There is quite a lot to weld spatter, ranging from its interference with the finish and beauty of elegant welding work to far more severe considerations on time management and productivity. Whether you are a professional welder or a hobbyist, it is vital that you develop an understanding regarding the causes of weld spatter and some of the ways to reduce such occurrences to improve your results overall. This post discusses some common causes behind weld spatter, details mechanisms aimed to reduce such instances, and implications for the work. By the end of the post, you will have some practical tips to help you perfect your welding technique and achieve cleaner, more professional finishes.

What Actually Is Weld Spatter?

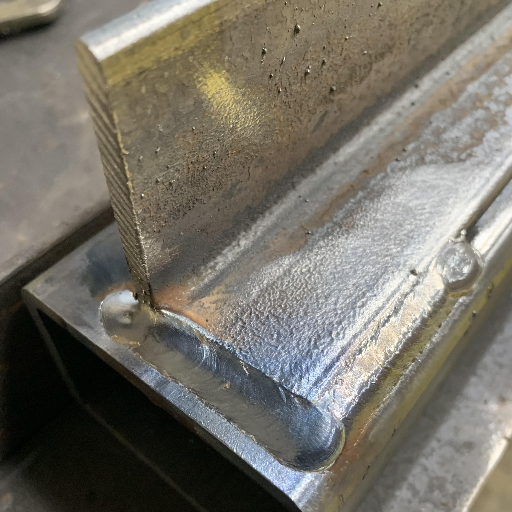

Weld spatter consists of those little molten-metal droplets expelled from a welding arc during welding. These droplets are prone to sticking to some nearby surface and may have a rough or grainy texture. They are the result of inadequate welding settings, an improper welding technique, or contaminated materials. Generally, spattering does not reduce weld strength but spoils the look of the finished product and makes some cleanup work necessary.

Definition of Spatter in Welding

Spatter in welding is the term used for small droplets of either molten metal or non-metallic material ejected from the welding zone, but they do not constitute any part of the weld. These particles may stick on their own to the surrounding material, creating an uneven surface that necessitates cleaning. Being dirty for the welding process, spatter impacts the visual quality of the weld and increases production time as it requires an annoying removal procedure.

Glimpses on the Spatter Formation

When arc instability occurs, when welding parameters are inappropriate, and when inappropriate welding technique is applied, spatter commonly occurs. If the heat or amperage is too large, there will naturally be a larger amount of molten material being expelled via spattering. When the electrode angle sets incorrect, or the distance of the electrode from the workpiece is wrong, or the shielding gas flow poorly adjusted, each negatives the chances of preventing spatter.

The increase in spatter with GMAW has been reported in recent studies and to be closely linked with improper voltage. For example, by keeping the voltage in the range of about 18-22 volts during GMAW of carbon steel one can reduce spatter. It is also wire feed speed. Wire feed speed in the vicinity of 300-500 in/min for materials of moderate thickness proved to considerably reduce the spatter level.

Furthermore, the right shielding gas is a must. It is well accepted that the choice of a gas mixture containing 75% Argon and 25% CO2 offers the most stable arc with the least amount of spatter during MIG welding. Field trials have demonstrated a reduction of spatter by up to 50% using this gas mixture versus the standard use of pure CO2.

Good weld preparation practices also reduce spatter. For example, cleaning the base material before welding from rust, oil, or dirt decreases the amount of spatter residue by about 20-30%. This not only increases weld quality but also reduces post-weld cleaning hours and labor.

By keeping a check on such parameters and maintaining an ever-present standard of control and consistency for the welding parameters, spatter can effectively be controlled, resulting in increased productivity and cleaner, professional-grade finishes.

Differences Between Spatter and Splatter

Spatter and splatter differ primarily in context and usage, with “spatter” referring to small drops or particles, often in controlled or technical scenarios like welding, while “splatter” implies messy, irregular sprays or splashes typically in more casual or descriptive situations.

| Key Point | Spatter | Splatter |

|---|---|---|

| Context | Technical | Casual |

| Definition | Small drops | Irregular spray |

| Precision | Controlled | Messy |

| Common Use | Welding | Everyday life |

| Implication | Professional | Random |

| Examples | Metal welding | Paint or food |

| Appearance | Uniform | Scattered |

| Impacts | Less cleanup | More cleanup |

| Tone | Formal | Informal |

| Frequency | Specialized | General |

Causes of Weld Spatter

- Incorrect Voltage or Amperage: Sometimes the wrong electric settings are applied on the machine creating unstable arcs hence excessive spattering.

