will be a very small heat-affected zone (HAZ), maintaining some mechanical properties and integrity of the surrounding materials-a great consideration in applications involving electronics manufacturing.

At large, a combination of laser welding with precision, efficiency, and adaptability makes it a big hammer in the hands of a fabricator. Further innovations are to be expected with continued development in laser technology, such as higher energy outputs, better beam quality, and material capabilities.

Importance of laser beam technology

Laser beam technology has become the basis of modern industrial and technological sciences with precision, efficiency, and versatility. According to some recent data, the laser technology market was valued at approximately $14 billion in 2022 and is projected to grow at a CAGR of 8% through 2030 from 2023. The growth is driven by rising demand across a host of industries, including automotive, aerospace, electronics, and healthcare.

One of the distinctive features of laser beam technology is to maintain the highest possible precision in the shortest time. Laser applications offer cutting and welding methods that achieve micron-level manufacturing accuracies important for microelectronics and intricate cosmetic production. For example, laser micromachining is now being used extensively to manufacture parts for semiconductors, minimizing defects and boosting performance specifications.

They are further diversified to work in different kinds of materials, including metals, polymers, ceramics, and even biological tissues. In a real sense, there are laser-assisted medical applications such as corrective eye surgeries and non-invasive cancer treatments where laser is used so that the surrounding healthy tissues are spared from damage.

This is also a major reason why laser technologies can be credited with energy efficiency improvement compared to traditional methods. For example, modern fiber lasers offer an electrical-to-optical conversion efficiency of about 45%, thereby reducing both energy consumption and operational costs of companies implementing them.

Therefore, three main points promote the importance of laser beam technology into the foreseeable future. It enables latte production via improvements in beam quality and further integration with AI-driven automation, making laser technology a production tool smart, fast, and truly green.

Applications across Industries

In view of its ability for precision, laser beam technology has come to play a pivotal role across industries. Below is an overview of recent applications and advancements being researched and implemented in varied fields of application:

Manufacturing and Automotive

In manufacturing applications, lasers have become the standard for cutting, welding, drilling, and engraving, the main reason for this being the extreme precision required by the processes. The new developments in the fiber laser have brought about an increase in efficiency and energy savings. Market reports in the beginning of 2023 state that the laser cutting market globally is expected to grow at a CAGR of 5.2% and reach $6.72 billion by 2028 with the largest share in manufacturing and automotive sectors. Nowadays, manufacturers are also incorporating AI-based laser systems that increase the speed of the process and minimize waste.

Healthcare and medical applications

Of course, laser technology is still applicable in treatments, surgeries, dermatology, and ophthalmology. One instance would be excimer laser in vision correction such as LASIK surgeries where, as research data reveals in 2023, more than 30 million surgeries had been carried out globally, which laser precision has helped in ensuring the success of the procedure and restoration of the patient in the shortest possible time. Dermatological treatments are on the rise as well, such as laser tattoo removal and laser skin resurfacing.

Communications and Electronics

Lasers are critical to microelectronics fabrication and the development of advanced optical communication systems. 5G technology and the need for ultrafast data transmission have provided added impetus to fiber-optic laser demand. According to industry data, the fiber optics market valued at $7.32 billion in 2023 is expected to witness huge growth stimulated by innovations in laser communication technologies.

Aerospace and Defense

The aerospace and defense sectors utilize laser technology for high precision material processing and guided-weapons systems. Directed energy weapons (DEWs) powered by high energy laser beams are at the forefront of worldwide testing and refinement. The global directed-energy weapons market is valued at $5.9 billion as of 2022 and is expected to grow to $12.1 billion by 2030 – an indicator of the increased embrace of laser tech for pinpoint combating solutions.

These steady appearances and emerging trends across laser technologies clearly point toward versatility and a distinct perspective toward shaping modern technologies. This phase opens the door for the laser system through its current R&D into industry adoption across sectors that will open new avenues of applications and growth potential.

Understanding the Basics of Laser Welding

Laser welding is the joining of materials using a concentrated beam of light. With this, one can get welding that is highly precise, speedy, and effective, catering to industries such as automotive, aerospace, electronics, and others. It creates strong welds of highest quality with very minuscule heat distortion to the surrounding area-the attribute much needed for fragile or heat-sensitive materials.

