In engraving or marking materials with precision and efficiency, CO2 laser marking machines stand out as marking technology that has changed the game. These machines are also versatile and capable of making marks on non-metallic surfaces such as wood, glass, plastics, and even fabrics with great precision. But how do they work internally, and why are they so popular across different industries? This article looks at the science and functionality of CO2 laser marking machines, including their key features, applications, and business benefits. Suppose you are coming across the concept for the first time or hoping to expand your understanding. In that case, this guide will be insightful to you and give you a glimpse of how these machines are paving paths in the laser marking technology industry.

What are the Applications of CO2 laser marking machines?

Due to precision combined with versatility, CO2 laser marking machines can be used across various industries, serving numerous purposes. These machines are Commonly used to engrave and mark non-metallic materials like wood, glass, acrylics, plastics, leather, and paper. For example, the ever-growing sectors of packaging, electronics, automotive, and even medical use CO2 lasers for engraving barcodes, serial numbers, logos, and decorative designs. With reliable efficiency in organic and synthetic materials, these machines are excellent in labeling, branding, and even traceability of products.

How are CO2 lasers used in various industries?

Due to their efficiency, precision, and flexibility, CO2 lasers serve multiple functions across various CO2 industries. In packaging, these lasers serve as CT scanners for rapid engraving and also enable the creation of barcodes, QR codes, expiration dates, and batch numbering on glass, plastic, and cardboard materials. CO2 lasers strive to meet industry requirements. It further intensifies the laser’s engraved markings.

Delicate processes such as engraving circuit boards and marking electronic components are all made possible through the CO2 lasers used in the electronics industry, making their company parts undamaged during non-contact engraving in semiconductors and microelectronics. A report regarding 2023 delved into depth, claiming that the electronics market continues to dominate the processor’s share due to their increasing dependency on intricate parts.

Medical instruments require identifying markings by serial number, company logos, and other important imprints, restricting them to critical tools. For plastic and leather components like wiring, seat covers, and dashboard pads, CO2 lasers allow automotive manufacturers to engrave permanent markings, which in return aids in the traceability of using such advanced instruments.

CO2 lasers are essential for the production of medical and pharmaceutical devices.

CO2 lasers impact the textile and leather industries. They allow for accurate engraving and cutting of designs on fabrics and leather accessories, which improves production efficiency. New approaches to laser technology have been developed recently, operating at greater speeds and minimizing material waste.

Forecasts suggest CO2 lasers will continue to increase in use as manufacturers from various industries increasingly seek durable, precise, and economical production techniques. Their many uses show that they can be used with different types of materials and changing market demands.

Can a CO2 laser engraving machine work on plastic parts?

Indeed, a CO2 laser engraving machine works on plastic parts excellently, producing precise and high-quality results. It is known that CO2 lasers work particularly well with many types of plastics because they cut or engrave the material by vaporizing the surface with infrared light. Examples of rubbers and plastics for CO2 laser engraving include acrylic, polycarbonate, polypropylene, ABS, and PVC. It is important to note that some plastics, like PVC, emit toxic fumes when engraving and must be verified before engraving.

Adjustments of the laser’s power and speed help meet the material’s requirements, which guarantees detailed engraving or precise cutting without the risk of melting and deformation of the plastic. For thinner plastics, for instance, a 40W or 60W CO2 Laser should be adequate, while demanding thicker materials would require stronger lasers. Also, accuracy and productivity are greatly enhanced with advanced CO2 laser systems that come with software auto-focus features. With the high propensity laser engravers reach, the resolutions are up to 1000 dpi, which invites the creation of remarkable graphics and texts on thermoplastic parts.

The adaptability of CO2 laser engraving machines makes them a go-to option for adding branding or part markings to plastic parts in the automotive and medical device sectors, as well as consumer product manufacturing. As the need for sustainable custom production techniques increases, CO2 lasers are, and continue to be, an effective technique when working with plastics.

What are the benefits of using laser marking systems for organic materials?

Systèmes de marquage au laser offrent des avantages considérables lors de la manipulation de documents, textile, cuir et bois. Leurs hautes prècisions et dèlicates entrées de details sur chaque partie faite de ces materials, n’impacte d the hurt of the material itself. One of the main advantages is the non_contact action that avoids the damage of material surface while providing good quality.

