With every new technological innovation, the CNC machining of tools and parts is becoming more precise and multifaceted. One such innovation is the 7-axis CNC machine, perhaps one of the most sophisticated tools today. It can manufacture intricate and accurate aerospace and medical technology parts. What exactly makes it a pinnacle of engineering? This guide explores the 7-axis CNC technology, how it functions, and why it’s essential in today’s world. It also covers the advantages it offers to contemporary manufacturing. Whether you belong to the industry, are passionate about machinery, or are just curious, this article will enlighten you on the reasons 7-axis CNC machines transform the future of production.

What is a 7-axis CNC Machine?

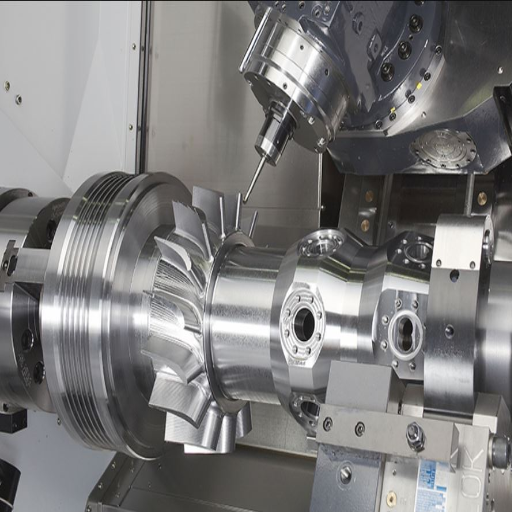

A 7-axis CNC Machine allows the most intricate cuts and notches on materials to be thoroughly and meticulously crafted. This type of machine is appropriately suited for complex part production since it has unrivaled efficiency and flexibility stemming from the ability to core operate on seven axes. These machines have the traditional three axes, X, Y, and Z, or base movements, plus the ability to rotate on those movements and an additional axis that helps with more refinement or adjustment. With this machine’s extra features, 7-Axis CNC Machines have the extraordinary ability to limit the number of times the workers have to rearrange the piece’s position, which aids in speeding up the production time and increasing accuracy, all while lowering the number of mistakes and inaccuracies. 7-Axis CNC Machines are heavily used in the medical, aeronautics, and automotive industries due to the intricate and precise designs that must be manufactured.

Definition and Overview of 7-axis CNC Machines

7-axis CNC machines are incomparable in high-precision industries due to their myriad benefits. One such advantage is complex multi-tasking machining operations conducted on a single setup. This feature optimizes time and mitigates the risk of severe damage that may arise from part transfers between different machines, which usually increases inaccuracies caused by shifting. Moreover, the 7-axis CNC machines are capable of delivering exceptional precision and achieving tolerances within micrometers, which is a necessity for components of aerospace turbines, medical prosthetic devices, and high-performance automotive parts.

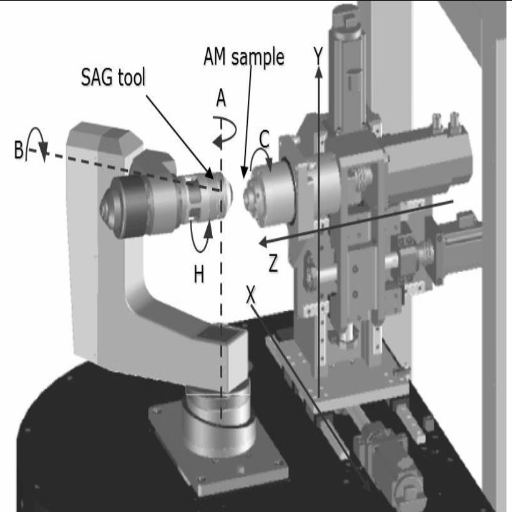

Another striking benefit of 7-axis CNC machines is sophisticated flexibility. Together with linear motions (X, Y, Z) and rotational movements (A, B, C), in addition to the 7th axis, complex contours and shapes can be effortlessly machined. For example, parts that must be fabricated with compound angles or parts that require machining from several sides can be easily achieved.

Market research indicates that 7-axis CNC technology adoption is on a steady rise, driven by the precision custom requirements for ITEMS manufacturers. It is anticipated that the global CNC machine market will reach over $115 billion by the year 2030, and 7-axis machines will significantly contribute to this projection.

As with many other industry tools, 7-axis CNC machines have grown with modern technology. The precision and automation these machines provide are unparalleled, from modeling to mass manufacturing, making them very useful in advanced interdisciplinary fields.

