3D laser marking machines have revolutionized the way industries approach precision engraving, marking, and designing. These cutting-edge machines are renowned for their ability to create intricate and durable markings on a variety of surfaces, unlocking new levels of creativity and efficiency. But what exactly makes them so powerful, and how can you leverage their capabilities to enhance your projects or business operations? This guide takes you on a deep dive into the world of 3D laser marking technology, exploring its features, benefits, and the endless possibilities it offers. Whether you’re a tech enthusiast, a business owner, or a professional in the field, this article will equip you with the insights you need to master the art and science behind these advanced machines. Get ready to uncover the secrets that make the 3D laser marking machine an indispensable tool in today’s innovative landscape!

What is a 3D Laser Marking Machine?

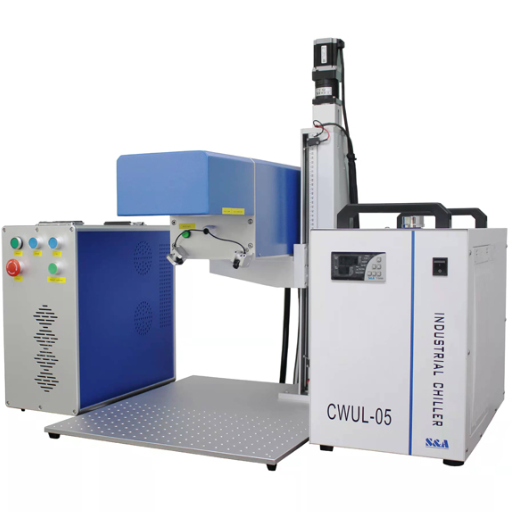

A 3D laser marking machine is a cutting-edge device used to engrave, etch, or mark a variety of materials with high precision. Unlike traditional 2D machines, it can work on curved, uneven, or complex surfaces, ensuring consistent and accurate results. These machines utilize advanced laser technology to adjust focus dynamically, allowing for detailed and durable markings across different depths and shapes. Commonly used in industries like manufacturing, aerospace, and electronics, 3D laser marking machines are valued for their efficiency, versatility, and ability to handle intricate designs.

Understanding the Basics of 3D Laser Technology

At its foundation, 3D laser technology operates by emitting a concentrated beam of light, which is then manipulated through a combination of high-precision optics and advanced software. The laser interacts with the target material by engraving, marking, or etching the surface, based on the intensity and focus of the beam. Unlike traditional 2D laser systems, 3D laser equipment excels in handling variations in material depth, curvature, and texture, making it ideal for complex applications.

This technology utilizes digitally controlled galvanometers and sophisticated algorithms to adjust the focal length dynamically, ensuring that the laser beam remains perfectly focused across uneven or complex surfaces. Research indicates that modern 3D laser systems minimize distortion and improve engraving consistency, achieving accuracy levels down to a few microns. These machines can process diverse materials, including metals, ceramics, plastics, and glass, without compromising on precision or detail.

The adoption of 3D laser technology continues to grow across industries. For example, the global laser marking market is projected to surpass $4 billion by 2027, fueled by demand in sectors such as automotive, aerospace, and medical device manufacturing. A driving factor is its ability to enhance productivity through reduced processing time and lower material waste, as well as its compatibility with sustainable production practices.

Differences Between 2D Laser and 3D Laser Marking

When comparing 2D and 3D laser marking technologies, the distinctions lie in their functionality, versatility, and application scope.

1. Axis of Operation and Depth Control:

2D laser marking systems operate on two axes (X and Y), limiting their ability to mark beyond flat or slightly curved surfaces. This makes them ideal for materials that require shallow engraving or surface marking. Conversely, 3D laser marking systems introduce a third axis (Z), enabling dynamic focus adjustments for marking on uneven or complex 3D surfaces such as cylinders, spheres, and sloped objects. For instance, in industries like aerospace where precision marking on intricate geometries is essential, 3D lasers offer unparalleled accuracy.

