Winning the race for precision manufacturing achieves a new level of accuracy with CO2 laser cutting. Known for its unparalleled efficacy and versatility across various sectors, from steel laser-cutting houses to fashion designers, this technology offers something for everyone. Be it a curious newcomer or an expert in CO2 laser cutting, grasping the basics will showcase the potential it holds for your projects. In this blog post, we will explore the world of CO2 laser cutting, discussing the process involved, the range of its applications, the costs, and the most critical settings. After reading this guide, all your questions like ‘how does CO2 laser cutting works?’ and ‘how to accurately and efficiently use it to get the desired results?’ will be answered. Join me as we explore why businesses and creators have come to rely on this remarkable technology that delivers accurate and high-quality outcomes.

What is the CO2 Laser Cutting Process?

CO2 laser cutting is a process that entails the use of a focused beam of infrared light to cut, engrave, or etch materials intricately. The procedure involves exciting a mixture of carbon dioxide gas with intense energy, which generates a due beam of laser light. The beam is focused through lenses or mirrors and onto the material in question. The concentrated heat melts, burns, or vaporizes the targeted area. If gas such as oxygen or nitrogen is used, the material is removed more efficiently from the cutting path. This method is preferred because of its speed, precision, and ability to work with wood, metals, acrylic, and plastics.

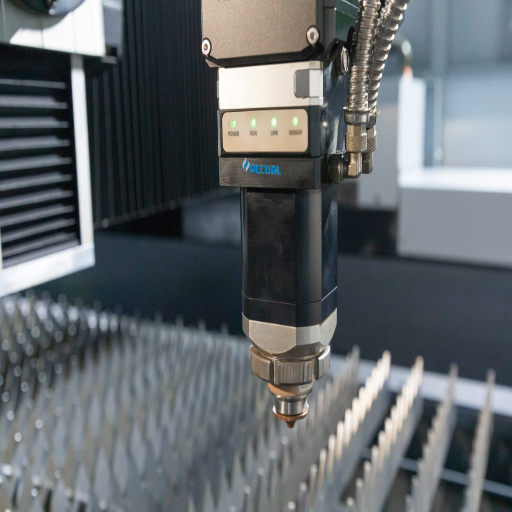

How does the CO2 laser cutting machine work?

Electrically stimulated carbon dioxide gas produces a high-power laser beam, serving as the primary operating principle of CO2 laser cutting machines. The beam is fine-tuned along the cutting area using specialized mirrors and optics, allowing unparalleled accuracy and energy propulsion. The process starts when an electric discharge excites a gas mixture of carbon dioxide, nitrogen, and helium, generating a concentrated infrared laser beam around 10.6 micrometers in wavelength.

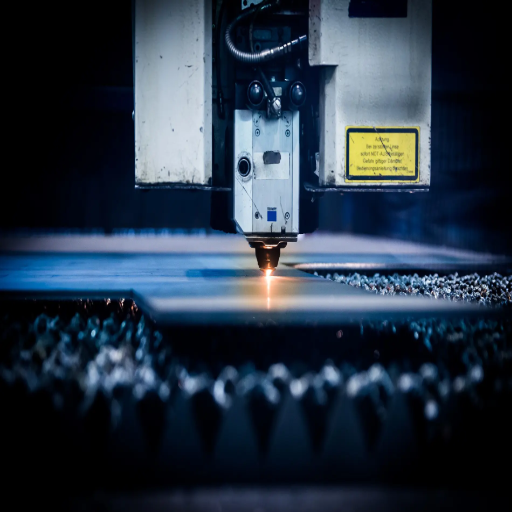

The laser beam is first directed to the cutting head, where a lens converts it into the most minor possible high-temperature spot, which, in extreme cases, can exceed 20,000°C (36,032°F). Any material that is melted or vaporized at the cutting point is rapidly expelled from the site with the aid of oxygen, nitrogen, or compressed air.

Modern CO2 laser-cutting machines can cut up to 30 meters per minute. The speed varies with the material type, thickness, and composition. Thin metals such as aluminum and stainless steel are often cut at higher speeds—10 to 20 meters per minute—with thicker materials requiring slower processing speeds for accuracy. Many machines offer automatic and real-time sensor-aided positioning and proactive CAD/CAM adjustments for intricate designs.