Laser Beam Welding Working Mechanism

The laser beam welding takes effect through the focusing of a high-energy laser into the joint regions of materials and melts them together. They usually use fiber or CO2 lasers because of their precision and power. A myriad of parameters like laser power, focus of the beam, and welding speed should be controlled in such a way that the best results can be achieved.

Within the latest developments in laser welding technology, efficiency and versatility have exponentially been increased. According to the most recent industry statistics, the modern laser welding systems can work with such speed, of something like 10 m/min, thus being very suitable for mass-production processes. Moreover, the precision of the laser beams enables weld widths to be as narrow as 0.1 mm, which is especially useful for electron device microfabrication and the development of medical devices.

Another very important benefit is the ability to weld dissimilar materials, a capability increasing in importance for EV battery manufacture. For instance, laser welding demonstrated it can reliably weld dissimilar materials such as aluminum and copper, which are crucial for lightweight and efficient EV batteries, according to a study performed by Fraunhofer Institute in 2023.

Minimizing the heat-affected zone means a reduction in the possibility of warping, which is an issue in most traditional welding methods. Research also shows about 10% lower heat input in laser welding, compared with arc welding, thereby greatly minimizing thermal distortion and maintaining the characteristics of the material.

These adoptions are what make laser welding compromise when it comes to applications requiring precision and speed across a plethora of industries, including automotive, aerospace, medical, and electronics manufacturing.

Different Types of Laser Used for Welding Purposes

Laser welding uses different types of lasers depending on the application, power, efficiency, and compatibility of different materials:

Fiber Laser

Fiber lasers are, today, amongst the most commonly used lasers for welding. These lasers exhibit very high energy efficiency, power conversion up till 30%. They can ensure very thin, precise welds and are excellent for welding reflective materials, such as aluminum and copper. As studies demonstrate, fiber lasers have been extensively used in the industries of automobiles and electronics, particularly where fast and highly accurate welds are concerned.

CO2 Laser

CO2 lasers operate on a gas mixture to produce the laser beam and are generally used for welding thick materials or sheet metal processing. These lasers have high power output and can weld non-metallic materials such as ceramics and plastics. However, their energy efficiency is relatively low compared to modern laser technologies, ranging from 10 to 20%.

Nd:YAG Laser

Nd:YAG lasers, or neodymium-doped yttrium aluminum garnet lasers, are also widely used to weld numerous types of metals and alloys. Their application is prevalent in precision-demanding medical device manufacturing and aerospace engineering. While their efficiency ranks somewhere between one and three percent, new developments on the diode-pumped Nd:YAG laser should enhance that.

Diode Laser

Diode lasers are very small and highly efficient, with the capacity to convert around 40% to 50% of the electrical energy applied into laser output. It is highly beneficial for welding thin sections and is widely used in areas ranging from automotive manufacturing and consumer electronics.

Component of a Laser Welding Machine

Laser welding machines consist of many components that, together, provide highly precise welding:

Laser Source

The laser source is where the focused light beam for welding is generated. Fiber laser usage is gaining popularity due to high power density and efficiency, with outputs often around 500 watts to 10 kilowatts, which allows welding of various materials at different depths.

Beam Delivery System

The system directs the laser beam from the laser source to the workpiece. Fiber-optic technology has given a competitive edge to modern beam delivery systems, with some achieving energy transmission efficiency greater than 90%.

Cooling System

Heat is generated in considerable amounts in laser machines, which, if not removed, can affect the stability of performance and reduce the lifespan of the machine. The more sophisticated machines are equipped with water-cooled systems that can dissipate heat even during continuous high-power operations.

Control Unit

Laser welding machines nowadays are fitted with computerized control units, which allow controlling parameters such as energy output, beam positioning, and welding speed more accurately. These systems also work under real-time monitoring and AI-driven optimization methods to better the weld quality and reduce material wastage.

Safety Features

Ensuring the safety of the operator is of the utmost importance. Laser welding machines are all equipped with safety enclosures, safety interlock systems, and other safety measures that include the use of special protective eyewear against damage from exposure to high-intensity laser radiation.

Applications of Laser Beam Welding

Laser beam welding finds applications in automotive, aerospace, electronics, and medical device manufacturing, a diverse range of industries. I would emphasize how the ability to create precise, high-quality welds with minimal heat distortion makes it ideal for joining complex components or materials that require very tight tolerances.

