In terms of versatility and precision, the powerful CO2 lasers reign supreme in various industries. From more advanced manufacturing projects for professionals to DIY creative endeavors for hobbyists, knowing what a CO2 laser can do for you is fundamental. Etching and engraving glass and wood, cutting out patterns from acrylic, and marking metals with extreme accuracy are just a few of the endless possibilities. In this guide, we will provide the most up-to-date information on the remarkable technology of CO2 lasers, including the materials they work with and their accuracy in transforming ideas into reality. Brace yourself as we unfold the amazing versatility of CO2 lasers and how they could change any type of project you might have.

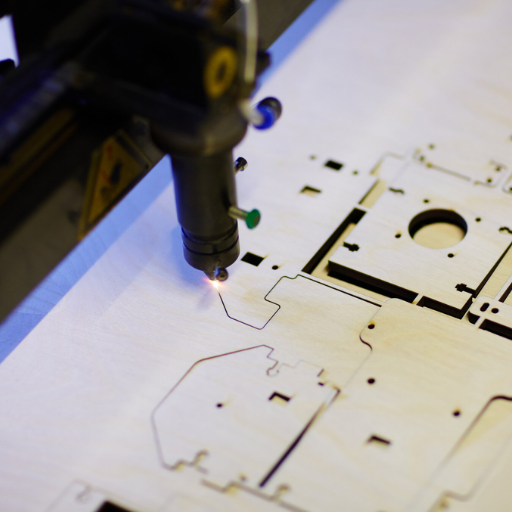

How Does a CO2 Laser Engrave Different Materials?

CO2 lasers engrave different materials by emitting a focused beam of infrared light that generates intense heat. This heat interacts with the surface of the material, vaporizing it or altering its structure to create precise designs. The effectiveness of engraving depends on the laser’s power settings and the properties of the material. For instance, CO2 lasers can easily engrave organic materials like wood, leather, and acrylic by burning or melting their surfaces to create clear and intricate patterns. They can also etch glass by micro-fracturing the surface. However, certain materials like some metals may require special coatings or adjustments to achieve optimal results.

What Types of Materials Can a CO2 Laser Engrave?

CO2 lasers are highly versatile tools capable of engraving a wide range of materials. Below is a detailed list of materials that can be engraved using a CO2 laser, along with relevant details about their compatibility and results:

- Wood

CO2 lasers excel at engraving various types of wood, including plywood, hardwood, MDF, and softwoods. The laser burns the surface to create crisp, detailed patterns. Lighter woods like birch and maple often yield higher contrast results compared to darker varieties.

- Acrylic

Acrylic engraving produces precise and smooth edges, making it ideal for signage, awards, and decorative items. Both cast and extruded acrylics can be engraved, though cast acrylic generally provides better-quality results.

- Leather

Natural and synthetic leathers are suitable for CO2 laser engraving, resulting in clean, sharp designs for products like wallets, belts, and custom accessories. The laser darkens the surface, creating contrast without damaging the integrity of the material.

- Paper

CO2 lasers can delicately engrave or cut paper without causing burns or warping, enabling the creation of intricate designs for invitations, packaging, or art projects.

- Glass

Laser engraving on glass involves micro-fracturing the surface to achieve a frosted, matte effect. This technique is commonly used for engraving mirrors, windowpanes, glassware, and trophies.

- Fabric

Certain fabrics like cotton, polyester, felt, and silk can be engraved for customization or decorative purposes. The laser lightly etches the surface without compromising the fabric’s structure.

- Rubber

Rubber materials, including rubber stamps, are suitable for CO2 laser engraving. The process creates fine, clear designs ideal for stamp production and industrial applications.

- Plastic

Many plastics, such as ABS, polycarbonate, and certain types of PVC-free materials, can be engraved. It is crucial to check the material’s composition to avoid potentially harmful fumes.

- Stone

Non-reflective stones like granite, marble, and slate can be engraved to achieve beautiful designs. The laser etches the stone surface, creating a permanent marking ideal for memorials, decorative plaques, and artwork.