CO2 laser cutting has one significant advantage over other types of cutting: its versatility. Depending on the output power of the laser (which ranges from 40W to 1,000W in industrial machines), the laser can cut through nonmetals such as wood, glass, and plastics, as well as metals up to 20mm thick. The technology is remarkably efficient and precise and achieves very low edge charring or deformation, making it an essential tool in automotive, aerospace, and textile manufacturing.

What are the key steps in the laser-cutting process?

- Preparing the Design

The first step involves creating a digital design, usually in CAD software. The design is then exported to a DXF or DWG file for the laser-cutting machine. It is essential to input the design accurately to minimize waste and achieve the most efficient cuts.

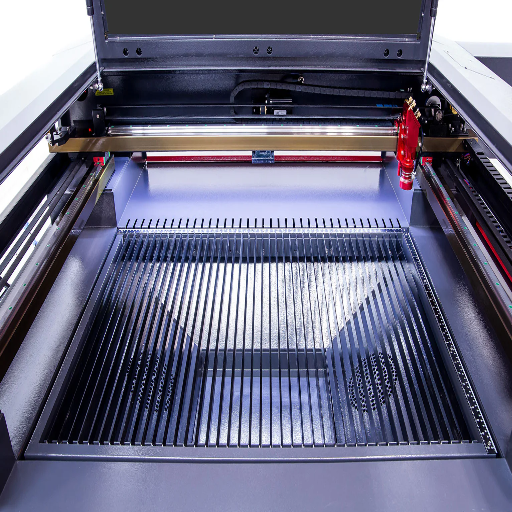

- Choosing and Setting Up the Material

The next step involves selecting the right material for the project, which may include metal, wood, plastic, or glass. The material is then clamped down on the machine’s cutting bed to eliminate any chance of movement during the cutting process. The type of material and its thickness determines the optimal settings for the laser.

- Optimizing Parameters and Calibration

Before cutting can begin, the laser cutting machine needs to undergo calibration. The cutting machine must have defined laser power, speed, and focus height values. For example, it is common to employ high-powered lasers, around 1,000W, to cut steel or aluminum, while softer and thinner materials require lower power settings. Proper setting values will result in minimal clean edges, damage, or imperfections.

- Execution of Laser Cutting

The first step is activating the laser beam once the equipment is set and the workpiece is clamped. The focused beam of light melts or vaporizes the substance along the predefined path based on the input drawing. Depending on the material characteristics, various tactics are used, such as vaporization and melt-and-blow cutting. Machines can cut thin metals at 20-50 inches/per minute, and fiber laser technology cuts metals much faster now.

- Finishing and Deburring

The work piece or material that is cut may or may not have sharp edges therefore it is at times required to be sanded, polished, or treated to remove scratches and burrs, this is done depending on the type of material and its application to achieve maximum smoothness and quality.

- Quality Assurance

The custom-cut parts undergo the last step of ensuring that they have been cut precisely to the requirements. To ensure the parts have met the criteria offered by the industry standards, high-tech machines and systems are used to check the dimensions, edges of the cut, and roughness of the surface area to the smoothness required, determining the standard criteria set by the industry.

As explained in this guide, laser cutting’s robotic precision and versatility have made it an irreplaceable technology for many industrial fields.

What types of materials are typically used for laser cutting?

Laser cutting is a dynamic form of technology that deals with various materials with laser-sharp accuracy. Metals like stainless steel, carbon steel, aluminum, and copper, to name a few, are also used due to their durability and conductivity. Nonmetallic materials like acrylic, wood, plastics, and glass can also be laser-cut to produce custom signs, decorative pieces, and prototypes. With the advancement of technology, laser cutting can be used on advanced materials like composites and ceramics, which are used in the aerospace, electronics, and medical fields. Specialized laser systems are often needed to cut these materials.

Older versions of lasers can be used on softer organic materials like wood and plastics, which require CO2 lasers for cutting at high speeds. New technology has developed lasers that can cut through thick reflecting materials. Modern fiber lasers can adequately cut through aluminum and stainless steel at 30mm and 25mm, depending on the system power and configuration. The precision and capability of dealing with various materials make laser cutting one of the most essential devices in countless industries.

What are the Applications of CO2 Laser Cutting?

CO2 laster cutting is at its finest in fields that require precise detailing and versatility. It is widely used for the following applications:

- Manufacturing: It is used for engraving and cutting different types of materials for industrial equipment, including plastic and wood.

- – Automotive: Accurately fabricates the detailing and trimming of non-metal automobile components.

- – Signage: Used for highly detailed logos and lettering on wood, acrylic, and other materials.

