There have been advancements in applying CO2 laser cutters within the design and manufacturing industries due to their unmatched versatility, efficiency, and precision. In any case, whether creating intricate designs, tailor-made products, or dealing with wood, metal, and acrylic, these machines are arguably one of the most potent tools for creators and businesses. Through this guide, we take you step by step through the captivating world of CO2 laser cutting, explaining the workings of the machines, the features, and the myriad modern manufacturing advantages they offer. At the end of the article, we hope that you understand the reasons behind the wide adoption of CO2 laser-cutting machines in various industries worldwide and how you can use them to enhance your projects.

What is a CO2 Laser Cutter, and How Does It Work?

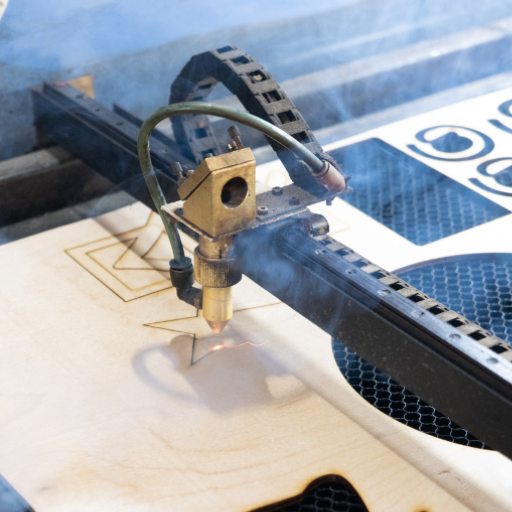

A CO2 laser cutter uses light technology to cut, engrave, or etch different materials such as wood, plastic, fabric, and metal. The laser beam is generated using CO2 gas, which, when excited, produces a focused light. Mirrors and lenses enhance this concentrated light, increasing the power to melt and vaporize materials along a pre-designed pathway. Due to their precision, speed, and versatility, these laser cutters serve vital roles in designing, crafting, and manufacturing.

What are the main components of a CO2 laser machine?

The CO2 laser machine’s key components are:

- Laser Tube

The laser beam is emitted from the laser tube, the core part of the machine. It is usually filled with a gas mixture that includes carbon dioxide (CO2) alongside nitrogen, helium, and, at times, minute quantities of hydrogen or xenon. The electrical excitation in the tube causes many powerful, coherent laser beams to be emitted. High-quality laser tubes last between 8000 and 20000 hours, depending on the construction and maintenance.

- Power Supply

This part is paramount as it ensures enough power to stimulate the gases in the laser tube. Advances in Power supply technology have improved efficiency, while modern systems tend to consume less energy overall. Power supply also plays an essential part in the stability and performance of the laser beam.

- Optical System

The optical system is composed of mirrors and lenses that aid in guiding, focusing, and directing the laser onto the material. The lens focuses the energy on a tiny, precise spot, while mirrors are placed to ensure the beam is reflected along the machine. High-efficiency optics minimize energy loss during transmission, thus increasing cutting or engraving accuracy.

- Cooling System

CNC laser cutters require significant heat management since the laser tube generates a lot of heat while cutting. To optimize the cooling systems, they can be either air-blown or water-circulated. Overheating of laser equipment is a critical issue as it leads to wear and tear, significantly affecting the life span of the laser tube.

- Control System

The software interface functions as a control system where the user input regulates the settings and movements of the laser machine. Based on the design files, the control system executes specific laser-cutting or engraving commands as defined in the logic. The first generation of CO2 laser cutting machines tends to have complex control interfaces, unlike the fourth generation, which can control and interpret SVG, DXF, AI files with and much more advanced user interfaces.

- Work Table

The work table refers to the dynamic equipment section of CNC laser cutters, where the materials are positioned for the operations to be executed. It has the added advantage of being height adjustable. Also, structures such as honeycomb or knife-grade may be present to reduce the amount of reflections that might take place while cutting.

- Exhaust System

Smoke and rough residue are byproducts of engraving or cutting. The exhaust system helps maintain workplace cleanliness by getting rid of those byproducts. It also helps keep the optics rust-free.