How Does a 7-axis CNC Machine Work?

A CNC machine with seven axes can perform intricate and delicate machining operations. It can also work on parts with very difficult geometric structures. The seven axes include the standard three linear axes (X, Y, Z) and three rotational axes (A, B, C), while the seventh axis is either an additional linear or rotational movement, depending on the machine’s design and configuration.

A machine with this many axes uses advanced computer software and a high logic level. For example, a CAD file is first created and then turned into a CAM file, which is then used for machining instructions. With this kind of logic, the machine is capable of performing multi-axis movements simultaneously, which minimizes the need for repositioning and manual work.

Due to the accuracy needed, 7-axis machines are commonplace, especially in the sectors of aerospace, automotive, and medical. More recent industry data suggests that these CNCs can easily work on complex structures like metal parts or composites and plastics.

The advancements in 7-axis CNC machines have also been aided by the incorporation of automation systems like robotic arms and tool changers, which have further enhanced their productivity by trimming up to 30% of production time compared to older systems. This innovation not only optimizes workflows but also allows manufacturers in competitive markets with strict timelines to exceed expectations with precision.

The adaptability of 7-axis CNC machines, alongside their extreme accuracy of up to plus or minus 0.0001 inches, makes them indispensable in modern manufacturing. These machines consolidate several machining procedures into a single setup, which drastically reduces the possibility of errors and eliminates unnecessary material use.

What are the Advantages of Using a 7-axis CNC Machine?

Such 7-axis CNC machines are an excellent asset for modern-day manufacturing because of the following advantages:

Capability of Accomplishing Numerous Operations within One Setup: Such CNC machines can perform multiple functions within a single setting, which enhances the work production throughput and optimizes work efficiency rather than optimizing work processes.

Exceptional Productivity: 7-axis CNC machines optimize workflow processes, saving time on the clock and performing tasks promptly.

Versatility: Such machines can be applied in various industries as they can work on many complex shapes and different types of materials.

High Precision: CNC machine achievers are accurate and precise, maintaining a reliability output of around 0.0001 inches.

Cost Saving: Such reduces chances of mistakes being made due to coming up with a streamlined plan, therefore decreasing production costs further down the lane over the long run.

Reduced Wasted Material: The chances of errors and carrying out processes separately decline. This increases the chances of profit while reducing expenses.

Increased Precision and Accuracy in Machining

Industries have experienced a tremendous change due to the introduction of modern 7-axis CNC machines with enhanced accuracy and precision features. Machines can now achieve tolerances up to ±0.0001 inches, ensuring the integrity of the specifications in complex components. Moreover, the ability to perform numerous multi-step single setup operations reduces the need for manual repositioning, a source of human-based errors and inconsistency in production runs.

Moreover, automatic tool calibration and feedback systems are constantly monitored and controlled. This allows for real-time adjustments during operation, thus maintaining optimal performance. Highly regulated industries such as aerospace, automotive, and health care reap immense benefits as components featuring complex geometries are manufactured alongside strict quality control measures. This fosters productivity and addresses unmet demand for high-performance and durable components in today’s competitive markets.

Ability to Create Complex Parts

3D printing, also known as additive manufacturing, is revolutionizing the accuracy and creativity with which sophisticated parts can be made. This method enables the mass production of complex shapes previously deemed impossible with traditional manufacturing methods or highly inefficient. Below is a detailed list of capabilities and data highlighting this ability:

- Customized Designs

Due to additive technologies, medical implants or aerospace parts can be produced with precision. For instance, 3D-printed implants have an astonishing 95% success rate in complicated procedures.

- Intricate Geometries

Industries such as automotive and aviation require the hollowness of a structure, lattices, and other intricate features for strength and lighter weight. 3D printing has shown that lightweight components can reduce aircraft weight by as much as 60%.

- Material Efficiency

The primary focus of 3D printing is cost-cutting. Here is why: unlike the subtractive method used in most types of manufacturing, additive techniques greatly minimize material waste. Many studies have proven that the efficacy of the material used in 3D printing can reach as high as 90%. This surely makes it economical and environmentally friendly.

- Rapid Prototyping

An additive prototype can be developed within a matter of hours. This dramatically reduces the number of repetitions in designs, making the product go to market faster than the competitors and dramatically speeding up the development cycles.