- Ceramics

CO2 lasers are capable of engraving unglazed ceramics or lightly etching on glazed surfaces to create subtle and permanent designs.

- Coated Metals

While bare metals usually cannot be engraved directly with a CO2 laser, coated metals like anodized aluminum or painted surfaces can be effectively engraved by removing their outer layers to reveal underlying textures or colors.

- Foam

Foams used in packaging and industrial settings can be engraved or cut with high precision to create custom inserts, branding, or logos.

By understanding the compatibility of these materials with a CO2 laser and applying the correct settings, you can achieve highly detailed, professional results across a broad range of engraving projects.

How Does the Laser Power Affect the Engraving Process?

Laser power directly determines the depth, contrast, and overall quality of an engraving. Higher laser power allows the beam to penetrate deeper into the material, producing more pronounced and detailed engravings. For example, in materials like wood or acrylic, higher power settings create darker and deeper etches, whereas lower power produces lighter, more delicate marks, ideal for intricate designs.

Power settings must align with the material and the desired outcome. For instance, studies suggest that engraving wood with a laser power of around 50-70% can deliver optimal results for medium-depth engravings. Excessive power may char the material, while too little power might leave an indistinct mark. For metals, where engraving requires more precision and energy, power settings can vary across machine models but often range up to maximum outputs for deeper etching or marking.

Additionally, laser power affects the engraving speed. Higher power settings typically enable faster processing as less time is needed for material interaction. However, striking the right balance is crucial—excessively high power may distort delicate patterns or compromise the material’s structural integrity. By testing and fine-tuning power levels, operators can ensure a precise and efficient engraving process tailored to specific needs.

What Are Common Applications for Laser Engraving?

Laser engraving has become a go-to solution across various industries due to its incredible precision, versatility, and reliability. One of its most common applications is in product branding and customization, where logos, serial numbers, or text are engraved on materials like metal, glass, wood, and plastics. This process ensures durability and a professional finish, ideal for high-quality branding.

In the electronics sector, laser engraving is used for marking components with identifiers like QR codes and serial numbers, essential for product tracking and inventory management. This method is favored for its ability to engrave minute details with exceptional clarity, even on compact items.

The jewelry industry also benefits significantly from laser engraving. Intricate designs, personalized messages, and fine detailing can be added to precious metals and gemstones without damaging the material. Markets have shown an increase in demand for personalized jewelry, with this feature becoming a key selling point.

Additionally, laser engraving has applications in the medical field. Instruments and devices are marked with precise and permanent details, ensuring sterility and compliance with regulatory standards. Research indicates the global market for laser marking and engraving in the medical sector is forecast to grow steadily, driven by the need for traceability and safety.

The arts and crafts industry has embraced laser engraving as a tool for creating unique decorative pieces, from customized gifts to intricately designed furniture. The growing popularity of home-based businesses and small-scale creators has fueled demand for these services.

Lastly, laser engraving is widely used in industrial manufacturing for durable marking of machine parts, tools, and equipment. With increasing automation requirements, scalable and efficient processes have become critical, making laser engraving a preferred choice.

Statistics suggest that the demand for laser marking and engraving is expanding rapidly, with the global market size projected to reach $4.8 billion by 2030, growing at a compound annual growth rate (CAGR) of 6.2% from 2023 onward. This growth highlights the rising importance of laser engraving in a multitude of applications and industries.

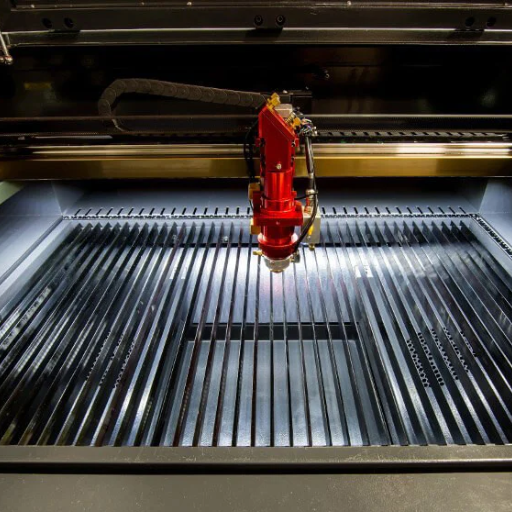

What Can a CO2 Laser Cutter Do?