Besides, laser marking systems can be used for almost any permanent marking, such as logos or serial number engravings. Studies show that laser marks made on wood remain unbroken in sight and even survive outdoors. In addition, this technology has also proven to be environmentally friendly because no inks or harmful substances are used, thus reducing waste.

Another advantage of modern laser marking systems is their incredible efficiency. Systems can now utilize high-speed laser marking, reaching 7,000 millimeters within a second without sacrificing quality. By changing the laser’s power and speed, systems can quickly adapt to many organic materials. These systems are vital in furniture, fashion, and packaging due to the need for exactness, eco-friendliness, and beauty.

What is the Difference Between CO2 laser engraving and Fiber Laser?

The effectiveness of CO2 and fiber lasers significantly differs in terms of operating techniques and material compatibility. For instance, CO2 lasers employ gas technology for engraving and etching on wood, glass, leather, acrylic, and other non-metal organic materials. They are suitable for projects requiring non-marring precision.

Unlike CO2 lasers, fiber lasers use solid-state technology and are the best option when working with metals and certain types of plastics. Industrial-grade lasers made from stainless steel, aluminum, and brass all require the high-density yet marked speed, durability, and low-maintenance laser engravers associated with fiber technology.

So CO2 lasers work best on organic surfaces, whereas fiber lasers work best for precision industrial metalwork projects. Each has a specific use based on the materials selected.

What materials can a fiber laser marking machine engrave?

Laser marking using fiber lasers on different surfaces is done efficiently and precisely, making these types of laser engravers very flexible. Fiber lasers have specific specialty domains, such as engraving on metals like gold, aluminum, stainless steel, copper, titanium, and brass. Also covered are anodized and tin-plated coated metals. In addition to fiber lasers being able to engrave on certain plastics like polycarbonates and PMMA, these machines are also capable of engraving on ceramic and composite materials, making them ideal for industrial and creative purposes. The additive composition, laser power, marking speed, and the requirements needed all control the material compatibility and selection. Combining high technology with high efficiency, fiber lasers provide detailed and permanent marks covered in high contrast on any surface.

How do CO2 laser machines compare to fiber lasers in terms of precision?

When it comes to accuracy, fiber lasers outperform CO2 laser machines when it comes to fine and detailed work. This is because fiber lasers have a shorter wavelength, which in turn means a smaller focal spot size and aggregated energy, ideal for intricate designs and delicate engravings. While CO2 lasers are still accurate, their strength lies in broader cuts or markings on non-metal materials such as wood or acrylic. Ultimately, it all depends on the use case and the level of detail needed.

Which is better for high-speed applications: a CO2 laser engraver or a fiber laser?

Fiber lasers are usually preferred in high-speed applications because they are more efficient and better suited to automation. They operate faster when marking or engraving metals and other materials suitable to their wavelength. Industries with quick production cycles, such as aerospace, automotive, and electronics, benefit from the precision they achieve even at higher operating speeds due to the lasers’ high beam quality and energy efficiency.

CO2 lasers are better suited for cutting or engraving non-metal materials (e.g., textiles, wood, and acrylic). While they can achieve decent speeds, they don’t excel to the same level as fiber lasers and are slower as well during work on dense or reflective surfaces.

Industry testing data highlights that fiber lasers achieve marking speeds of up to 7000 millimeters per second, a significantly faster pace than most CO2 systems. In addition, fiber lasers outperform CO2 lasers regarding operational lifespan, averaging 50,000 to 100,000 hours of use. CO2 lasers only last for an approximate 20,000 hours, which increases downtime and maintenance costs needed in high-demand environments.

Fiber lasers are the optimal choice for high-speed applications owing to their intricate processing speed, precision, and material versatility. Still, project specifics, like material type and result, must also influence the decision.

How Does a CO2 Laser Engraving Machine Work?

