The transformation of industrial design and precision manufacturing has been made possible by CNC routers and mill technology. While these two advanced tools share similarities, knowing which one meets your needs is essential. Regardless of whether you are exploring computer-controlled machining or are a seasoned expert, knowing the advantages of both technologies is vital. This article explains the core features, functions, and advantages of each technology to help you make the right choices. By the end of this article, we ensure every reader will know the distinct differences of strengths of various tools and offer guidance on which option would work best for their particular endeavor. With that said, let’s dive into the enchanting universe of routing and milling.

What exactly is a CNC router and how does it differ from a CNC mill?

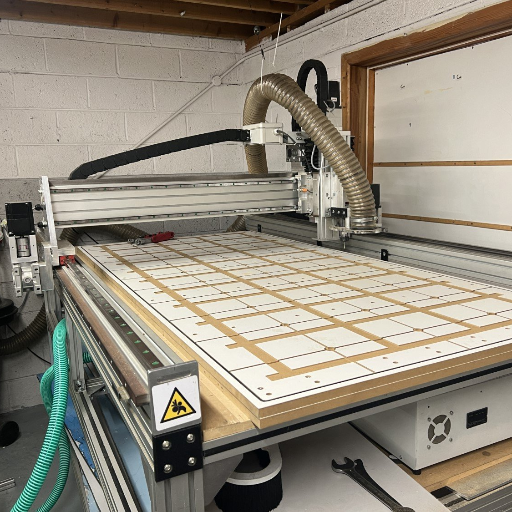

A CNC router is a computer-controlled machine that cuts, carves, and shapes various materials including wood, plastic, and soft metals. Its speed makes it suitable for less rigid materials and detailed work like engraving or cutting large sheets.

A CNC mill is meant for precise and heavy-duty tasks. It can work with more difficult materials, such as steel, and creates intricate pieces with great accuracy. Unlike a router, a mill has a stationary workpiece, which allows for greater precision in machining as the cutting tools rotate.

The primary distinction is in the intended application of each machine. Routers are designed for speed and detail on softer materials, while mills exert greater power and precision on harder materials.

CNC Router Machines and Their Applications

Industries have been revolutionized by CNC (Computer Numerical Control) router machines, which automate material processing tasks. It is designed to cut, engrave, and shape a variety of materials which include wood, plastic, acrylic, aluminum, and even certain composites. With pre-programmed instructions, precision and speed are guaranteed as complex designs are produced with little human intervention.

Automatic tool changers, high-speed spindles, and real-time monitoring systems are just some of the features on modern CNC routers. Efficiency is what high-end CNC routers offer—cutting speeds of up to 25,000 RPM. Not only do these machines accomplish tasks rapidly, but they also achieve high standards of accuracy. Like the older models, modern CNC routers incorporate vacuum hold-down systems, further improving their functionality by ensuring the material is held in place during cutting.

In the furniture, automotive, and aerospace industries, the CNC router market is projected to grow at a compound annual growth rate (CAGR) 4.5% from 2023 to 2030. The ability to produce more intricately designed products at lower costs is a significant factor contributing to this growth. The furniture industry can now take advantage of CNC routers; those time-consuming carvings that were incredibly difficult to achieve with traditional tools can now be performed with ease.

CNC router machines are transforming the manufacturing industry, meeting the standards of diverse industries through their speed, precision, and versatility.

The Key Differences Between a CNC Router and a Milling Machine

CNC routers serve the purpose of manufacturing products similarly to a milling machine, but the difference is the mechanism of operation and application. For example, a CNC router is constructed to cut through softer materials of wood, plastic, and some metals. It moves at a higher RPM making it suitable for large-scale projects to be cut like signage. They are also often used in the furniture industry. CNC Routers have a stationary bed and only the gantry moves which gives it increased range for large workpieces.

Milling machines have the capability of much more heavy-duty applications as compared to CNC Routers because they can machine more dense materials like steel, aluminum, and alloys. Another distinguishing factor is that with milling machines, the workpiece does not move unlike with CNC routers. Also, the tools at the mills rotate. This makes it easier to make smaller, more precise cuts which need a much higher torque. Industries like aerospace, automotive, and medical manufacturing parts with tight tolerances are heavily reliant on milling machines.