- – Packaging: Cuts and shapes cardboard, paper, and other materials for custom detailing on packages and parcels.

- – Textiles: These are used for high-speed cutting and engraving patterns on fabric.

- – Art and Decoration: Detailed engraving of leather, wood, and other creative materials to produce unique pieces.

These applications show the ability and effectiveness of C02 laser technology in various industries.

In which industries are CO2 laser cutting commonly used?

CO2 laser cutting has rapidly become one of the most applicable technologies by allowing great versatility. It is helpful in several core industries, such as:

- **Manufacturing and Engineering**: Industrial manufacturing can use these lasers to cut metals, plastics, and composites while ensuring minimal waste. Recent industry reports also show that the global laser-cutting market is estimated to reach $6.72 billion by 2026. This shows the importance of laser-cutting technology in today’s production world.

- **Automotive Industry**: Due to its precision, CO2 laser cutting further enhances the creation of intricate parts within the automotive industry. It cuts airbags, dashboards, and even customized parts of vehicles, which helps improve safety alongside aesthetics.

- **Electronics**: CO2 lasers serve as a further aid within the electronics manufacturing industry, performing highly precise work such as cutting thin circuit boards and engraving components. With the growing need for small, lightweight, but efficient electronic devices, rapid advances in this field render lasers necessary.

- **Aerospace**: Aerospace material engineers and designers rely on CO2 lasers, which are best for cutting lightweight yet strong materials such as aluminum and titanium. With aircraft parts, greater precision with well-finished surfaces is important, and these lasers help achieve that, which in turn improves performance and safety.

- Textiles and fashion: In the textile sector, CO2 lasers are becoming more popular for cutting fabrics, engraving patterns, and detailing clothes. Their rapid cutting and precision help fulfill the needs of fast fashion and customized clothing.

- Advertising and signage: CO2 lasers are great for producing high-quality engravings of logos and detailed designs on acrylic. They can also easily create intricate signs. This industry relies heavily on the ability to work with many materials and their precision.

- Medical Equipment: CO2 lasers help manufacture delicate medical devices and parts, such as surgical instruments and implants. The precision and cleanliness needed for these healthcare tools are of high standards, so CO2 lasers are used.

These examples from different industries show how effective CO2 lasers are in speed, cutting precision, and adaptability to diverse materials, which, in turn, encourage growth in many worldwide market segments.

What are the benefits of using CO2 lasers for cutting?

CO2 lasers uniquely guarantee accuracy and speed so they can cut several materials such as metals, plastics, wood, and even ceramics. They possess a high degree of accuracy, which allows for fine detailing. This, in turn, decreases the amount of material wasted and makes it possible to produce complicated designs. Since a non-contact approach is used in the cutting process, the mechanical stress placed on the material is reduced, preserving the material’s integrity, and the risk of damage during manufacturing is also mitigated.

Another significant benefit is the efficiency of CO2 lasers. They surpass traditional methods in terms of speed. This means their productivity in industrial settings is enhanced. For instance, CO2 laser systems can achieve cutting speeds of twenty meters per minute depending on the material and thickness. With such speed, they are beneficial for mass production.

These lasers feature energy efficiency due to the optimized power consumption of technological advancements. Although modern CO2 lasers boast high outputs, they are designed to conserve energy. Moreover, the ability to cut through materials of varying thicknesses and materials without tool changes reduces time and operational costs.

Lastly, they are not limited to just cutting applications. CO2 lasers possess versatile applications, including engraving, welding, and surface treatment. The ability to perform multifunctional tasks is essential in multiple sectors, such as automotive, aerospace, electronics, and medical device manufacturing, which require high precision and quality. This multi-faceted flexibility ensures that CO2 lasers are indispensable for modern manufacturing.

What are some innovative applications of laser technology?

Applications of laser technology have developed quickly in the precision, efficiency, and versatility of many sectors. Here are just a few examples:

- 3D printing

The aerospace and healthcare sectors have especially benefitted from lasers because of how precisely and quickly the material can be fused. Lasers accelerate the construction of intricate components layer by layer. According to industry reports, 3D printing has slashed prototyping levels, surpassing 50% in many industries. Selective Laser Sintering and Direct Metal Laser Sintering are two techniques that also aid additive manufacturing.

- Surgical and medical procedures

Laser integration has made A range of surgeries easier to perform accurately. Eyesight-correcting procedures, tumor removal, and skin resurfacing are popping up more commonly and are a basic necessity for a large segment of people. Targeted recovery is minimizing damage to surrounding areas of the body, which means patients recover a lot quicker. Accurate treatments have become possible and highly reliable, with Lasik eye surgery examples showing 96% success.