A CO2 laser cutter is a versatile tool capable of cutting, engraving, and etching a wide range of materials. It works effectively on wood, acrylic, leather, fabric, and paper, making it ideal for both creative and industrial applications. Additionally, it can mark certain coated metals and engrave glass with precision. CO2 laser cutters are widely used in industries like manufacturing, design, and crafting due to their ability to produce detailed and high-quality results efficiently.

How Does a CO2 Laser Cut Through Various Materials?

A CO2 laser operates by generating a highly concentrated beam of light in the infrared spectrum, typically at a wavelength of 10.6 micrometers. This infrared light is absorbed efficiently by many materials, allowing the laser to cut, engrave, or etch with exceptional precision. The process begins with the laser’s optical system focusing the beam into a tiny point, often less than 0.1 millimeters in diameter. The intense energy at this focal point rapidly heats, melts, or vaporizes the material.

For materials like wood and acrylic, the laser beam effectively burns through the surface, creating clean edges without requiring physical contact. When cutting metals coated with specialized finishes, the energy absorbed by the coating allows for precise etching, while uncoated or reflective metals are cut using assist gases like oxygen or nitrogen, which improve cutting efficiency and prevent oxidation. For materials such as glass and stone, the laser produces micro-cracks that allow for meticulous engraving, though these require precise control due to their brittle nature.

Recent advancements have enhanced both the speed and accuracy of CO2 laser cutting systems. For example, modern lasers deliver cutting speeds up to 200 inches per minute depending on the material’s thickness and the system’s power, which can range from 30 watts for detailed engraving up to 400 watts or more for cutting thicker materials. The combination of advanced optics, high energy efficiency, and computer-controlled precision enables diverse applications, from industrial machining to custom design.

Which Materials Are Suitable for Laser Cutting?

Laser cutting is a versatile technology that can process a wide range of materials with precision and speed. Common materials suitable for laser cutting include:

- Metals – Metals like stainless steel, aluminum, and carbon steel are common in laser cutting. With high-powered systems, even thicker sheets of these metals—up to 1 inch or more for steel—can be cut accurately. For finer or intricate designs, metals as thin as 0.02 inches can be processed with minimal heat-affected zones.

- Wood – Laser cutters are frequently used on materials like plywood, MDF, and hardwood. Depending on the wood type, lasers can cut thicknesses up to 3/4 inches or engrave fine details for customized designs like decorative panels or furniture components.

- Plastics – Acrylic is one of the most popular plastics for laser cutting due to its clean edges and excellent clarity. Thicknesses between 1/16 inch to 1/2 inch can typically be cut seamlessly. Other plastics, like polycarbonate and ABS, can also be laser-cut, though care must be taken to avoid melting or fumes.

- Textiles and Leather – Fabrics such as polyester, cotton, felt, and leather are ideal for laser cutting and engraving. Lasers allow for intricate patterns without fraying, making them widely used in fashion, upholstery, and craft industries.

- Paper and Cardboard – For industries like packaging, prototyping, and art, laser cutting is an effective tool for creating detailed designs and crisp edges on paper or cardboard. Thickness tolerances often range from 0.1 mm to 3 mm depending on the density.

- Glass and Ceramics – While challenging due to their brittleness, lasers can engrave and mark glass and certain ceramics with extreme precision. This is particularly useful for decorative etching or product branding.

Each material type requires specific laser settings, such as power, speed, and focus, to ensure optimal results without imperfections. Additionally, safety considerations must take precedence when working with materials that produce harmful fumes or pose ignition risks.

What Are the Limitations of a CO2 Laser Cutter?

