Meticulous activity or work demands meticulously welded components which themselves demand integrity and support through these peculiar welding aids, equipment, and fixes. All of us–no matter how skilled or unskilled we are in any area of activity like welding–can work on and improve our ability to design welding equipment or fixes particularly. However, what are the features that make the best welding structure and how do you organize such structures to help integrate production and ensure standard work? This post is more practical – it addresses two more advanced levels for trainees and aims to introduce them to these methods. It aims to address the problem that this site’s target population appears to have in welding fixture design through developing the perfect content that reveals why their approach to welding folding is wrong and needs to be corrected.

What is a Fixture in Welding?

Fixtures play a crucial role in achieving efficiency and precision in the welding process. These tools are meticulously designed to provide stability and maintain alignment across workpieces, reducing the likelihood of errors. According to a recent industry report, the use of welding fixtures can increase production efficiency by up to 30%, as they streamline the workflow and minimize rework caused by misalignments.

One of the primary advantages of welding fixtures is their ability to ensure repeatability in large-scale manufacturing processes. With advanced modular fixtures, manufacturers can easily adjust and adapt to different project requirements. For example, adjustable clamping mechanisms allow for versatility when working on various shapes and sizes of materials.

Modern advancements in technology have also led to the development of automated and computer-controlled welding fixtures. These systems enhance precision by integrating sensors to detect and correct misalignments immediately. Data from recent studies show that robotic welding systems combined with automated fixtures can achieve accuracy levels within 0.1 millimeters, a significant improvement over manual setups.

By investing in high-quality fixtures, companies can not only improve welding quality but also save on costs by reducing material waste and ensuring consistency across production runs. Choose the right fixtures based on project requirements to unlock their full potential in your welding operations.

Types of Welding Fixtures

- Manual Clamps: These require the adjustment and positioning by an operator and are made applicable only for low-volume or non-standard projects.

- Pneumatic Clamps: These require the utilization of air pressure in the act of clamping to the object and are very efficient in leveling of the repetitiveness of the welding tasks.

- Hydraulic Clamps: These provide high actuating or clamping loads and are mostly associated with heavy or precision fabrication technologies such as welding.

- Adjustable Clamps: Due to their flexibility, these clamps can be reconfigured to meet the specific requirements of the project.

- Modular Clamps (Beams and Blocks): These are comprised of exchangeable elements and are intended solely for purposes of welding.

Picking the right Welding Fixture for the Project

Apt selection of the welding fixture plays an inescapable role in the success, accuracy and efficacy of the work at hand. Making such a choice is tied to several determinants including the nature of the work, the material at work, the size of the operation and the money at hand. Below are the key things to look at:

- Type of Welding Process – some welding processes such as TIG, MIG, or resistance welding may require specific types of fixtures. For example, in some cases, MIG welding can perform much more efficiently using pneumatic or hydraulic fixtures because of the repetitiveness of that particular work piece. While modular fixtures are good for TIG welding which needs precision tightness.

- Material Properties – Considerations as to the nature of the material and how thick it is, determine whether the choice is the better alternative. For instance, where the materials are heavy, Care need to be taken to choose hydraulic fixtures which will be able to apply the required clamping pressure and on finishing the job, adjustable fixtures might be more suited for projects with different materials together, and more so different sizes.

- Production Volume – In some cases, high volume production lines such as in the automotive industry can use pneumatic or modular fixtures because of the ease in setting up. Studies have noted that quick-change insertion methods can save up to 40% of the necessary setup time as opposed to having static fixture systems, thus considerably increasing the efficiency levels of work.

- Finance Versus Expanse – For businesses which are small or with new varieties, it would be unwise to build hydraulic components. Taking the case of Zimbabwean small business workshops at risk of competitive exclusion, it has been noted the operating cost of such firms through fixture system has decreased by 30%.

- Precision and Repeated Welding – Compared to situations when the input of precise work is needed hydraulic and modular fixtures are over time the most appreciated. After locating precision independent units, the spatial relationships can now be set consistently to allow for spot welding with a 30% risk of the process collapsing.

Working their way through these parameters and appealing to the modern alternatives of positions held in the form of the modular fixtures and the space that is adaptive, fabricators may improve both the efficiency in dealing with their workload and the quality of the welding provided.

How to Set Up a Welding Table for Maximum Efficiency?

- Choose the Right Location – Place the table in a well-ventilated area with ample lighting. Ensure there is enough space around the table for movement and storage of materials.