Additionally, an analysis carried out by SmarTech suggests that the global adoption of milling machines is on the rise, with a demand growth of roughly 10.5% CAGR between 2022 and 2028. At the same time, Advanced CNC router technology continues to improve productivity on a consistent basis. Manufacturers can now achieve accuracy within ±0.003 inches, illustrating a significant advancement in precision manufacturing. The differentiating strengths and capabilities of both tools ensure their evolving roles in the manufacturing industry.

Factors Affecting the Decision To Select Between Routers and Spindles

Several considerations arise when selecting routers and spindles for specific manufacturing processes. Among them are precision level, materials to be worked on, speed requirements, and overall cost effectiveness. Spindles are particularly popular among industries that deal with precision machining, for instance, aerospace and automotive manufacturing, because of their unmatched cutting power and rock-steady performance at high speeds. Modern CNC spindles can achieve speeds of 240,000 RPM, which is extremely beneficial for performing complex machining operations on aluminum, titanium, and composite materials.

Routers certainly outperform other tools when the task requires multi-functionality and speed, even if precision is not the primary concern. Routers have found use in woodworking, plastic machining, and machining softer metals – all providing reasonable priced services with high productivity. As an example, newer routers have shown cutting speeds of the order of 75 inches per second which makes them very useful in industries focusing on rapid prototyping or large production volumes.

Furthermore, advances in technologies of both spindles and routers have improved the tools’ energy efficiency as well as their longevity. For instance, spindles with integrated cooling systems and routers with wear-resistant parts have greatly enhanced the maintenance cycles. There also seems to be a trend in the market towards automated systems where these tools are integrated with advanced software for real-time monitoring and fine-tuned control of the machining operations.

When these tools are combined with automated systems, manufacturers can remain competitive in the industrial arena by maximizing operational productivity, resource efficiency, and the quality of the final product.

What materials can you process with CNC routing?

- Wood – Acceptable softwoods and hardwoods as well as plywood and MDF.

- Metals – Processes aluminum, brass, copper, and certain types of steel.

- Plastics – Acceptable acrylic, polycarbonate, PVC, and other thermoplastics.

- Foam – Best for polystyrene, polyurethane, and other light-weight foams.

- Composites – Fiberglass and carbon fiber are some of the materials accepted.

Efficiency and Precision of CNC Router Operations

The productivity and accuracy of CNC routers are subject to some important parameters, which include the feed rate, the spindle speed, and the selections of cutting tools. Feed rate is the rate at which the material moves in relation to the machine; higher feed rates increase the rate at which the workpiece is machined, however, some levels of cut quality will be sacrificed. Different materials have different optimal spindle speeds; for example, sawing through softer materials like foam is easier and slower than harder materials like aluminum. Also, the choice of tools such as end mills or engraving bits impacts the quality of the part features and surface finish of the part.

Some of the most recent advancements related to CNC machine tools have significantly optimized and enhanced their capabilities. For instance, modern software with CNC integration provides for greater flexibility in customization as well as real-time parameter monitoring, which in turn reduces material wastage by nearly thirty percent in some situations. Furthermore, the modern precision guiding and sophisticated cooling aids in extending the tool life, operational accuracy, and retention of accuracy even in high-velocity operations. The addition of automation in the form of material loading and unloading systems has added value to workflow and productivity as well, allowing the firms to expand their output while reducing operational costs.

This is how CNC routers are being developed to suit the requirements of various sectors: metal and wood working, aerospace industry, prototyping, and so on. Understanding and taking advantage of these factors will greatly optimize system utilization and ensure repeated high-quality outcomes.

Is it possible to cut through aluminum and other tough materials?

CNC routers and machining systems can cut aluminum and other hard materials with remarkable precision, provided the right tools, settings, and techniques are utilized. For cutting aluminum, specialized bits such as carbided or coated tools, are necessary to ensure durability and thermal resistance. Additionally, the spindle speed and feed rates have to be balanced to avoid overheating and to achieve optimal cut cleanness. As an example, with aluminum, a feed rate of 200-300 inches per minute should be maintained depending on the router’s power and the thickness of the material.

Furthermore, a consistent mist or air cooling system should be in place to get rid of heat during the cutting process. This will prevent the warping of materials and prolong the life of the cutting tools. Recently observed industry data indicates that with the introduction of new cooling methods and cutting tools, CNC systems have been able to process titanium, stainless steel, and other hard alloys, broadening their scope of use in aerospace and automotive industries which are highly reliant on these features.