- Multi-Material Capabilities

Today’s advanced 3D printers allow the integration of various materials into one print, producing parts with distinct characteristics, such as flexible and rigid zones. For example, multi-material prosthetics manufactured using additive processes have multi-functional and comfortable features.

- Functionally Graded Materials (FGMs)

The use of additive manufacturing allows the production of FGMs characterized by having spatially varying material properties throughout the part to optimize it for a specific usage.

These capabilities highlight the revolutionary phenomena brought by additive manufacturing relative to other processes regarding innovation and productivity across diverse sectors.

How Does a 7-axis CNC Machine Differ from a 5-axis CNC Machine?

The difference between a 7-axis CNC machine and a 5-axis machine is in the range of movement and complexity of operations each can perform. Unlike a 5-axis machine that permits tool movement along the X, Y, and Z axes with A and B rotations, a 7-axis machine adds two additional rotary or linear movement axes. This allows for further sophisticated machining without manually repositioning the workpiece. Furthermore, 7-axis machines can automate the machining of highly intricate details with greatly reduced workpiece setups, significantly improving efficiency, production time, and cost compared to 5-axis machines. These advancements make 7-axis machines ideal for high-precision components manufacturing in aerospace and medical industries.

Understanding the Differences in Axes

When comparing 3, 5, and 7-axis CNC machines, it is important to analyze their functionalities in terms of their operations and benefits. A 3-axis machine is equipped to work on the X, Y, and Z axes and is suited for simpler operations such as milling and drilling. However, it is not competent to perform tasks that require sophisticated geometry, undercuts, or other intricate work.

The 5-axis machine adds rotational movement on two additional axes, the A and B axes. This added flexibility allows for more complex geometric parts to be machined with fewer setups, saving more time and increasing accuracy. 5-axis machines are frequently used in the aerospace and automotive industries for the manufacture of components of high complexity, such as turbine blades and engine parts.

The 7-axis CNC machine takes the functionality further because it can rotate and move the tool or workpiece on seven axes. This increased freedom makes it possible to perform operations on complicated shapes in one single setup, thus making it ideal for intricate components. For instance, 7-axis machines can use prosthetic limbs and surgical tools with incredible precision in the medical field. Additional automation capabilities also promote efficiency by increasing machinery functioning, lowering the need for human operators, and reducing mistakes. Various studies show that switching from 5-axis to 7-axis machining can yield up to 30% more efficient production in certain areas, especially in detail-oriented industries.

These differences help CNC Machine manufacturers identify the right machine for their procedures without overcomplicating things, ensuring efficiency and minimizing costs.

Applications of 5-axis vs. 7-axis CNC Machines

- Aerospace Industry

Aerospace uses 5-axis CNC machines for expert turbine blades, propellers, and other structural components. The sophistication of these parts, along with their tight tolerances and aerodynamic requirements, make these machines a remarkable asset to the industry.

- Automotive Industry

5-axis machining increases the quality and precision of prototypes, molds, and engine parts. Its precision reduces the time needed for production while improving the results of the components manufactured.

- Medical Devices

Intricate designs are required for surgical implants, dental prostheses, or even models. These 5-axis machines provide exceptional precision in the medical domain, which is crucial to ensuring patient safety.

- Tool & Die Industry

5-axis CNC machining simplifies making molds and dies with soft surface features. The availability of these machines reduces finishing time and dramatically increases product quality.

- Energy Sector

Oil and gas machinery, along with wind turbines, have ever-more-demanding precision needs. 5-axis machines increase the effectiveness and warranty of these vital energy industry components by providing unparalleled precision.

- Robotics Manufacturing

Advanced robotic systems require great flexibility in their components. The Global System in a 7-axis CNC machine can move in many directions, allowing more easily the manufacture of very complex robotic parts.

- Parts Used in Aerospace that Require High Precision

A 5-axis machine is commonly used in aerospace; however, a 7-axis machine is preferable for UAVs (Unmanned Aerial Vehicles) and other advanced propulsion systems parts that require high flexibility and more movement.

- Medical Implants Tailored for Individuals

Due to their highly sophisticated movements, 7-axis CNC machine tools are best suited for advanced sculpting of replacement joints, resulting in custom-fitted medical implants.

- Military And Defense Uses

These machines are ideal for crafting sophisticated weaponry components and building strategy-grade hardware since they require precision and versatility for defense purposes.

- Hybrid Additive Manufacturing Influence

For rapid prototyping and designing complex models, 7-axis machines can easily be combined with additive techniques to create a hybrid system, which is especially beneficial in automotive and aerospace.