2. Efficiency and Speed:

3D laser marking is typically faster than its 2D counterpart in tasks involving complex surfaces. The ability to adjust focus dynamically on the Z-axis reduces setup time and manual intervention while maintaining high-quality output. Utilization of 3D technology can increase operating efficiency by up to 30% in manufacturing environments requiring multi-dimensional engravings.

3. Application Flexibility:

While 2D laser marking is restricted to flat surfaces and simple designs, 3D laser marking can handle a broader array of materials and shapes. It’s particularly advantageous for marking materials such as curved glass, tapered metal parts, or molded plastics. For example, in the automotive industry, 3D laser marking is employed for permanent identification on complex engine parts and curved dashboards.

4. Depth of Engraving and Precision:

3D laser systems enable deeper engravings without compromising precision, as they can accommodate material height variances within the same process. This capability has been crucial for creating visually striking branding elements, detailed serial numbers, and durable markings resistant to wear.

5. Cost and Initial Investment:

Although 3D laser marking systems typically involve a higher initial investment compared to 2D systems, their enhanced capabilities and efficiency lead to better long-term ROI. The growing trend toward automation and the increasing demand for flawless precision in industries have made 3D lasers a future-proof solution.

Both technologies serve specific needs depending on the application; however, the adaptability, precision, and efficiency of 3D laser marking make it the favored choice for advanced manufacturing environments. As industries continue progressing toward more complex designs and higher standards of quality, the adoption of 3D laser systems is set to expand significantly.

The Role of Fiber Laser in 3D Marking Machines

Fiber lasers play a pivotal role in the evolution of 3D marking machines, providing unmatched precision, speed, and durability. These lasers are particularly well-suited for intricate tasks, as their high beam quality ensures crisp, permanent marks on an extensive range of materials, including metals, plastics, and even reflective surfaces.

One of the standout advantages of fiber lasers is their energy efficiency. With an estimated electrical-to-optical conversion rate of up to 50%, fiber lasers significantly reduce power consumption compared to traditional laser systems. This not only minimizes operational costs but also aligns with modern sustainability goals. Additionally, fiber lasers offer a longer operational lifespan, often exceeding 100,000 hours of use, which drastically reduces maintenance requirements for manufacturers.

The versatility of fiber lasers in 3D marking is unparalleled. They excel at creating detailed and complex markings such as QR codes, logos, serial numbers, and barcodes with minimal distortion, even on uneven or curved surfaces. This is particularly critical in industries like aerospace, automotive, and electronics, where readability and durability of the marks are non-negotiable. For example, in automotive manufacturing, fiber lasers have become an essential tool for tracking parts throughout production processes, ensuring quality control and traceability.

Furthermore, advancements in fiber laser technology are enabling the development of higher-powered systems that can tackle deeper marking applications while maintaining accuracy. These innovations are making fiber lasers an indispensable asset in high-demand environments requiring top-notch precision and speed.

How Does a 3D Laser Engraving Machine Work?

A 3D laser engraving machine works by using a focused laser beam to etch designs into materials with precision and depth. The process begins with a pre-programmed design, often created through specialized software. This design guides the laser as it moves across the material in layers, adjusting its intensity and focus to create detailed 3D effects. Unlike standard engraving, 3D laser engraving allows the laser to vary in depth and dimension, producing a sculpted appearance. These machines are capable of working on various surfaces, such as metal, wood, and plastic, delivering accurate and consistent results.

Exploring the 3D Laser Engraving Process

Modern 3D laser engraving technology integrates precision and versatility, making it a game-changer across various industries. One of its standout features is the use of high-powered lasers capable of producing incredibly fine details on a range of materials. These systems utilize advanced software that converts complex designs into precise instructions, allowing for unparalleled accuracy. For instance, modern diode or fiber lasers can achieve depth variations within microns, enabling sharp contrasts and intricate textures.

