The 3-axis CNC machines allow for versatility in manufacturing, and they truly operate as workhorses in the industry. However, what exactly can these machines accomplish? Their capabilities go far beyond what is usually expected of CNC machines. These foundational CNC tools can carve detailed designs on wood and even machine strong parts from metal. This blog aims to help you grasp the core functions and astonishing adaptability of a 3-axis CNC machine. Whether you are an experienced machinist or a curious newcomer wanting to learn more, you will understand the key operations, industries served, and transformational potential these machines have on your projects. So, prepare yourself to take full advantage of this indispensable piece of equipment!

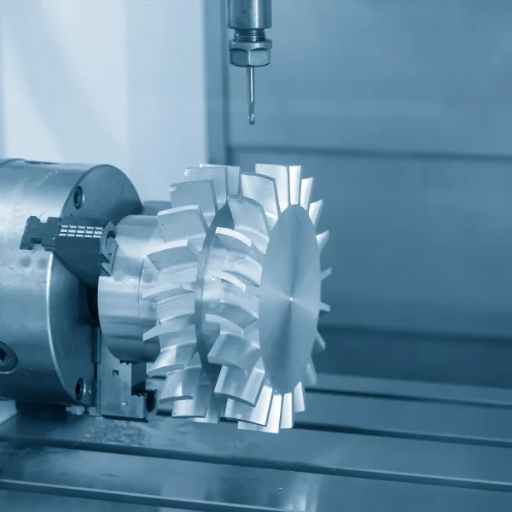

How Does a 3-Axis CNC Machine Work?

A 3-axis CNC machine operates by positioning a cutting tool or workpiece at the three primary axes of movement: X (left to right), Y (up and down), and Z (front to back). The machine cuts, drills, and shapes materials into forms as the computer terminal sends orders and runs programs controlling its movement. These machines are widely used for manufacturing planar parts and are suitable for milling, drilling, and engraving operations.

Factors Influencing the Performance of 3-Axis CNC Machine

Performance and accuracy of a 3-axis CNC machine are impacted by several distinct characteristics. One of the most important is spindle speed since higher speeds allow smoother cuts. Balancing speed with material type and tool life is critical, since overheating can be caused by too much speed. In addition, tool wear has a major effect on cutting quality, so tools must be replaced frequently to ensure accuracy in machining processes.

Another area where output value is determined is cutting feed rates. Softer materials, for example, may require more aggressive feed rates compared to harder materials such as steel. With adaptive feed rate technologies, modern 3-axis CNC machines can change machining speeds in real time, which helps enhance efficiency.

Recent developments in CAD-CAM integrated CNC machines enable them to utilize software capable of reading tolerances as minute as ±0.0001 inches, demonstrating the engineering capabilities axes CNC machines have come. In addition, integrated CAD/CAM significantly augments workflow within manufacturing environments by reducing production setup times by as much as 50%.

Additionally, to achieve optimal results and ensure operational efficiency when utilizing a 3-axis CNC machine, the machining material directly influences the selection of the cutting tools and the machining parameters greatly. Softer materials, such as plastics, necessitate less power and specialized tool coatings to prevent deformation, while tougher materials require advanced carbide or diamond tools designed to endure extensive stress and wear.

Maximizing CNC Machine Efficiency Using Cutting Tools

Efficient and precise machining processes are heavily influenced by the choice of the cutting tool and its corresponding cutting parameters. The invention of new cutting tool materials, including coated carbides, ceramics, and polycrystalline diamonds, has allowed for unprecedented levels of performance because of enhanced durability and heat resistance. Newer coating techniques like titanium nitride (TiN) or aluminum titanium nitride (AlTiN) are known to improve productivity and reduce operating costs by increasing tool life by up to 50% while also increasing cutting and feed rates.

We must not forget the consideration of cutting parameters and the workpiece material with each other. For example, turning hardened steel demands tools with some of the most wear resistant materials, such as CBN (Cubic Boron Nitride) inserts, meant for extreme pressure and temperature environments. Studies show that using proper Tool Material and geometry can cut machining time by as high as 30%. This is a great decrease in production cost.