Laser Welding in Automotive Industry

Laser welding has transformed the automotive industry by enabling manufacturers to create production processes of much greater precision and efficiency. Recent market studies expect the global automotive laser welding market to witness a compound annual growth rate (CAGR) of 7.8% between 2021 and 2030, with lightweight vehicles and electric vehicles (EVs) being the major drivers of demand. Laser welding is employed in welding of high-strength steel, aluminum, and other materials that are used to reduce the weight of vehicle components.

Major automotive applications of laser welding include the manufacture of automotive body parts such as roof joints, doors, and hoods that benefit from the low heat distortion of laser welding in the maintenance of structural integrity. Laser welding also becomes crucial in the manufacture of batteries for electric vehicles, ensuring battery module assemblies are safe and durable. It effectively increases product lifespan and reliability while maintaining affordability, as well as complying with rigorous regulatory standards of safety and performance. Such developments further establish laser welding as an enduring source of innovation in the new age of automotive manufacture.

Laser Welding in Aerospace Industry

In the aerospace industry, where precision and durability are paramount, laser welding is important. The ability to generate high-strength and lightweight joints is critical for aircraft components subjected to extreme stress and temperature variations. The recent study also claims that laser welding can bring about a 20% weight reduction of aerospace parts that in turn results in increased fuel efficiency and performance. Furthermore, the method provides an unparalleled level of precision for joining materials such as titanium and nickel-based alloys, which are often favored in aerospace engineering due to their high strength and corrosion resistance characteristics.

One key advantage of laser welding in aerospace is the ability to produce defect-free welds in critical areas. NASA and other aerospace agencies utilize this welding technique for rocket components where component failure is not an option. Because of the low thermal distortion caused by laser welding, it preserves the structural integrity of the materials, which is of utmost importance for the dependability of aircraft and spacecraft.

The market trends also depict повышение adoption of laser welding in aerospace with a CAGR of approximately 7% from 2023 to 2030 in its global market. The growth is due to the increasing demand for sustainable and efficient aircraft and continuous improvement in welding technologies that enhance those weld capabilities. For example, recent improvements in hybrid laser welding combine traditional welding methods and laser accuracy for faster and more reliable production operations.

These advancements emphasize the significance of laser welding as a critical technology means in taking aerospace further, enhancing safety, and catering to the evolving demands of lighter, stronger, and efficient components.

Laser Welding in Electronic Manufacturing

Laser welding plays the dominant role in electronics manufacturing, enabling precise and efficient assembly processes for miniaturized and complex electronic components. Such welding is needed in microelectronic devices, circuit boards, sensors, and other high-performance components where traditional welding processes fail.

Research has proven laser welding to be highly precise, creating welds as small as 0.1 millimeter, vital for packing tiny electronic parts. Industry reports very clearly point out that laser welding occurs with a very small heat-affected zone, thus ensuring the soldering intensity is not high enough to damage already manufactured sensitive components. On the other hand, fiber laser systems have successfully improved welding speeds in electronics manufacturing by 30% maximum when compared with the conventional techniques.

Market analyses show a high demand for laser welding in electronics. According to a report from MarketsandMarkets, the global laser welding equipment market shall rise from $2.4 billion in 2021 to $3.8 billion by 2026, primarily driven by advancements in electronics and semiconductors. As electronics manufacturing continues to evolve, this growth illustrates the importance of laser welding for precision, reliability, and automation.

Advantages and Disadvantages of Laser Welding

What I feel is that one of the major advantages of laser welding is its ability to offer great precision and create high-quality, reliable welds. It can weld in complex or delicate electronic components. With faster process times and easy automation capabilities, laser welding is great for high-volume manufacturing. To further add, I would say that the disadvantages include very costly initial investment in laser welding equipment and the need for skilled operators to work with the technology. Not every material can be laser welded, which also limits the applications.

Advantages of Laser Welding

Laser welding can create extremely precise and clean welds, making it the method of choice in the automotive, aerospace, and electronics industries. According to the newest data, laser welding can weld at speeds of the order of several meters per second, thereby increasing greatly the production efficiency when compared to conventional welding methods. In addition to speed, another way that laser welding can achieve joining with minimal distortion is the precision that allows joining with minimum heat-affected zone.

Another advantage is its flexibility, as laser welding handles many different materials such as steel, aluminum, titanium, and co-existence of materials. For example, a market analysis in 2023 says one important application for the automotive sector is laser welding of light weight materials; such as aluminum to steel welding is preferred to meet vehicle weight reduction targets for better fuel efficiency. Besides this, use of laser welding systems in automation allows integration into assembly lines, thus ensuring even quality and lesser human errors.