Acquiring high-quality end mills and investing in newer technologies will immensely improve performance when machining harder materials. Adopting this strategy will enable companies to boost machining accuracy and productivity, even on complex tasks.

Routing CNC Composite Materials

Routing CNC composite materials require accuracy as well as proper tooling. To achieve the best possible cutting and avoid material fraying, I make use of special router bits manufactured specifically for composites. Furthermore, I adjust the feed and spindle speeds of the router to align with the properties of the material while minimizing tool wear, thereby enhancing the end result.

What are the main types of CNC routers available?

- Industrial CNC Routers: These types of machines are intended for precise work or heavy production. Because of their robust construction, they are capable of enduring heavy workloads, and can process a wide range of materials such as wood, metal, and composites.

- Desk CNC Routers: These types of machines are small in size which makes them suitable for small scale operations. Because of their light weight, they can easily work on materials such as wood, plastic, or soft metals.

- Specialized CNC Routers: Customized to accomplish particular tasks, these routers are suited for specific materials or processes, such as working on intricate patterns with metal alloys.

Capabilities and Applications of 3-axis and 5-axis CNC Routers

For a correct evaluation of the capabilities of 3-axis and 5-axis CNC routers, one must make a distinction in the levels of precision, versatility, and scope of application.

3-axis CNC Routers have three linear axes (X, Y, and Z) as lines of movement; hence, they are best suited for simple and 2.5 dimensional cutting, contouring, shaping, and engraving. They are widely used in engraving, cutting, and surface milling industries with wood, foam, and soft metals. The advantage is that 3-axis machines are less expensive and adequate for intricate designs. Unfortunately, the limitation of these machines is the inability to perform undercuts due to restricted movement.

On the other hand, 5-axis CNC Routers incorporate an additional two rotational axes (A and B), meaning that a tool or workpiece can be held at almost any position. This greatly improves the ability to manufacture complex and multi-faceted shapes which are crucial for aerospace, automotive, and medical manufacturing industries. For instance, they enable high-precision machining of turbine blades and orthopedic implants among other sophisticated parts.

Recent industry research suggests that the transition towards 5-axis CNC routers is increasing with the demand for more efficient and streamlined production processes. 3 Noteworthy research suggests that 5-axis machines can overall decrease the amount of machining time by 50%-70% compared to 3-axis machines due to less repositioning or multiple setup requirements.

The 5-axis routers, while offering enhanced features, must be considered within the context of project budget, complexity, and volume. Both techniques remain integral to modern manufacturing within an appropriate context and have a broad spectrum of possible applications.

Best CNC Machines for Hobbyist Woodworking

Desktop CNC machines are becoming more affordable and useful for hobbyist woodwork ing. These machines are small enough to fit in a workshop and offer shape-changing capabilities of their larger counterparts. A good example is the Shapeoko 4 or X-Carve models, which enable DIY-enthusiasts create detailed custom-made furniture or perform delicate engraving.

The price range of Desktop CNCs have become favorable too. Machines that cost from $1,000 to $3,000 now have features like industrial spindle speed, multi-purpose material compatibility, and larger carving areas. Advanced models like the LongMill MK2 boast accessible cutting dimensions of over 30×30 inches, enabling extensive projects.

The smart technology being integrated into these CNC machines has all but eliminated the steep learning curve for new users. Many systems now offer good tutorials and designs through their interfaces such as the provided Easel and Carbide Create to help them streamline from design and production. These along with YouTube and online forums dedicated to assisting new users make learning the tech easy.

Modern desktop CNC machines now offer professional-grade accuracy of precision linear guides and hybrid stepper motors. For example, some models boast repeatability as good as 0.003 inches, which is phenomenal for intricate woodworking tasks. This accuracy guarantees that enthusiasts can achieve excellent results time after time.

Assessing the working area, construction, and software compatibility of the CNC are among the most important considerations to look at when buying a desktop CNC. For woodworking hobbyISTS, this technology presents limitless possibilities, allowing them to design and carry out projects seamlessly right at home.

Industrial CNC Machines with Automatic Tool Changer Systems

Machines that fall under industrial CNC category with automatic tool changer (ATC) systems are key in improving productivity and precision in heavily automated production settings. ATC enabled machines further enhance productivity by reducing the amount of time needed for tool changes during machining. This feature substantially improves cycle time and allows for a constant flow of work.

