It’s no secret that CNC machines have changed the face of manufacturing with their unrivaled precision, efficiency, and versatility. As with everything good, there is a challenge to face. With so many types of CNC machines available in the market, selecting the best fit for your requirements can feel really frustrating. Each type has its purpose and capabilities which means you need to differentiate between each before making a selection.

Don’t worry, this is not yet another manual that lists machine types without any additional insights. You have come to the right place. I will guide you through the five primary types of CNC machines, their specialties, functionalities, and peak performance areas. Now, as a professional you may already own some machines, while others may be feeling the allure of this technology for the first time. Don’t fret, this guide will help optimize your production and provide you with everything needed to make an educated decision. With me, you will be diving into the enigmatic yet fascinating world of CNC machines, so let’s get started on figuring out which one suits your next endeavor the best.

What Are the Different Types of CNC Machines?

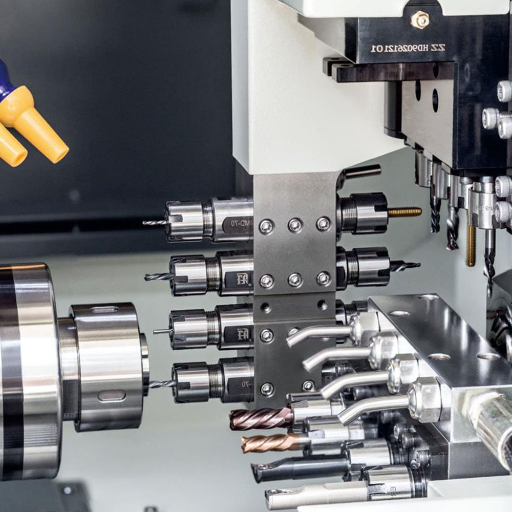

- CNC Mills- Ideal for the creation of intricate components. Accomplishes precision cutting, drilling, and shaping with the use of rotating cutting tools.

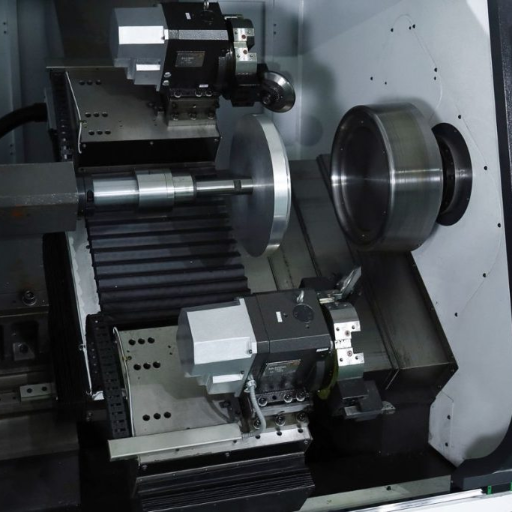

- CNC Lathes- Primarily designed for shape symmetrical and cylindrical components. The workpiece is rotated while cutting tools are employed to shape it.

- CNC Routers- Frequently utilized within the furniture industry as well as sign making. They cut softer materials such as wood, plastic, and foam.

- CNC Plasma Cutters- Metals such as steel or aluminum that conduct electricity are cut using a plasma torch.

- CNC Laser Cutters- Small projects and artistic pieces are done using these cutters as they cut and engrave materials with a concentrated beam of laser, giving the finest details.

- CNC EDM- In the molding and tooling industries, hard materials are shaped using discharges of electricity known as CNC discharge machines.

Factors Influencing CNC Machine Efficiency

Hierarchical structure, type and configuration of the employed measuring tools, as well as the exploits precision and particular features of the workpiece. For example, more robust tools ought to be employed to ensure the machines longevity when cutting hard materials as they require slower cutting speeds.

The use of modern technologies like adaptive control systems and real-time tracking is Integrated Improvement Aiding performance of CNC machines. Implementing such systems is estimated to increase production efficiency by 20 percent and improvement in dimensional accuracy by 15 percent. It offers quicker responsiveness and enhanced quality of outputs which is important in production.

Furthermore, proper machine care is an essential supporting factor that affects performance. Timely maintenance adds value, through extending the useful lifespan of the CNC machine and effectively avoiding machine downtime. In the long term, proactive machine care is estimated to decrease repair cost by 30 percent over the machine’s life cycle, which adds significant value in long term investments in CNC technology.

Types of CNC Machines And Their Operation

All CNC machines are set according to specific instructions for their operations. They are activated by a code that specifies control milestones: the machine’s movements, directional speed, and other relevant tracks. For instance:

- CNC mills employ rotary tools, from above the workpiece, which cuts and carves the material as per the instructions given in the computer.