Each of these components works together with CO2 laser machines, which can be used in many different industries for tasks such as cutting, engraving, and etching. Regular maintenance on each component will guarantee that the machine functions optimally and increase the device’s overall lifespan.

How does a laser cutter work?

What is a laser cutter? A laser cutter is a device that cuts or engraves materials by concentrating high-power, focused beams of light as a laser, using precision.

CO2 laser cutters are a type of laser cutter that uses carbon dioxide gas to derive light alongside gas mixtures such as helium or nitrogen. Carbon dioxide lasers transform into pumping lasers, and so require additional amplification, which can be done with mirrors and lenses to excite the light super. Once the light is amplified and harnessed, it can then be focused using a lens to stroke the surface of the material and assembled vision an emitting gun.

In CO2, laser cutters apply staled gas functions to expel red light so that the temperature is higher than 10000 degrees Fahrenheit. Mendel’s apparatus made a rigorous shot recoil machine that can pop, burn out, and steam various materials like fabric, wood, metal, and acrylic. The laser employed editing designer vision rototiller that flows pre-defined paths. Modern laser cutters are capable of exceptional detail, achieving tolerances as tight as 0.001 inches.

### Additional Sources

– Assembly vision

– Editing designing vision rototiller

#### Citation

[1] Carpenter relent elektromuntin poor sewing education.

In addition, using laser cutters consumes less energy than traditional cutting tools; they use 20-50% less energy when cutting thin materials. Furthermore, they can cut faster than older models, slicing through metals such as steel at 100 inches per minute, depending on the machine’s strength and setup. Because of their speed, adaptability, and accuracy, laser cutters have become vital to aerospace, automotive, and manufacturing industries, which require precise measurements and detailed designs.

What is the cutting process in CO2 lasers?

Compared to other methods of cutting, CO2 laser cutting offers not only great speed but also great accuracy. The cutting method revolves around using a laser that has an infrared light beam (10.6 micrometers) focused onto a material. In simpler terms, coaxing a laser into a material with intricate optics will yield the desired results. Additionally, CO2 lasers can cut through stainless steel or aluminum sheets and, depending on the power of the machine, the material, and the machine’s power, they can reach cutting speeds of 600 inches per minute.

When it comes to cutting, both air and gases are used for added precision. Air cuts away the molten material deposited during cutting, while oxygen is often used for cutting thicker materials as it accelerates the process. Unlike oxygen, though, nitrogen ensures cleaner cuts without oxidation, leading to pristine results.

Modern CO2 laser cutters integrate advanced motion control systems and CNC technology, which allow for complex and precise cutting of different materials. The tolerance level of cutting in CO2 lasers can go as high as ±0.003 inches for thin materials, making them best suited for high-precision industries. Furthermore, the latest cooling developments in these systems allow CO2 laser devices to maintain functionality and extend their working life by eliminating the risks of overheating during fast-paced operations.

What Materials Can a CO2 Laser Cutting Machine Cut?

CO2 laser cutting machines are adaptable, as these tools can work with a breadth of materials, which includes:

Wood: Rogers offers laser cutting and engraving services for plywood, MDF, and solid wood.

Acrylic and Plastics: Rogers also offers cutting polycarbonate and smooth acrylic sheets and non-PVC plastics, which require the production of precise and clean borders.

Paper and Cardboard: Routinely employed when precise cuts are required for artistic and packaging implements.

Leather and Fabrics: Technologically treated exponents which enable precision engraving on textiles and their cutting.

Rubber: Able to treat specific nonmetallic, industrial, and ornamental rubbers.

Apart from these, CO2 lasers are not ideal for cutting metals unless the piece is thin and covered with a layer. They remain one of the best options for non-metal cutting tasks.

What is the range of materials suitable for CO2 laser cutting?

CO2 lasers have broad application ranges as they can scan and process all non-metallic materials with great utility. The following are some of the most cut or engraved materials:

- Wood and Wood-Based Materials: Advanced CO2 systems can cut plywood, MDF, softwoods, and hardwoods up to 20 mm thick, which is beneficial in the design and crafting of furniture, models, and various crafts.