One of the most notable benefits of ATC systems is their handling of complex projects that employ multiple tools; to list a few, end mills, drills, and engraving tools. The machine automatically determines the proper tool for each step in the machining process. For example, in expansive manufacturing sectors like aerospace or automotive, ATC equipped CNC machines can save up to 40% of the production time according to numerous industrial estimates.

Precision and repeatability is another key feature of CNC machines ATC industrial grade. More sophisticated models contain high-speed spindle, tool position sensors, and advanced programming, which guarantees consistent results with reduced supervision. Unlimited leading CNC brands support tool magazines of 10 to 100 tools, ensuring effortless execution even in extreme details.

When talking about software complements, modern CNC machines with ATC features are offered with sophisticated CAM (Computer Aided Manufacturing) software. This software allows operators to design the machining procedures and virtually execute them ahead of time. Moreover, performance monitoring systems have started to highlight the error, performance, safety, and operational oversight tracking metrics during machine runtime.

With respect to the CNC machining industry, automatic tool changer systems have proven to be immensely transformative innovations, and they come with numerous benefits, including decreasing human error, enhancing productivity, and many more.

How is the CNC routing process performed?

Just as with any CNC processes, routing starts with part definition through CAD software. This design is translated into a set of instructions, also known as G-code, which is later uploaded to the CNC machine. Step-by-step CNC routers operate by following instructions that tell them how to guide the cutting tool along specific paths. The multiaxis machine then executes movements based on the program, cutting, shaping, or engraving the material which has been fastened to the machine bed. Repetitive execution of the same command will yield flawless results and meticulous patterns.

Identifying Detrimental Aspects Related to the CNC Router’s Performance

There are many aspects that can directly or indirectly impede the performance of CNC routers, all of which are critical in upholding the standard of quality and effectiveness throughout the work process. One concern is focused on the feed rate, the action of setting the speed of the cutting tool on the surface of a material. A drop increase higher than this rate causes increased flaking, while lower than optimum leads to excessive burns. An efficient value mitigates tool damage and enhances surface finish.

Another important factor is the spindle speed. Spindle speed is measured in revolutions per minute (RPM) and it affects the rate of material removal, as well as cutting quality. For tougher materials like metals, lower spindle speeds are needed, while softer materials like wood and plastic can be machined at faster speeds.

The material also greatly influences the performance parameters of the machine. For example, materials that are dense in nature will need more powerful tooling and slower cutting rates, while lightweight materials, on the other hand, are quicker to process.

Further software development has increased the capabilities of CNC routers. Currently available software systems are now capable of simulations where CNC routers visualize machining beforehand. These simulations further ensure that grinding paths are set without errors that could lead to increased costs and time wastage.

Recent data from the industry indicates that productivity greatly improves by adding automated features like tool changers and material sensors. Automated tool changers minimize the downtime between operations and material sensors guarantee consistent cutting by compensating for changes in material thickness or positioning.

As a whole, incorporating new technological innovations and operational considerations, CNC routers provide efficient, precise, and repeatable results with a variety of applications.

The Best Router Bits and End Mill Cutters

Achieving the best results while performing CNC machining requires choosing the right end mills and router bits. Selection is predicated on the material to be cut, the cutting feed rate, and the finish quality desired. Single flute bits, for instance, work best on soft metals such as aluminum or plastic, since they improve chip removal and decrease heat in the cutting zone. Multi-flute end mills are preferable for more difficult metals like steel, since they produce softer finishes and greater strength.

The recent research highlights that cutting tool coatings are important for achieving maximum tool life and productivity. For example, titanium nitride (TiN) or diamond-like coatings (DLC) improve wear and heat resistance at elevated cutting speeds, which allows for lower machining times. Other bits with special geometry like compression bits are very important for some wood and lay laminate products because they reduce tear-out and provide clean cuts on top and bottom surfaces.

Efficient tool use can increase machining efficiency to 30% and material waste by nearly 15% simultaneously. To top it off, tool manufacturing has progressed, allowing for smoother and more tightly controlled finish bits to improve precison on intricate designs. When handling CNC tools, remember to always maintain a balance of efficiency and quality by taking the shank diameter, flute length, and material type of the tool into consideration.