- Equipment for Energetics and Construction on An Industrial Scale

The 7-axis machines excel at generating bulky and large equipment parts like those used in construction or energy production. Device repositioning shifts time and costs, meaning if the devices don’t need adjusting, they’ll save both.

Considering the machine’s capabilities for each process, these industries stand to optimize their workflow, reduce costs and time, and improve productivity.

What Industries Use 7-axis CNC Machines?

The 7-axis CNC machines are utilized in various industries because of their accuracy and flexibility. Key industries include:

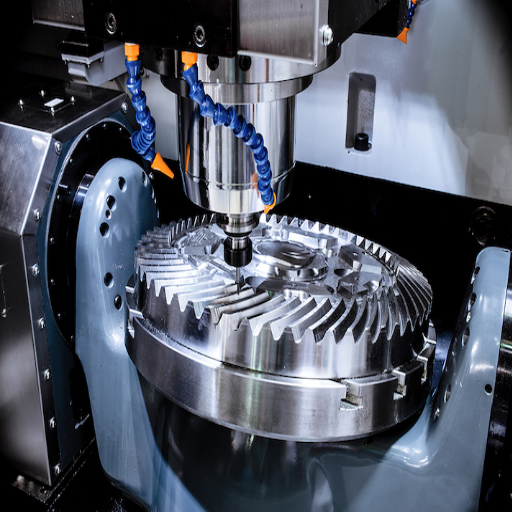

- Aerospace: For producing structural components like turbine blades alongside lightweight and complex parts.

- Automotive: For the manufacture of complex and high-performance engine components.

- Medical: For the detailed crafting of surgical instruments and implants of various designs.

- Energy: For use in producing turbines and other related large-scale power generation computer elements.

- These industries custom advanced weapons and other specialized components for defense purposes.

These industries benefit from the machine’s ability to perform complex design tasks precisely.

Typical Applications in Aerospace and Automotive Industries

Advanced machining technologies are applied heavily in the aerospace and automotive industries to ensure precision and peak operational efficiency. Listed below are frequent use cases in the mentioned sectors:

Aircraft Engine Components: Critical components like turbine blades and engine casing are manufactured using high-precision machines. Turbine blades, for instance, undergo advanced machining processes due to the complex cooling channels that require enduring extreme temperatures. With meticulous requirements, precision has to be achieved in microns.

Structural Parts for Aircraft: To ensure safety during flight and guarantee accuracy, large-scale structural components like fuselage frames and wing sections need to be produced with exceptional precision. Titanium and composites are used as lightweight materials to enhance the aircraft’s strength without increasing its weight.

Spacecraft Components: The components that manufacture satellites, rockets, and other spacecraft are produced using manufacturing tools. These parts must be made within specific parameters, such as a vacuum environment and extreme temperatures for space travel.

Automotive Engine Blocks and Cylinders: The engine blocks cylinders, and pistons all go through advanced machining processes to ensure every measurement is precise and surface smooth to reduce fuel consumption.

Transmission Systems: Gearbox components, such as the gears and shafts, are machined for optimal accuracy, structural strength, and power efficiency.

Parts of Electric Vehicles: Utilizing vehicles that rely on electricity has created an EV market that requires the manufacturing of compact and lightweight electric motors and battery casings that maximize energy efficiency.

Prototyping and Testing: Innovation in design is diverse in both sectors. It can be achieved through the rapid prototyping process, which uses precision additive and subtractive machining.

Aerodynamic Testing Models: Automobiles and aircraft can add and refine scaled models, which undergo extensive wind tunnel testing for better performance and fine-tuned detailed design.

The automotive and aeronautic industries are constantly pursuing advanced techniques in machining and performance, precision, safety, and reliability for vehicles that better serve consumers’ needs.

Use in Medical Device Manufacturing

Due to its accuracy, dependability, and working capabilities with complex materials, CNC machining is crucial to the medical device manufacturing industry. Devices tend to have complex features and small tolerances to ensure the best possible operation and safety for the patient. Surgical instruments, orthopedic implants, prosthetics, dental devices, diagnostic equipment, and other CNC medical device manufacturing components are machined using CNC technology.