Furthermore, computer technology has greatly advanced, and it is now central in the determination of many cutting parameters. The cutting force, tool wear, and even surface finish can be guaranteed within microns of tolerances by using high-speed machining simulations. Modern CNC machine tool manufacturers can achieve remarkable precision and economical efficiency in CNC machining with advanced calibrated tools and checked uttering.

Spindle Dynamics and Z-Axis Optimization

The Z axis and spindle are the main determinants of precision and productivity of CNC machines. The spindle must be able to hold and rotate the cutting tools as they are used to dictate the CNC machine’s cutting performance and quality of surface finish. As an example, some advanced spindles can achieve rotational speed greater than 60,000 RPM, permitting the accurate high speed machining of highly complex parts. With the addition of dynamic balancing systems to the spindle, these vibrations are further reduced resulting in longer tool life and smoother operations.

In contrast, the Z-axis which control vertical movements contributes to the accuracy of depth. Linear encoders and sophisticated servo motors are utilized by modern CNC systems, providing consistent positioning within sub-micrometer ranges even for complex geometric parts, and consistency is maintained across complex shaped parts. Research indicates that closed-loop control systems for Z-axis will improve the repeatability of the part by up to 40% making the yield more efficient and material waste minimal.

Through the advancement of these innovations, healthcare, automotive, and aerospace professionals are availed with parts that are consistently high in quality. These advancements are further signs toward an effective and productive CNC machining evolution.

What Are the Machining Capabilities of a 3-Axis CNC Machine?

The operations of drilling, milling, and cutting can easily be achieved on a workpiece, since a 3-axis CNC machine can move along three linear axes-X, Y and Z. It is mostly used for producing flat geometries, as well as simple shapes. The parts being machined using this machine do not need complex detailing or multi-sided cutting and thus, it is preferred for less complicated parts.

Common machining processes and manufacturing process

With a 3-axis CNC milling machine, the most common processes include milling, drilling, and tapping. These processes are extremely helpful for creating accurate holes, slots, and even flat surfaces. A 3-axis CNC machine can easily accomplish many simple tasks that require movements along the X, Y, and Z axes. Because of this, the machine can be relied on to produce parts accurately and quickly. This makes the 3-axis CNC machine essential in a variety of businesses.

Progress 3D Machining for Challenging Geometric Shapes

The introduction of 3-axis, 4-axis, and 5-axis CNC machining technologies have transformed fully automated part production. Modern 3D machining enables elaborate curves or complex undercuts to be part features on components which could not easily be done using traditional methods. A recent survey indicates that over 40% of manufacturers multi-axis CNC systems to cater custom orders surge in aerospace, automotive, and medical devices sectors.

Key improvements include advancements in design software with simulation tools that allow for effective design verification before actual production, thus saving resources in terms of materials and time. Productivity has also been greatly improved by high-speed machining technology which incorporates faster spindle rotation and better cooling systems. Studies indicate that material removal rates are higher by 300% with high-speed machining over non high-speed methods , depending on the Material being processed. Innovative technologies not only improve the ability to satisfy complex design needs, but also improves sustainable practices in manufacturing by reducing waste and energy use.

Benefits of Subtractive Manufacturing Methods

Within my experiences, these techniques did very well when creating straightforward or flat components due to their high accuracy and precision. With the addition of advanced 3D machining techniques, the methods are capable of producing complex shapes as well.

What Are the Types of CNC Machines and How Do They Compare?

- Milling Machines – This type of machine cuts and shapes objects using a rotating cutting tool which acts on a stationary work piece. It is suitable for creating flat surfaces, slots, and complicated outline surfaces.

- Lathes – Lathes are machines that rotates the work piece while a stationary cutting tool removes material from its surface. This is used for cylindrical parts like shafts and screws.

- Laser Cutters – These machines use lasers to cut through or engrave materials in a very detailed and precise way. They are commonly used in sectors that need sophisticated designs and cuts to be done with precision.