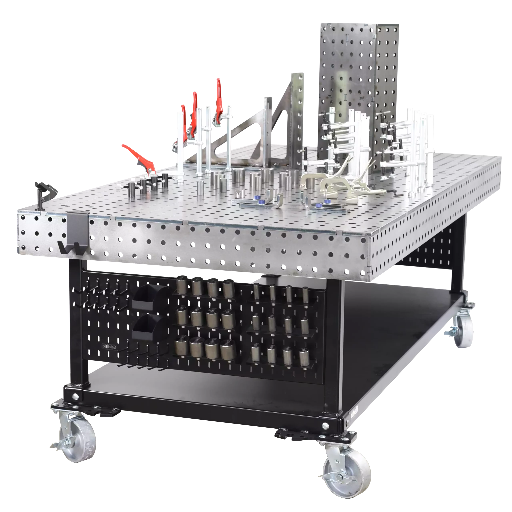

- Equipment a Strong Table – For purposes of welding, acquire a table that is both sturdy and made from high temperature resistance material, preferably without holes found on the surface. Make sure the table is able to take load of your working materials as well as other necessary tools.

- Arrange Tools and Materials – Have clamps, welding machine, and working materials are available for use without bending way too much. Serve them with a suitable storage system and with the help of some containers one can clear off some clutters.

- Grounding – Adding an appropriate electrical grounding element near the table will help in eliminating any possible electrical harm.

- Follow the Safety Rules – While working, avoid fire breakout and injury by placing fire extinguishers at strategic location, putting on safety apparattus at all times and making sure that the working environment stays hygeinic.

Components of a Welding Table that cannot be left out

- Equipped With A Suitable Working Platform-The table must possess a flat, long lasting and heat resistant surface usually steel made to withstand the intensity of the welding process.

- Clamping Means – Welding is much more precise and stable when the items are held down by clamps.

Dust Extractor Or Ventilation System – In most cases, it is necessary to have a ventilation or fume system to remove the welding fumes from the work area. - Storage Options – Provide shelves, hooks or containers for all tools and accessories so that they are easy to access and neatly arranged.

- Variable Work Surface – Allowing for a change in the height of the working surface provides additional convenience and flexibility, allowing different user activities and needs to be satisfied.

Optimizing Table Layout for Various Welding Tasks

In optimizing a table’s correspondence with various activities to be carried out on a table it’s important to have enough space and minimize clutter. If any working tools and objects are likely to be used frequently, bring them closer to the technician to save time. You should install such clamps in different parts of the table so as to be capable of being changed and made available. Having safety equipment such as welding screens or shields for maintaining welding tables clean and free of debris as it helps in a free environment.

Welding Table Care Usage Hints

Speaking of maintaining your welding table, one should indeed ensure constant neatness on the table in order to eradicate dirt, weld slag, or spatters especially in places where there was an activity in progress. Keep an eye on the state of the table and its elements in comparison to new condition and make any necessary repairs to ensure there are no ‘waves’ on the working surface. Make sure that internal surfaces are adequately protected at all times, moreover, it is recommended to coat antable with antispatter or a layer of wax to prevent rusting. Do not leave tools and equipment unattended after the job is done because it will make the place undone and unproductive.

What Are the Best Clamp Options for Welding Fixtures?

- C Clamps: General welding work is most convenient to be performed with the help of the clamps, which have a broad range of applications and ensure the firmness of pieces between its jaws.

- Vise Grips: These offer the advantage of a tight grip with a quick application, idea for fast paced jobs.

- Vise Clamps: They are more suitable for welding which involve permanently joined parts as this requirements often need a good holding but quick release clamp.

- Hand or Job Holder: Some other clamps, like Magnetic clamps come in good for hands free operations and working with ferrous materials is done on that stage.

Exploring Different Types of Welding Clamps

The different types of welding clamps include C-Clamps, Locking Pliers, Toggle Clamps, and Magnetic Clamps.

| Clamp Type | Key Feature | Best Use | Advantage | Limitation |

|---|---|---|---|---|

| C-Clamps | Versatile | General welding | Secure hold | Slower setup |

| Locking Pliers | Quick grip | Repetitive tasks | Ease of use | Limited span |

| Toggle Clamps | Quick release | Fixed setups | Reliable hold | Less flexible |

| Magnetic Clamps | Hands-free | Ferrous metals | Convenient | Magnet only |

How to Use Clamps Effectively

Using a clamp needs a little care so that the clamps will not cause some destruction. Before one can fully enjoy the advantages of using a clamp, one must take some steps and checks in first. The most resources that will save one’s clamps themselves from any mechanical devise marking issue are well placed waste boards. Regularly Check The Clamp’s Condition so as To Reduce Any Accidental Injuries. Use Any Appropriate Clamping Surfaces That are Available for You.

