Pulsed laser technology is transforming industry worldwide with its unmatched precision, speed, and efficiency. From micro-machining of sensitive materials to advanced procedures in medicine and intricate engraving on hard surfaces, this innovative technology excels in many ways. But what is the charm of the pulsed lasers? What is the difference between them and their continuous wave counterparts, and why are they gaining preference in so many domains? This article analyzes the advantages of the pulsed laser technology focusing on its versatility, applications in industry, and innovation. Get to learn the secrets of this incredible tool and the future of manufacturing, healthcare, and other industries.

What is a pulse laser?

As the name suggests, a pulsed laser emits light in the form of short bursts, or pulses, rather than a continuous beam of light. As a result of the laser’s configuration, these pulses may be extremely brief, and can last anywhere from milliseconds to femtoseconds. The ability of pulsed lasers to deliver extreme energy levels in concentrated bursts makes them ideal for precision applications like material processing, medical procedures, and scientific research.

What is the working principle of a pulse laser?

The operation of a pulsed laser is the emission of light in the form of concentrated bursts, which is done through energy storage, stimulation, and emission. The system has an active laser medium, which can be a crystal, glass or gas, an optical cavity with mirrors, and an energizing source that excites the medium. Q-switching, pulse formaing, or mode-locking is what gives rise to the pulsing mechanism. These techniques control the emitted pulses in terms of frequency and intensity.

Q-switching permits energy storage within the laser medium before emission in a pulse of high energy while mode locking creates a train of ultra-short pulses which are evenly spaced in time. In both approaches, the method employs a pulsed laser that results in achieving a peak power level that is significantly greater than that of a continuous-wave laser. As an example, femtosecond pulsed lasers can achieve peak powers on the order of terawatts, but only for a short duration, which improves the accuracy and reduces the heating effects on materials.

Factors Affecting Speed of Laser Marking

Marking speed of the laser is subject to change due to a number of different factors such as the power of the laser, marking method, properties of the material, and the wavelength used. In general, higher power means faster marking speed since more energy is provided to the material in a given time. However, the type of material also plays a very important role in the marking process, for example, metals with high thermal conductivity such as aluminum tend to be more difficult to mark and require more energy compared to plastics or ceramics.

Modern engineering developments have reported that marking speed is improved by optimized scanning algorithms as well as galvo laser based devices. These systems in some industrial applications can reach spectacular speeds of 7,000 mm/s, but this is highly dependent on the resolution and level of detail demanded. Moreover, pulse frequency is of utmost importance since it determines whether the material in question burns or not without exceeding the desired limit.

Continuing developments in marking lasers, including fiber lasers and ultrafast pulsed lasers, still improve the efficiency of marking process. Nowadays, most industries are equipped with fiber lasers because of their great beam quality and low maintenance requirements. Their efficiency is astonishing, between 30% and 50%, thus confirming their economical, ecologically, and efficient nature for high speed marking processes.

What is the structure of a pulse laser?

The primary components of a pulse laser are a laser gain medium which increases the light, a pump source that supplies energy to the medium, and a resonator together with mirrors that feedback light to amplify the light in the system. There is a modulator that governs the timing and duration of the pulses which helps in accurate pulse generation.

What are the key advantages of pulsed laser?

Pulsed lasers are beneficial for tasks like cutting, engraving, or material processing that require precision and high control. They achieve this through the marked minimization of heat-affected zones, enabling work on sensitive components with reduced damage. Because energy is delivered in short, intense bursts, even challenging materials can be processed cleanly and efficiently.

What is the effect of pulse duration on material processing?

The range of duration of the pulse is one of the most influential parameters determining the efficiency and quality of work done on the material. Imposing energy in ultrafast times (picosecond or femtosecond ranges) makes it possible to deliver the energy so fast that thermal diffusion is almost nonexistent. This extreme precision needed in laser ablation for accomplishing the best results is most commonly used in medical device manufacturing and microelectronics, which is referred to as no-thermal impact.