- Plasma Cutters – They cut by means of ionized gas known as plasma to pass through electrically conductive materials. Plasma cutters are best used in cases involving metals like steel or aluminum.

- 3D Printers with CNC Functionality – It is now possible to have both additive/applique and subtractive processes done for intricate pieces from one machine.

Difference Between 3-Axis and 5-Axis CNC Machines

3-axis and 5-axis CNC machines differ primarily in the range of motion the cutting tool or the workpiece can achieve. One of the most prominent moves of a 3-axis CNC machine is cutting in 3 directions with X, Y, and Z coordinates. This machine configuration can only do so much. It only aids in machining simple components, which include drilling, milling, or slotting.

While a 5-axis CNC machine can perform much more. Along with the X, Y, and Z coordinates, it also utilizes the A and B axes for rotational movements which allows the needed workpieces to tilt during cutting. Unlike the 3-axis counterpart, this machine is designed to help in shaping complex structures that need precision such as turbine blades or medical implants. सब्ब This feature is extremely helpful as it lowers the amount of repositioning needed on a workpiece.

In recent developments, adoption of 5-axis CNC machines across the globe is increasing because of their efficiency and precision. As per the industrial report, the entire market for CNC machines is estimated to expand and witness a CAGR of 5.5% till 2030, due to the growing needs of the automotive, aerospace, and healthcare industries. This is indicative of the trend where 5-axis machines are made important as manufacturers focus on increasing output and decreasing material waste.

Market Intelligence and Progress through the Prism of CNC Innovations

As Precision Technologies integrate newer methods within the production lines, the CNC industry keeps progressing. One of the new innovations in this sector is the use of hybrid CNC machines, which are a combination of additive and traditional subtractive CNC. With this, complex geometries can be manufactured in a much more efficient manner which simultaneously reduces production costs and time.

As recent market reports suggest, the adoption of 5-axis CNC machines is likely to increase greatly, with Asia-Pacific at the forefront owing to the pace of industrial development in the region. In the automotive industry, for instance, CNC technology is being used for the manufacturing of weight-efficient parts in compliance with modern emission regulations. Equally, the aerospace sector is making good use of CNC machines for the production of turbine blades, engine casings, and other highly sophisticated and intricate structural components.

A report from MarketsandMarkets suggests that the CNC machine market would grow to $132 billion by 2030. This growth is anticipated due to the automation of processes and the introduction of IoT technologies. Automation increases efficiency and reduces production costs. IoT-integrated smart CNC systems allow manufacturers to identify inefficiencies and reduce idle time.

Moreover, CNC machines are in demand for the production of other components because the manufacturers in healthcare require precise medical equipment and customized implants. The adaptability and precision of CNC machines make them essential tools across different sectors which have significant implications for the future of manufacturing.

Common Workpieces for Each Kind of CNC Machines

CNC machines serve different industries and are defined by the kinds of workpieces they create. For example, parts such as molds and prototypes along with engine components are produced by CNC milling machines. Current industry research indicates that nearly 40% of CNC machine utilization worldwide is attributed to CNC milling operations and their wide range of applications.

CNC turning is almost exclusively used for the production of bushings, shafts and various other fittings. These components are crucial elements in the automotive and aerospace industries and are used in various machines and engines. Furthermore, by 2021, CNC turning machines held nearly 25% of the market share for CNC machines, underlining the demand for these parts.

CNC machines that are used for cutting and engraving metals, wood and plastics are classified as CNC laser cutting machines. These systems are exceptionally precise, with modern systems achieving accuracy margins as tight as 0.001 inches. Value-added operations in industries such as electronic component manufacturing and jewelry are now done faster and at a higher quality because of CNC laser solutions.

Developments in CNC technology have also increased their utilization in specialized fields. For instance, the aerospace and healthcare sectors are now benefitting from 3D printing hybrid CNC machines which create extremely complex prototypes. Such systems are capable of both additive and subtractive manufacturing, allowing for intricate designs that were once impossible. One estimate suggests hybrid systems like these have grown in popularity by over 20% in the last three years.