How to Conduct a Successful Weld Test?

In order to accomplish a highly effective weld test, the test area should be clean, with no dirt and any other contaminants in place. One should employ the necessary testing technique according to the requirement of the project, such as but not restricted to, visual tests, radiography, and bending methods. It is also necessary to ensure that the welding results align with the intended designs from edges, strengths, alignments, and that the welded material is the right size. If improvement is required meeting these plans, they should be put in action and tested once and for all.

How to Get Ready for Welding Tests?

When preparing for a weld test, it is important that all materials and equipment are prepared and utilize the right working condition for the certain test. Make sure the metallic surfaces are clean so as to eliminate all forms of oil, rust and dirt among other dirt particles. The welding apparatus will also have to be checked for properly calibrated as well as qly functional. Adhere to the protocols concerning safety and wear protective equipment as well as resolve individual task related queries or benchmarking in case the standard is not enough in implementing the test.

Common Mistakes to Avoid During Weld Testing

- Neglecting Proper Surface Preparation – Cleaning and preparing the surfaces for welding help in the elimination of problems associated with weak welding practice as well as inconsistency. Examine the presuppositions and work only after the surface has been cleaned.

- Inappropriate Settings Of Apparatus – Selecting incorrect welding parameters with respect to the material or welding process normally has other workarounds. It has to be one’s part to ensure that the equipment is properly calibrated and such equipment settings are at the best possible level.

- Lacking Sharpening – One more factor that does not call for a hasty decision in a test is that the test is quite simple not to carry out drills on the subject. Before the test study in contrast the tools you must rely on during the test.

- Failure to Obey Safety Regulations – Raised balcony, unprotected head, violation of the rights of children, dangers without a program on the procedures and the restriction of self-control may cause obstacles and excessive palpitations.

- Wasting the Process – As with the process of getting engaged aggressively hurried into the weld. Take as much time as you need in ensuring that the alignment is taken care of and the process goes according to the standards.

Analyzing Weld Test Results

In the area of interpretation of results of weld tests, my main task consists in finding and detailing possible defects of cracks, porosity, or lack of welder fusion that might weaken the strength of the completed weld. Also the use of nondestructive testing such as ultrasonic testing or radiography allows me to examine the soundness of the weld without any structural failure. Where these methods are not practical, I tend to make use of results as per certain standards and accepted norms to ensure that stakeholders provide accuracy. These issues are amongst the important factors that influence the determination of the weldability of items; to rework the joint if necessary.

What are the Key Considerations for Welding Pipe and Tube?

- Material type: Identifying the type of material for wise-border work is necessary, as different metals and alloys have different effects fillers, techniques, and heating amount.

- Joint Design: Pinpoint the best joint design to use that will ensure the right placement and durability of the joint in the application.

- Preparations: Prepare the appropriate surface finishes, including thorough cleansing of contaminated surfaces covered in oils, dust or rust, as it might destroy the weld area.

- Welding: Considers such factors as the particular welding process chosen: see GMAW, TIG or Stick as a few of the possible options, the material, the thickness of the pipe or tube and the scope of the project before welding is initiated.

- Heat Management: A proper regulation of the heat is necessary to much deformation, cracking, and over a weakening of the material during the welding process or process.

- Examination and Progressing: At every development cycle a team that has an agility range higher or equal to 1530 of each project team operates a full-backlog lot of business value or AT cores on their current existant hardware

Welding Pipe Techniques

- Preparation of the Joint: Once the preparations have been accomplished, it is pertinent to ensure that the pipe edges are free of oil, grime, and sloped correctly with their ends beveled to render a stiff and fine weld.

- Welding Positioning: Position of welding is welded to be appropriate for. horizontal, vertical or overhead based on the pipe and direction of the pipe work to them.

- Continual Technique: Posses a firm and white hand and movement of uniformity in good speed so that the welds are created in an even manner that enable connections to provide reinforcement as well as ligametry.

- Regular welding: Make use of the normal welding process and dow welding correctly with the help perfection over the edges thereby making the development of volume and regular welding possible.

- Proper Equipment Settings: Amperage and voltage both change the piece making them two of the most important factors in getting best results based on the material and the plate thickness.

Challenges of Welding Tubes and How to Overcome Them

- Mismatch in Joint Fit-Up: Gaps or misalignment in tube joints can weaken welds. To overcome this, ensure precise preparation and alignment of the tubes before welding. Use clamps or fixtures to hold them securely in place.