For example, research indicates that femtosecond lasers perform cutting and detailing processes on polymers and silicon profoundly clear and intricate, frequently requiring little to no post-processing work. Conversely, pulse durations in the nanosecond range are preferable for processes like cutting or welding at an industrial scale, where a somewhat larger heat-affected zone is more tolerable. In a 2019 report, the Laser Institute of America reported that marked metal with nanosecond pulsed lasers had over 30% improved throughput compared to using continuous wave lasers, all while precision was maintained which was deemed reasonable.

It is clear that optimizing pulse duration with regard to laser application and material properties greatly improves productivity and quality in laser processes. Often, the choice of pulse duration is dictated by the material type, surface geometry, and the specific goals to be achieved.

The Advantages of Using High Energy Pulsed Lasers in Industrial Applications

High energy pulsed lasers has a variety of benefits in industrial applications, particularly when precision and perfection are paramount. These lasers provide short, intense bursts of energy that can be directed towards a material with minimum damage to the adjacent regions. For example, in material marking operations, marked engravings on metals and plastics (and other materials) are formed with intricate designs by pulsed lasers due to their vaporization abilities.

Pulsed laser marked engravings on metals and plastics and other materials fufilled highly demanding expectations using the latest advanced machinery. Recent data shed light on the efficacy of high energy lasers, which is in Pulsed laser engraving studies results showed that using pulsed lasers, processing time was reduced by 40% (or more) in engraving tasks compared to the use of continuous wave lasers, which are instantaneous devices). This is while maintaining superior quality to serve the ever-increasing demand. Beyond this, microelectronics or the manufacturing of medical devices which are delicate require cutting the components using lasers with extreme control, and because of this, the thermal distortion effect already caused is advantageously minimized.

Moreover, these lasers are energy-efficient because they consume energy only when engaging in short, concentrated bursts, rather than maintaining a continuous operation. This feature is particularly pertinent to the fostering of environmental sustainability and the reduction of expenditure in industrial environments. Businesses incorporating novel advanced technologies employing pulsed lasers have documented noticeable gains in quality and increases in production throughput in many industries.

Pulsed lasers with high energy output capabilities underscored the importance of speed and accuracy alongside cost efficiency, solidifying their place as invaluable assets to modern manufacturing sectors.

Understanding Peak Power in the Context of Pulsed Lasers

Peak power serves as an important indicator in the field of pulsed laser technology because of its impacts towards the efficiency of interaction with materials and processing of those materials. It defines potential carving surface’s spatial resolution, that is how much details with which an object is to be captured in the photograph or sketch or regardless of long it takes to get the photograph taken–along with its width contraction phase. High peak power, crucial for the purpose of clean and accurate material removal, enables applications including but not limited to: surface engraving, cutting, and shaping.

For instance, in laser micromachining, the peak power of a laser affects the edge quality and material removal rate, especially for metals and ceramics. High peak power lasers do more accurate work at higher speeds, hence improving productivity. Recent studies show that increasing the peak power by 20% in certain industrial laser systems increased the processing speed by 30% while keeping the product quality excellent.

Moreover, peak power is also important in minimizing the heat-affected zone (HAZ). Material can be worked on without undue thermal impact to the surrounding areas when energy is directed in the form of high intensity bursts over short time intervals. This feature is important for soft and heat sensitive materials in the electronics and medical device manufacturing industries.

The combination of increased optimization of peak power, control systems, and beam modulation continue to enhance the innovation capability of pulsed lasers, enabling operators from various sectors to enjoy the benefits of speed and precision at low operational costs.