- Acrylic and Plastics: Depending on the power of the laser, acrylic sheets up to 25 mm in thickness are polished and smoothly cut for signage, decoration items, and other acrylic products.

- Paper and Cardboard: These items require a certain level of detail, translating well into elegant and precise cuts. This works well with packaging, invitations, and other creative projects that require fine detail.

- Leather and Fabrics: Fashion and interior design use many fabrics, and CO2 lasers can leave intricate designs and patterns on genuine leather, felt, and synthetic polyester textiles. The type and thickness of the fabric determine how precise the setting will be.

- Glass and Ceramics: CO2 lasers cannot cut glass; however, they can engrave delicate patterns on their surface. This has numerous applications, such as customizing drinking glasses, awards, and decorative glassware.

- Rubber: Non-metallic specialized rubbers such as those used in creating stamps or seals can also be processed with lasers, allowing for precise definition.

- Foams: CO2 lasers are used to custom-cut various types and densities of foam for industrial packaging or other custom-shaped products, achieving optimal precision.

With appropriate power and speed settings, advanced CO2 laser systems can contend with these materials’ variable thicknesses. Due to their speed, reliability, and flexibility, these systems are often used for coining, design, manufacturing, and prototyping. Metals are not typically associated with CO2 lasers; however, the diverse non-metallic resources that can be processed make these systems useful in various applications.

Which materials should be avoided for CO2 laser cutting?

Despite CO2 lasers being exceptionally adaptable, some materials, like PVC, should be avoided due to safety issues and poor cutting results. PVC and vinyl are particularly hazardous materials to cut with lasers because they produce highly poisonous chlorine gas. This gas harms human health and slowly damages the laser machine’s parts.

Polycarbonate is one material that should also be avoided because cutting it with a CO2 laser produces smoke and foul odors. Additionally, materials like ABS (acrylonitrile butadiene styrene) should be avoided because they create a lot of melting instead of clean cut,s which is very dangerous due to the fumes they give off. Fiber-reinforced composites like fiberglass also fall under unfit materials due to their composite nature, which makes them react unpredictably during laser cutting and emit toxic particles into the atmosphere.

Reflective aluminum and other reflective metals are generally unfit for CO2 lasers unless extensive treatments are done beforehand due to the damage they inflict on the laser optics. Always verify the material’s specifications and ensure there’s adequate airflow to the area of work when utilizing a CO2 laser system equipped with a vacuum to maximize efficiency and improve safety.

How does CO2 laser cutting handle thicker materials?

The more powerful lasers and their innovative cutting techniques seem optimal for handling thick materials using CO2 laser cutting. Including acrylic, steel, wood, and other dense materials, CO2 lasers with power levels of more than 150W to approximately 400W are used to cut these materials. The material type and the laser’s wattage are directly proportional to the cutting depth. A case in point, a 150W CO2 laser can cut mild steer of up to 12 mm (around 0.47 inches) thick, while a 400W laser can cut 20 mm (approximately 0.79 inches) thick materials.

Working with thicker materials can enhance performance using auxiliary gases such as oxygen or nitrogen. For steel containing oxygen, combustion fuels cut the material faster. Nitrogen aids in producing clean and free-of-oxidation edges for stainless steel or aluminum but does not affect the material as much. Moreover, to achieve better results, changing the focus point of the laser slightly beneath the material surface helps the laser achieve smooth surfaces and precise edges. The cutting speed and quality of thicker materials is further enhanced by newer technologies in lasers which include dynamic beam focusing and pulse shaping.

To maintain working efficiency with sufficient material thickness, optimal performance requires thorough maintenance of the laser system, including routine cleaning of mirrors and lenses. CO2 lasers, when integrated with other advanced processing tools and high-powered lasers, are dependable and effective tools for slicing thicker materials in numerous fields.

What Are the Benefits of Using a CO2 Laser Cutter?