Additionally, innovations in speed and efficiency have redefined productivity. High-speed galvanometer systems allow lasers to operate at exceptional rates, significantly reducing production times without compromising detail. Recent developments report engraving speeds of up to 4 meters per second, a remarkable improvement for industries requiring high throughput.

Another critical development lies in material adaptability. From soft organic materials like wood and leather to hardened steel and even translucent surfaces like glass, 3D laser engraving offers consistent quality. These machines also accommodate varying surface curvatures by employing dynamic laser focus technology, ensuring uniformity on uneven objects.

The combination of these advancements has seen 3D laser engraving flourish in applications ranging from personalized consumer goods and intricate jewelry patterns to industrial mold manufacturing and architectural designs. With its ability to balance precision, speed, and adaptability, the technology continues to push the boundaries of what’s possible in engraving.

The Function of the Laser Beam in Marking and Engraving

The laser beam functions as the central tool in marking and engraving, utilizing concentrated light energy to create precise and enduring marks on various materials. Its operation relies on the conversion of electrical energy into highly-focused light through stimulated emission, producing consistent and intense wavelengths. This precision enables controlled material removal, surface restructuring, or even color changes, depending on the type of material being engraved.

Laser engraving is renowned for its speed and accuracy, with modern systems achieving engraving speeds of up to 7,000 millimeters per second while maintaining superior detail. Additionally, the wavelength of the laser beam is crucial in determining how effectively it interacts with the substrate. For instance, infrared CO2 laser beams are optimal for organic materials like wood and leather, whereas fiber lasers, with higher energy density, excel on metals, ceramics, and certain plastics.

Recent advancements in laser technology, such as pulsed vs. continuous wave lasers and ultra-short pulse durations, provide even greater control over heat-affected zones (HAZ), reducing the risk of distortions on sensitive materials. This functionality ensures that the laser not only engraves with unparalleled accuracy but does so while preserving the integrity of the object.

Statistically, the laser engraving market reflects this effectiveness, with annual growth rates of approximately 8.4% in the manufacturing industry globally, driven by the demand for intricate designs and durable markings in sectors such as automotive, aerospace, and medical devices. This interplay of precision, efficiency, and technological innovation underscores the laser beam’s critical role in modern marking and engraving processes.

Adjusting the Laser Head for Precision

Properly adjusting the laser head is a key step to achieving high precision and consistent results in laser engraving or cutting. First, ensure the laser head is correctly aligned with the focal point of the material being processed. Many modern systems include automated or manual adjustment mechanisms, allowing fine-tuning of the focal distance for distinct material types and thicknesses. Studies indicate that improper laser head alignment can reduce engraving accuracy by up to 30%, particularly when working with delicate or complex designs.

Additionally, maintaining the correct angle of the laser beam is essential to ensure uniform energy distribution across the surface. Advanced machines are now equipped with auto-focusing technologies, which have been shown to improve production speeds by as much as 20% by minimizing manual alignment errors. Regular cleaning and maintenance of the lens and mirrors inside the laser head is equally important, as tiny debris or residue buildup can scatter the laser beam, reducing precision. Complementing these steps with high-quality optics and software calibration ensures that each project is executed with maximum sharpness and detail, which is increasingly essential in industries requiring exact tolerances, like medical device manufacturing and aerospace components.

What Are the Advantages of 3D Laser Marking?

3D laser marking offers several significant advantages across various industries. It provides unparalleled precision and consistency, ensuring high-quality marks on complex, curved, or uneven surfaces. This technology excels in versatility, accommodating a range of materials, including metals, plastics, ceramics, and glass, without compromising performance. Additionally, 3D laser marking is highly efficient, reducing production time and costs while eliminating the need for additional tooling. Its non-contact process minimizes material damage, ensuring durability and longevity of the markings. These benefits make 3D laser marking an ideal solution for industries requiring accuracy, reliability, and efficiency.