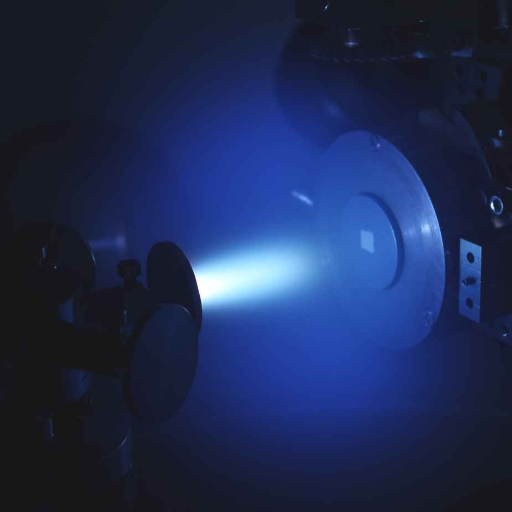

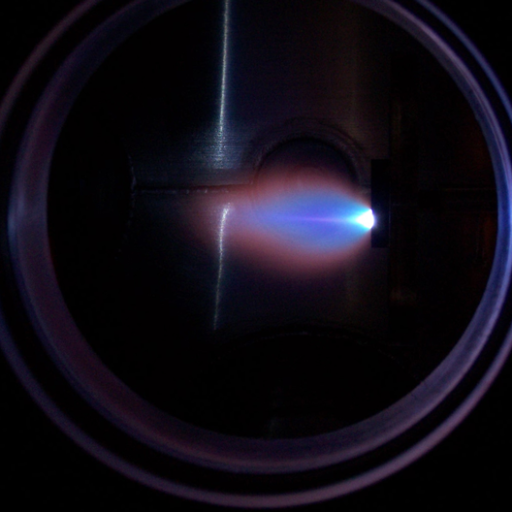

How does pulsed laser deposition work?

Pulsed laser deposition employs the use of high-energy lasers targeted at a specific starting material to erode, evocatively termed as “vaporized,” the material out of a “target.” The vaporized material condenses back onto the substrate in a thin film structure, referred to as “plasma plume.” The process occurs within a highly controlled environment, usually within a vacuum or nitrogen filled chamber, to guarantee perfect precision in the material properties and film growth.

Allowable materials for pulsed laser deposition

As a broad and general definition, PLD possesses a range of complex and sophisticated techniques yielding unparalleled diversity in the types of materials that are plausible for deposition. This includes but is not limited to complex oxides, nitrides, semiconductors, superconductors, and even polymers. Some of the more popularly used materials include titanium dioxide (TiO₂), zinc oxide (ZnO), and yttrium barium copper oxide (YBCO) due to their wide-reaching uses in thin film transistors, energetics, and optoelectronics.

The latest improvements show that PLD can manage complex materials with accuracy. The technique guarantees stoichiometric transfer from the target to the substrate without changing the material’s structure. PLD has become a mainstay in the fabrication of hightemperature superconductor thin films, with critical current densities of YBCO films surpassing 10⁶ A/cm² at liquid nitrogen temperature, for example. Moreover, PLD makes it possible to produce highly uniform thin films required for electronic components, chemical sensors, and protective coatings.

Reactive gases, laser parameters, and the dynamics of plasma plume all provide the means to customize thin film properties, thus, tailoring PLD for the fabrication of high performance materials. This versatility assures continued use in advanced materials research.

What is the process of pulsed laser deposition?

- Target Treatment: The process commences with the selection of a target material whose composition suits the thin film to be deposited. A target is usually provided in the form of a dense bulk pellet for easy and uniform ablation.Laser Ablation: The material in question is targeted using a high-powered pulsed laser, typically an Nd:YAG laser or excimer laser. The laser energy flux inflicts localized heating, melting, and vaporization of the target surface. Subsequently, a plasma plume is formed. Different studies have shown that optimal ranges of laser fluence varies from 1-10 J/cm² depending on the material used and the application.

- Plasma Plume Expansion: Due to the temperature and kinetic energy gradients, the plasma plume containing a plethora of atoms, ions, and molecules from the target material expands rapidly towards the substrate. The kind of gas, whether vacuum or controlled, significantly influences the dynamics of the plume and the outcomes of deposition. For example, oxygen is a good example if oxide films are considered. More recent research recommends using pressures ranging between 10⁻² and 10⁻³ Torr for optimal control of the thin film’s crystallinity.

- Thin Film Growth: The reactive species in the plasma plume undergo a reaction and condense to deposit on the substrate. Moreover, factors such as rate of deposition, temperature of the substrate, and gas composition in the environmental chamber have crucial impact on the structure, adhesion, and morphology of the film. For instance, substrate temperatures of 500-800°C have shown to increase complex oxide films’ crystalline quality.