CO2 Laser cutters have become widely adaptable globally due to their many advantages. These laser cutters provide precise and accurate measurements, allowing for detailed and intricate cuts on various materials. Its range of capabilities is extensive, allowing for cutting, engraving, and marking work on wood, acrylic, plastic, fabric, and metals. CO2 Laser cutters work cleanly and efficiently as they create clean cuts with little material wastage. In addition, CO2 laser cutters are simple to use and require very few manual adjustments, which aid in the increase in productivity, a decrease in errors dealing with human hands, and a positive outcome from automation. Their reliability and ease of use proven performance on CO2 laser cutters for industrial and creative purposes is unmatched.

What advantages does CO2 laser cutting offer over other methods?

Compared to other cutting methods, CO2 laser cutting is recognized for its precision, versatility, and cost-effectiveness. Its ability to achieve intricate and detailed cuts with minimal distortion is a primary advantage. CO2 lasers can powerfully and precisely cut through many different materials, including wood, plastics, glass, and even fabrics, which makes them suitable for many industries, such as manufacturing, automotive, and creative design.

The speed and efficiency of the process is another benefit. For instance, CO2 lasers can cut stainless steel sheets at speeds of up to 20 meters per minute, depending on the material thickness. This high-speed performance increases productivity while cutting operating costs in the long run. CO2 laser systems also come with automated control through computer numerical control (CNC) systems, which helps to lower human error and ensure the same quality consistently.

The non-contact nature of CO2 lasers alone offers more advantages by lowering maintenance expenses, decreasing the number of tools needing replacing and reducing overall tool wear. Additionally, the work yield is frequently less in post-processing work, which is more effortless, thus saving more time, money, and resources. For environmentally conscious businesses, CO2 lasers contribute to eco-friendly initiatives because they create almost no waste.

In balance, CO2 laser cutting offers the precision required, the time expected, and higher-than-average expense efficiency, making it the optimal choice for most modern industry design applications.

How does cutting speed compare with other lasers?

In comparison to CO2 lasers, it is noted that parts made of non-metallic materials like wood, plastics, and acrylic are processed more quickly with CO2 lasers due to their higher efficiency in heat generation. However, when cutting metals such as stainless steel or aluminum, CO2 lasers are surpassed by fiber lasers in both speed and precision, particularly with thinner metals. For example, CO2 lasers take about 13 seconds to cut a thin metal sheet (under 6mm). In comparison, fiber lasers take only four seconds, gauging the increased energy density and shorter wavelengths, which are better absorbed by metals.

Also, increases in fiber laser technologies have bolstered the speed at which materials may be cut using a fiber laser, with newer methodologies enabling cutting speeds exceeding 40m/min in some situations. CO2 lasers tend to operate at more uniformly slower rates than fiber lasers;. At the same time, they are adaptable, CO2 lasers are multifunctional, albeit at the expense of operational speed, cutting with more versatile, higher quality edging capable at increase foam thicknesses.

Diode lasers are also becoming more popular competitors due to their slower performance in pure cutting. Ultimately, the choice is limited predominantly by and depends on material, thickness, desired outcome quality, and laser speed. While speed may seem like the primary factor, it is context-dependent.

What industries benefit from using a CO2 laser cutting machine?

CO2 laser cutting machines are versatile tools that cater to a wide range of industries due to their precision, efficiency, and ability to cut through various materials.

- Manufacturing and Fabrication

These machines are integral to manufacturing industries for cutting and engraving applications. They are widely used in creating metal parts, custom components, and intricate designs. For instance, the global laser cutting market is projected to grow significantly, driven by the increased demand in automotive and aerospace manufacturing, where precision and quality are paramount.

- Signage and Advertising

Businesses specializing in signage benefit significantly from CO2 laser-cutting machines. These machines’ ability to handle materials like acrylic, wood, and plastics allows for the production of high-quality signs with sharp edges and detailed designs. Their rapid turnaround time meets the fast-paced demands of the advertising sector.