While CO2 laser cutters excel in versatility and precision, they also have notable limitations that users must consider. One major drawback is their inability to cut through highly reflective materials, such as aluminum or copper, as these materials reflect the laser beam, reducing cutting efficiency and potentially damaging the laser itself. Additionally, CO2 lasers struggle with cutting materials such as polycarbonate or certain vinyl-based plastics due to the production of toxic fumes and poor-quality cuts.

Another limitation lies in the material thickness that CO2 lasers can effectively cut. For example, they tend to be less effective or require higher power levels when working with metals or thick materials compared to fiber lasers. The maximum thickness for clean and efficient cutting is usually around 10-20 mm for non-metallic materials, depending on the machine’s power output.

Maintenance and operating costs can also be challenging over time. CO2 lasers require periodic replacement of consumable parts like laser tubes, mirrors, and lenses, which can add up in expense. Unlike solid-state lasers, the CO2 system also demands consistent alignment for optimal performance.

Finally, CO2 laser cutters consume more energy than other modern laser types, such as fiber lasers, making them less energy-efficient. This can lead to higher operational costs, especially for extensive or continuous usage. Understanding these limitations is essential to selecting the right laser cutter for specific applications and ensuring optimal results.

Can a CO2 Laser Cut and Engrave Metal?

Yes, a CO2 laser can cut and engrave certain types of metal, but it requires specific conditions to do so effectively. Typically, CO2 lasers are more suited for non-metallic materials; however, metals like stainless steel or aluminum can be processed if the system is equipped with a high-powered laser and assisted by oxygen or another gas to enhance the cutting or engraving process. For thin, coated, or anodized metals, engraving can be achieved more easily. However, for cutting thicker or reflective metals, more advanced laser systems like fiber lasers are generally preferred due to their superior efficiency and precision.

What Type of Laser is Needed to Cut Metal?

When determining the best type of laser for cutting metal, several factors come into play, including the material type, thickness, and desired precision. Today, fiber lasers are widely regarded as the most efficient technology for cutting metals due to their high power density and ability to focus sharply on the material. These lasers are particularly effective for cutting reflective metals such as aluminum, copper, and brass, where traditional CO2 lasers may struggle.

Fiber lasers operate at a wavelength of approximately 1.06 microns, which is significantly smaller than the 10.6-micron wavelength of CO2 lasers. This smaller wavelength allows for better absorption by metallic surfaces, translating into faster and more precise cuts. Research has shown that fiber lasers are capable of cutting materials up to 1 inch (25mm) thick for steel and around 3/4 inch (19mm) for aluminum when paired with power outputs of 6,000 to 12,000 watts.

For industries that require a high degree of accuracy, such as aerospace or automotive manufacturing, fiber lasers are often preferred due to their ability to produce smooth edges and intricate details. Additionally, they require less maintenance and consume less energy compared to other laser types, making them an economical choice for high-volume operations.

On the other hand, CO2 lasers, although less effective for reflective or thick metals, are still a viable option for thinner coated metals and non-metallic materials. Their larger wavelength allows them to excel in applications such as cutting wood or acrylic, making them versatile for mixed-material use cases.

Ultimately, the selection of a laser type depends heavily on the user’s specific cutting needs, the properties of the metal, and other operational priorities such as cost, precision, and energy efficiency.

How Does a CO2 Laser Engrave Metal?

CO2 lasers engrave metal using a combination of intense heat and precise control. Unlike fiber lasers, which directly interact with the surface of metals, CO2 lasers typically require a marking agent or coating for effective engraving on bare metals. The process starts with the laser emitting infrared light, which is then absorbed by the surface material. When a marking agent is applied, the laser’s heat causes a chemical reaction, leading to a permanent mark.

This type of laser operates at a wavelength of 10.6 micrometers and is highly efficient for non-metallic materials. However, for metals, the limitation lies in their reflective properties, which reduce direct energy absorption. To counter this, common solutions include pre-coating the metal surface with specialized pastes or sprays. These materials react under the laser beam, creating durable and high-contrast marks.