- LiDAR for Self-Driving Cars

LiDAR is one of the most critical components for self-driving cars. LiDAR technology uses lasers to 3D map an environment in real-time by setting laser beams and recording the time taken for reflection. This technology facilitates self-driving cars by improving navigation systems, detecting obstacles in the way, and ensuring the car’s safety. Recent technological advancements in the miniature size and lower price of LiDAR systems are increasing their adoption in the auto industry.

- Cultural Preservation And Restoration

Lasers are revolutionizing the delicate cleaning and reconstruction of historical artifacts and monuments. They allow the removal of dirt, grime, and contaminants while maintaining fragile substrates underneath intact. One famous example is Michelangelo’s sculptures, where lasers were used to accurately restore fine details due to the unparalleled precision provided by lasers.

The use of lasers in Quantum computing makes them extremely important. In Quantum Computing and Photonic Chips, Data transfer within photonic chips occurs with the velocity of light. This changes how data is stored and processed. Many companies are showing notable progress in the application of laser technology for efficient quantum data processing, claiming it will greatly enhance computing speed.

These new ways of using lasers show their impact on different industries by improving accuracy and efficiency.

How does Laser Cutting Cost compare?

Costs for laser cutting will depend on the project’s complexity, the material’s thickness, and its type. Traditionally, laser cutting is more precise and cost-effective on intricate designs than traditional methods due to reducing material waste and machining time. Though the upfront costs may be steep, it remains a highly accurate and efficient solution for enduring setups in the long run, making it ideal for many applications.

What factors influence the cost of laser cutting?

Material Type and Thickness

The type and thickness of the material significantly affect laser-cutting costs. Steel, aluminum, and acrylic are common materials; however, each differs in speed and complexity of cutting. For example, cutting stainless steel takes comparatively more energy and time than cutting softer, thin materials like acrylic. On average, thicker materials take more time and increase power consumption, which leads to higher costs.

Design Complexity

Sculptured and more intricate designs require more time and adjustment during cutting. More advanced geometries about complex shapes require additional programming time along with slower cutting speeds, which can lead to higher costs. Projects involving detailed engraving or multiple curves and tight corners require precise laser control, which impacts the expense.

Machine Type and Power

Laser-cutting machine selection is another primary consideration. For specialized uses and efficiencies, high-powered fiber or CO2 lasers are available. Fiber lasers cut metal faster than CO2 lasers, which tend to be cheaper for non-metal materials like wood and plastic. The downside is that high-powered lasers use more energy, slightly raising detailed projects’ operating costs.

Setting Up

All projects involve some level of preparation, as design file changes, calibration, and testing need to be done. The setup time is most critical for custom or one-off pieces, as the preparation time is not offset by mass production. This overhead makes smaller-scope projects more expensive per unit compared to larger batch quantities.

Production Quantity

Economies of scale strongly impact the costs associated with laser cutting. The unit cost is lesser when there is a larger production run because setup and operational costs are divided by the number of items. For instance, the manufacturing cost per piece for 1,000 parts is always lower than for a single prototype.

Additional Finishing and Post-processing

If a project’s secondary processes involve polishing, edge smoothing, or other surface finishing, the overall project cost increases. Laser cutting is one process that produces clean and accurate edged cuts. However, additional cosmetic or functional finishing through other techniques may be required due to some specific applications, which raises the cost.

Energy Pricing and Operational Efficiency

Energy prices in certain regions directly affect the cost of laser cutting because the energy consumed by the machines influences these prices. Highly efficient laser systems with good energy usage will lower operating costs but may be in areas with high electricity costs and thus influence pricing.

How does CO2 laser cutting compare to other types?

The most significant benefits of CO2 laser cutting include it being precise, flexible, and applicable to organic and inorganic materials. CO2 lasers are superior to fiber lasers for non-metal materials such as wood, fabrics, and plastics. They are non-metal and softer metal cutters that need to be detailed, and CO2 lasers provide them with clean edges and minimal distortion. These factors make CO2 lasers the industry-preferred choice.

CO2 systems tend to be cheaper in terms of initial investment in terms of cost and energy consumption. However, CO2 systems generally operate at a higher cost when running. Modern fiber lasers outperform CO2 lasers in power to work required ratio, operating at 70% efficiency compared to CO2’s 10-20%. However, many industries using high-volume manufacturing could benefit from lower operational costs in the long run.