- Textile and Apparel Industry

CO2 lasers are used for precision cutting and engraving of fabrics in the fashion and textile industries. Their non-contact process minimizes fabric distortion and ensures intricate patterns are produced efficiently. This technology is particularly valued in high-volume production environments.

- Arts and Crafts

As CO2 lasers become familiar, we see their application in engraving wood, leather, glass, or paper, revealing new market opportunities for businesses selling custom engravings or decorations.

- Electronics Industry

A common application of CO2 lasers is marking and cutting parts in the electronics industry. They are especially critical for intricate circuits and sensitive component housings that must work in advanced devices.

The growing use of CO2 laser-cutting machines in these sectors shows the need to improve production processes, material wastage, and product quality to stay ahead of the competition. It also reminds businesses of the return on investment they would gain if they invested in these technologies.

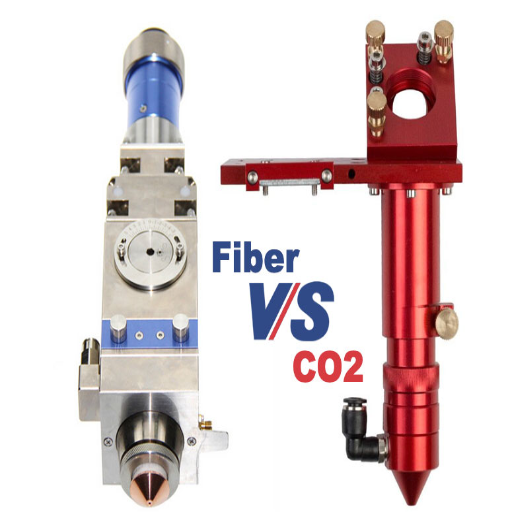

How Does a CO2 Laser Cutter Differ from a Fiber Laser Cutter?

The finest difference between CO2 laser and fiber laser cutters is their light source and purpose. A CO2 laser uses a gas mixture to produce infrared light, which is excellent for cutting non-metal materials such as wood, acrylic, and textiles. Conversely, fiber lasers cut and engrave metals with precision and speed because they use a solid-state configuration to produce longer wavelength laser beams. In addition, fiber lasers are more economical than CO2 lasers in the metalworking industry because they require less maintenance and energy.

What are the key differences between CO2 and fiber laser technologies?

- Compatibility with Wavelength and Material

Due to their operating wavelength of 10.6 microns, CO2 lasers can efficiently process non-metallic materials such as wood, acrylic, and plastic. Fiber lasers operate at a shorter wavelength of about 1 micron, allowing greater focus on metals. Because of this, they excel at metal cutting, engraving, and marking. Some non-metallic materials become problematic for Fiber lasers, as the shorter wavelengths are absorbed differently.

- Power Efficiency

Fiber lasers are much more energy efficient than CO2 lasers. They convert approximately 30 to 50 percent of input power into output power, whereas CO2 lasers convert only 10 to 15 percent. This means lower electricity costs for fiber lasers economically, especially in high-demand industrial settings.

- Maintenance Requirements

CO2 lasers will often require cleaning and maintenance because mirrors, lenses, and other optical parts need regular upkeep. These parts are also likely to suffer damage over time, making them require replacement. On the other hand, Fiber lasers use fully enclosed optics and solid-state mechanisms. This means they are much more durable and require less maintenance, resulting in long-term cost-effectiveness. Speed and Precision

For thin metals and more detailed designs, fiber lasers are very effective. The precision is remarkably high in both speed and quality. Because the wavelength of fiber lasers is smaller, the focal point is finer, leading to better quality beams, finer diameter waves, enhanced processing times, and quicker speeds. Engraving and high-speed cutting is made easier thanks to fiber lasers. CO2 lasers, on the other hand, have a slower cutting speed with metals but are much more efficient than fiber lasers when cutting large non-metal surfaces.

- Initial and Operational Costs

Unlike fiber laser systems, CO2 laser systems require a lower initial investment. However, operational costs, including energy consumption and maintenance, favor the fiber laser system over time because it is more efficient and has less wear and tear on the optical components.