Recent technological advancements have bolstered CO2 laser capabilities. For example, engraving speeds can reach up to 1,500 mm/s, depending on the material and machine specifications, allowing for efficient batch processing in industries such as manufacturing and automotive. Additionally, CO2 lasers can achieve resolutions as high as 1,200 DPI, providing unparalleled precision for intricate designs or text engraving.

CO2 laser systems have also become increasingly energy-efficient, consuming approximately 200-500 watts for most engraving tasks, which keeps operational costs manageable. This balance of precision, speed, and adaptability makes them a popular choice across various industries for metal engraving when paired with appropriate preparation techniques.

Are There Special Settings for Engraving Metal?

Yes, engraving metal with a laser requires specific settings to achieve optimal results. The choice of settings depends largely on the type of metal, the depth of engraving desired, and the laser system being used. Key parameters such as laser power, speed, and frequency must be carefully adjusted to ensure precision and avoid damaging the material.

For softer metals like aluminum, lower power settings combined with moderate engraving speeds are often sufficient, while harder metals like stainless steel require higher power levels for deeper penetration. For instance, a CO2 laser may need a power setting of 100% and a speed of 15% to engrave stainless steel effectively when using a marking spray. On the other hand, fiber lasers, which are particularly suited for metals, often operate at a wavelength of 1064nm and achieve excellent results with power settings between 20-30W, depending on the metal type.

Additionally, introducing auxiliary tools—such as a marking compound or paste—enhances contrast and clarity, especially when working with CO2 lasers on untreated metals. The frequency or pulse per inch (PPI) should also be calibrated; a range of 500-800 PPI is typically recommended to ensure smooth and detailed engravings. Preheating certain metals or employing a rotary attachment for cylindrical objects can further improve precision and consistency.

Ultimately, testing and fine-tuning are critical, as each material and design presents unique challenges. These settings, combined with proper preparation and maintenance of the laser system, ensure high-quality and durable engravings suitable for various applications.

What Are the Differences Between Fiber and CO2 Laser Machines?

The key distinctions between fiber and CO2 laser machines are their wavelength, efficiency, and the types of materials they can work with. Fiber lasers are more effective for metals as they operate at a smaller wavelength, cutting through aluminum, brass, and even reflective stainless steel with ease. Their benefits further extend to greater efficiency, faster processing speeds, and lower maintenance demands. CO2 lasers have a longer wavelength, allowing them to work with wood, acrylic, leather, glass, and other non-metal materials more effectively. While more versatile in cutting and engraving, CO2 lasers have a higher maintenance demand than fiber lasers.

What Are the Advantages of Using a Fiber Laser?

Fiber lasers offer several advantages that make them an excellent choice for various applications. First, they are highly efficient, delivering faster processing speeds and requiring less energy, which helps reduce operational costs. Second, their low maintenance needs make them reliable and cost-effective over time. Additionally, fiber lasers excel in precision, making them ideal for detailed and intricate work. Their ability to handle a wide range of metals with outstanding accuracy ensures exceptional results for complex projects. Overall, fiber lasers provide a powerful, efficient, and versatile solution.

How Does the CO2 Laser Compare to Other Laser Types?

When comparing CO2 lasers to other types, I find that CO2 lasers excel in cutting and engraving non-metallic materials like wood, acrylic, and textiles, thanks to their efficient absorption of infrared wavelengths. While fiber lasers are often more suited for metals due to their shorter wavelengths and higher precision, CO2 lasers provide a broader surface area impact, making them ideal for applications requiring smooth finishes on organic or polymer-based materials. However, CO2 lasers typically have higher energy consumption and maintenance needs compared to newer solid-state options, which can be a consideration for long-term use.

Which Laser Machine is Best for Specific Projects?