- Wrong Wire Feed Speed: When the wire feed goes faster or slower than the recommended speed, welding is hindered and splatters may be formed.

- Materials Contamination: Dust, grease, or rust on the welds can interfere with the welding operation, causing increased splatter with much more intensity.

- Shielding Gas Discrepancies: Sometimes the shielding gas quantity supplied is insufficient or inappropriate from the standpoint of correct arc operation.

- Operator Technique: Another major reason for spatter is an incorrect angle with which the operator holds the gun, or simply moving too fast.

Common Factors Leading to Weld Spatter

Increased weld spatter may be caused by cumulative influences, each of which affects the qualitatively clean nature of the weld. Understanding what paralyzes and diminishes spatter will allow operators to achieve improvement in spatter and results. Following are some elaborations, data, and perspectives:

- Voltage Mismatch: A voltage unmatching settings during the welding process may lead to the formation of an unstable arc with the result that spatter positives higher to be produced. It is said in reports that with a good voltage setting, defects occur about 30% times less, thus bettering weld quality.

- Wire Feed Speed Issues: Wire-speed control is crucial in welding. High wire feed speed causes abundant wire flow into the weld pool that leads to splatter. On the contrary, a slower wire-speed might cause inconsistent wire flow with frequent arc disruptions. Studies indicate that keeping wire feed speed in the range recommended by the manufacturer would significantly reduce instances of spatter.

- Material Contamination: Surface preparations matter. It can be noted that welded joints employing clean and uncontaminated surfaces present up to 40% fewer cases of spatter than those processed on a surface with traces of oil, rust, or dirt. Make cleaning the surface a prior task before welding to bind well and render smooth wetting.

- Improper Usage of Shielding Gas: The weld spattering reaction depends directly on the kind, pressure, and flow rate of shielding gas utilized. Actually, optimizing arc stability and minimizing spatter can be achieved by using the proper gas mixture, i.e., 75% Argon and 25% CO2 for MIG welding. Results show that following the gas mix recommendations leads to about 25% reduction of spatter.

- Manual Errors in Technique: Spatter control depends mainly on the skill level of the user. Frequently these insufficiencies include errors in travel speed or consistence of angle variations and less-than-ideal electrode distances. Through training, welders will be able to maintain a consistent 15-20° angle along with steady movement that enhances arc stability, thereby reducing the frequency of spatter.

Hence, by controlling these common causes following the best advice, welders will be able to produce cleaner welds with present spatter reduction, thus saving time and enhancing weld productivity.

The Role of Welding Technique in Spatter Formation

Correct weld techniques are likely to minimize spatter formation. Travel speed, angle, and electrode distance are the main considerations. Following these common techniques will provide the welding world with an exceptionally stable arc, reduce spatter, and allow for better welds. Training welders on a regular basis will surely make the practicing go fine.

Influence of Material and Environment on Spatter

Materials and surrounding environmental conditions play an important role in spatter formation. Highly impure materials on base metal, such as rust, oil, and mill scale, tend to increase spatter. In contrast, welding on galvanized steel usually promotes spatter because the zinc coating vaporizes during welding and creates arc instability.

Environmental factors are also important: temperature, humidity, and wind currents. Welding during cold weather can make surfaces condense, hence hindering arc stabilities and consequently affecting spatter. Recent industry data points to the fact that maintaining an ambient temperature between 50°F and 90°F (10°C to 32°C) and clean surfaces can cut down spatter by 35%. Moreover, wind or draft velocity above 5 mph over the work area can disrupt shielding gas coverage versus causing increased spatter and undermined weld integrity.

Gaining precedence in these factors and minimizing their interference-welding parameters, pre-cleaning of materials, and environmental controls-can gain a crippled leading toward tremendous improvement in weld efficiency and quality.

The Impact of Spatter on Work Quality

Weld spatter means the uneven surface of the root weld-must be cleaned and finished. Excessive spatter wastes material and labor, creating an ugly appearance that undermines efficiency and product integrity. Minimizing spatter ensures a high-quality finish with fewer post-weld corrections by adopting proper welding techniques and environmental controls.

Effects on Weld Integrity and Appearance

The weld spatter impairs the integrity of the welded joint and adversely impacts its appearance, which may threaten the structural strength and aesthetic value of the final product. Data from the welding industry indicate that excessive spatter can increase labor time by as much as 25% because of the extensive grinding and smoothing of surfaces that have to take place post-weld. The increased labor time, therefore, puts the project behind schedule, causing production inflation.