Precision and Versatility of 3D Laser Technology

3D laser technology has revolutionized various industries by introducing unparalleled precision and adaptability. Its ability to engrave, etch, and mark complex three-dimensional surfaces with micron-level accuracy is transforming manufacturing processes. Studies indicate that the accuracy of 3D laser markings can reach tolerances within 10 microns, making it essential for industries like aerospace, automotive, and medical device production where precision is critical.

The versatility of 3D laser systems extends to handling intricate geometries and functional surfaces with ease. For instance, modern 3D laser markers can dynamically adjust the focal point across curved, uneven, or irregular surfaces without needing reconfiguration, saving significant production time. A widely cited industry report highlights that integrating 3D laser systems can enhance production throughput by up to 40%, underscoring its efficiency.

Additionally, 3D laser technology is eco-friendly. Unlike traditional marking processes that might rely on consumables like inks or chemicals, 3D lasers are non-contact and use only light energy. This not only reduces waste but supports sustainability efforts by lowering the carbon footprint of manufacturing processes.

The combination of speed, precision, and adaptability ensures that 3D laser technology will remain at the forefront of industrial innovation, paving the way for cutting-edge advancements across multiple domains.

Efficiency of Laser Machines in Industrial Applications

The efficiency of laser machines in industrial settings stems from their ability to deliver precise, consistent, and high-speed operations, drastically improving productivity. Modern laser systems, such as fiber and CO2 lasers, offer energy efficiencies of up to 50%, significantly reducing operational costs compared to traditional machining methods. These machines can operate continuously with minimal downtime due to their robust build and automated maintenance processes.

Laser cutting, for instance, can achieve edge tolerance levels as tight as +/- 0.1 mm, ensuring unparalleled accuracy in manufacturing. Additionally, they excel in material versatility, processing everything from metals and ceramics to non-metallic substances like plastics and textiles. This adaptability reduces the need for separate machines, optimizing workspace utilization. Reports indicate that industries utilizing laser technology have seen a 30% reduction in waste material due to the precision of cutting paths, further reinforcing sustainability.

Furthermore, advancements in automation technology have enabled the integration of laser machines into smart manufacturing systems. By leveraging tools like IoT sensors and AI-driven monitoring, manufacturers achieve real-time diagnostics and production efficiency improvements of up to 40%. This integration highlights the alignment of laser machines with Industry 4.0 initiatives, setting new benchmarks for industrial innovation and operational excellence.

Cost-Effectiveness of 3D Fiber Laser Marking Machines

When evaluating the cost-effectiveness of 3D fiber laser marking machines, several critical factors make these systems a standout investment for industries. To start, their exceptional durability and low maintenance requirements significantly reduce long-term operational costs. Unlike traditional marking methods that require consumables such as inks or chemicals, fiber lasers operate without these ongoing expenses. This leads to cost savings of up to 30-50% over time compared to conventional methods.

Additionally, the efficiency of 3D fiber laser marking machines stems from their ability to handle intricate patterns, variable surfaces, and complex geometries with precision and speed. Across industries like automotive, aerospace, and electronics, this capability translates to faster production cycles and fewer errors. For instance, advanced 3D fiber lasers can achieve marking speeds greater than 7000 millimeters per second, allowing high-volume manufacturers to meet tight production deadlines without compromising quality.

Energy efficiency is another key driver of cost reduction. These machines consume significantly less power compared to CO₂ or older laser marking systems, lowering energy expenditures. Some models utilize up to 70% less power than their counterparts, contributing not only to reduced utility costs but also to more sustainable production practices.

Lastly, their adaptability ensures seamless integration into existing manufacturing workflows, further minimizing the need for extensive capital investments in customized systems. With a projected lifespan of over 100,000 operational hours, 3D fiber laser marking machines offer a reliable, scalable, and sustainable solution, making them a cost-effective choice across diverse industrial applications.

What Materials Can Be Used with a 3D Laser Engraving Machine?

The diverse range of materials that can be processed explains the versatility of a 3D laser engraving machine. Similar to other laser engraving machines, it can accurately mark metals such as stainless steel, aluminum, and brass, as well as non-metals like wood, acrylic, glass and ceramics. In addition, it works well on coated plastics and some plastic composites. This makes the machine applicable in several industries including manufacturing, automotive, and even in art and design.