The type of material also affects speed and performance. CO2 systems are slower than fiber lasers for thin metal sheets, taking three times longer on average. On the other hand, CO2 lasers have a longer wavelength, allowing them to be smoother and more polished when cutting through 10 mm thick acrylic.

Service maintenance is another element to note. CO2 lasers, for example, have a more rigorous servicing schedule than fiber lasers. This is because CO2 lasers require maintenance to mirrors and lenses alongside other parts, while fiber lasers have a far simpler servicing schedule. That being said, CO2 remains a viable technology option because it is both challenging and can be changed for specific uses.

Ultimately, the choice will be determined by the needs of the cut, the type of material, the budget, and how efficient the desired output is. Both technologies offer something unique, but CO2 lasers are still used in industries specializing in precision cutting nonmetals and intricate designs.

Are there ways to reduce laser-cutting costs?

Reducing expenses for laser cutting is significant for a business seeking to improve its internal processes for efficiency and profitability. Here are a few approaches to help achieve cost reduction while maintaining quality:

- Improve resource allocation

Efficient material use prevents resource waste while saving costs. Nesting design software allows you to organize your designs in a way that maximizes the use of the available sheet space. Proper nesting can lead to material savings of about 20% per design, depending on its level of intricacy.

- Use the right materials.

The choice of materials can drastically change operational costs and increase speed. Using thinner sheets or cutting less dense metals will increase speed and decrease the cost of cutting. Additionally, acquiring the materials at wholesale prices in bulk significantly lowers the price paid per piece.

- Batch processing and standardization

Integrating distinct designs into one cutting session reduces the time spent setting up machines for each individual piece, reducing operational costs significantly. Standardizing parts or designs also improves long-term spending.

- Periodic maintenance of laser cutting machines

Ongoing maintenance greatly improves the efficiency of the machine’s performance, making expensive downtimes less likely. For example, cleaning lenses and replacing worn covers can boost the system’s energy efficiency by 10% at the absolute minimum.

- Utilize High-Speed Sales Cutting Methods

Pulse cutting is an advanced fiber laser cutting method that economically consumes energy per cut. When these methods are utilized where possible, production costs are directly lessened.

- Outsource Servicing When Necessary

When the demand for work is not too high and when the needed equipment and skills are not available, working with a trained specialist laser cutter can be less expensive than bringing the work in-house. These vendors often have more streamlined and large-scale systems that capture economies of scale, in contrast to performing the work through in-house capabilities.

- Adopt New Technology

Switching equipment to newer ones, such as fiber laser cutters and sharper tools, tends to reduce the amount of power utilized to operate the machines. For example, CO2 lasers use about twice as much electricity as fiber lasers, which makes them relatively expensive over time.

Following these procedures helps companies exercise better control over the costs incurred from laser cutting while maintaining the desired standard and quality in the products manufactured, thereby ensuring optimal and consistent production processes.

What are the Settings for CO2 Laser Cutters?

Each CO2 laser cutter has its unique settings relative to the material it cuts, including its thickness and the outcome. Following are some settings to pay attention to:

- Power: Wielding power must match the material. Thicker or harder materials require more power, while fragile or thin materials require relatively less.

- Speed: The quality of the cut hinges precisely on the speed of cutting. Thinner materials can be cut faster, while thicker materials require precision cutting at slower speeds.

- Focus: The laser really needs to be focused for clean and accurate cuts. The cutting focal point should depend on the thickness of the material.

- Air Assist: Turn on the air assist to remove debris and prevent charring. This enhances the quality of the cut and increases the lifespan of the machine.

- Frequency (Pulses Per Inch): Set the pulse rate according to the material’s requirements because not all materials are the same. A higher frequency is required for smoother edges, and a lower frequency is needed to minimize heat for certain materials.

In order to achieve the best possible outcome, precision test cuts need to be made while following the manufacturer’s instructions.

What are the recommended laser power settings?

The desired outcome, material type, and thickness greatly influence the laser power settings. Common materials have some general guidelines, which are outlined below.

Acrylic (3mm-6mm):

Power: 50%-70% to ensure no burns occur and clean cuts are achieved.

Speed: 10-15 mm/s.

Notes: Ensure complete cuts for thicker acrylic by increasing power or reducing speed.

Wood (3mm-6mm):

Power: 60%-80%.

Speed: 8-12 mm/s.