Researchers have pointed to the criticality of the control of weld spatter in order to maintain high standards of the end product. For example, the reduced spatter effect through shielding gases such as argon or argon blends comes from the stabilization of the welding arc whereas proper voltage and amperage settings help to further lessen the spatter-related defects. Another solution can be automated welding, which studies have suggested to reduce spatter by 30% more than manual welding. By utilizing these methods, manufacturers achieve better weld consistency while minimizing waste, production costs, and hence, giving the product a cosmetically clean finish.

Safety Concerns of Weld Spatter

These safety concerns range from hazards to the operator and the surrounding work environment. Molten particles cause painful burns if they fall on unprotected skin. A further fire hazard can be created if it falls on or close to flammable materials. According to OSHA, about 25% of the welding-related injuries in the workplace can be traced back to inadequate protection from spatter burns. Therefore, it is of utmost importance to use appropriate PPE such as heat-resistant gloves, protective clothing, and safety glasses.

In addition, an accumulation of spatter on machines or on other surfaces causes equipment failure in due course, limiting their operational efficiency. Since the introduction of fume extraction systems and anti-spatter products, some industries have gone on to report a 40% reduction in spatter-related safety incidents. Implementation of these modern safety measures with the advanced welding solutions will aid to much reduce the hazards, leading to a safer and productive workplace.

The Long-Term Effects of the Spatter

Uncontrolled weld spatter can have long-term consequences, besides safety, encompassing operational and maintenance costs, and the longevity of the equipment. In excess, spatter accumulation on machinery can increase maintenance bills by up to 30% annually, resulting from increased wear-and-tear of components, according to recent findings. Also, spatter residues have become a cause of hindrance with robotic welding operations that start functioning abnormally and increased production delays. Incorporating top-class anti-spatter solutions with fume extraction systems has been shown to extend equipment life by 20-25%, as told by the industry leaders. In addition to this, the organizations that have adopted regular cleaning schedules and invested in high-tech welding technology have decreased defect rates to a considerable extent, thus enhancing efficiency in an overall manner. These offer a clear indication of why treating spatter should be a matter of immediate concern on both economic and operational grounds in the long term.

Methods of Reducing Weld Spatter

- Set Welding Parameters Properly – The voltage, amperage, and travel speed must be set correctly for the material and welding process at hand.

- Use the Correct Shielding Gas – A shield gas mixture should be selected in accordance with the welding task, such as argon with CO2 for MIG welding, to reduce the formation of spatter.

- Keep Clean Surfaces – Dirt, rust, and grease must be removed from a workpiece to ensure clean welding.

- Use Anti-spatter Spray – Spray anti-spatter in the welding area and on the tip to help prevent the build-up of material and ease cleaning.

- Proper Selection of Electrodes and Wires-Using high-grade electrodes or filler wires compatible with the work material results in cleaner welds.

Best Practices with MIG and TIG Welding

If you want the best possible outcome using MIG (Metal Inert Gas) and TIG (Tungsten Inert Gas) welding procedures, you will need to work methodically. Further supporting details and data-gathered methods are provided below to maximize efficiency, safety, and weld quality:

Shielding Gas Application

The right shielding gas can really influence how well MIG welds perform. Typically, an argon (75%-95%) and CO2 (5%-25%) mix is employed due to its anti-spatter qualities and for forming a neat weld bead. Conversely, TIG welding demands pure argon for almost any metal as it offers the best arc stability and shielding. Trials have revealed that the use of wrong shielding gases can lead to a reduction in weld capacity of about twenty percent.

Distance of Torch

In order to obtain uniform welds, maintaining an ideal distance from the torch to the workpiece is important. For MIG welding, a distance of 3/8 inch to 1/2 inch is generally kept from the workpiece. For TIG welding, a steady hand and precise control over the torch angle (usually 15-20 degrees from vertical) are required to provide even heat distribution and reduce the opportunity for contamination to occur.

Pre-heat for certain materials

Pre-heating aids welding by preventing cracking and encouraging fusion in metals such as aluminum and stainless steel. Some studies state pre-heating between 300°F and 400°F to be very useful, especially for thick aluminum workpieces.

Heat input control

Overheating distorts the weld material and causes damage to the weld joint. For MIG welding, do not use too much voltage and wire-feed speed; this will ensure you do not overheat. As for TIG, the heat input can be controlled with its amperage level usually using foot or finger control, which is great for operations on thin materials. Experts recommend minimizing the extent of the heat-affected zone to maintain material integrity.