Compatible Materials for 3D Engraving and Marking

When it comes to compatible materials for 3D engraving and marking, I would focus on options that ensure both quality and versatility. Metals like stainless steel, aluminum, brass, and titanium are ideal for their strength and durability. At the same time, non-metallic materials such as wood, acrylic, glass, plastic, and leather provide creative flexibility for decorative or functional projects. Even ceramics and coated surfaces can be engraved or marked with precision, making them suitable for a range of applications. These options allow for exceptional results tailored to diverse needs.

Engraving on Curved Surfaces with 3D Laser

3D laser engraving has revolutionized the ability to engrave on curved or uneven surfaces with remarkable precision. Unlike traditional engraving methods, the advanced 3D laser systems utilize dynamic focus technology, allowing the laser beam to adjust to varying surface depths and contours automatically. This results in immaculate engraving, even on challenging geometries such as cylindrical items, spheres, and irregularly shaped objects.

Key applications range from personalizing metal water bottles and custom jewelry to high-precision industrial components. According to industry data, the introduction of 3D laser engraving has improved engraving efficiency by up to 30% compared to 2D systems. This increased productivity stems from reduced setup times and the technology’s ability to engrave complex surfaces in one seamless operation.

Material versatility is another critical benefit. 3D laser systems can mark metals such as stainless steel and titanium while also handling non-metals like glass and ceramics. Furthermore, engraving on medical devices, automotive parts, and aerospace components has become more accurate and durable, meeting stringent quality standards.

Another advantage lies in consistency. The depth and sharpness of engravings remain uniform across the entire surface, regardless of curvature. This precision has made 3D laser engraving an invaluable solution for sectors requiring intricate details, such as branding, serial numbering, or QR coding on products with complex shapes.

Through these advancements, 3D laser engraving on curved surfaces has become a cutting-edge solution, offering unmatched flexibility, speed, and precision for countless industries.

How to Choose the Best 3D Laser Engraving Machine?

When choosing the best 3D laser engraving machine, consider the following key factors:

- Material Compatibility – Ensure the machine can engrave the types of materials you work with, such as metal, wood, glass, or plastic. Versatility is essential if you need to handle a range of materials.

- Precision and Accuracy – Look for a machine with high-resolution capabilities to produce detailed and consistent engravings, especially for intricate designs.

- Software Compatibility – The machine should support user-friendly and widely compatible software for easy operation and design customization.

- Engraving Area and Size – Choose a machine that accommodates the dimensions of the objects you need to engrave, especially if working with larger or curved surfaces.

- Budget and Reliability – Balance your budget with quality; opt for a machine with durable components and positive customer reviews to ensure long-term performance.

By focusing on these factors, you can confidently select the right 3D laser engraving machine for your needs.

Key Features to Consider in 3D Laser Engravers

Precision and Accuracy

When selecting a 3D laser engraver, precision is paramount. Modern machines often boast resolutions as fine as 0.01mm, making them ideal for intricate designs and highly detailed work. This level of accuracy ensures that engravings remain consistent, whether you’re crafting delicate patterns or handling complex geometries.

Suitable Material Compatibility

Different projects demand versatility in the materials a machine can handle. Look for a laser engraver that supports a wide range of materials, including wood, metal, acrylic, glass, and even specialized composites. For example, CO2 laser engravers are known for excelling with non-metal materials, while fiber lasers are often preferred for marking metals due to their superior performance.

Laser Power and Speed

Laser power directly impacts the depth and speed of engraving. Machines with higher wattages (e.g., 40W or above for CO2 lasers, and 20W+ for fiber lasers) allow for faster operations and deeper cuts, which are beneficial when working with hard or thick materials. Coupled with advanced speed settings, high-powered engravers enhance productivity while maintaining quality.