- Post-Deposition Annealing (Optional): For specific purposes, the film may undergo post-deposition annealing to refine its structural and functional attributes. Research conducted in 2023 indicated that 800°C oxygen annealing enhanced the ferroelectric characteristics of BaTiO₃ thin films by 20%.

- Characterization: Ultimately, the thin film is characterized by its crystallinity, surface uniformity, and thickness using X-ray diffraction (XRD), atomic force microscopy (AFM), or Raman spectroscopy. Using state-of-the-art PLD setups, films as thin as 10 nm and high uniformity can now be achieved.

Control over these processes and parameters can create tailored and reproducible thin films for use in electronics, photonics, and energy storage. Further refinement in precision and flexibility of PLD processes has been provided with recent advancements in laser technologies, deposition chambers, and in-situ monitoring.

Positives of Using Pulsed Laser Deposition (PLD)

As with any laser process, pulsed laser deposition offers distinct advantages that make it a preferred method of thin film synthesis in both industry and research. The most pronounced advantage of PLD is its capacity to maintain the stoichiometry of the target material. This is extremely important in areas of research like superconductors, multiferroics, and semiconductors because the thin films deposited must have the same chemical constituents as the source material.

Moreover, the processes associated with PLD allow for control of the film’s thickness down to atomic dimensions. Control knobs such as pulse duration, energy density, and repetition rate permit the deposition of ultra-thin films with nanoscale precision. This has opened new frontiers in the fabrication of engineered materials aimed at sophisticated applications like quantum computing, optoelectronic devices, and advanced sensor systems.

The appeal of PLD has been enhanced even further by the latest developments in technology. One example includes the use of Reflection High Energy Electron Diffraction (RHEED) and Spectroscopic Ellipsometry that allow for real time monitoring of film growth. This function aids in optimizing the process and allows for immediate problem solving during deposition. In addition, advanced deposition chambers have the capability to control the complexity of the atmosphere, thus creating films under engineered conditions like high vacuum, or specific gas mixtures.

Recent studies show that PLD is relatively efficient. For instance, PLD produced films have been shown to have better epitaxial quality and uniformity than other techniques such as chemical vapor deposition (CVD) or sputtering. Also, the use of high power femtosecond and picosecond lasers in advanced PLD setups increase the deposition rate while maintaining quality, which meets the industry demands for thin film production in photovoltaics and microelectronics.

PLD’s ability to work with a variety of materials such as oxides, nitrides, and metals further proves its versatility in material engineering. It allows for the integration of multi-layer and composite structures which presents new opportunities for the development and design of high end devices.

What are the optical properties of a pulsed laser?

Pulsed lasers are distinguished by their high peak power, short pulse duration, and accurate energy delivery which are accompanied by unique optical properties. It is due to these properties that the lasers are capable achieving high spatial resolution while inflicting minimal thermal damage or impact to the target materials. Also, these types of lasers are suitable for a wide range of applications including material processing, and medical techniques due to the adaptability with the wavelength tunability.

The Effect of Pulse Duration on the Quality of a Laser Beam

One of the most important features in a different application of a laser beam is the precision of the pulse width for reproducible results. A determining feature is its distribution in regard of energy, the interaction with the material, and the heat changes created. Lower pulse widths increase peak power, making it easier to accomplish work without overheating the workpiece. This feature is important in tasks such as micro-machining and engraving delicate materials. An example is the use of femtosecond lasers which have pulse widths of less than a picosecond which translates to minimal thermal damage.

The other side of the coin is that longer pulse widths distribute energy over a longer time frame which creates greater thermal interaction. This may be favorable for some processes such as cutting thicker materials where the laser needs to further penetrate the material. Research proves that using nanosecond pulsed lasers on metals achieves the most optimal energy efficiency balanced with removal rates of materials at average beam quality (M2 factor) enduring high at most industrial applications.