When deciding which laser machine is best for specific projects, I consider the materials and the desired outcomes. For intricate and detailed work on metals, I prefer fiber lasers due to their precision and efficiency. On the other hand, for projects involving wood, acrylic, or other organic materials where smooth edges and broader cuts are essential, I find CO2 lasers to be the optimal choice. Additionally, I factor in energy consumption and maintenance—fiber lasers often have an edge in long-term cost efficiency, while CO2 lasers may require more upkeep but deliver exceptional results for particular applications.

How to Optimize Laser Cutter Settings for Different Projects?

- Understand Your Material

Different materials require specific laser settings. For instance, wood generally needs lower power but slower speed settings for clean cuts, while metals often demand higher power for effective engraving or cutting. Always consult material guides or perform small test cuts to determine the best setup.

- Adjust Power and Speed

Optimize the laser power and speed for precision. Higher power works for thicker materials but may cause burns or distortions, while slower speeds allow for cleaner and more detailed cuts. It’s crucial to find a balance that suits the specific project.

- Set Proper Focus

Ensure the laser is focused correctly for optimal cutting depth and clarity. Improper focus can lead to uneven cuts or incomplete processing.

- Select the Right Resolution

For engraving, adjust the resolution based on the desired level of detail. High resolution provides finer details but may increase processing time.

- Use Air Assist (if available)

Air assist helps reduce material scorching and ensures smoother cuts by blowing away debris during operation. This feature is particularly useful for cutting wood or acrylic.

- Save and Track Your Settings

Once you identify the ideal settings for a specific material, save them for future use. Keeping a record of successful configurations can save time and improve consistency.

Experiment and refine these settings as needed to achieve the best results for each project. Always prioritize safety and follow the manufacturer’s recommendations.

What Are the Key Settings for a CO2 Laser Machine?

When operating a CO2 laser machine, understanding the key settings is crucial for achieving precise and consistent outcomes across different materials. Here are the essential settings to consider and optimize:

- Power

Power determines the intensity of the laser and is typically measured as a percentage of the machine’s maximum output. Higher power settings are used for cutting thicker materials, while lower power is ideal for engraving detailed designs. For example:

-

-

- Cutting 3mm acrylic: 60-80% power

- Engraving wood: 20-30% power

-

Adjust power carefully to avoid overburning or insufficient cutting depth.

- Speed

Speed relates to how quickly the laser head moves across the material. Higher speeds are suitable for engraving, while slower speeds ensure clean, deep cuts. Common recommendations include:

-

-

- Cutting 3mm plywood: 10-15 mm/s

- Engraving glass: 200-300 mm/s

-

Balancing speed with power is fundamental to achieving the desired result without compromising precision.

- Frequency (or Pulse Rate)

The frequency dictates how many laser pulses are emitted per second, usually measured in Hertz (Hz). For most materials, lower frequencies (e.g., 100-500 Hz) are better suited for cutting as they reduce heat buildup, while higher frequencies (e.g., 10,000 Hz) work well for engraving detailed patterns.

- Focus

Proper focus ensures that the laser beam is concentrated accurately on the material. Most machines have an adjustable focal point, and using a focus gauge or manual adjustment ensures the correct distance between the laser head and the surface. Misaligned focus can lead to poor cutting or engraving quality.

- Air Assist

Air assist uses a stream of compressed air to blow away debris, smoke, and heat from the cutting area. This feature not only improves cutting precision but also prevents material charring. For instance, when cutting metal or acrylic, enabling air assist on medium to high settings produces cleaner edges.

- Material Type and Thickness

Different materials and thicknesses require adjustments to all the above settings. For example:

-

-

- Cutting 6mm acrylic might need 70% power, 12 mm/s speed, and 500 Hz frequency.

- Engraving leather may only require 30% power, 150 mm/s speed, and 5,000 Hz frequency.

-

Refer to the manufacturer’s guidelines or perform small test runs to fine-tune these parameters effectively.

By carefully managing these settings and tailoring them to the material you are working with, you can enhance the quality of cutting and engraving on your CO2 laser machine. Regular maintenance and periodic calibration of the machine also contribute to consistent performance over time.

How to Adjust Laser Power for Various Materials?