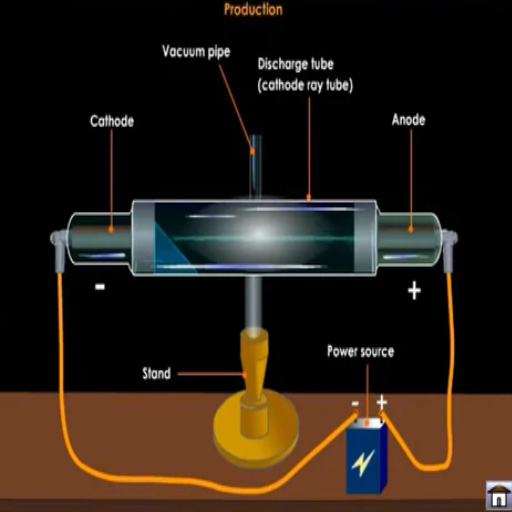

A CO2 laser engraving machine utilizes a focused beam of infrared light to cut out a particular design or pattern and remove the upper layer of a pre-defined object. This physical object, represented with a specific pattern, is produced, and this results in the creation of a beam. A CO2 gas laser uses a fitting mixture of carbon dioxide gas. Triggers and gages are placed over this gas, and with the aid of electrical energy, the gas is excited, and light radiates. Precision lenses and mirrors focus the highly concentrated laser beam on the engraving material. The clean, detailed designs are created by applying high heat from the laser, which either burns or vaporizes the material. A computer controls the laser, guiding it through the stored information to digitally etched files, translating to patterned or textual figures. These CO2 laser engravers are great for glass, wood, acrylic, and leather.

What is the laser source in a CO2 laser machine?

Typically, the source of a CO2 laser machine’s laser is a gas mixture located in a sealed tube. Carbon dioxide (CO2), nitrogen (N2), helium (He), and sometimes hydrogen (H2) or xenon (Xe) comprise the gas mixture based on the manufacturer’s specifications. The electric current flowing through the gas mixture excites nitrogen molecules, which transfer energy to CO2 molecules, producing infrared laser light.

A CO2 laser machine’s frequency range is about 10.6 micrometers, which is ideal for engraving and cutting non-metallic materials. The efficiency of CO2 lasers is approximately 20%, which means a reasonable amount of energy is transformed into laser energy from electrical energy. These machines have different power options, with laser powers of 20 watts for engraving and more than 400 watts for industrial-grade cutting. The versatility of CO2 laser sources makes them useful for different industries such as manufacturing, art, and prototyping.

What is the marking process involved with laser engraving?

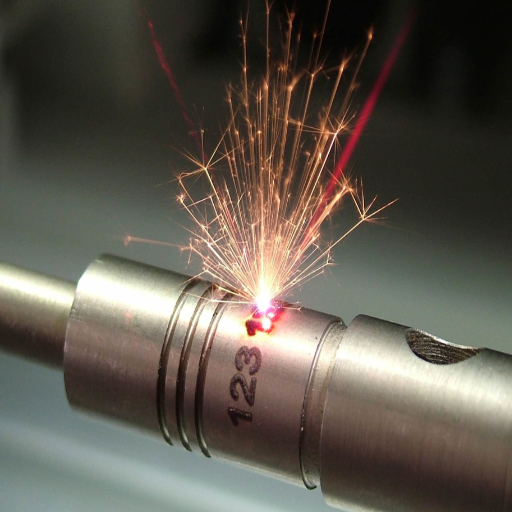

Marking in laser engraving refers to the permanent engraving of marks on the surface of a material using a very high-powered laser beam. Laser marking is done by removing surface material through the processes of ablation, melting, discoloration, and surface removal. These processes take place for marking purposes. The generation of a mark from a beam of laser results in a material change, such as vaporization or chemical reaction from heat, to change a mark to be permanent, unlike other processes.

Among the various laser marking processes, one of the most commonly used is direct engraving. In this process, a laser focuses on a specific point to generate sufficient heat for vaporization. Engraving for metals can be achieved through an immense laser beam coupled with oxidative markings. However, with organic items such as leather or wood, the surface is evenly burned to a desired depth, leading to contrasting patterns. The power of laser engraving is unparalleled in speed and efficiency. The engraving can be as slow as 10 mm/s for highly detailed designs but can surpass 1000 mm/s for more industrial-level work, all while maintaining a precision of 0.01 mm. With the rise of new laser source technologies, such as fiber lasers, accuracy has improved while power requirements have decreased significantly. Today, it is possible to engrave a wide range of designs, including serial codes, logos, decorative elements, barcodes, etc., on metals, plastics, ceramics, and organic materials, which is crucial for the manufacturing, medical devices, and jewelry industries.