- CNC lathes works by turning the material to be worked on, while the cutting tool is made to slide over the rotating material. Works best on cylindrical parts.

- CNC routers operate by moving the tool which the workpiece is fed into and scraped or engraved in a particular design as required.

- CNC laser cutters utilize a sharpened laser beam for accurate engraving and cutting of various materials.

All device types perform based on their capabilities and characteristics. However, they share the common principle of performing a digital design using automated, exact movements.

Which Type of CNC Machine Is Best for Your Needs?

Your specific goals will determine the best type of CNC machine. CNC lathes would be perfect if you wanted to cut or shape cylindrical parts. For more intricate cutting or engraving on flat surfaces such as wooden or plastic boards, CNC routers are a good choice. If you need precise cutting or engraving regardless of the material, CNC laser cutters are the most effective. Think about the material and how intricate the design is, then decide the level of accuracy your project needs for the best outcome.

Importance of Laser Strength and Speed in Engraving CNC Laser Machines

While considering a CNC laser machine, one aspect that should be looked into is the ratio of laser marking speed and laser power especially because these affect productivity. Materials that can be worked with also depend on the balance. More laser power will likely increase the speed at which engraving or cutting is done on metals, wood, or acrylic because more energy means getting deep enough to mark and cut surfaces. A good example would be the 60W laser- it is more efficient than a 30W laser when cutting thin wood and plastic. On the other hand, operating costs can rise with higher power and might lose some crispness on detailed designs if not calibrated properly.

Based on the recent analysis by industry experts, it appears that high-accuracy operations, such as engraving intricate patterns or dealing with delicate materials like thin plastic films, work best with lower laser power settings. On the other hand, deeply cutting harder materials—such as stainless steel and thick wood—requires the use of powerful industrial lasers exceeding 100W. Moreover, studies show that increasing the marking speed with appropriate power settings can reduce workflow times by as much as 30%. This is a critical aspect for companies seeking to improve productivity. It is best to adjust the laser power to the speed and accuracy required for the work at hand in order to achieve optimal results.

Examining Different Options of CNC Machines

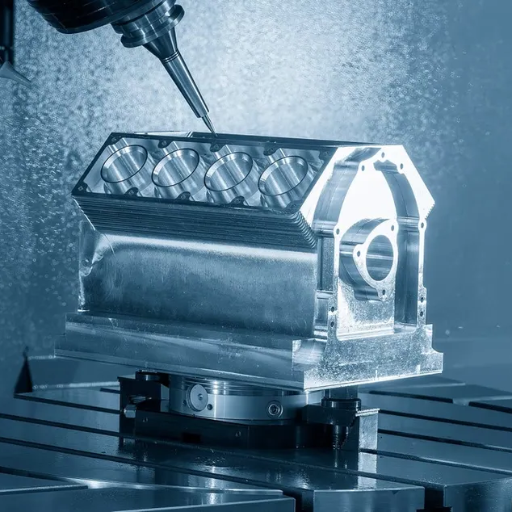

When exploring different kinds of CNC machines, it’s advisable to look at their functions, capabilities, and applications. For instance, CNC milling machines are renowned for their precision and strength when dealing with metals, plastics, and composites. These machines utilize advanced 3-axis or 5-axis systems that allow them to perform intricate cuts and designs with complex multi-dimensional features at unparalleled accuracy. Insight from the most recent CAD/CAM industry survey revealed that there are milling machines in the market today that provide tolerances of as accurate as ±0.0002 inches, which is crucial for both aerospace and automotive manufacturing.

On the contrary, CNC routers are best used when cutting softer materials such as wood, foam, and acrylics. Their speed is exceptional, often achieving around 25,000 RPM which is beneficial in furniture making and sign carving. The addition of automatic tool changers (ATC) has made these machines even more efficient by reducing idle time in big production processes.

Finally, CNC plasma cutters are also known for cutting thick sheets of metal (like steel or aluminum) with ease. A plasma torch cuts with heat of up to 50,000 degrees Fahrenheit and can effortlessly smooth cut metal plates of about 1 inch thick. In addition, many of the new models come with automated CAD/CAM design software which improves the productivity and efficiency of getting work done.

With the consideration of your specific project requirements, be it high-precision milling, heavy-duty plasma cutting, or router rapid prototyping, you can select the proper type of CNC machine to achieve optimal productivity while maintaining the desired results on a deadline.

Benefits and Uses of the Popular CNC Machines

The precision, efficiency, and multitasking ability of CNC machines make them popular in many sectors. The automotive and aerospace industries make use of CNC milling machines to manufacture sophisticated products such as engine components and turbine parts. In woodworking CNC routers aid in making signs and furniture, enabling the industry to cut and engrave intricate designs.