These innovations prove the wide ranging capabilities of CNC machines in contemporary manufacturing and how they further aid industrial expansion.

When Should You Use a 3-Axis CNC Milling Machine?

The 3-axis CNC milling machine works best for projects that involve machining simple and flat surfaces or parts with basic geometric shapes. It does the most effective work of drilling, cutting, or shaping materials where the tool only has to move in the X, Y, and Z coordinates. These machines are dependable in the production of parts with accurate measurements and are useful in automotive and aerospace industries and furniture manufacturing where detailed craftsmanship is not needed.

Technological Improvements on Applications and CNC Efficiency

Proficient modern machining technologies have evolved recently with creative features designed to improve accuracy and precision. For instance, Computer Numerical Control (CNC) systems now come with modern software features that increase the precision of controlling the movements of the X, Y, and Z axes. Industry research also states that CNC machines equipped with high-speed spindles are capable of attaining cutting speeds as high as 30,000 RPM, significantly faster than average production speed for both simple and complex parts. Furthermore, the manufacturing processes of multi-purpose CNC machines that integrate milling, drilling, and cutting are highly efficient and require less time and manual work.

Another notable advent is high-performance tooling materials such as carbide and polycrystalline diamond (PCD), which improve durability, resistance during machining and overall wear. These tools have been reported in studies to last as much as 25 times longer than traditional cutting tools. This extends overhead costs and aids sustainability in the automotive and aerospace industries.

Also, automated systems alongside real-time monitoring have now made predictive maintenance possible, thus reducing downtime by 25%, according to a McKinsey report. Innovations like these set the stage for increased efficiency and lower costs in machining processes used in multiple industries.

Enhanced Efficiency Through Single Setup Machining

“Done-in-one” or single setup machining has greatly improved manufacturing workflows by decreasing manual tasks and increasing operating efficiency. Single setup machining consolidates numerous machining processes into one setup which optimizes production and reduces both the setup time and errors. A 2023 Manufacturing Global survey states that industries that have adopted single setup machining have reduced their production lead times by up to 40%, thus improving costs and output capacity.

In addition, multifunction CNC machines have contributed greatly to single setup machining. These machines allow high-precision operations such as turning, milling, and drilling to be done in one piece without having to move them to different machines. TechInsights’ research shows manufacturing plants with 5-axis CNC machines performing single setup operations have reported a 30 percent improvement in achieving the correct measurements relative to traditional methods.

Moreover, single setup machining allows more accurate repeatable in pre-defined workouts, which is great for businesses like aerospace and medical due to requiring high-performance, safety-critical parts. Other industry data cites reduced material scrap rates by 20 percent due to reduction in errors during handling. All of this evidence means single setup machining integrated into conventional systems will enhance streamlined manufacturing methods.

Limitations and Challenges of Using a 3-Axis Machine

3-axis machines, despite being dependable, have some restrictions which impact their use in more sophisticated manufacturing technology and processes, making them useful for only a limited range of applications. These machines are primarily limited by their inability to perform multi-directional machining and four or more axes of movement for complex shape machining. Machine 3 consists of one rotating and two linear translational movements, which gives it low precision for intricately shaped and deep undercuts. These features often require more advanced equipment, such as 5-axis machines, for undercut portions in intricate design and deep cavity filling.

Besides this, production efficiency is hindered further because of increased setup times. With a 3-axis configuration, the part is mounted to the fixture and 3D line geometric contours are executed with a variety of tools spacers. Multiple setups are aligned to achieve the same geometry which prolongs the production cycle, which contributes to increased lead times and total costs. In a 2023 survey on the state of the art technologies in the field of machining, 35% of all respondents stated that traditional 3-axis systems set up costs and setup errors as a primary disadvantage.

Another equally important challenge is the selective use of deviceable materials. The use of titanium alloy and nickel based super-alloys in medicine and aerospace components add value, but relaxing them and cutting them add troubles due to being very hard and require efficient removal of heat and coolant which these devices are not capable of applying. Industry sources report these materials tend to have a lower machining speeds 3-axis systems and higher Incidence of tool wear digs and cuts compared to systems.