Modern laser systems offer higher-energy-efficiency better beam quality from the fiber lasers, which further improvesIndustrial adoption. According to the recent report, the fiber laser welding system reaches an energy conversion efficiency of above 30%, which greatly cuts down the operation cost at the end of the day. This is being seen as a sustainable and economic-friendly solution by most manufacturers who seek precision and productivity.

Disadvantages of Laser Welding

Even though laser welding offers many advantages, some disadvantages should be kept in view by manufacturers. The first major disadvantage is the very high initial capital investment involved in the purchase and setting up of laser welding equipment. Market and Industry reports have gone into depth to reveal that the price of an industrial-grade fiber laser welding machine usually varies between $50,000 to over $200,000, which is a severe limitation for small to medium-sized enterprises.

Also, laser welding requires setup and alignment with particular attention to good welding conditions. The very small focal spot of the laser requires precision in positioning, and any misalignment will result in defective welding; hence the machine either has to be set up by highly advanced automated control systems or operated by highly skilled personnel, thus increasing costs.

Another challenge is the limited appropriateness of laser welding to a certain class of materials and thicknesses. For example, welding highly reflective materials like copper or aluminum can cause lasers to disperse energy and result in uneven welds. Also, laser welding performs very well for thin materials within the range of 0.5 mm to 12 mm, but for thicker sections, the performance would be unsatisfactory.

Finally, a laser system’s maintenance-demanding and expensive-option cannot be overlooked. Proper maintenance of the optics and cooling system guarantees long-term working efficiency. If faults occur in the equipment, the price of repairs can be very high, thereby worsening workflow production. Although laser technology is continuously overcoming some of these disadvantages, manufacturers must consider these disadvantages very carefully against the advantages before making a final decision on laser welding implementation.

Comparative Analysis with Traditional Welding Methods

Laser welding excels over traditional welding methods in precision, speed, heat input, flexibility, and suitability for automation.

| Parameter | Laser Welding | Traditional Welding |

|---|---|---|

| Precision | Very high | Variable |

| Speed | Faster | Slower |

| Heat Input | Minimal | Higher |

| Flexibility | High | Limited |

| Automation | Easy | Difficult |

| Material Fit | Tight required | Tolerant |

| Cost | Higher | Lower |

| Setup Time | Short | Long |

| Durability | High | Variable |

Popular Trends in Laser Beam Welding Technology

Laser welding is famed for its applications in products requiring high precision, faster speed, and minimal heat input, and for being highly adaptable to automation. Of course, compared to traditional welding joints, laser welding requires higher capital investment and very tight fit-up tolerances. Hence, with shorter setup times and consistent weld joint durability, it offers highly efficient and advanced welding techniques for varied applications.

Recent Developments and Innovations in Laser Welding Machines

The recent developments in the laser welding machine have dramatically increased the scope of their application across industries. The AI-driven control system is capable of enhancing the precision and adaptability of the process, removing the dependence on human operators for accuracy, and lending itself to making real-time process parameter adjustments on the parameters being interacted with in the workspace. Also, hybrid laser welding technology, combining laser and arc welding, has made it much more efficient in terms of deeper penetration and welding speed.

One of these developments is fiber lasers, which provide higher power efficiency and flexibility than traditional CO2 lasers. Newer fiber laser machines on record can, for instance, exceed the power output threshold of 10 kW and shall thereby weld thicker materials with relatively less difficulty. Market reports further reveal that the fiber laser welding machine market worldwide is expected to continue growing at a CAGR of about 5.1% during the forecast period of 2023-2030; the automotive, aerospace, and electronics sectors being the driving factors.

And then, developments have occurred in beam shaping with the use of adjustable beam profiles that enhance weld quality over different materials, including reflective metals like aluminum and copper. These developments have been fulfilled with high engagement in the manufacture of EV batteries where welding needs to be very fast and accurate. As an example, Tesla utilizes laser welding operations that are more advanced for its battery modules and realize a high throughput rate while maintaining the level of consistency in performance.

Industry 4.0 also gives rise to smart laser welding systems connected to IoT that provide remote monitoring capabilities and features like predictive maintenance. This would surely enhance productivity while limiting occurrences of downtimes, which makes competitions with operational efficiency possible. Now, this combination of technological innovations modes laser welding as an important weapon in modern manufacturing.