Notes: Use slower speeds to prevent charring when engraving and keep power lower for less intense burns.

Leather (2mm-3mm):

Power: 40%-60%.

Speed: 15-20 mm/s.

Notes: Test a small area before cutting to ensure no scorching damage occurs, as leather density differs across types.

Cardstock/Paper:

Power: 10%-20%.

Speed: 30-40 mm/s.

Notes: Avoid powering settings that result in burning or igniting materials.

Stainless Steel (when coated):

Power: 80%-100%.

Speed: 5-10 mm/s.

Notes: Fiber lasers are typically needed when cutting uncoated stainless steel.

Your specific model of laser cutter will require adjustments to the optimal power and speed settings to achieve the desired precision without wasting material. Test runs on scrap materials are necessary to find the right power, speed, and frequency balance.

How does cutting speed affect quality?

As with any machining process, cutting speed is critical in determining the quality of the cut. Zones of almost no reaction will generally overheat or burn; this is commonly known as the heat-affected zone (HAZ). Increasing laser cutting speeds bare the risk of not fully completing the cut due to melting at a nominally confined temperature, which will also result in jagged edges. Discoloration, secondary burns, and lack of sharpness result from too slow measurable results. Rough precision is moved further away from the ideal when the zones of the material being worked on involve porous and expansive areas.

Research and studies yield balance with minimal effort spent during the work on acrylic and moderate levels of power set at 15-20 mm/s. Contrarily, stainless steel requires lower speeds set at 5-10 mm/s to achieve controlled penetration and finishing when using specific lasers. The power level and speed combination warrant careful consideration to avoid balancing the system and fretting the material beyond repair. Increased power at higher ranges does alleviate some damage incurred by the material, but not without fault.

Each project has unique requirements and limit focusing on thermal features, sought-after traits involve thickness. Conducting preliminary rounds for each project will systematically lead to success.

What design tips for laser cutting should I consider?

- Choose Thoroughly For Optimal Results

Consideration of factors such as tools, equipment, and environment is important when working with heavily detailed designs. Acrylic glass options will work best when the cut edges require finishing. On the other end of the spectrum, acrylic has a certain level of finishing, and plywood has a natural aspect to it. Plywood cuts do require some adjustments based on thickness and density.

For more complex designs, remember to account for the kerf, which is the width of the cut. Fitting designs may require tighter interlocking parts to be more precise in terms of allowances. The kerf value depends on the settings applied to the device, machine, materials used, and equipment configuration. Please remember to make the set cut test measurements precise.

Take care that there is no overlap with cuts, as this leads to duplicate cut lines, which wastes time and causes material burns. Design your project correctly and ensure that there are no additional lines prior to beginning the cutting stage. Many design software programs offer access to path detection and redundancy elimination.

- Concentrate on Scaling and Measurements First

Precision laser fabrication requires careful attention when cutting components that fit together. Make sure your design is scaled appropriately, and all measurements are accurate, especially if the design has multiple components. If you use appropriate vector graphic software, you will not have issues with precision and compatibility with laser cutting machines.

- Optimize Flow and Cut Time with Design Arrangement

In the arrangement of the design, place like shapes together and orient them to reduce laser head movement. This is an effective way of reducing both cutting time and energy usage. Also, spacing between parts should be maintained appropriately to reduce the possibility of thermal expansion and material bending.

- Adjust the Setting Per Layer for Cutting and Engraving

If your design includes cutting and engraving, separate engravings from other parts of the design and assign them distinct layers with power and speed settings. For example, you can set engravings to lower power and higher speed than cutting. Arranging your design this way will always yield seamless workflow and enhanced detail in your work.

Evaluating laser settings and how the material reacts by testing different sections of the design before making full cuts helps in avoiding unwarranted costs tied to intricate designs. This enables better results, especially in large-scale designs, allowing for enhanced adjustments during execution.

Applying these tips will allow you to produce strong, precise, and visually stunning projects such as laser cutting work while increasing the quality of your work.

What Materials to Avoid for CO2 Laser Cutting?

While operating a CO2 laser cutter, there are materials to steer clear of for cutting quality and safety issues:

- **PVC (Polyvinyl Chloride)**: Creates chlorine gas when cut, posing a danger to both health and equipment.

- **Polycarbonate**: Not cut well, garners a messy and subpar output.

- **Foam Core Board**: Can easily catch fire and is hard to cut cleanly.

- **Fiberglass**: Contains epoxy resin, which generates terrible fumes when heated.