The criticality of filler material selection

Correct filler selection is very important to durability and performance of welds. For instance, ER4043 is mainly used as a filler for aluminum in TIG welding with good corrosion resistance and strength. It has been statistically proven that failure rates may increase by more than 15% when incompatible filler is selected.

Regular maintenance of equipment

All MIG and TIG equipment require regular upkeep, such as cleaning the contact tips, inspecting the power cables, and checking for adequate gas flow. It has been shown that poor maintenance can reduce weld quality and productivity by around 25%.

By learning and implementing these practices, welders can increase efficiency, reduce waste, and ensure reliable, high-quality results. Proper technique, coupled with ongoing training and up-to-date equipment, ensures that MIG and TIG welding goes above and beyond accepted industry standards.

A Detailed Examination of Flux Welding and Flux Core Welding

Flux welding and flux core welding stand as essential types of welding in the modern era of fabrication. Various applications suit one or the other methods with their particular advantages. Flux-cored arc welding uses tubular wire filled with flux to provide a protective shield against atmospheric contamination. This is especially good for outdoor jobs in strong winds that might otherwise disrupt the shield gas during MIG welding. According to recent data, flux core arc welding has a higher deposition rate than solid wire; thus it is more time-saving in heavy-duty works.

By comparison, traditional flux welding with coated electrodes is generally used for smaller jobs and repair work. Being simpler and having a lower initial apparatus cost, it suits the hobbyist and smaller shops well. Trends in 2023 indicate a growing implementation of flux core processes in construction and shipbuilding, with reports stating that welding times have decreased by 15% and overall productivity increased by as much as 20% while using FCAW.

Through combining these welding processes with automated welding systems, further gains in precision and cost savings can be achieved. Investing in adequate training and equipment with the future in mind that best exploit the flux and flux core technologies guarantees a win-win situation in the industrial and the small-scale arena.

Adapting Welding Parameters to Suit Spatter Reduction

To adjust welding parameters for spatter reduction, I concentrate on voltage, amperage, and travel speed for stable arc conditions. I also watch electrode stick-out and maintain the correct shielding gas mix for the specific material welded. I keep the work surface clean and constantly keep an eye on equipment settings for spatter minimization.

Contrasting the Spatter Inhibitors

When comparing anti-spatter products, the focus should be on performance, ease of application, and ease of residue removal. Common examples include aerosol sprays and gels, where sprays facilitate a fast application process and gels are excellent for more hard-to-reach areas. For optimal results, choose an option suitable for your welding process and materials. You should also check that it contains no toxic fumes or ingredients and complies with workplace safety standards.

Anti-Spatter Solutions Offered in the Market

A wide range of anti-spatter products are offered in the market for different welding needs and circumstances. It consists of aerosol sprays, gels, and water-based formulas. Here’s a rundown of the more popular choices:

Aerosol Spray

Aerosol sprays have a very user-friendly application and provide a huge coverage area. They work well for jobs that need to be done quickly or cover large surfaces. Brands such as Weld-Aid Nozzle-Kleen or Krylon’s Weld Spatter Spray guarantee up to 80% reduction in spatter adhesion. Some of the aerosol products may, however, need a reapplication when the temperature is high, or the work is carried on for a longer time.

Gel Products

Anti-spatter gels, including Radnor Anti-Spatter Gel and Blue Shield Gel, allow for much more precise application. They are especially useful for coating welding torch nozzles that extend the life of nozzles by preventing clogging. Unlike sprays, gels also usually provide a thermal barrier that lasts through heat extremes.

Water-Based

Water-based anti-spatter formulas, for instance, EcoWeld and Walter E-WELD 4, emphasize safety and environmental compliance. Those solutions contain no solvents or fumes and are thus a fine choice for any workplace that considers health and environment priorities. According to recent studies, high-grade water-based sprays reduce spatter adhesion by up to 90%, so there’s no need to lose effectiveness when going green.

High-Heat Resistant Products

Said to be advanced welding applications, and thus heavy-duty industrial welding, grant MS Spatter Shield High Heat fortification against extreme situations. These solutions retain their ability to operate even under prolonged high temperatures.

When selecting an anti-spatter, consider comparing the application methods, compatibility with base materials, SDS, and cease all possible user review efficacy. Testing several products always ends up finding the one that works best for one, ensuring a cleaner weld and less time spent on cleaning up after the weld.