Cooling System Efficiency

Effective heat management prevents overheating and protects the laser’s longevity. Many machines come equipped with water-cooled or air-cooled systems. Higher-end models often feature advanced cooling mechanisms that are quieter and more efficient, which is essential for continuous operation in commercial contexts.

User-Friendly Software Integration

An intuitive interface and robust software capabilities streamline the engraving process. Compatibility with design programs such as AutoCAD, CorelDRAW, or Adobe Illustrator is a critical consideration. Additionally, support for multiple file types (e.g., SVG, DXF, JPEG) ensures flexibility and ease of use for diverse projects.

Safety Mechanisms

Operational safety cannot be overlooked in laser engravers. Protective features such as automatic shut-off mechanisms, enclosed designs, and effective venting systems to manage fumes are critical for maintaining a safe working environment. Machines compliant with international safety standards, like CE certification, offer added peace of mind.

Maintenance and Upgradability

Regular maintenance is easier with machines that feature modular designs or easily replaceable parts, such as laser tubes or lenses. Furthermore, considering a model that allows component upgrades ensures you stay ahead with evolving technology without requiring a full replacement.

By emphasizing these key features, you can select a 3D laser engraver tailored to meet specific operational demands while optimizing both efficiency and quality.

Comparing Laser Power and Capabilities

When evaluating laser power in 3D laser engravers, it is critical to understand how power levels impact performance and material compatibility. Laser power, typically measured in watts, determines the machine’s ability to cut or engrave a range of materials. For instance, lower-powered lasers, such as those rated at 40W, are ideal for delicate engraving tasks on materials like paper, leather, or thin acrylics. On the other hand, higher-powered lasers, such as 100W or more, are essential for cutting through thick materials like hardwood, metal, or dense plastics.

Additionally, advancements in laser technology have introduced capabilities like adjustable power settings, which offer greater flexibility for operators. For example, a high-powered laser can be calibrated for precision engraving by reducing its intensity rather than maximizing it for cutting tasks. Machines with dual-laser options, which combine two laser sources, provide users the versatility to switch seamlessly between fine detail work and robust cutting operations.

Data also highlights the diverse processing speeds linked to laser power. High-performance lasers with greater wattage tend to deliver faster engraving or cutting speeds, effectively enhancing production efficiency for industrial use. However, striking the right balance between power and application requirements remains essential, as overpowered lasers can lead to material burnout or wasted energy if not properly managed.

By carefully considering the laser power you need and its associated capabilities, you can ensure optimal performance across a variety of materials while maximizing the efficiency of your 3D laser engraver.

Understanding 3D Dynamic Focus Technology

3D Dynamic Focus Technology represents a groundbreaking advancement in the field of laser engraving and cutting, allowing for precise depth control and improved efficiency in handling complex, multi-layered workpieces. By utilizing a dynamic focus lens system, this technology automatically adjusts the laser beam’s focus point to correspond with varying heights and curves of the material, ensuring consistent beam quality and precision.

One of its primary advantages lies in its ability to operate seamlessly on materials with uneven or intricate surfaces. For example, in industrial applications, this technology can effectively engrave on cylindrical objects, curved surfaces, or materials with varying thicknesses without requiring manual repositioning, which saves both time and labor costs. Additionally, with adjustments measured in microseconds, the adaptive laser focus maintains high-speed engraving up to 1,000mm/s while preserving sharp detailing.

The incorporation of 3D Dynamic Focus Technology also significantly reduces material waste. By precisely targeting the area to be engraved, energy is concentrated only where it’s needed. This is particularly valuable when working on high-value materials like metals, ceramics, or specialty composites.

Furthermore, modern 3D systems often include advanced software integration, which allows operators to design more intricate patterns with enhanced depth scaling. Studies show that businesses employing 3D laser systems with dynamic focus capabilities have reported up to a 25% increase in throughput compared to systems without this feature, primarily due to reduced downtime and more efficient material handling.

This technology is rapidly becoming a standard in industries such as aerospace, automotive, and personalized manufacturing, making it a must-have for users looking to take their engraving projects to the next level with precision and performance scalability.