Another growing use of CNC devices is in jewelry cutting and circuit board manufacturing due to delicate work requiring precision, meaning greater demand for CNC laser cutting machines. The plasma CNC machine market is anticipated to grow at a rate above five percent by 2030 because of higher demand for precision work and lowered labor costs. CNC plasma machines are popular because they can cut thick conductive materials such as steel and aluminum, making them crucial in the shipbuilding and heavy machinery manufacturing sectors.

CNC machines integrated with the Internet of Things (IoT) technologies enable real time monitoring and predictive maintenance enhancing efficiency by reducing downtime. The competitive advantage with IoT enabled CNC machines is that they have boosted operational efficiency for businesses by 25 percent. Multitasking also delivers an edge over other manufacturers.

Choosing the right type of CNC machine and integrating modern technology allows industries to reach unmatched precision, consistency, and productivity in their processes.

What Are the Elements of a CNC Machine?

- Controller – A CNC machine’s controller is the command center and processes the programmed information.

- Machine Tools – Each machine tool has an enabled task such as drilling, cutting, and shaping into defined geometrical forms.

- Cooling System – monitors and eliminates excessive heat during cutting operations, allowing for a cooling, obstruction-free operation.

- Workpiece – the material upon which cutting or shaping operations are performed.

- Sensors – monitor and report each step undertaken by the machine during the operation to report failure or success thereafter during verification.

How Do CNC Machines Work?

The working principle of CNC machines is that they follow commands from software to control tools and mechanisms. The whole procedure begins with creating a design on CAD software which later gets transformed into a code through CAM software. The generated code is in a machine language, thus understandable by the machine. The machine executes operations such as cutting, shaping, or adding material and applies precision. It interprets the code using chauffeur-moteurs, drive mechanisms, and cutting tools while computer sensors check for correctness at each stage.

Role of Cutting and Machine Tools

Every manufacturing process is dependent on the precision application of these processes. Through the use of these tools, a lot of work is done with regards to forming materials. Cutting tools take excess material from a workpiece, and machine tools cause the requisite motion and provide support essential during cutting operation. Both of them make certain that quality and level of work in the industry is good and uniform.

How Do Different Types of CNC Machines Operate?

As per the instructions fed to different categories of CNC machines, their movements and actions are controlled by a computer. CNC machines have a computer system that decodes the given instructions, which outline the movement, velocity, and activities of the tool. A CNC milling machine, for instance, uses a rotating cutter to incrementally “mill” out material. On the other hand, CNC lathes shape workpieces by spinning them and applying stationary tools. CNC machines, in general, require careful programming to yield repeatable, reliable, and accurate results.

Working Principle of CNC Lathes

CNC lathes hold the workpiece stationary as it spins about its axis, performing cutting, drilling, shaping, or other operations to the workpiece to achieve the desired geometry. Highly versatile, these machines can work on a range of materials including metals, wood, and plastic, which makes them crucial in several fields such as aerospace, automotive, and manufacturing. Modern CNC lathes have also seen advancements such as the incorporation of live tooling, which allows milling and drilling to be done simultaneously during the turning processes.

CNC lathes have the ability to achieve tight tolerances and high repeatability, with common tolerances reaching ±0.001 inches (±0.025 mm) or better. With automation features, these machines increase production speed while minimizing human error, thereby improving overall efficiency. In addition, the latest software integration alongside real-time monitoring ensures that operators are able to supervise the machining process from a distance, improving ease and increasing accuracy while minimizing downtime. Recent reports suggest an expected significant growth in the adoption of CNC lathes, projecting a compound annual growth rate (CAGR) of roughly 6.5% on the CNC machinery market between 2023 and 2030 due to heightened precision engineering requirements.

The Operation of CNC Mill and Mill Machines

CNC mill and mill machines play an integral role in contemporary manufacturing by offering precise machining operations that meet intricate design requirements. These machines are particularly efficient in the cutting, drilling, and contouring processes on a diverse range of materials such as metals, plastics, and composites. Standard CNC mills are configured with multiple axes to perform on three axes (X, Y, Z) and more advanced models are able to add a fourth or even fifth axis, which enables the machining of highly detailed geometrical shapes with unmatched precision.Some recent trends show a significant increase in the use of 5-axis CNC mills due to their use in aerospace, automotive, and medical device industries. These machines optimize production by decreasing the number of setups which subsequently reduces production times and increases efficiency. The most recent insights suggest that the growth of multi-axis CNC machining is a major driver of the growth in the CNC machinery market as its global revenue is expected to surpass $120 billion by 2030. This growth is accelerated by the heightened demand for precision and automation in mass production.