Biocompatible materials such as titanium, stainless steel, and some medical-grade polymers illustrate the advantages offered by CNC machining. For instance, titanium-alloy orthopedic implants depend on CNC for accurate contouring and surface treatments to achieve proper fit into the human body, a process termed integration. Reports claim the medical device manufacturing industry is expected to grow aggressively and reach almost $800 billion by 2030, marking CNC machining’s strategic contribution to high-precision component creation.

CNC also enhances development speed by allowing easy production of functional prototypes, essential in medical innovation pre-testing. This capability facilitates the rapid prototyping cycle of various iterations. This is critical for the part’s production CAD model of artificial joints, multiple parts of pacemakers, and stents, which have numerous regulatory requirements.

CNC machining has revolutionized medical device manufacturing by transforming its use in healthcare globally. This is achieved by improving innovation alongside healthcare outcomes. Thanks to unmatched accuracy, CNC machining scales production while maintaining consistency and quality.

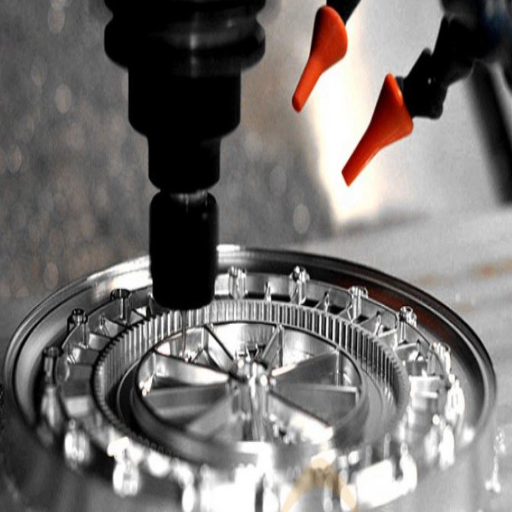

What are the Key Features of a 7-axis CNC Milling Machine?

An outstanding engineering tool is a 7-axis CNC milling machine. Every form of manufacturing requires versatility and unmatched precision, and a 7-axis CNC machine provides just that. The following is a list of its salient features.

- Simultaneous Multi-Axis Movement: The machine functions on seven axes, which allows it to make sophisticated and intricate cuts using complex angles on a workpiece without having to reposition it.

- Enhanced Flexibility: The capability to use a variety of materials can benefit the medical, aerospace, and automotive industries.

- Improved Efficiency: The 7-axis machine lessens the amount of manual adjustments needed, thus lowering production time and streamlining the entire process.

- High Precision: Brand consistency is vital when producing intricate parts with tight tolerances, thus it assures consistent precision.

- Integrated Automation: Including robotic systems for loading and unloading enhances productivity while lowering labor costs.

With all these features, 7-axis CNC milling machines are perfect for applications requiring unmatched detail and unparalleled performance.

Overview of Milling Capabilities

The productivity and ease of manufacturing processes due to the advanced 7-axis CNC milling machines are remarkable. These machines make drilling, cutting, turning, and contouring operations of multi-step processes automatic and require no manual involvement or setup between each step. The machine kinematics of 7-axis systems can be enhanced; parts can be positioned and rotated in complex manners. This allows for better complex reachability positioning, which can reach difficult areas in the machines for faster production time.

Exemplifying this is the unbeatable accuracy achieved in tolerances, which are especially valued for aerospace, medical device manufacturing, and other industries at the utmost levels. These devices ensure that titanium machining is done with cutting excess heat and wear regulation controls. Recent updates for automated 7-axis milling machines can increase the productivity of the machines by 30% while decreasing 20% of waste material. Not only does this reduce costs, but it also makes the machines ecologically friendly. Under CAD/CAM software control additions, integration offers ease of design through production, helping to manufacture exact replicas of the design.

The recently expanded processes for integrating sophisticated machining tools for titanium, Acharcom alloy composites, and aluminum have also advanced.

This highlights, again, the importance of 7-axis CNC machines in contemporary precision engineering, which combines features of mechanical mass production with singular bespoke parts manufacturing.

Types of Materials Suitable for 7-axis CNC Milling

The highly adaptable 7-axis CNC milling machines can work with various materials across different industries. These machines can process metals, plastics, complicated composites, and even alloys with unparalleled precision and efficiency.

Metals

Some of the most frequently milled metals include aluminum, titanium, and stainless steel. Aluminum is easily one of the most used metals due to its lightweight and endurance. It’s helpful in the tools for aircraft, automobiles, and many other applications. Likewise, titanium’s strength and corrosion resistance also make it very useful in medical and aerospace components. Steel and Stainless Steel are critical for manufacturing tools, heavy machinery, and industrial components, which require high-precision machining.