Adjusting laser power is essential for achieving optimal results when working with different materials on a CO2 laser machine. Each material reacts differently to the laser’s intensity, requiring precise power settings to avoid over-burning or under-processing.

1. Wood

Wood is commonly used in laser cutting and engraving due to its versatility. Softer woods like pine typically require lower laser power settings, while harder woods like oak may need higher settings. For example, cutting 3mm plywood might require 60-70% power at a speed of 20-30 mm/s. Always consider the thickness of the wood, as thicker pieces require more power or slower speed for a clean cut.

2. Acrylic

Acrylic is a popular material for engraving and cutting, and it responds well to higher laser power. Thin acrylic sheets (e.g., 3mm) can be cut efficiently with 50-60% power and a moderate speed of 25-30 mm/s. For engraving, lower power (30-40%) ensures a smooth finish without excessive melting. Always consider using cast acrylic for engraving, as it delivers a frostier, more detailed result compared to extruded acrylic.

3. Leather

Leather is highly sensitive to burning, making precise adjustments critical. For cutting natural leather, start with 40-50% power at a slower speed of around 15-20 mm/s to produce clean edges. Engraving leather typically requires less power, around 20-30%, to avoid excessive scorching.

4. Glass

Glass engraving is more about surface marking than deep etching. Using lower power settings, around 15-25%, combined with high-frequency settings (e.g., 5,000 Hz), yields the best results. Slower engraving speeds, such as 10-15 mm/s, help maintain precision and avoid chipping.

5. Metal

CO2 lasers generally cannot cut metals without additional coatings or materials designed for laser processing. For engraving coated metals, start with 20-30% laser power and test small areas to find the ideal balance for clean and precise results without damaging the coating.

6. Fabric

Fabrics, including cotton, polyester, and felt, often require lower power settings to avoid burning. Cutting thin fabric can be done with 10-20% power at faster speeds of 50-80 mm/s to ensure a clean cut without fraying. Engraving fabric may demand even less power to prevent perforation.

What Safety Precautions Should Be Taken When Using a Laser Cutter?

When working with a laser cutter, ensuring safety is paramount to avoid potential hazards. Here are key precautions that should always be followed:

- Wear Proper Protective Gear

Always wear safety goggles specifically rated for the laser wavelength being used. Laser light can cause serious damage to the eyes, even from brief exposure, and ordinary glasses do not provide adequate protection. Additionally, wearing gloves and avoiding loose clothing can prevent accidental injuries.

- Ensure Adequate Ventilation

Laser cutting produces fumes and particulates that can be harmful when inhaled. Install a reliable fume extractor or ventilation system to remove potentially toxic gases, especially when working with materials such as acrylic, PVC, or plywood, which can release dangerous chemicals when burned.

- Avoid Flammable Materials in the Workspace

Keep all flammable materials away from the cutting area. Sparks, overheating, or errors during operation can ignite such materials, resulting in fires. For added safety, always have a fire extinguisher (Class ABC recommended) nearby and ensure that it is easily accessible.

- Inspect the Laser Cutter Regularly

Regular maintenance of the laser cutter is essential to prevent malfunctions that could pose safety risks. Clean the lens, mirrors, and exhaust system frequently to keep the machine functioning optimally. Additionally, before each use, check for any worn parts or loose components that might compromise safety.

- Supervise the Laser Cutter During Operation

Never leave the laser cutter unattended while it is in use. Fires can ignite quickly due to overheating or material combustion. Operating the machine while actively monitoring its process ensures that any issues can be addressed immediately.

- Use Approved Materials Only

Certain materials are unsafe to cut or engrave due to the toxic fumes they produce or their highly flammable nature. Avoid using items like PVC, vinyl, and foam unless their suitability for laser cutting has been verified. Rely on manufacturer guidelines to ensure all materials used are safe for laser processing.

- Understand Emergency Shutdown Procedures

Familiarize yourself with the laser cutter’s emergency stop button and power-off mechanisms. Operators should be trained on how to respond swiftly in case of emergencies, such as equipment failure or fire outbreaks.