- Lifespan

Regarding lifespan, fiber lasers have a considerable advantage over CO2 lasers. A fiber laser has over 100,000 operating hours, while the best CO2 laser would be around 20,000 hours, depending on the equipment’s usage. This makes fiber lasers more effective for long-term industrial projects.

Every type of equipment has its own strengths and weaknesses, which makes the process of selecting a suitable one based on industry needs quite compelling. Ultimately, every decision made regarding the materials used, the type of lasers, and enhancing precision and speed needs to be well thought out.

Which type of laser is better for cutting metal?

Fiber lasers are the best choice for cutting metal because of their effectiveness, accuracy, and flexibility. Having a wavelength of roughly 1 µm, fiber lasers are more proficient in cutting metals such as aluminum, brass, and copper because they reflect light better. Furthermore, like all other lasers, they are highly productive when dealing with thin metals.

Research suggests that fiber lasers can cut certain thicknesses, such as 5mm of mild steel, three times as fast as CO2 lasers. They are also lower cost because they are easier to maintain, last longer, and use less energy, which is beneficial for large industrial operations.

CO2 lasers are still effective for non-metallic materials with a wavelength of 10.6 µm, although some previously more reflective metals cut well at more considerable depths. Being slower and demanding more maintenance makes them less favorable for mass production of metal objects.

In any case, fiber lasers surpass CO2 lasers in almost every aspect of cutting metal, so more industries prefer them nowadays.

In what scenarios would you choose a fiber laser cutting machine over a CO2?

Because of their accuracy, efficacy, and versatility with materials, a wide array of scenarios can be tackled with fiber laser cutting machines. One example includes working with highly reflective metals like brass, copper, and aluminum. Cutting fiber lasers are far superior for these materials due to having a high absorption and lower wavelength, which significantly increases the chances of damaging the machine with reflected laser energy.

Another instance would be working on thin-layer stainless steel or carbon steel sheets that are under 5 mm thick, where speed and efficiency become of the utmost importance. When slicing thinner materials, fiber lasers can cut three times as fast as CO2 lasers, significantly increasing productivity in sectors with tight deadlines. For instance, fiber lasers outperform CO2 technology with thinner stainless steel gauges by processing at over 20m/min.

Moreover, CO2 laser fibers outperform them in cost-effectiveness when it comes to long-term operations. Their maintenance is lower due to having fewer moving parts, and they consume far less energy—some cases up to 50% less—than CO2 lasers. Because of these advantages, they become far more appealing to manufacturers wishing to maintain a reduced operational cost without compromising output quality.

Precise applications in medicine and electronics require accuracy to the degree of micrometers. As compared to other laser types, fiber lasers are beneficial for precision work. Their superior beam focus ensures that even the most detailed cuts maintain exceptional edge quality.

Environmentally sustainable industries will likely favor fiber lasers, too. Unlike other types of lasers, fiber lasers do not use gas, which decreases energy consumption and reduces carbon footprint.

The combination of advanced performance, speed, and unmatched efficiency makes fiber laser cutting machines invaluable across various industries, including automotive, aerospace, and electronics.

What is the Laser Cutting Technology Behind CO2 Lasers?

CO2 laser cutting technology uses a gas combination, mainly carbon dioxide, to make the laser beam. That gas gets electric stimulation and emits a highly concentrated beam of light. This beam is then focused through several lenses and carefully aimed at the area of the material surface. Because of the extreme heat it generates, it can cut, melt, or vaporize materials. For non-metallic materials like acrylic and plastic, CO2 lasers work effectively; these nonferrous materials also make a wide multi-purpose use of those lasers.

How does the laser beam interact with materials?

When the laser beam interacts with a material’s surface, it considers its attributes, such as thermal conductivity, absorption, and reflectivity. For example, materials such as wood and plastics have high absorption rates and can easily be set to cutting, engraving, or vaporization because of the laser’s concentrated energy. With metals, one would more often than not find reflective surfaces that demand higher energy levels or special coatings to increase absorbance.