Reference Sources

-

Research and Development of Laser Engraving and Material Cutting Machine from 3D Printer (2020)2:

- Focus: Explored the integration of laser engraving capabilities into 3D printers.

- Key Findings: By modifying a 3D printer to include a laser module, the machine can perform both 3D printing and laser engraving. This dual functionality enhances prototyping capabilities, allowing for engraving and cutting of materials like wood and acrylic.

- Methodology: The study detailed the design modifications, control systems, and operational adjustments required to integrate laser functionality into a 3D printer.

-

Laser Marking Methods (2015)3:

- Focus: Systematized various laser marking methods, including 3D applications.

- Key Findings: Highlighted the importance of selecting appropriate laser marking techniques based on material properties, marking type, and production needs. The study emphasized the flexibility and precision of laser marking systems.

- Methodology: Analyzed different laser marking methods and their applications across industries.

-

Projection Algorithm for 3D Laser Marking (2015)5:

- Focus: Developed a projection algorithm for 3D laser marking.

- Key Findings: Introduced a new algorithm for mapping 2D data onto 3D models with high precision and no distortion. This approach improves the accuracy and quality of 3D laser marking.

- Methodology: Utilized mathematical models and triangular mesh structures to achieve distortion-free projection and efficient texture mapping.

- Top 3D Laser Marking Machine Manufacturer and Supplier in China

Frequently Asked Questions (FAQs)

Q: What is a 3D laser marking machine?

A: A 3D laser marking machine is a device used for marking on various surfaces, including curved or uneven surfaces, by utilizing a high energy density laser. It is capable of deep engraving and creating intricate designs on different materials.

Q: How does a 3D laser marking machine differ from a 2D laser marking machine?

A: Unlike a 2D laser marking machine, which is generally used for flat surfaces, a 3D laser marking machine can handle marking on curved or irregular surfaces. It uses 3D specified software and control to adjust the laser beam for accurate engraving on three-dimensional objects.

Q: What types of materials can be marked using a 3D laser?

A: 3D laser engraver machines can mark a wide range of materials including metals, plastics, ceramics, and glass. The marking effect can vary depending on the material and the laser’s power settings.

Q: Is a 3D laser marking machine compatible with 3D laser engraving systems?

A: Yes, a 3D laser marking machine is compatible with 3D laser engraving systems. It can perform both marking and engraving tasks, offering versatile engraving capabilities for various applications.

Q: Can 3D laser marking be used for deep engraving?

A: Yes, 3D laser marking can be used for deep engraving. The 3D fiber laser engraving machine is particularly effective for deep engraving on metals and other materials due to its high energy density laser.

Q: What is the role of 3D specified software and control in a 3D laser machine?

A: 3D specified software and control are crucial in a 3D laser machine as they allow for precise adjustments of the laser beam to follow the contours of a 3D model. This ensures accurate marking on curved or complex surfaces.

Q: How does UV laser technology enhance marking work?

A: UV laser technology enhances marking work by providing a precise and clean process that minimizes heat-affected zones. This is particularly useful for sensitive materials that require high precision and minimal thermal impact.

Q: What are the advantages of using a 3D fiber laser engraving machine?

A: The advantages of using a 3D fiber laser engraving machine include its ability to handle complex designs, create high-quality engravings on varied surfaces, and offer high-speed processing with minimal maintenance requirements.

Q: Can a 3D laser marking machine be used for both marking and cutting tasks?

A: While primarily used for marking, some 3D laser machines are also capable of cutting tasks, especially when equipped with the right laser settings and cutting machine capabilities. However, their cutting abilities may be limited compared to dedicated laser cutting machines.

Q: What should be considered when choosing the right laser for 3D laser marking?

A: When choosing the right laser for 3D laser marking, consider factors such as the material to be marked, the required marking effect, the machine’s compatibility with 3D designs, and the specific engraving capabilities needed for your application.