Recent studies suggest appropriate pulse width choice is crucial to the efficiency of the process. For example, in laser micro-drilling more precise machining was achieved when pulse width was decreased from 100 ns to 10 ns due to less thermal diffusion into surrounding material which further resulted in an increase in thermally induced structural damage (ablation). In spectroscopy, as well as other fields, shortening pulse width increases temporal resolution and enhances the signal-to-noise ratio.

In summary, adapting pulse width to the needs of the process gets better laser output quality while lowering primary damage to the material and energy waste, proving the significance of modern laser technologies.

The Importance of Relation of Laser Wavelength for Pulsed Lasers

The laser’s wavelength is very important for the various pulsed laser systems because of how such lasers interact with different materials. Every materials has distinct set of characteristics called optical properties, which, along with absorption coefficients, define how the specific material absorbs the laser energy at certain specific wavelength. For example, metals like aluminum or gold reflect strongly at certain wavelengths which makes it necessary to finely adjust the laser wavelength to allow easy energy coupling.

UV lasers produce lower wavelengths than 355nm which allow greater precision with smaller zones of heat pyrogenic altering which softens to them micromachining and semiconductor working components of greater intricacy. On the other hand, infrared wavelengths such as those emitted by fiber lasers are more appropriate for marking and cutting applications in facing a variety of metals and plastics. A study remarks that such materials as plastics tend to gain higher absorption with 1064 nm lasers when adept markings are done than changing to other wavelengths.

The range of a laser’s wavelength determines its focal spot size, with the smaller wavelength producing smaller focused areas with high energy. This makes marking and cutting at the micro-level very precise and distinct. Also, modern developments in laser technology includes expanding the range of available wavelengths to include tunable systems that can dynamically change wavelengths for particular applications, which improves flexibility and usefulness during industrial and scientific processes.

By using lasers with specific wavelengths that relate to particular materials, industries are able to optimize efficiency, quality, and operational costs which highlights the importance of the pulsed laser wavelength in the technologies used.

The Effect of Pulse Energy on Optical Applications

Pulse energy is described as the energy sourced from a single laser pulse, and this is very important in many fields that require optics, especially in glasses manufacturing, material processing, and other forms of laser micromachining. Pulse energy is important in all optics, but it is most critical in precision work. The increase value of pulse energy enables deeper penetration of materials and greater levels of ablation, which is ideal for cutting, drilling, or engraving dense materials such as metals and ceramics.

For example, in pulse laser engraving, the energy is related to the depth and sharpness of the marks. Optimal energy levels will achieve the desired outcome without damaging the periphery thermally. Recent research suggests that ultra-short pulse lasers achieve microfabrication while maintaining minimal heat-affected zones with increased pulse energy. It has been proven using picosecond lasers with modified pulse energy capabable of forming features as tiny as a few micrometers in size. This is highly advantageous in the electronic and medical device manufacturing industries.

Further, pulse energy affects the efficiency of some nonlinear optical processes such as frequency alteration. Experiments show thatenhanced pulse energy improves efficiency in conversion processes such as second harmonic generation. This provides energetic sources for wavelengths that would otherwise be inaccessible using fundamental laser sources. Through detail-oriented optimization of pulse energy, a laser platform has advanced process throughput and precision, thus enabling sophisticated optical applications.

What are the industrial laser techniques employing pulsed lasers?

- Laser Cutting: A broad selection of materials such as metals, plastics, and ceramics can be efficiently cut using pulsed lasers.

- Micro-Machining: This technique can be applied for the fabrication of small intricate features in components used in medical and electronic devices.

- Welding: The use of pulsed lasers results in accurate and reliable welds with significant depth for stronger, delicate materials.

- Marking and Engraving: Engraving or marking of serial numbers, logos, or patterns on materials is done widely using lasers.

- Surface Texturing: Pulsed lasers fundamentally alter the surface properties of a material by adding textures that can be tailored for specific functional or visual purposes.

In what ways are pulsed lasers used in welding?