Other factors include advancements in automatic tool-changing and adaptive machining which enable real-time materials monitoring. Advanced software and IoT allow manufactuers to collect, analyze predictive data that optimizes workflows, maintenance schedules, reduces downtime, and lowers expenses. These developments reinforce the focus on operational efficiency which positions these manufacturers competitively in the ever-evolving dynamic industrial climate.

Important Benefits of 5-Axis CNC Technology

Efficient manufacturing methods have been enhanced by the introduction of 5-axis CNC technology owing to its surpassing accuracy and adaptability. Its capacity to complete the machining of complex parts in a single setup is a significant advantage. It reduces the mechanized repositioning as well as increases accuracy. It is beneficial especially for aerospace, automotive, and medical device manufacturing industries that require highly intricate designs and tight tolerances.

Recent studies claim that 5-axis CNC machines are more efficient than 3-axis systems. They can save production time by as much as 50% when working with complicated geometries. In addition, advanced simulation software tools guarantee more accurate calculated tool paths which make way for material error wastage. Based on industrial data, adopting businesses are said to have benefitted from 30% productivity improvement owing to lower manual work and higher automation focus with 5-axis technology.

The aeronautics industry, which employs these alloys extensively, requires parts to be manufactured from titanium and nickel alloys, which are hard to machine. The technology also enables manufacturers to monitor and adjust the performance of machines in real time using IoT systems, boosting operational effectiveness. With these benefits, 5-axis CNC technology proves its worth to businesses striving to remain relevant in today’s industrial world.

What Are the Advantages of Using Common CNC Machines?

- CNC machines are able to manufacture components with exceptional precision achieving CNC accuracy, maintaining a standard value of quality regardless of the size of the production run.

- CNC Machines Compared to Manual Machines

- Compared to recently used manual machines, CNC machines reduce production time significantly earning an overall increase in output.

- CNC Machines: An Overview

- Common varieties of CNC machines can work with a huge range of materials including metals, plastics, and composites – granting these machines the ability to serve multiple purposes across different industries.

- CNC Machine Cons and Pros

- Other than programmable labor, CNC machines allow receded manual supervision. When set up, CNC machines can run with little to no human intervention.

- CNC machines are guaranteed to have repeatable manufacturers for the same components which can be achieved quickly and dependably.

Automatic Tool Operations Benefits

Automatic tool operations, such as in CNC machining and other modern manufacturing processes, are unmatched in precision and manufacturing efficiency due to advanced technology. With improvements like high-speed spindles and adaptive control systems, tools can perform cuts at speeds over 50,000 RPM greatly reducing production completion times. Furthermore, optimized toolpaths have recently been shown to increase material removal rates by up to 20% in a recent industry study.

The competitive edge brought by automation proves to further be a reduction in the waste of material used. Companies using automated tools were reported to be more sustainable with a lower scrap rate of 30%, according to a 2023 report on sustainable manufacturing. Moreover, advanced automated monitoring systems allow for real-time diagnostics, decreasing machine downtime by 15%.

These advancements in technology have also facilitated mass customization. It has become easier to reprogram tools and, as a result, manufacturers can now produce complicated designs in small quantities with complex details. This is helpful to the aerospace, automotive, and medical industries. Because of these advantages, automatic tool operations continue to expand the manufacturing industry’s scope and redefine global industrial standards.

Enhanced Capabilities in CNC Router Machines

Manufacturing CNC router machines, along with other types of routers, transformed industries by enhancing speed and precision across multiple sectors. In combination with sophisticated software, these machines achieve accuracy of 0.0004 inches, which helps to minimize errors and material waste. In addition, the latest automated systems have incorporated new spindle motors with rotation speeds over 24000 RPM, which increases the rate of cutting cycles and the quality of the finish.

Moreover, figures from 2023 reveal that facilities with newer generation CNC router machines have enhanced production efficiency by an average of 20%. Their competency in multi-material processing, such as metals, plastics, and composites, has rendered them pivotal in sectors like furniture manufacturing, automotive component fabrication, and industrial prototyping. The seamless integration of IoT technologies for performance metrics monitoring, maintenance forecasting, and configuration optimization, further enables real-time control and enhances drone adoption. These innovations continue to encourage industries towards greater efficiency and eco-friendliness in manufacturing processes.