How is the wavelength significant in laser technology?

The wavelength of the laser is fundamental in determining how it interacts with different materials and how it is used in various industries. Due to their smaller beam size, UV lasers (wavelengths around 355 nm) are better at greater precision in material processing, for instance. They are exceptional at focusing energy so accurately that it can be described as extreme. This means that industries that employ micromachining or marking small parts, such as electronics or medical devices, are best served by these lasers.

On the contrary, IR lasers (wavelengths around 1064nm) are better at cutting and engraving thick or highly absorbent materials. In metal processing, for instance, IR lasers do exceptionally well due to their strong absorption by metals, which gives them efficient and seamless cutting results. Data shows that fiber lasers operating at 1064 nm can achieve energy efficiencies of over 30 percent compared to CO2 lasers, which makes them cheaper and better for the environment.

In addition, a material’s absorption characteristics also depend on the wavelength. For example, many organic materials, such as plastics, have good absorption close to 10,600 nm, which is associated with CO2 lasers, making marking or cutting smoother and more manageable. Selecting a specific wavelength allows industries to tailor laser operations to particular requirements, thus improving productivity, accuracy, and energy consumption.

What are the Advantages of Using a CO2 laser marking machine?

Using CO2 laser markings machines comes with several advantages, including:

- They ensure high-precision markings, which are sharp and intricate on delicate or complex surfaces.

- These machines are versatile because they can mark a wide range of materials, such as wood, glass, leather, and plastic.

- Unlike other marking methods that are prone to wear, CO2 lasers are unmatched in durability. Their marking is timeless, permanent, and resistant.

- CO2 Laser marking machines are noncontact machines. They do not physically touch any surface, minimizing distortion or damage to the material being worked on.

- Compared to other machines, CO2 laser machines require low maintenance, work at high speed, and are, therefore, cost-effective.

- These systems were eco-friendly. They help in reducing waste by maintaining responsible operational levels.

Laser marking machines are widely accepted in many industries because they are efficient and reliable.

How does high precision affect marking and engraving?

Achieving high accuracy during marking and engraving not only improves quality but also fulfills requirements in detail-sensitive industries. Modern CO2 laser systems with advanced technology enable the precision of microns for microelectronics, medical devices, and high-grade jewelry. For example, medical devices require high-precision laser engravers for precise and accurate serial numbers, barcodes, logos, and high regulatory standard laser compliance.

Moreover, greater precision means fewer errors, translating to cost savings on time, material, and production. Processes requiring accuracy at the micron level are critical in producing functional components, such as circuit boards. Studies using advanced high-precision laser technologies show improvements in repeatable batch efficiency of 20% or more. Cuts and marks at high precision are cleaner, reducing finishing work and optimizing operational efficiency. Failure to meet these intricate detail requirements from industries with zero tolerance for mistakes may result in devastating consequences.

What makes CO2 lasers suitable for marking a wide range of materials?

CO2 lasers are known for their remarkable capabilities in marking materials such as wood, glass, plastics, textiles, ceramics, and some metals with specialized coatings. One major consideration is their wavelength, which generally is about 10.6 microns. This is useful for non-metallic materials because CO2 lasers can be efficiently absorbed. In this sense, CO2 lasers become the preferred choice when precision and flexibility are required.

Moreover, CO2 lasers allow for proficient control of marking depth and speed, providing detailed engraving or cutting without altering the shape of the material. The energy density of these lasers is high, which helps maintain a constant marking outcome. This is essential for manufacturing, automotive, and electronics industries. Other industries also stand to gain from developments in CO2 lasers as they improve with each passing day in terms of power efficiency and lifetime—many laser tubes now last over twenty thousand hours, which is a boon regarding maintenance work. Furthermore, the marking method does not touch the material, so any strain on the surface is eliminated.