Adhering to these safety measures not only protects the operator but also ensures the longevity and efficient performance of the laser cutter. By creating a safe workspace and staying vigilant, you can reduce risks and focus on achieving precise, high-quality outcomes from your projects.

Reference Sources

-

“An Overview Study on the Laser Technology and Applications in the Mechanical and Machine Manufacturing Industry”1:

- Key Findings: This study highlights the versatility of CO2 lasers in cutting, etching, and marking various materials, including metals and non-metals. It emphasizes the precision, high processing speed, and smooth cutting surfaces achievable with CO2 lasers. The paper also discusses the role of lasers in Industry 4.0, showcasing their applications in manufacturing, material handling, and metal processing.

- Methodologies: The study provides an overview of laser technology, including its principles, types (solid, gas, liquid lasers), and applications. It also explains the mechanics of laser cutting, such as the use of high-energy beams and CNC systems for precision.

-

“CO2 Laser Cutting” by John Powell2:

- Key Findings: This book provides a comprehensive guide to CO2 laser cutting, covering both metals and non-metals. It discusses the physical and chemical reactions in the cutting zone, offering practical advice for operators and technical insights for researchers.

- Methodologies: The content is descriptive, focusing on practical applications and troubleshooting, rather than mathematical modeling. It includes safety guidelines and alternative cutting methods.

- Top Co2 Laser Marking Machine Manufacturer and Supplier in China

Frequently Asked Questions (FAQs)

Q: What kinds of materials can a CO2 laser engraver cut or engrave?

A: A CO2 laser engraver is versatile and can cut or engrave a wide variety of materials. Common laser cutting materials include wood, acrylic, paper, leather, and some plastics. However, the laser cutter can cut through these materials with varying degrees of efficiency depending on the power of the laser used.

Q: Are there any materials that should not be cut using a laser cutter?

A: Yes, certain materials should not be cut using a laser cutter. These include PVC, vinyl, and certain types of plastics that can release harmful fumes when burned. Additionally, metal materials generally require a more powerful laser than a typical CO2 laser engraver.

Q: How does the power of the laser affect what the laser cutter and engraver can do?

A: The power of the laser determines the thickness and types of materials that can be cut or engraved. A higher watt CO2 laser can cut through thicker materials and is often used for more demanding cutting projects. In contrast, for lighter materials, a diode laser may be sufficient.

Q: Can CO2 lasers engrave metal materials?

A: Generally, CO2 lasers cannot engrave metals directly unless the metal is coated, such as anodized aluminum. For uncoated metals, a more powerful fiber laser is usually required for engraving.

Q: What are some common uses of a laser cutter and engraver?

A: Laser cutting machines are often used for creating intricate designs in crafts, signage, model making, and custom parts production. They’re also popular in industries such as fashion for cutting fabric and in technology for creating prototypes.

Q: How does a laser engraving machine differ from a cutting machine?

A: A laser engraving machine is primarily used to etch designs onto surfaces without cutting through the material, while a cutting machine is designed to slice through materials. However, many modern laser machines, like the Aeon Laser, can perform both functions.

Q: What are the advantages of using a CO2 laser cutting machine over other types of laser technology?

A: CO2 laser cutting machines are generally favored for their ability to cut a wide range of non-metal materials with high precision and speed. They are also more cost-effective for non-metal applications compared to fiber lasers, which are better suited for cutting metals.

Q: Can diode laser engravers replace CO2 lasers for cutting projects?

A: Diode laser engravers can be used for certain cutting projects, especially those involving thin or less dense materials, but they lack the power and versatility of CO2 lasers for more demanding tasks. The choice of laser depends on the specific requirements of the project.

Q: What safety precautions should be taken when using a laser machine today?

A: When using a laser machine, it is important to wear appropriate protective eyewear, ensure proper ventilation to avoid inhaling harmful fumes, and follow all manufacturer guidelines to prevent accidents. Regular maintenance of the machine also ensures safe and efficient operation.