- **ABS Plastic**: It cuts very stringently, notwithstanding any harmful gasses released.

Not using these materials significantly improves the safety of equipment and working conditions. For a detailed list of recommended materials, consult your machine manual.

What are the common materials to avoid for CO2?

Each material poses a particular danger when a CO2 laser cutter is in use; avoiding them altogether will improve safety and prolong the equipment’s durability. Some of the items on the following list require further explanation.

- PVC (Polyvinyl Chloride): There is no question that PVC is one of the most dangerous materials. The moment it is cut, chlorine gas, which is extremely toxic, can be found in it. The respiratory system suffers greatly during this process. In addition, chlorine can corrode the laser cutter’s metal components, potentially leading to costly damage.

- Polycarbonate (PC): A CO2 laser does not cut Polycarbonate with great precision; the edges often have burns and a bad finish. It is also a health hazard, as its fumes can cut humans down.

- Carbon Fiber: Laser-cutting carbon fiber sheets is possible, but only if they are skinny. Those with epoxy or resin backings, however, are a hard no. These backings emit hazardous fumes, making both humans and machinery vulnerable.

- Teflon (PTFE) and similar fluorinated polymers: Relying on these materials can severely damage respiratory systems. This is without taking into account the needless fumes these items emit, such as hydrogen fluoride, which is corrosive and extremely toxic.

- Glass and Metals: CO2 lasers are inefficient in cutting most metals or glass. Trying to do so could damage the laser due to reflective feedback. Only materials with special coatings or reflective surfaces, such as mirrored metals, might be attempted, but they must be approached with extreme caution.

- High-Density Polymers or Thick Plastics: Besides emitting dangerous fumes when heated, these materials are cleanly cut with great effort. The task is also inefficient, requiring several passes, which strains the laser.

The risks that come with these materials highlight the need to focus on research beforehand. Following manufacturer instructions and maintaining proper airflow will enable the safe use of CO2 laser cutters.

Why are certain materials not suitable for CO2 lasers?

While CO2 lasers operate conveniently for specific materials, other operational alternatives are met with safety and performance-related challenges. For example, the welding of polyvinyl chloride (PVC) and chlorinated plastics results in dangerous chlorine gas emissions, which can greatly endanger an operator and internal machine components. Additionally, this corrosive gas can severely damage expensive laser optics and mechanical parts, posing a risk to clean maintenance.

Fiberglass, a composite resin of EIF and glass, is equally challenging to use a CO2 laser cutter. The resin’s fumes are highly noxious, while the glass fibers pose a significant risk of damaging the entire laser system. Furthermore, the use of polytetrafluoroethylene (PTFE), or Teflon, poses grave concerns as it emits fluorine-based compounds and other toxic gases, turning the area into a confined space lacking sufficient ventilation.

Polyurethane foam and other foam-like materials are highly flammable, making them a dangerous source of fire. They also release toxic smoke that contaminates the workspace. Carbon materials, especially those rich in dense carbon, pose an entirely different challenge. The high rate of absorption of laser energy can greatly affect edges, leading to inefficient cutting and choppy cuts.

To protect CO2 laser systems and ensure their maximum operational lifetime, the provided MSDS guides for materials must be followed, fume extraction systems must be utilized, and all manufacturer recommendations must be observed. Controlled testing of materials eliminates risks while optimizing the cutting outcomes for only approved materials.

What are the environmental impacts of laser cutting?

As precise and efficient as laser cutting is, there are some environmental considerations to look after. One of the most essential concerns is the energy use of operating laser cutting machines. High-powered CO2 and fiber lasers, for instance, consume quite a bit of energy since they are linked to electricity and carbon emissions during operational periods when the CO2 is not renewable. According to industry reports, the average industrial laser cutter consumes roughly anywhere from 3 to 8 kWh per hour. Sustaining energy value has become one of the most essential features in modern society.

In addition, laser cutting entails some emission of gases and particles and the use of particular processes. Cutting some synthetic materials scales down plastic entails letting go of some harmful volatile organic compounds (VOCs skirt banning fumes, as well as toxic fumes not properly). Thus, effective fume extraction and filtration systems become instrumental in addressing some of these issues.

The other crucial issue is sculpturing and the final results of cleaning. As opposed to traditional processes, laser cutting does produce a low amount of material waste. However, the waste that is created, such as scraps and remnants from composite materials, can sometimes become very hard to recycle due to the chemical changes made in the cutting process.