Manufacturing Productivity and the Role of Laser Power

The latest innovations in laser technology have transformed the industrial landscape by increasing accuracy, rapidity, and overall operational efficiency. For example, higher-powered lasers are capable of faster processing speeds, which significantly reduces the time needed for various production tasks. Research indicates that greater laser power increases marking speeds considerably for certain materials like metals and plastics. For instance, one study showed marking with a 100-watt laser took less than 40% of the time needed with a 30-watt laser while maintaining the same standard of quality.

In addition, today’s laser systems have improved energy efficiency, which reduces energy and operating costs. Research shows that with the proper beam control and cooling systems, laser marking systems can realize energy savings of as much as 20%. This not only enables a reduction in emitting harmful gases, but is also supportive of the increasing concern for eco-friendly construction practices.

Along with improved productivity, the accuracy of lasers also minimizes material waste due to the clean cuts or engravings performed. Industrial case study statistics show that high-powered laser systems greatly increase performance, with a reported waste reduction of approximately 25%. These technological advancements alongside improved metrics reinforce the importance of laser power for optimizing costs and environmental sustainability.

Reference sources

- Future Trends and Technologies in Additive and Subtractive Manufacturing2:

- Key Findings: This chapter explores the integration of additive and subtractive manufacturing technologies, highlighting advancements in CNC machining. It discusses the role of CNC machines in achieving precision and efficiency in subtractive manufacturing processes.

- Methodology: The study compares additive and subtractive methods, focusing on their applications, materials, and future trends in manufacturing.

- Recent Research Development of CNC-Based Milling Machining Conditions4:

- Key Findings: This paper reviews advancements in CNC milling, emphasizing the optimization of machining parameters like cutting speed, feed rate, and cooling techniques. It highlights the importance of CNC milling in achieving high-quality surface finishes and reduced tool wear.

- Methodology: The study compiles findings from various experiments on CNC milling, including the use of advanced cooling methods like cryogenic and Minimum Quantity Lubrication (MQL).

- Top Mini CNC Router Manufacturer And Supplier In China

Frequently Asked Questions (FAQs)

Q: What are the five common types of CNC machines?

A: CNC lathes, CNC milling, CNC plasma cutters, CNC grinders, and CNC electric discharge machines are all common types of CNC machines. Each of these machines can perform specified operations under the broader category of precision CNC machining and manufacturing.

Q: How do CNC lathe machines work?

A: The CNC lathe machines work by spinning a workpiece on its axis while a cutting tool moves in two dimensions to sculpt out desired shapes. CNC lathes are crucial for the manufacturing of round and rotational objects such as shafts and fittings.

Q: What are the uses of CNC plasma cutting machines?

A: CNC plasma cutting machines are employed for the cutting of operational steel and aluminum sheets used within the Vacuum Chamber. These cutters use jets of hot plasma which are directed numerically through a computer to achieve a range of piping and shaping cuts giving high precision results.

Q: What is the purpose of a CNC grinding machine?

A: CNC grinding machines play a pivotal role in the finishing operations of the manufacturing process because they impose surfacing requirements on the finished product with the highest accuracy. Furthermore, these machines also Apply CGR to the CNC surface. CGR works when the material is removed, achieved by CNC with predetermined precision and multifaceted parts increase control capability and quality engineering in accuracy.

Q: What function do CNC electrical discharge machines serve?

A: CNC electrical discharge machines or EDMs work by the means of electrical sparks in cutting of metal workpieces. This is needed to make very fine features such as contours and other intricate shapes and is especially difficult because they are made out of hard materials and very hard to machine using conventional methods.

Q: What other operations can be performed with a 3-axis CNC mill?

A: The 3-axis CNC milling utilizes a rotating multi-tooth tool to cut the work piece, which advances along orthogonal coordinates (X,Y,Z). While these operations are basic, other CNC machines will have additional advanced and more flexible features enabling sophisticated machining works.

Q: Why is precision CNC machining important for machine shops?

A: The need for precision CNC machining in a machine shop is critical as it guarantees the correctness of part production and repeatability. In particular, this capability is important in the aerospace, automotive, and medical device industries because of their exceptional quality requirements.

Q: In what ways do CNC machine tools improve manufacturing productivity?

A: The productivity of manufacturing operations is improved by CNC machine tools performing complex machining operations as they reduce the manual work done and speed up production. The implementation of the computer numerical control system promotes exact and uniform results which enhances productivity and reduces redundancy.

Q: What is the advantage of CNC water jet cutting?

A: With CNC water jet cutting it is possible to achieve cutting without heating the material, which is an advantage in cutting a wide variety of materials. The process involves directing a stream of water mixed with abrasives at high pressure and guided by CNC systems to make cuts with a lot of accuracy and little wastage of the material.