Welding is one of the common uses of pulsed lasers when precision and control is required throughout the whole process, which is essential for many industries. It works exceptionally well in cases where the weld is processes with very little heat and high quality is a necessity. The small area of laser energy that is applied in the pulsed manner gives far greater control of the heat affected zone (HAZ) which ensures that distortion to surrounding materials is kept to a minimum while maintaining the integrity of very thin and delicate materials.

Cutting-edge research indicates that for micro-welding processes such as the joining of terminals in electronic devices or in medical equipment, pulsed lasers are increasingly being used. For example, in the construction of pacemakers, lasers can pulse weld together extremely small and fragile parts with great precision. As per some recent industrial statistics, the application of pulsed lasers in micro-welding has resulted in an improvement of around 25% to 30% in the efficiency of production as compared to conventional methods of welding.

Moreover, the increasing use of robotics in modern manufacturing systems makes pulsed laser welding ideal for automation in aerospace, automotive, and other industries. The ability to change pulse duration and pulse energy enables manufactcturers to customize welds for various materials ranging from steel alloys to aluminum and titanium, which are non-ferrous metals. These advantages stress the importance of pulsed lasers in high-tech manufacturing environments, where maintaining a high level of productivity while improving weld quality is crucial.

Pulsed Lasers and Their Function in Laser Ablation Process

In laser ablation processes, pulsed lasers add value by improving the accuracy, efficiency, and speed of these systems. The ability of pulses of energy to be sent in short, confined intervals makes it possible to remove material without excess thermal damage to the surrounding material area. This is very important in microelectronics and medicine device manufacturing, which require intricate patterns with deep cuts and precise measurements.

Recent research indicates that the use of femtosecond pulsed lasers can achieve an ablation rate that is ten times higher than with the use of traditional continuous wave lasers while also maintaining precision standards. Furthermore, studies suggest shorter pulses, picoseconds or even femtoseconds, are significantly less likely to cause heat diffusion which results in cleaner edges. Femtosecond pulsed lasers are very useful for delicate materials like polymers and ceramics as well as thin films which increases their importance in precision demanding industries.

The recent developments demonstrate the flexibility of using pulsed lasers in laser ablation procedures. In the semiconductor region, for instance, lasers are utilized to process the wafers at the level of a few micrometers. This degree of precision guarantees that small, dense, and high-performance devices are manufactured. This versatility is also seen in medicine, where lasers are used in the construction of stents or surgical devices, proving their reliability in performing consistent work in highly specialized fields.

Enhanced technologies continue to improve pulses lasers’ energy efficiency, system integration and other capabilities used in laser ablation. These continuous advancements are showcasing new, innovative possibilities that are boundless across numerous high-tech industries.

In what ways do pulsated lasers assist in spectroscopy?

Pulsed lasers assist greatly in spectroscopy through their ability to specify and finely analyze material thanks to the high resolution provided. By producing short, powerful bursts of light, ultrafast events like molecular and chemical processes can be examined in real-time. For example, femtosecond pulsed lasers are used in time-resolved spectroscopy to capture images of events occurring over short time duration, for better understanding of electronic processes like electron transfer and molecular vibration.

In the context of the application of pulsed lasers, quantitative data underscores their usefulness. For instance, in laser-induced breakdown spectroscopy (LIBS), they generate micro-plasmas by ablating a sample’s surface. The light emitted by this plasma is analyzed to ascertain the composition of the material. This method is efficient in numerous industries, from the detection of trace elements in geological samples to the monitoring of alloys used in metals during manufacturing.

Through the continuous research, the capabilities of pulsed lasers are enhanced with regards to stability of the wavelength, pulse energy, and quality of the beam. These improvements have facilitated advances in instrumental techniques such as Raman and fluorescence spectroscopy, in which the lasers offer reliable and always adjustable light sources for varying experimental requirements.

Reference sources

- Alpha Particle Production via Laser-Driven Fusion1:

- Key Findings: This study explored novel targets for proton-boron fusion using pulsed lasers. It achieved high alpha particle yields, demonstrating the potential for energy generation and medical applications.

- Methodology: Experiments used a 10TW laser system with targets of varying compositions. Radiative-hydrodynamic and particle-in-cell simulations supported the findings.