Newer models of fiber lasers and other more powerful and energy-efficient laser technologies are being developed to ensure that laser cutting is more eco-friendly. Additionally, utilizing renewable energy sources to run laser cutting systems, abiding by strict emission standards, and powering these systems significantly lowers the eco-footprint. Thoughtful choices of raw materials, as well as innovative recycling, help minimize waste, thus aiding in sustainable manufacturing practices, which are further enhanced by laser cutting.

Reference Sources

-

Cutting Techniques for Facilities Dismantling in Decommissioning Projects2:

- Focus: This study explores various cutting techniques for dismantling nuclear facilities, including CO2 laser cutting.

- Key Findings: CO2 laser systems effectively cut metal and concrete structures. They offer precision and reduced contamination risks, making them suitable for decommissioning tasks.

- Methodology: The research involved analyzing different cutting methods, their waste generation, and their efficiency in minimizing radioactive contamination.

-

Latest Developments of Laser Cutting3:

- Focus: This paper discusses advancements in laser cutting, including CO2 lasers, for various materials.

- Key Findings: Innovations like dynamic beam shaping and dual-wavelength lasers have improved cutting efficiency and quality. The study also highlights the potential of green CW lasers for non-metal materials.

- Methodology: The research reviewed recent technological advancements and their applications in cutting metals and composites.

-

CO2 Laser Ablation for Microfluidic Devices1:

- Focus: This study examines CO2 laser ablation for creating microfluidic devices.

- Key Findings: CO2 lasers provide a low-cost and precise method for patterning elastomeric materials, suitable for DNA amplification and point-of-care applications.

- Methodology: The study tested various laser settings to optimize the ablation process for microchannel fabrication.

- Top Co2 Laser Engraving Cutting Machine Manufacturer And Supplier In China

Frequently Asked Questions (FAQs)

Q: What is laser cutting technology?

A: Laser cutting technology is a manufacturing process that uses a focused laser beam to cut or engrave materials with high precision. It is known for its ability to create precise cuts and is widely used in various industries.

Q: What are the different types of laser cutting processes?

A: There are several laser cutting processes, including CO2 laser cutting, fiber laser cutting, and solid-state laser cutting. Each type has its unique advantages and is suitable for different applications.

Q: How does a CO2 laser machine work?

A: A CO2 laser machine generates a focused laser beam using carbon dioxide gas, which is then directed to the laser head through mirrors. This beam is used for cutting and engraving various materials, particularly non-metallic ones.

Q: What materials can a CO2 laser machine cut?

A: CO2 lasers can cut various materials, including wood, acrylic, glass, and certain plastics. They are especially effective for cutting non-metallic materials due to their high efficiency.

Q: Can CO2 laser machines be used for metal cutting?

A: While CO2 laser machines are primarily used for cutting non-metallic materials, they can also cut certain types of metal. However, fiber laser cutting machines are generally more effective for cutting metals.

Q: What are the benefits of using a CO2 laser cutter?

A: The benefits of using a CO2 laser cutter include high precision, versatility in cutting various materials, faster cutting speeds, and the ability to create intricate designs with minimal material wastage.

Q: How does the intensity of the laser beam affect cutting results?

A: The intensity of the laser beam directly impacts cutting efficiency and results. A higher intensity allows for faster cutting speeds and cutting thicker materials while maintaining quality cuts.

Q: What are some typical applications for laser cutting work?

A: Laser cutting work is commonly used in industries such as manufacturing, automotive, aerospace, and art. Applications include creating prototypes, custom signage, and intricate designs on various materials.

Q: What should I consider when choosing cutting equipment for laser cutting?

A: When choosing laser cutting equipment, consider factors such as the types of materials you will be cutting, the thickness of those materials, the required precision, and the overall cutting speed needed for your projects.

Q: How do CO2 lasers compare to fiber laser cutting machines?

A: CO2 lasers are ideal for cutting non-metallic materials and are known for their versatility, while fiber laser cutting machines are more efficient for cutting metals due to their focused laser beam and higher cutting speeds. Each type has its specific advantages, depending on the application.

- CNC Cutting vs Fiber Laser Cutting: Which is the Better Option?

- Laser Cutter vs CNC Machine: Understanding the Difference Between CNC Cutting and Laser Cutting

- Understanding the Crucial Differences Between Laser Engraving vs Laser Marking: A Complete Guide

- Top 10 Countries for Best CNC Machining Services: Global CNC Machine Industry Guide