Finally, as manufacturing technologies progress toward automation and smart factories, 3-axis machines, like all other machines, also lack integration features present in more sophisticated systems. The inability to interface with real-time monitoring systems or AI optimization systems can limit efficiency in highly automated environments. With this in mind, it becomes critical for manufacturers to balance the potential benefits against the opportunity costs of implementing 3-axis machines into their workflows.

How to Optimize Using a 3-Axis CNC?

- Setting Up Toolpath: Make sure to set toolpaths with the appropriate settings to achieve the highest efficiency during the machining process. Using the right cutting strategies, such as adaptive clearing, can capture significant value.

- Cutting Tool: Make sure that the cutting tools are well maintained—they should be sharp, strong, and suitable for the material. Performance tools have less wear and improve accuracy.

- Routine Checks: Keep the machine in order by routinely checking alignment, lubrication, and tools. Preventative maintenance allows consistent operation with virtually no downtime.

- Operator Training: Fully trained operators can fully utilize the capabilities of the machine, detect lapses in productivity, and employ the most effective methods to complete machining operations.

Identifying Common Issues in 3-Axis CNC Milling and Solutions

- Selecting the Right Materials: Selecting an inappropriate material may lead to excessive wear and degrade the quality of work produced. Use materials that are of a higher standard and those that align with the capabilities of the machine.

- Tool Inspections: Regularly scheduled tool inspection will curtail unplanned stops due to breakage and ancillary processes such as precision machining at scheduled service times.

- Programming Mistakes: Checking programs is crucial, including running through CNC check simulations to diagnose and rectify prior to cuts being made.

- Vibration Control: Ensure that the machine is well supported and that the rotating unit is running at favorable speeds to eliminate vibrations.

Reasons Persuasive Towards Optimized Cutting Tool Utilization

One of the areas that can drastically bump up cutting tool effectiveness is the material, working conditions, and geometry of the tool. Recently, some tool coatings have been receiving attention due to their measurable performance improvements. A good example of this is the TiAlN coating which has been reported to increase the tool life by as much as 50 percent when used in high speed machining (HSM) because of heat and friction benefits.

As previously highlighted, proper selection of cutting speeds and feed rates relative to the machined material have also been studied. Softer materials, like aluminum, typically require higher cutting speeds, whereas stainless steel, a harder material, requires slower cutting speeds to avoid excessive tool wear.

Advancements in sensor technology also make it possible to exploit real-time information in CNC machines. Sensors can track amounts of temperature, vibration, and force the machine is operating with, thus enabling operator oversight which is sometimes more hands-on during the operation. Such adaptive approaches have proven to enhance operational efficiency by 20 percent in some industry trials.

By applying these strategies, the overall operational cost, production downtime along with precise manufacturing attributes.

How to Maintain CNC Machines for A Longer Life

Consistency and proper maintenance of CNC machines is crucial for achieving their maximum lifespan as well as ensuring their optimum performance. Cleaning as well as calibrating machine parts such as spindles, axes, and cutting tools is essential. Also, a routinely scheduled maintenance increases machine reliability by reducing failures.

Preventive maintenance, especially when combined with predictive instruments such as vibration analytics or thermal imaging, can mitigate larger issues from arising. Industry reports demonstrated that $260,000 is spent per hour from unplanned downtime, further portraying the significance of injury and defect prevention. For instance, monitoring vibrational spindles which indicates bearing wear can ensure timely replacements, therefore preventing unforeseen damage.

Additionally, machine alignment alongside periodic recalibration preserves precision. Moreover, coolant fluid solvents increase equipment effectiveness whilst combating friction-induced damage caused by overheating. Preventive maintenance can drastically enhance a manufacturer’s annual savings by 30%-40% due to reduced repair expenses.

Comprehensive monitoring coupled with advanced defection technologies allows maintenance goals to be achieved, therefore heightening operational productivity.