- Non-Fourier Heat Conduction in Nanosystems2:

- Key Findings: Introduced a fractional model for heat transfer in nanomaterials, highlighting the role of pulsed lasers in improving thermoelectric device efficiency.

- Methodology: The study employed dual-phase lag and fractional derivatives to model heat conduction in nanostructures.

- Mechanisms of Pulsed Laser Ablation in Biological Tissues5:

- Key Findings: Detailed the interaction of pulsed lasers with biological tissues, emphasizing precision and minimal thermal damage.

- Methodology: Combined experimental observations with theoretical models to analyze ablation dynamics.

- Top Pulse Laser Cleaning Machines Manufacturer And Supplier In China

Frequently Asked Questions (FAQs)

Q: What are the primary advantages of a pulsed laser?

A: A pulsed laser has its primary advantages in high power delivery enabling precise material processing and reducing thermal effect damage. It is also helpful in applications such as laser ablation and cutting owing to the high peak power and short pulse duration.

Q: How does a pulsed laser differ from a cw laser?

A: A pulsed laser differs from a cw (continuous wave) laser in that the former emits light in short bursts, while the latter emits it continuously. Due to this functional difference, pulsed lasers are able to peak power and density, making them suitable for applications requiring minimal thermal effects.

Q: What is the effect of laser pulses on materials?

A: The effect of laser pulses on materials encompasses cutting, ablation, and surface modifications. Irreparable damages are avoided through the application of high precision during the process of material manipulation. Controlled laser irradiation enables precise thermal damage mitigation through high pulse power and low width of the pulse.

Q: Why is the term “pulsed laser” significant in laser technology?

A: The term is significant because it defines lasers that are capable of emitting short bursts of energy, as opposed to operating in a continuous mode. Such pulsed operation is critical in areas that require high precision medicine and intricate manufacturing processes.

Q: Explain how the average power of a pulsed laser compares with other types of lasers.

A: The average power of a pulsed laser is lower than that of a cw laser; however, its peak power is significantly higher. This feature makes pulsed lasers ideal for applications that require rapid bursts of energy useful in high temperature and high pressure processing.

Q: What role does pulse power have in the advantages of a pulsed laser?

A: Pulse power is critical in the advantages of a pulsed laser since it determines how powerful and effective each pulse will be. High pulse power enables efficient material processing like the laser zinc ablation with minimal thermal damage to other surrounding parts.

Q: Can you explain the advantages of using laser pulses in medical applications?

A: Medical procedures are enhanced by using laser pulses because the tissues can be targeted without much damage via thermal effects. This is seen in laser surgery and other skin procedures which involve the use of lasers, where more precise control over the energy delivered by the laser results in improved outcomes and rapid recovery time.

Q: What types of different laser sources are used in pulsed laser technology?

A: Different laser meager sources employed in pulsed laser technology are q-switched lasers, dye lasers, excimer lasers, ruby lasers and nanosecond lasers. Each type has specific advantages depending on the appliqation and may include, high output power or speficic wavelength requirements.

Q: How does the ns pulse length affect the performance of a pulsed laser?

A: A result of ns (nanosecond) pulse length is that a very high power can be delivered over very short time periods which improves the performance of a pulsed laser. This is particularly important in applications such as micromachining and laser ablation, where the duration of exposure must be very short in order to reduce thermal diffusion and increase accuracy during processing.

- Maximum CNC Router Cutting Thickness: What Thickness Can Your CNC Router Cut Through Wood?

- Laser Cutting vs Plasma Cutting: A Comprehensive Comparison of Cutting Methods

- Choose the Best Metal for Laser Engraving: A Guide

- Understanding CO2 Laser Cutting vs. Fiber Laser Cutting Machines

- Discover the Versatility of a CO2 Laser: What It Can Cut, Etch, or Mark?

- Top 10 Countries for Best CNC Machining Services: Global CNC Machine Industry Guide

- How Does a Laser Marking Machine Work? Discover the Secrets of Laser Engraving

- How Accurate is Laser Cutting: Understanding Laser Cutting Tolerances