The outcome is still dependent on the intensity and wavelength of the laser. As an illustration, CO2 lasers with a wavelength of about 10.6 micrometers will interact more effectively with organic materials because it can be absorbed efficiently, hence cutting wood or fabric with precision. Research indicates that depending on the material’s thickness and the laser’s power, one can achieve cutting speeds of up to some meters per minute. Furthermore, advancing technology in lasers has meant straying from the conventional systems and allowing higher levels of precision so that some systems reach tolerances as acceptable as 0.001 inches, resulting in deeply detailed designs while ensuring reduced material wastage.

By adjusting parameters like beam focus, intensity, and movement speed, we can tailor how the laser interacts with the material for clean cutting, deep engraving, and delicate etching.

What role do mirrors guide the laser beam?

Mirrors or beam delivery optics are critical in directing the laser beam from its source to the intended target with high precision. Because of their high power density thermal management and low thermal distortion, such mirrors are fabricated from silicon, molybdenum, or copper.

These mirrors must be well-aligned and high-quality to ensure the laser system functions appropriately. An example of a suboptimal condition is beam splitting, which results in reduced accuracy in engraving or cutting and negatively influences precision. Some advanced systems use mirrors set at different angles to reflect the laser beam along different axes, thus enabling sophisticated movements required in industrial processes.

Some modern laser systems employ compensatory measures for external vibrations, using real-time changes to maintain beam focus, which ensures consistent performance even at high speeds. Data shows that optimized designs tailored for precision can increase efficiency in beam delivery by roughly thirty percent while minimizing energy and maximizing quality.

What is the laser output, and what is its significance?

The term ‘laser output’ encompasses the total energy or power provided by a laser system, which is measured in watts (W) for continuous wave lasers or joules (J) for pulsed lasers. This output value is essential for a laser system’s application in manufacturing, medicine, and scientific research since it dramatically affects the usefulness of a laser system for these applications. High-power lasers, for instance, are necessary in the industry for performing cutting and welding processes because energy must be delivered to the material efficiently and precisely, such as steel, aluminum, or titanium. Research suggests that with the development of fiber laser technology, processing speeds with operational cost savings in large-scale manufacturing have surged with laser outputs above 10 kW.

Moreover, other outputs, such as the control and stability of laser output, are significant for consistent performance. Medical fields like dermatology or ophthalmology require more sophisticated tools that need fine-tuned systems to precisely deliver energy to avoid damaging tissue while still performing the procedure. Operating with emerging technologies has also concentrated on exercising control over energy efficiency when performing operations with new diode-pumped solid-state lasers that reach conversion efficiencies of as high as 50%, thus optimizing performance by reducing energy waste.

Industries can make new advancements in precision, accuracy, efficiency, and environmental sustainability by adjusting to users’ customization needs and understanding the requirements of lasers.

Reference Sources

-

“State-Of-The-Art and Trends in CO2 Laser Cutting of Polymeric Materials—A Review” (2020):

- Key Findings: This review highlights the application of CO2 laser cutting in processing polymeric materials like thermoplastics and thermosetting plastics. It discusses challenges such as heat-affected zones (HAZ), kerf width, surface roughness, and dross formation. The study emphasizes optimizing parameters like laser power, cutting speed, and assisting gas pressure to improve cut quality.

- Methodologies: The paper reviews experimental and theoretical studies, analyzing the effects of laser parameters on cut quality. It also identifies research gaps, such as the need further to explore polymeric materials and their optimal cutting parameters.

-

“Laser Cutting Technique: A Literature Review” (2022):

- Key Findings: This study reviews the use of CO2 lasers for cutting various materials, including metals and polymers. It optimizes parameters like scanning speed, laser power, and gas pressure to enhance material removal rates and minimize defects like dross and surface roughness.

- Methodologies: The review consolidates findings from multiple studies, examining experimental and computational approaches to optimize laser cutting processes.

-

“CO2 Laser Dye Patterning for Textile Design and Apparel Manufacture” (2017):

- Key Findings: This research explores using CO2 lasers for digital dyeing and patterning of synthetic textiles. It demonstrates the potential for on-demand processing, reducing energy and water usage compared to traditional methods.