The Relevance of CNC Routers for Intricate Shaping Precision

CNC routers sliced another level of precision into the manufacturing industry, even handling the most complex shapes effortlessly. With computer control, these machines are able to execute a design with a mark precision of ±0.001 inches – a feat that would be nearly impossible by hand. Dimensions of this high precision are crucial when dealing with sensitive areas like aerospace, automotive, and medical devices industries because they hardware will create major issues for them if malfunctioned even slightly.

In addition, the latest models of CNC routers come equipped with real-time adaptive monitoring and cutting systems. These systems enable routers to maintain peak efficiency, even on difficult materials such as titanium, carbon fiber, and plastics. More recent estimations indicate operational production time for CNC routers is reduced by 40% and offers a 25% reduction in error rates, which further improves productivity and lowers costs for manufactories.

Thanks to multi-axis functionality, complex geometries such as undercuts, pockets, and 3D contours can be achieved on CNC routers with no further manual or secondary processes required. This makes CNC routers essential for crafting tailored parts, artistic pieces, or small volume productions where accuracy and intricacy is crucial.

What are the most common uses of CNC routers?

- Woodworking: In this carpentry discipline, furniture and cabinetry as well as decorative carvings are made with special attention to detail and efficiency.

- Signmaking: This type of carpentry involves cutting and engraving materials such as wood and plastic, and even metals, to create custom signs.

- Prototyping: In different industries, prototypes are needed and this work specializes in delivering them as rapidly as possible.

- Metal Fabrication: The work specializes in cutting and shaping metal for parts used in machines, tools, and other equipment.

- Art and Design: This field specializes in coming up with intricate designs and sculptures including 3D artworks out of different materials.

Enhancement of CNC Router Applications with New Technology

The addition of new technology has significantly enhanced CNC routers, making them more efficient and flexible in many applications. For example, in woodworking industries, the availability of software for precision cutting and engraving complex designs has proved to be great. Recently, it was reported that the CNC router market is expected to grow globally with a steady increase of 3.75% every year from 2023 to 2028 due to higher automation demands in manufacturing and the creative sectors.

The CNC routers in woodworking are applied in furniture making, cabinetry and in making intricate and artistic carvings. One of the studies noted that the CNC woodworking technique is capable of reducing material waste to 30% which aids in the sustainable goals of the industry while cutting down on costs. Furthermore, it allows for customization of intricate patterns and details for furniture which helps manufacturers meet consumer demands.

CNC routers have a wide range of application beyond woodworking. They are equally important within the scope of prototyping and metal fabrication. By employing new methods of tooling, CNC routers can now more accurately and quickly cut tougher materials such as metal which improves performance in tasks involving tough materials. These developments are a testament to the ability of CNC routers to revolutionize industrial and artistic processes.

Musical Instruments with Precise CNC Carving

CNC routers have greatly simplified the production of musical instruments with their range of precision and speed. For hand made instruments, a lot of time was spent on laborious processes such as hand generating each part which frequently led to mistakes. Utilizing CNC carving ensures that every guitar neck, violin body, or piano key will be produced to exact measurement and design as every piece will be machined with pinpoint precision.

For example, the production of acoustic guitars involves the use of CNC routers to accurately slice the wooden components—top, back, and sides—because perfect symmetry is crucial for optimal sound resonance. A manufacturing report in 2023 stated that CNC automation, in contrast to manual methods, enhances production speed by up to forty percent and decreases material waste by twenty to thirty percent. Furthermore, more sophisticated CAD software permits design experimentation, thus enabling luthiers and technicians to tailor the instrument’s tonal quality and visual appeal to particular musical preferences.

Integration of CNC technology into the workings of musical instruments greatly enhances production speed while upholding the artistry and quality demanded by musicians. This remarkable feat combines tradition with modern engineering.

Commercial and Industrial Applications for CNC Routing

The introduction of CNC routing greatly enhanced various industries by solving design and manufacturing issues requiring high precision, efficiency, and scalability. The use of CNC routing extends to woodworking, metalworking, plastics, and composites, allowing rapid prototyping and detail customization for different commercial sectors.

As an illustration, CNC routers are widely used in the woodworking sector to engrave or carve furniture or cabinets with intricate designs and patterns. Their use greatly improves consistency and precision over manual methods. Recent figures show that the adoption of CNC technology in the furniture manufacturing sector has enhanced productivity by as much as 50 percent. Likewise, cnc routers are used in metal working to manufacture parts with high precision to reduce material waste and improve overall costs.