As noted by industry studies, CO2 lasers can accomplish marking speeds of up to 600 mm per second, making them particularly useful in high-speed production areas. These lasers also work with computer-aided design and drafting systems, which provide precision reproducibility in extensive operations. These features have made CO2 lasers a powerful tool for diverse marking requirements in many industries.

What are the Common Features of Laser Marking Machines?

- High Precision—Laser marking machines achieve the maximum level of accuracy when marking intricate and detailed designs.

- Speed and Efficiency – With maximum operating speeds, they are ideal for bulk production because they do not compromise quality.

- Durable Markings – Permanently marked engravings not subject to fading, abrasion, or scratching are the hallmarks of laser machines, ensuring durability over time.

- Compatibility with Materials—This includes metals, plastics, ceramics, and glass, as these machines are adaptable to a wide variety of materials.

- User-Friendly Interfaces – many laser marking machines’ accompanying software provide customization and ease of operation.

- Low Maintenance – Designed with robust and reliable features, these machines do not require frequent servicing.

In many industries where efficient, high-precision results are needed, laser marking machines provide the best accuracy, speed, and quality.

What types of laser tubes are used in laser engraving machines?

Current technologies enable the production of laser tubes for engraving with different functionalities suited for different engraving applications:

- CO2 Laser Tubes

The most popular type of laser tube used in laser engraving machines is the CO2 laser tube. They function by excitation CO2 gas within the tube to obtain a laser beam of sufficient intensity. They are especially good for engraving various types of non-metal materials like wood, acrylic, plastic, leather, glass, and others. Their greatest advantages are their low price and long lifespan compared with other types (generally between 1,000 and 10,000 hours, depending on the make and model).

- Fiber Laser Tubes

Fiber laser tubes employ a solid-state laser source, using optical fibers doped with ytterbium. They are specially designed for applications requiring precision and engraving speed, such as metal engraving. Their average lifespan of over 100,000 h makes them very robust for industrial usage. Moreover, they have low maintenance requirements compared with other types.

- UV Laser Tubes

The range of UV laser tubes is around 355 nm. Because of their relatively lower wavelength, they are very effective when marking delicate materials. They are frequently used for delicate markings on glass, some plastics, and electronic components. The engravings are accurate and strikingly contrastive, which means they do not distort the material with heat. Specialized industries value these UV laser tubes due to their effectiveness and versatility.

- Diode Laser Tubes

The main use of the diode laser tube is engraving lighter materials; it is a light and compact tube. They are very common in woodworking engraving machines for home and small businesses as they are popular for engraving soft materials. Although these tubes may seem weaker in power, especially when compared to CO2 or fiber laser tubes, they are an optimal choice for beginners because of their lightweight and low cost.

The selection of a laser engraving machine’s parameters is guided by the engraving’s material, required precision, the purpose of the engraving, and how often it will be used. According to modern ones, fiber, and UV lasers are surging in popularity because of their increased flexibility and strength and use in modern production technologies.

How do laser marking systems ensure high-speed operations?

Sophisticated cutting-edge technologies are the basis for the design strategies employed in laser marking systems, which guarantee operations at high speed. Galvanometer scanners, also called high-speed scanners, are a critical system characteristic. They can control the position of laser beams with incredible swiftness and accuracy. Currently, galvanometers can operate at speeds more than the gold standard of 10,000mm/second, which marks feeble text or designs. These speeds are sufficient to rapidly engrave text or elaborate patterns on many materials.

Besides, new laser sources like fiber lasers also add to their operational speed. Fiber lasers are known for their superlative beam quality and energy proficiency. Thus, marking speed is not affected, nor is the quality or intensity of the engravings. For example, power level adjustments and rapid pulse repetition rates in fiber lasers facilitate speed modification and power regulation, thereby accomplishing enormous productivity for industrial-scale usage.

High system performance is also a function of specialized intelligent software systems algorithms that enhance path planning and eliminate idle motion. Research data suggest that such system software improvements will enhance marking efficiency by 30%.

Finally, modern laser marking machines offer high-speed operations in rugged environments because of their compact and sturdy designs. These systems are perfect for automotive, aerospace, and electronics manufacturing industries that require long-term precision and speed. This is possible due to the effective performance and reduced maintenance lasers offer over time.