Criteria for Selecting Anti-Spatter Products

It is essential to consider a variety of performance parameters, safety, usability, and cost-efficiency to be assessed in the selection of an anti-spatter product. The criteria below consider the oldest and the most up-to-date research:

- Efficacy and Performance

Reducing the adhesion of weld spatter and thereby minimizing cleanup is the main function of an anti-spatter product. Products should be selected for their proven performance under actual welding conditions. These tests have recently, for example, shown that silicone-based products tend to afford better resistance to thermal abrasion and longer-lasting protection when compared to water-based products. Confirm that the product specifications are compatible with high-temperature applications, especially for use on difficult metals.

- Application

Depending on your workflow, the method of applying the product could make or break your efficiency. The anti-spatter is available as an aerosol spray, as a liquid to be applied with a brush, or as a gel. Aerosol sprays offer quick cover and even application, but there may be overspray. The brush-on liquids and gels allow for more forensic application, but perhaps need some time to be precisely positioned.

- Material Compatibility

Anti-spatter products differ in their compatibility with various base materials. For example, some formulas might be fine for use on stainless steel, aluminum, or mild steel, but others might create problems like discoloration or residue formation. Check product labels/STDs carefully for compatibility with the materials they will be used upon to ensure that no adverse reaction ensues before or during welding.

- Environmentally Friendly and Safe

Today, safety and environmental friendliness greatly affect product choice. Contemporary options, therefore, provide biodegradable and non-toxic formulations. The absence of any dangerous chemicals like chlorinated solvents or VOCs makes for a safer work environment and reduces their environmental impact. Moreover, make sure the product meets workplace criteria, such as OSHA standards.

- Ease of Removal

Post-welding, an anti-spatter product should be easy to clean off. Results from trials conducted with users reveal that a high-quality product will leave little or no residues that are sticky, thereby facilitating a smoother post-weld cleaning operation. Use the reviews of users and manufacturers to identify those that claim to be residue-free.

- Cost-Efficiency

Compared to efficacy, it is crucial further to compare the product price against the benefits received for industrial and personal use. Bulk options also tend to bring down costs for business use where the product is in great demand. Choosing lasting formulas helps prevent waste by offering more coverage per loss in unit of product.

- User Feedback and Testing

Lastly, using user feedback and subjecting a multitude of products to testing in one’s working environment would propel decision-making processes. Online reviews, welding forums are are excellent resources for gathering data on specific products and gaining insight as to their advantages and disadvantages from real-world situations.

By considering these criteria in detail, welders and professionals in the field may identify those anti-spatter products that make the work more efficient, give more safety, and provide lasting value, regardless of the application being undertaken.

Effective Product Use Case Studies

Case Study 1: Efficiency Improvement Using Silicone-Based Anti-Spatter Spray

A fabrication workshop in Texas used silicone-based anti-spatter spray to achieve high weld spatter during production. According to the study in the year 2023, the product halved time spent on cleaning after welding. The workers reported that it prevented spatter from sticking to workpieces as well as welding tools. Increased ability to work enhanced the overall workflow as they maximized the use of heavy equipment in their manufacturing processes.

Case Study 2: Savings Through Eco-Friendly Way

An auto repair shop in California adopted a water-based anti-spatter product considered environmentally friendly. As per customers’ reviews in welding forums, this solution was very effective in eliminating use of caustic chemicals thereby slashing about 25% of operational costs within a timeframe of six months. Besides being environmentally compliant and green-friendly, the product did not compromise on performance.

Supporting Data from Welding Forums

Some recent threads on WeldingWeb and Reddit’s r/Welding claim that 75% of users favor anti-spatter products that are residue-free and easy to clean. User surveys have put silicone sprays at the top for professional welders working stainless steel, while hobbyists often go after inexpensive water-based ones for mild steel.

Which clearly underlines how important choosing the right anti-spatter product is, given individual requirements and circumstances.

Reference sources

- A Spot Welding Spatter Monitoring System Based on Machine Vision

- Authors: Xiaodong Wang et al.

- Published: 2023

- Conference: 2023 3rd International Conference on Electrical Engineering and Mechatronics Technology (ICEEMT)

- Citation: (Wang et al., 2023, pp. 76–80)

- Summary:

- This study presents a machine vision monitoring system designed for resistance spot welding. The system captures thousands of frames during a single welding duty cycle to identify key frames that exhibit significant spatter features.

- Key Findings:

- The system can calculate the amount of spatter and classify its types.