- Access Limitation: The welding area is small and limited. There are special instruments which may be used in order to deal with constrained and difficult to access locales such as orbiter welding.

- Distortion: If a relief on heat buildup is not employed, the thermal stress on the mechanism may cause it to distort. Take particular care of excessive heating by adopting reduced welding heats and permitting enough interpass cooling.

- Sensitivity of Material: Some metal is so readily reactive that, at this boundary, deformation or cracking may be very apparent. Use best interference fit via interlocking and sealing and consider a clean atmosphere.

Ensuring a Strong Joint in Pipe and Tube Welding

It is of paramount importance to focus on proper preparation and skill to guarantee a strong joint in pipe and tube welding. One of these is to remove any oils or greases from the surfaces being sealed including any other contaminants that might reduce the quality of the weld. Furthermore, the right welding technique, machine and parameters that support the material and wall thickness must be employed. Similarly, reasonable alignment and fit-up should be ensured in order to prevent openings or improper fit. The ultimate step involves checking the filled welds for any cracks, porosity or any other forms of defects to ascertain the structural strength and quality.

Reference sources

- Design of Rigid-Locking Variable-Angular-Span Welding Fixture (2024) (Kadam et al., 2024)

- Key Findings: The paper presents the design of a rigid-locking variable-angular-span welding fixture that can accommodate different workpiece configurations and orientations.

- Methodology: The fixture design process involved concept development, material selection, and analysis of the welding conditions to ensure proper alignment, clamping, and heat management during the welding process.

- Performance Evaluation of a Smart Welding Fixture and Jig Assembly (2023) (Sibanda et al., 2023)

- Key Findings: The smart welding fixture and jig assembly, which includes a compressor, proximity sensors, thermostat, cooling system, and control panel, demonstrated the potential to save 32.26% of the total time during manual welding operations.

- Methodology: The performance evaluation was carried out by comparing the pressure and time taken for clamping and unclamping activities at different pressure ranges.

- Design And Implementation Of A Fixture For Robotic Welding – Discusses the design and implementation of fixtures for robotic welding, including cost analysis and practical applications.

- Welding Fixture with Active Position Adapting Functions – Explores the design of versatile welding fixtures with active position-adapting capabilities.

Frequently Asked Questions (FAQs)

Q: What is a welding fixture?

A: A welding fixture is a tool which is designed specifically to secure the objects being welded in place. It allows the parts being worked on to be accurately positioned and held firmly together during the welding operation. It therefore aids in the production of consistent high quality welds.

Q: How does a welding fixture improve the welding process?

A: Welding fixtures improve the process by maintaining accurate alignment and positioning of parts, because it eliminates the annoying process of constantly changing the parts alignment in fixing the welding parts. This tends to result in time that is not wasted but rather used efficiently, reduces even errors, and ensures high accuracy in application and welding issues.

Q: What materials are commonly used for making welding fixtures?

A: The most commonly used materials in welding fabrications are cast iron, aluminum and steel. Other materials are also used depending on the needs of a project, these are materials that are tough and resist heat and pressure during welding operations.

Q: Can magnetic fixtures be used in welding?

A: Absolutely, magnetic fixtures can be used for holding parts in place especially during welding, depending on the rectangular area that the parts have. They are highly useful for applications where mechanical clamping is difficult, such as in sheet metal, and in cases of awkward parts, it is more of a chisel.

Q: What are the benefits of using a jig in welding?

A: The jigs are of much use in welding as they help in keeping the parts where they ought to be during assembly and welding and this helps the accuracy and repeatability of welds in this case. There is also the advantage that they do not cost as much to use in production and it helps the assembly processes to be less complicated.

Q: How does a welding fixture contribute to safety in the shop?

A: Welding fixtures also play a role in ensuring safety in a working term since they help to immobilize the parts which minimizes the chances of shifting while those McDonalds Corporation Factory Welding Fire Causes Include such wear. All of this lessens the risks of accidents and therefore injuries also reduces the hazards to the bond due to absence of the opposing forces.

Q: Why is fixturing important for welding with aluminum?

A: Its importance lies in welding aluminum because it deals with the latter’s high thermal expandance as well as thermal conductance to some extent. A proper fitting fixture part, however, will prevent any adverse deflections or misalignment under the welding process.

Q: What is the significance of hole diameter in fixture tables?

A: The hole diameter in fixture tables is important in terms of the kinds of clamps and accessories that comfortable fit either readymade or custom design. The hole size needs to be up to the standard so that it can be easily interfaced with different fixturing tools thereby enhancing the possessiveness of the table and its capacity to perform an extensive range of welding tasks.