Reference sources

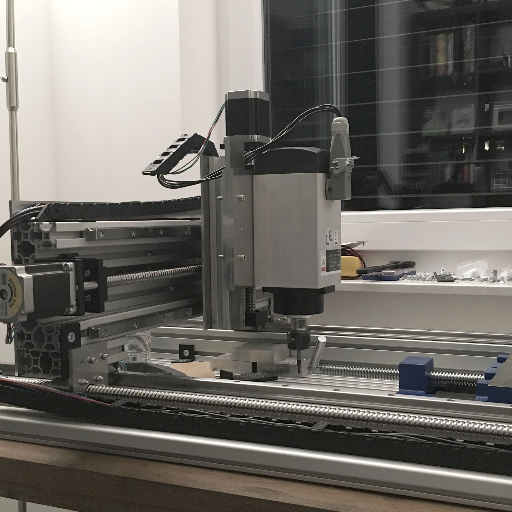

- Design and Fabrication of a PC-Based 3 Axis CNC Milling Machine3:

- Key Findings: This study focused on developing a cost-effective, small-scale 3-axis CNC milling machine. It demonstrated the machine’s ability to cut various geometric shapes with reasonable accuracy, making it suitable for small facilities and hobbyists. The machine uses off-the-shelf components to reduce costs and maintenance.

- Methodology: The machine was designed with a vertical frame structure using aluminum extrusion profiles. It employed Mach4 software for control and tested its capabilities by machining Ultra High Molecular Weight Polyethylene (UHMW-PE) samples. The study validated the machine’s efficiency and stability through machining tests.

- Top Mini CNC Router Manufacturer And Supplier In China

Frequently Asked Questions (FAQs)

Q: What is a 3-axis CNC machine?

A: A 3-axis CNC machine is a type of machine that moves with five degrees of freedom along three straight lines: X, Y, and Z. These are the standard axes for CNC machining, allowing for operations to be performed on flat surfaces.

Q: What can a 3-axis CNC machine do?

A: A 3-axis CNC machine can perform a variety of operational functions such as drilling, milling, and cutting. It is very efficient for designing and sculpting on two-dimensional objects by guiding the machine tool to the workpiece along three axes.

Q: How does 3-axis milling work?

A: In 3-axis milling, the cutting tool is moved in the three orthogonal coordinates (X, Y, and Z) to remove material and form the desired geometry. This is the framework of standard 3-axis CNC milling and forms the basis of many simple machining processes.

Q: What are the limitations of traditional 3-axis CNC machines?

A: The other limitation of a 3-axis CNC machine is that it can only work in one region of space at a time and need to be repositioned to work on a different part of the workpiece which more sides could be worked on without a change in position. They readily work in non-complex shapes which need multi directional workpiece alignment but not undercuts.

Q: What are the differences between a 3-axis CNC machine and a 5-axis machine?

A: The main distinction from a 3-axis CNC machine to a 5-axis machine is the number of axes. A 5-axis machine has two more rotating sections which allows for much more intricate and precise machining operations to be done without the need of turning the workpiece.

Q: What are the advantages 3-axis milling machines have?

A: 3-axis milling machines have advantages because of their simplicity and low cost. They are great for computer numerical control tasks. They are straightforward, simpler to program, and easier to operate.

Q: Can high accuracy and precision of 3-axis CNC machining be achieved?

A: Yes, precision and accuracy with 3-axis CNC machining can be achieved, especially for parts without complicated geometries. The precision however, depends on the machine used and the quality of the tool utilized.

Q: What additional advantages does 4-axis CNC machining have over 3-axis?

A: 4-axis CNC machining allows the user to rotate the workpiece which permits machining on different sides without having to do manual resetting which saves time and effort.

Q: What kinds of machining are utilized for creating complex parts?

A: Multi-axis machining, like 4-axis and 5-axis CNC milling, is frequently employed for complex parts. These types of machines can perform multi-faceted, intricate designs and need less setup because they can reach multiple sides of the part.