- It distinguishes spatter caused by various factors, including electrode pressure and current.

- Methodology:

- The system was developed using C++ and employs high-speed industrial cameras to monitor the dynamic process of spot welding.

- Study of Droplet Transfer and Spatter in Pulsed Gas Metal Arc Welding for Pressure Pipeline Welding

- Authors: Tao Liu et al.

- Published: 2024

- Conference: 2024 The 9th International Conference on Power and Renewable Energy (ICPRE)

- Citation: (Liu et al., 2024, pp. 259–263)

- Summary:

- This research investigates the droplet transfer and spatter generation processes in pulsed gas metal arc welding (GMAW-P), particularly for pressure pipelines.

- Key Findings:

- The study identifies that inappropriate droplet transfer modes and electric parameters can lead to excessive spatter, negatively impacting weld quality.

- It aims to provide insights into optimizing welding parameters to reduce spatter.

- Methodology:

- The research utilizes high-speed cameras and electrical sensors to monitor the welding process in real-time.

- The Formation Mechanism and Suppression Strategies of Spatter in Pulsed Gas Metal Arc Welding for Titanium Alloy

- Authors: Zhendan Zheng et al.

- Published: 2024

- Journal: Welding Journal

- Citation: (Zheng et al., 2024)

- Summary:

- This paper explores the mechanisms behind spatter formation during pulsed gas metal arc welding (GMAW) of titanium alloys and proposes strategies for spatter suppression.

- Key Findings:

- The research identifies two types of spatter: large and small particles, with distinct formation mechanisms.

- Strategies such as increasing detachment current and decreasing pulsing frequency significantly reduce spatter rates.

- Methodology:

- The study employs high-speed imaging and synchronous electrical signal analysis to investigate spatter formation mechanisms.

Frequently Asked Questions (FAQs)

Q: Why does weld spatter occur in MIG welding?

A: Weld spatter during MIG welding originates mainly from the interaction between the welding wire and the molten weld pool. It may also occur due to reasons such as wrong polarity, voltage settings, or the quality of the welding wire. If the voltage is pretty low, or the amperage is not proper, one can have an unstable arc and these little droplets of molten material get catapulted out from the weld pool.

Q: How can spatter be minimized on MIG welding?

A:In order to reduce spatter in MIG welding, it is important to consider the correct classification and combination of wire and gas, maintain a good gun angle, and keep an appropriate arc length. Using the right amperage and voltage will also ensure proper heat and penetration are applied, thereby alleviating issues of excessive spatter caused by welding.

Q:Does the arc length influence weld spatter?

A:Arc length determines the amount of weld spatter produced. A short arc length increases heat concentration inside the molten pool that stabilizes the weld and keeps spatter to a minimum. On the other hand, if the arc length is too long, the molten metal is forced to spit because less energy is focused on the weld pool.

Q:How does the speed of moving the MIG gun affect the spatter?

A:Speed of migration of the MIG gun plays a key role in the control of spatter. Moving too slowly will increase heat in the molten pool, causing excessive spatter, while moving too fast will lack penetration that is enough and will lead to poor weld quality. Hence, it is important to maintain a balance in order to reduce spatter.

Q:Will anti-spatter spray work in reducing spatter?

A:Yes, anti-spatter sprays will indeed reduce spatter occurring during welding by creating a shield that prevents spatter from sticking to surfaces, thereby allowing an easier cleanup. Such sprays do not compromise on efficiency.

Q:What are the best techniques for weld spatter removal?

A:The best methods for removing weld spatter include using hand tools such as wire brushes, putty knives, or flap wheels. For more stubborn spatter, an aggressive treatment, such as grinding or applying a chemical spatter remover, may be in order. Maintaining cleanliness of the work area and application of protective coating will also minimize spatter accumulation.

Q:How does the welding wire type affect the degree of spattering?

A:The welding wire used can greatly influence the spatter produced. Different wire compositions have different melting points and fluidity; thus, they affect the behavior of molten metal to a greater degree. Choosing a welding wire suitable for the particular welding application and conditions can reduce spatter significantly throughout the welding process.

Q:What’s globular transfer mode, and how does it relate to spatter?

A:Globular transfer is a form of welding in which large droplets of molten metal are transferred from the welding wire to the weld pool. Because of the larger size of the droplets, this mode usually generates much spatter. To minimize spatter, spray transfer mode would be preferred, or settings should be adjusted to obtain a cleaner transfer of molten metal.