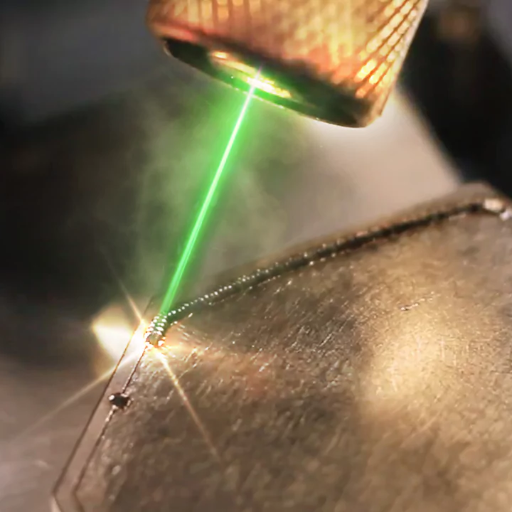

Emerging Technologies: Hybrid Laser-Arc Welding

Hybrid Laser-Arc Welding (HLAW) is an advanced technique that combines the precision of laser welding with the flexibility of arc welding, creating a process that leverages the strengths of both methods. This hybrid approach allows for deeper penetration, faster welding speeds, and enhanced gap-bridging capabilities. Utilizing the laser’s focus and the arc’s adaptability, HLAW ensures superior weld quality even in the most challenging conditions.

One of the prominent benefits of HLAW is its capacity to weld thicker materials in a single pass, which reduces the requirement for numerous passes and also lessens production time. Data prove that this method attains welding speeds that are two to three times faster than those typical weldings, whereby the world-class joint integrity is sustained even though work proceeds at a faster pace. Furthermore, much to the delight of the correctness and precision needs put forward by aerospace, automotive, and shipbuilding industries, the heat-affected zones are significantly minimized when distortions are controlled with HLAW.

Modern HLAW technology offers an unprecedented control level and efficiency through integrating real-time monitoring systems and IoT connectivity. Recent industry reports further claim a surge for nearly 30% in production efficiency as companies utilizing this welding type, alongside energy consumption with a great diminution compared to traditional ones, thus rendering HLAW a solution in the forefront of manufacturing: profitable yet environmentally friendly.

Trends in Laser Welding Research and Development

Recent research concerning laser welding has focused more on enhancing precision, improving efficiency, and more adaptability. Advanced AI technology and machine learning algorithms have been integrated into laser-welding systems. These technologies promote real-time simulation and optimization of welding parameters to reduce defects and improve product quality. For example, an AI welding system can monitor and detect weld seam anomalies with over 95% accuracy, hence providing a very reliable production warranty.

Another focus area is the rising interest in the use of high-power fiber lasers because they offer far superior beam quality and energy efficiency. According to market surveys, the global laser welding industry is anticipated to expand above the 5% CAGR threshold between 2023 and 2030 as a result of pricing interventions from the automotive, aerospace, and energy sectors. The automotive sector alone covers about 35% in total laser welding applications with heavy scrutiny on EV manufacturing.

Another one of the major discoveries is the introduction of hybrid laser-arc welding (HLAW), which is used for demanding industrial work. In combining the flexibility offered by arc processes with the excellent precision of laser welding, HLAW is a popular technique for big projects involved in shipbuilding and pipeline construction. Reports from studies suggest that it can weld three times faster compared to conventional methods, while weld quality is ensured greatly.

Environmental sustainability is another driving force behind laser welding trends. Energy-efficient laser systems and scrapped minimization are the general strategies for reducing carbon emissions in manufacturing. This marriage between technology and sustainability makes laser welding a common name in the present industry.

Reference sources

1. Evaluation of Residual Stresses in CO2 Laser Beam Welding of SS316L Weldments Using FEA

- Authors: Harinadh Vemanaboina et al.

- Published in: Materials Research Express, 2023

- Key Findings:

- The study utilized Finite Element Analysis (FEA) to simulate the CO2 laser welding process on SS316L plates.

- It was found that laser welding results in lower residual stresses compared to conventional welding methods, with stresses remaining within safe limits for the base material.

- The predicted residual stresses showed close agreement with experimental measurements, with a deviation of about 10%.

- Methodology:

- A Gaussian heat source model was developed and simulated using ANSYS software.

- Thermal profiles were analyzed at the joint cross-sections to assess temperature distribution and residual stress levels(Vemanaboina et al., 2023).