- Methodologies: The study employs a 10-watt Synrad laser marker system and CAD software to create patterns on polyester fabrics. It compares hand-applied dyeing methods with industry-standard procedures and analyzes results through microscopy.

- Top Co2 Laser Engraving Cutting Machine Manufacturer And Supplier In China

Frequently Asked Questions (FAQs)

Q: What is the difference between CO2 and fiber laser cutting?

A: The difference between CO2 laser cutting and fiber laser cutting lies primarily in the source of the laser beam. CO2 lasers use a gas mixture to produce a powerful laser beam, while fiber lasers utilize a solid-state medium to generate the laser light. This leads to variations in cutting quality and the types of materials each can effectively cut.

Q: What materials can I cut using a CO2 laser cutter?

A: CO2 laser cutters are suitable for cutting various materials, including wood, acrylic, plastics, glass, and metals. However, fiber lasers are often preferred for reflective materials like aluminum and copper due to their cutting efficiency.

Q: How does the cutting method differ between CO2 and fiber lasers?

A: The cutting method for CO2 lasers involves focusing a powerful laser beam into the material, which allows for precise cutting of various materials. Fiber lasers, on the other hand, utilize a different approach that often results in faster cutting speeds and higher efficiency, particularly for metals.

Q: What are the advantages of using a CO2 laser cutting machine?

A: CO2 laser cutting machines offer several advantages, including the ability to cut a wide variety of materials and a high level of precision. They are particularly effective for laser engraving and cutting non-metallic materials. They can also be more cost-effective for specific applications than fiber lasers.

Q: Can a CO2 laser cutter be used for metal cutting?

A: CO2 laser cutters can cut some metals but are generally less effective than fiber laser cutters. CO2 lasers are more suitable for thicker or non-reflective metals, while fiber lasers excel with thinner andmore reflective materials.

Q: What should I consider when choosing the right CO2 laser cutter?

A: When choosing the right CO2 laser cutter, consider factors such as the types of materials you plan to cut, the laser power required for your applications, and the cutting quality you expect. It’s also essential to evaluate the cutting head’s size and the machine’s overall capabilities.

Q: How does the laser head affect the cutting quality of a CO2 laser cutter?

A: The laser head plays a crucial role in determining the cutting quality of a CO2 laser cutter. A well-designed cutting head effectively focuses the laser beam into the material, resulting in cleaner cuts and better precision. Adjustments to the laser head can also optimize the cutting speed and quality.

Q: What are industrial CO2 laser cutting machines typically used for?

A: Industrial CO2 laser cutting machines are commonly used for applications such as sign making, woodworking, and manufacturing where precision cutting of various materials is required. They are valued for their ability to handle large volumes and complex designs with high accuracy.

Q: How do fiber laser cutters work compared to CO2 laser cutters?

A: Fiber laser cutters produce a laser beam using a solid-state medium, which is then directed through fiber optics to the cutting head. This method allows for a more concentrated and efficient cutting process, particularly for metals, compared to CO2 laser cutters that rely on a gas mixture.

Q: What are the applications of waterjet cutting compared to CO2 laser cutting?

A: Waterjet cutting is often used for thicker materials and applications where heat-affected zones must be minimized. While CO2 laser cutting is effective for thinner and non-metal materials, waterjet cutting provides versatility in handling various materials without altering their physical properties.

- How Does a Laser Marking Machine Work? Discover the Secrets of Laser Engraving

- Unlocking the Power:Advantages of Pulsed Laser Technology

- Unlocking the Potential: How to Use a Laser Marking Machine for Engraving and Etching

- A Comprehensive Guide to the Most Common Types of Laser Marking

- Laser to Cut Tree Branches: Transforming Sci-Fi Concepts into Reality

- The Ultimate Guide to Laser Cutting Plywood: Mastering the Art of Precision

- Understanding the Crucial Differences Between Laser Engraving vs Laser Marking: A Complete Guide

- Solve Power Drop Issues in Fiber Laser Cutting Machines: Discover Effective Solutions