The automotive and aerospace industries also benefit significantly from CNC routing. These routers are crucial for fabricating the necessary components of vehicles and aircraft which are lightweight yet high-strength. Employing sophisticated CAD/CAM software together with CNC systems allows the manufacturers to cut down the time spent on creating prototypes by 30 percent, speeding up the introduction of cutting-edge concepts into the market. CNC routing can produce parts with intricate shapes and tight tolerances, making it vital for these industries.

In addition, the use of CNC routers has revolutionized the engraving and signage industries and graphic design by making it possible to cut and engrave foam, acrylic, and aluminum with precision. Today’s businesses using modern CNC systems can work with a variety of materials, giving them more room for creativity. As it stands, the global CNC machine market is forecasted to grow 7.3% annually between 2023 and 2030. This tells us that the world will continue to adopt CNC routing in commercial and industrial practices.

Reference sources

- Study: Structural Design of a CNC Router Based on Optimization Technique1

- Objective: To enhance the structural design of CNC routers using optimization techniques for improved performance and material efficiency.

- Methodology: The study applied structural optimization methods to refine the design of CNC routers, focusing on reducing material usage while maintaining technical and aesthetic standards.

- Key Findings:

- Optimized designs resulted in lighter, more efficient CNC routers.

- The study demonstrated the potential of structural optimization to improve the functionality and cost-effectiveness of CNC routers.

- Applications highlighted include woodworking, prototyping, and precision manufacturing.

- Study: Realization of Prototypes and Models Using a CNC Router3

- Objective: To explore the use of CNC routers in prototyping and model-making across various industries.

- Methodology: The study reviewed the capabilities of CNC routers in creating prototypes and models, emphasizing their precision and adaptability.

- Key Findings:

- CNC routers are widely used for creating detailed prototypes and models in industries like architecture, engineering, and product design.

- Their ability to work with diverse materials, including wood, plastics, and metals, makes them versatile tools for innovation.

- The study underscored the role of CNC routers in advancing modern manufacturing and design processes.

- Top Stone CNC Router Machine Manufacturer And Supplier In China

Frequently Asked Questions (FAQs)

Q: What is a CNC router and how to use a CNC router effectively?

A: A CNC router is a machine that cuts various tools and works the same as a router. To make accurate cuts, chose CAD/CAM software tailored for the desired design, and chose and secured the correct fixturing for the workpiece, used the right speed to move the tool forwards and backwards, and the optimal drill to select. With the appropriate settings, the CNC Router will convert the digital sketch into veritable cutting diagrams, thus allowing for precision borders. Start with basic tasks and, as proficiency improves, gradually increase the complexity.

Q: What is the difference between CNC routers and other cutting machines?

A: The primary difference between CNC routers and other cutting machines lies in their uses and what they can do. CNC routers cut and carve flat sheet materials, while CNC milling machines do heavy metalworking. Compared to CNC laser cutters, routers perform three-dimensional machining rather than solely penetrating a material. CNC Routers perform CNC machining of soft materials and wood using rotary cutting tools like handheld routers that are computer-controlled. CNC plasma cutters are for metal only while CNC routers can work with many more materials like wood, plastic, foam, and soft metals.

Q: What is the process of engraving using CNC routers on various materials?

A: The engraving process of CNC routers is quite broad due to the ability to control the depth and width of the cutting bit. While wood engraving, a CNC router, can achieve stunningly intricate grain-following patterns with variable depth carving. When engraving metals, specific carbide or diamond-tipped bits are required, and proper speeds and feeds must be set. Additionally, plastics and acrylics can be cut deeply or frosted during engraving, and CNC routers are able to perform both. CAD/CAM software controls the engraving process where design depth, tool choice, and cutting parameters are set. Numerous CNC routers are capable of v-carving as well, that is where a v-shaped bit generates lines of varying width based on cutting depth which is perfect for text and detailed patterns.