2. A Review on Dissimilar Laser Welding of Steel-Copper, Steel-Aluminum, Aluminum-Copper, and Steel-Nickel for Electric Vehicle Battery Manufacturing

- Authors: Amirhossein Sadeghian, N. Iqbal

- Published in: Optics & Laser Technology, 2022

- Key Findings:

- The review discusses the challenges and advancements in dissimilar laser welding, particularly for materials used in electric vehicle batteries.

- It highlights the importance of understanding the intermetallic compounds formed during welding and their impact on joint strength and durability.

- Methodology:

- A comprehensive literature review was conducted, analyzing various studies on dissimilar welding techniques and their applications in battery manufacturing(Sadeghian & Iqbal, 2022).

3. Weldability Analysis and ANFIS Modelling on Laser Welding of Inconel 718 Thin Sheets

- Authors: P. Thejasree, P. Krishnamachary

- Published in: Materials and Manufacturing Processes, 2022

- Key Findings:

- The study investigated the effects of laser power, welding speed, and pulse duration on the weld characteristics of Inconel 718.

- ANFIS (Adaptive Neuro-Fuzzy Inference System) modeling was used to predict the quality of welds based on input parameters.

- The optimal conditions for achieving high-quality welds were identified, focusing on penetration and bead geometry.

- Methodology:

- A Taguchi approach was employed to analyze the influence of various input variables on weld characteristics, followed by ANOVA for statistical validation(Thejasree & Krishnamachary, 2022, pp. 1190–1202).

Frequently Asked Questions (FAQs)

What happens in the fusion welding process in laser welding?

The fusion welding process involves melting and fusing with concentrated laser energy. This technique allows precise control of the heat input; thus, welds are bestowed with strength, and little distortion is imparted. On focusing the laser beam onto the joint area, there occurs deep penetration and efficient melting of the base materials.

What are the common types of laser welding?

Generally, laser welding can be conduction welding, keyhole welding, hybrid welding. Conduction welding produces a weld from heat conduction, while keyhole welding obtains deeper penetration because a vapor cavity is generated within the weld. Hybrid welding combines laser welding with another process whereas improving weld quality and speed.

What of the cost of laser welding equipment against conventional arc welding?

Laser welding equipment is generally expensive when comparing its initial cost with conventional arc welding set. The accumulated benefits, nonetheless, which include reduction of labor cost and increased efficiency, outweigh the initial investment. By also selling faster and performing better welds, laser welding becomes worthy of consideration.

What are the advantages of the handheld laser welders?

Handheld laser welders are quite versatile and easy to use, allowing operators to undertake welding work in several positions and on different materials. Especially useful in welding dissimilar metals and in applications where utmost precision is required, the handheld laser welding machines can be carried to places and are suitable for remote laser welding.

Can laser welding weld high-carbon steels?

Laser welding could satisfactorily weld high-carbon steels. The focused laser beam allows the most appropriate control of the heat input that must be administered to control the thermal effects on high-carbon materials. By so doing, problems like warping are reduced and quality welds achieved.

What is the laser energy’s role in the welding process?

Laser energy is responsible for melting and fusing the materials together. The laser beam can be set up with a certain intensity to different welding modes and types such as deep penetration welding or surface welding depending on the requirements of the application.

How is keyhole welding different from other kinds of welding?

Keyhole welding is distinct from the usual welding methods as it creates a vapor cavity for deeper penetration into the material. With this method, the welding procedure is enhanced regulating strength of joints in comparison with usual methods. The keyhole effect would be most beneficial for thick materials and high-speed applications.

Where are laser weldings generally applied?

Laser welding finds applications in among others, automotive manufacturing, electronics assembly, and aerospace components. Valued for welding dissimilar metals, forming precise joints, and achieving high welding rates, it is therefore suitable for both production and repair tasks.

- Density of Concrete: Properties and Measurement

- The Comprehensive Guide to Ethyl Acetate

- Solve Power Drop Issues in Fiber Laser Cutting Machines: Discover Effective Solutions

- Best Laser Cutter & Engraver: Wood Laser Complete Guide

- Complete Guide: ATC vs MTC – Understanding Automatic Temperature Compensation and Manual Controls

- Harnessing the full potential of technology Fiber Laser: A Step by Step Guide

- The Ultimate Guide to Choosing Your Portable Handheld Laser Marking Machine for Metal

- CNC Router: Metal Cutting & CNC Machine for Metal