Reference Sources

-

Laser Marking Methods (2015)

- Authors: Lyubomir Lazov, Hristina Deneva, Pavels Narica

- Summary: This paper systematizes various laser marking methods, focusing on their applications across different materials and shapes. It emphasizes the importance of selecting the appropriate method based on material type, marking requirements, and production needs. The study highlights the flexibility and adaptability of laser marking systems in meeting diverse customer demands.

- Key Findings: The research identifies specific opportunities and fields of application for different laser marking methods, providing a database for manufacturers to optimize their processes.

- Methodology: The study analyzed existing laser marking techniques and their effectiveness on various materials.

-

Laser Marking (2021)

- Author: Terry J. McKee

- Summary: This chapter from the “Handbook of Laser Technology and Applications” discusses using laser marking for alphanumeric codes, barcodes, and decorative designs. It compares laser marking with ink marking, highlighting the advantages of indelibility and reliability. The study also explores the interaction of laser energy with polymers for decorative marking.

- Key Findings: Laser marking offers superior durability and aesthetic appeal compared to traditional methods. The effectiveness of marking depends on the material’s response to laser energy.

- Methodology: The research focuses on the imaged-mask marking technique and its application to various materials, particularly polymers.

- Top Co2 Laser Marking Machine Manufacturer And Supplier In China

Frequently Asked Questions (FAQs)

Q: What is the main difference between a CO2 laser marker and a fiber laser machine?

A: The primary difference lies in their laser generation technology. CO2 laser markers use a gas-filled tube to generate the laser beam, making them ideal for marking organic materials like wood and acrylic. In contrast, fiber laser machines utilize fiber optic technology that performs well for marking metals and other materials.

Q: Can CO2 laser markers be used for laser cutting applications?

A: CO2 laser markers can be used for laser cutting, especially for organic materials like acrylic and wood. They excel in cutting these materials due to their high marking precision and stable performance.

Q: What are the advantages of CO2 laser technology over fiber laser machines?

A: The advantages of CO2 laser technology include effectively marking organic materials like wood and acrylic. CO2 lasers also tend to be more cost-effective for engraving applications involving these materials.

Q: Which type of laser machine offers better performance for marking metals?

A: Fiber laser machines typically perform better for marking metals due to their high precision and stable power output. Compared to CO2 laser markers, they can mark a wide range of materials quickly and efficiently.

Q: How does the engraving speed compare between CO2 lasers and fiber laser machines?

A: Fiber laser machines are generally times faster than CO2 laser markers when engraving and cutting metals. However, CO2 lasers provide excellent results with high marking precision for organic materials.

Q: What types of materials can fiber laser machines effectively mark?

A: Fiber laser machines can effectively mark various materials, including metals, plastics, and ceramics. They are mainly known for their capability to engrave metals with exquisite beam quality and stable performance.

Q: Are specific focus lenses required for CO2 laser markers and fiber laser machines?

A: CO2 laser markers and fiber laser machines require specific focus lenses to achieve optimal marking results. The lens choice can significantly impact the quality and precision of the engraving.

Q: Can a single machine handle CO2 and fiber laser marking needs?

A: No. Typically, a single machine is designed either for CO2 laser marking or fiber laser marking. Each type is optimized for specific materials and applications, making choosing the right machine based on your marking solutions essential.

Q: What kind of maintenance is required for CO2 laser markers and fiber laser machines?

A: Regular maintenance is necessary for both types of machines to ensure stable performance. This includes cleaning the laser generator, checking the optics, and ensuring proper alignment. Proper maintenance can extend the machine’s long working life and maintain excellent performance.

- Understanding Speed in Laser Marking: How to Optimize Your Laser Marking Machine

- CNC Router Vs Laser Cutter: Which Cutting Machine is Right for You?

- The Ultimate Guide to Laser Cleaning: How This Revolutionary Rust Removal Technology Works

- How Laser Cleaning Technology Works: Laser Cleaner Basics

- Color Laser Engraving: Everything You Need to Know About Laser Engraving Work

- Unlocking the Secrets of the 3D Laser Marking Machine: A Comprehensive Guide

- Laser Marking vs. Engraving vs. Etching: Understanding the Key Differences and Applications

- Choosing the Best Wood for Laser Cutting and Engraving Projects