Q: What are the CNC router technology benefits industries

A: A variety of industries make use of CNC router technology. In the woodworking industry, businesses utilize CNC routers for furniture fabrication, cabinetry, and architectural millwork. The signage industry also uses CNC routers for dimensional letters and custom displays. Aerospace manufacturers have specialized CNC routers for cutting composite materials. In the automotive industry, CNC routers are used in the manufacture of interior components and prototyping. In addition, CNC routers are used extensively in the construction of musical instruments, pattern and mold making, and the manufacturing of electronic enclosures. Smaller CNC routers are also used by schools and hobby shops to teach design and practical work skills.

Q: How do CNC routers achieve accurate precision cutting?

A: CNC routes capture a design via CAD and convert it into machine code, referred to G-code for engraving, aligning along the X, Y, and Z axis. With the aid of a CNC controller, motors maneuver the spindle to execute the cuts. The routers are equipped with servo or speed-enhancing step motors that operate through ball screw or rack and pinion systems to elevate accuracy. The key to precision is the cutting performed by a rotating bit lift, which shreads material along a pre-set trajectory. Enhanced CNC routers are fitted with automatic tool changers, vacuum tables for holding the workpiece and enhanced dust collectors.

Q: What features best fit my requirements for a CNC router?

A: In moving into a new workstation, a CNC router requires that you think about a number of factors like the workspace (the largest piece of material that can be worked on), spindle power (stronger spindles are able to work on tougher materials), precision work (this is a must for delicate jobs), frame rigidity (the stronger the frame, the lower the vibrations during cutting and better the cut), and controller software compatibility. You also need to balance the cost of Owning the CNC apart from the purchase price including bit prices, maintenance and software upgrades. Think if you actually need 3-axis or further to 4 or 5-axis capabilities. Beginners might consider DIY CNC router kits while professionals do not shy away from buying industrial machines. Lastly consider the manufacturer’s support, training, warranty, and other service options before making this decision.

Q: What are the advantages of CNC routers vs manual routing methods?

A: CNC routing systems are more advantageous than manual routing methods. This is because CNC routers have greater efficiency, speed, and accuracy since they are controlled by computers. Another benefit is that CNC routers allow for more intricate designs and details to be added compared to manual powering tools. Productivity increases with CNC routers as they can work continuously without the need for breaks, yielding higher and consistent output. They can also be left to operate unattended, further improving productivity after initial setup. Unlike humans, computers make almost zero errors, ensuring material optimization is achieved by using nesting software for waste conservation. Optimized safety is achieved because operators are kept away from dangerous zones when the tools are activated cue automatic sawing. The final benefit is consistent quality. CNC Controlled routers ensure Arguably the biggest advantage on consistent quality is that irrespective of operator skill, quality will still be achieved with CNC controlled routers. With manual routers, outcomes heavily rely on the expertise of the user.

Q: What types of projects can a CNC wood router complete?

A: The range of projects that a CNC router can accomplish is extensive. In the field of furniture making, it can create joinery, ornamental features, as well as entire furnishings. For home décor, CNC routers produce custom signs, wall art, clocks, and various other artistic pieces. Architectural moldings and sculpting such as corbels, rosettes, and other detailing trims are also done. Parts of musical instruments are manufactured superbly with CNC routers. Guitar bodies, necks, and sound boards are some of the examples. For the kitchens, engraving and inlay work on cutting boards as well as serving trays can be crafted with CNC routers. Many CNC routers are capable of making jigs and fixtures used in other woodworking processes, custom fitted cabinetry, and complicated wooden toys and puzzles. The adaptability of CNC wood routing makes them ideal for personal endeavors and imaginative pursuit alongside industrial settings.

Q: What are the challenges CNC router users need to be cautious of?

A: CNC routers, like all other machines, come with some distinct practical challenges and limitations that users must pay close attention to. Many CNC routers might encounter difficulties with extremely tough materials requiring specialized machines like titanium or hardened steel. The accompanying CAD/CAM software, for instance, comes with its own learning hurdles that will take time. From the perspective of a small business, or an enthusiastic hobbyist, the initial setup expense might pose the most difficult obstacle. Thin materials also face hurdles, as CNC routers don’t cut as fast as laser or plasma systems do. Because of the rotary cutting motion, internal radii corners will have a minimum radius equal to the bit’s diameter. Additionally, hold down of the material can be a problem because smaller pieces can be unmanageable during cutting. Furthermore, compared to other digital fabrication tools, CNC routers are quiet rough. They need to be properly ventilated while cuts are made as they create large amounts of dust. Also, hearing protection is needed due to the loud noise the routers produce.