Plastics

Engineering-grade plastics like ABS, PEEK, and Delrin are also used in 7-axis CNC milling. These materials are popular among the electronics, healthcare, and even consumer goods industries because of their lightweight, superb resistance to chemicals, and excellent thermal stability. With 7-axis capabilities, precision is guaranteed when machining tiny, intricate plastic parts.

Composites

Aeronautical engineering and high-end sporting goods utilize advanced composites like carbon fiber-reinforced polymers (CFRP) and glass-reinforced plastics (GRP) because of their strength-to-weight ratio. The control and accuracy of 7-axis systems guarantee cutting these difficult materials will be executed smoothly and accurately.

Exotic Alloys

Industry uses high-temperature and corrosion-resistant exotic alloys such as Inconel and Hastelloy. They are widely used in energy, chemical processing, and aerospace. The tough CNC machine 7-axis capabilities enable precision machining of tough alloys while maintaining their structural integrity.

7-axis CNC milling machines make a wide range of materials possible, allowing manufacturers to fulfill the ever-growing needs for precision and complexity across industries. These machines continue to evolve and remain a considerable part of modern manufacturing strategy.

Reference Sources

-

“A hybrid 5-axis CNC milling machine”

This study discusses the design of a small hybrid 5-axis motion platform and showcases its potential for precise and compact machining applications1. -

“Accuracy enhancement of five-axis CNC machines through real-time error compensation”

This paper explores methods to improve the accuracy of 5-axis CNC machines by implementing real-time error compensation techniques2. - Top Mini CNC Router Manufacturer And Supplier In China

Frequently Asked Questions (FAQs)

Q: What is the difference between 5-axis and 7-axis CNC machining?

A: The primary difference lies in the number of axes available for movement. A 5-axis CNC machine can move along five axes, allowing for complex shapes and angles. In contrast, a 7-axis CNC machine includes additional rotary axes, which enhance its flexibility and machining capabilities, making it suitable for more intricate designs.

Q: When should I choose a 7-axis CNC machine over a 5-axis one?

A: You should choose a 7-axis CNC machine when your project requires advanced machining capabilities, such as intricate geometries and multi-sided machining. The additional two axes allow for better access to the workpiece, reducing the need for multiple setups and improving efficiency.

Q: Can a 7-axis CNC machine perform all tasks that a 3-axis CNC machine can?

A: Yes, a 7-axis CNC machine can perform all tasks that a 3-axis CNC machine can do, but with added capabilities. The 7-axis configuration provides more flexibility in tool positioning and access to the part, which can enhance the overall machining process.

Q: What are the benefits of using a 4-axis CNC machine compared to a 3-axis CNC machine?

A: A 4-axis CNC machine offers an additional axis of rotation, allowing for more complex machining operations. This can significantly enhance the machining capabilities for parts that require more intricate designs or features, reducing the need for manual repositioning of the workpiece.

Q: Are 9-axis CNC machines available for custom CNC projects?

A: 9-axis CNC machines are available and can be particularly beneficial for highly complex projects. They provide additional axes of movement, which can significantly improve precision and efficiency in machining intricate parts or components.

Q: What types of materials can be machined using a 5-axis CNC milling machine?

A: A 5-axis CNC milling machine can machine many materials, including metals (like aluminum and titanium), plastics, composites, and more. The machine’s flexibility allows it to handle various material types depending on the required machining capabilities.

Q: How does a 3-axis CNC milling machine differ from a 4-axis CNC machine?

A: A 3-axis CNC milling machine operates along three linear axes (X, Y, and Z), while a 4-axis CNC machine adds a rotary axis, allowing for more complex part shapes and orientations. This additional axis enables machining features on multiple sides of a workpiece without manual repositioning.

Q: What is the significance of rotary axes in 7-axis CNC machining?

A: Rotary axes in 7-axis CNC machining are significant because they allow the tool to approach the workpiece from various angles. This capability is crucial for creating complex geometries and achieving high precision in machining operations, which is essential for the aerospace and medical manufacturing industries.

Q: What should I consider when choosing between a 5-axis CNC and a 7-axis CNC machine?

A: When choosing between a 5-axis and a 7-axis CNC machine, consider the complexity of the parts you need to machine, the required precision, your budget, and the available space. If your projects involve intricate designs that require multiple orientations, a 7-axis CNC machine may be the better choice.