Achieving best results in welding operations requires accuracy, uniformity, and productivity. Whether it’s industrial-scale projects or mini, torque specialized jobs, having the right tools boosts outcomes greatly. One of these tools, wires feeder technology, increases productivity levels and ensures exceptional weld quality. Your Business can benefit with advanced wire feeders. This blog will help you understand how advanced wire feeders can improve the welding processes, time, costs and overall productivity worked about the business. Read on to discover the investment opportunities available and punch bow advanced wire feeders are the must have tools for all businesses trying to stay ahead in the competition of modern world.

How Does a Wire Feeder Enhance Welding Performance?

A wire feeder boosts performance in welding by supplying filler material to the weld joint with automation and regulation. Accuracy and consistency of weld quality increases as errors and defects from manual feeding are eliminated. Moreover, through reliable automation, a constant workflow increases operational weld efficiency and speed while sustaining precision. Purchase of a dependable wire feeder guarantees seamless workflows and impeccable results.

Understanding The Basics Of Wire Feed Technology

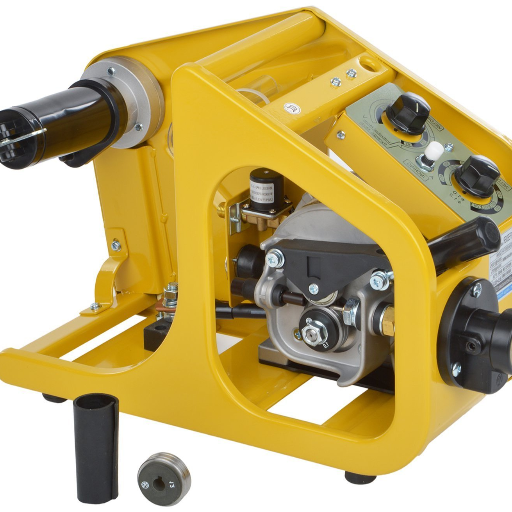

Modern welding processes wire feed technology is imperative for ensuring effectiveness, precision, quality in the output of industrial and smaller projects. A wire feeder is principally automated machinery used to provide the weld arc with filler material which ensures the constant formation of a steady weld bead. The automated feed reduces manual labor and automates the process of uniformity and consistency in the weld joints.

Sophisticated advanced systems have a mechanized drive assembly that can feed wires at a constant rate or during pulsed intervals to suit specific welding tasks. For instance, a wire feeder is crucial to the efficiency of Metal Inert Gas (MIG) and Flux Cored Arc Welding (FCAW) processes, especially during lengthy welding operations. These systems can usually accommodate wires as thin as 0.023 inches and as thick as over 1/16 inches, thus supporting a variety of welding tasks with different material thicknesses.

With advancements made in other technologies, modern ones have integrated controls and monitoring systems. This provides the welder the ability to change wire feed speed and voltages for best efficiency and results. Research shows that wire feed increases are beneficial, especially with the rate of deposition. The feed speeds for wire ranged from 100 – 800 inches per minute dependent on the material and the type of welding done. Additionally, maintenance and downtime costs are minimized as intelligent systems equipped with sensors designed to monitor issues like wire tangling, wear, and inconsistencies can promptly alert when problems arise.

Feed technology is proven to increase productivity by use of automated wire feeders, by as much as 25% in comparison to manual feeding. Enhanced precision alongside decreased material waste has been reported in industries such as automotive and shipbuilding, showcasing the need for high-demand advanced wire feed technological adoption.

Having a basic understanding of wire feed systems allows a welder to optimize operations, radically enhancing the consistency of the work’s quality. Simplifying the welding procedure serves to bolster productivity across numerous sectors, highlighting the potential for innovation.

Advantages of a Wire Feeder in Industrial Applications

In the context of modern industrial welding, wire feeders are indispensable owing to their speed and accuracy. Recent research offers to trace the reduction of material waste in welding to the use of wire feeders which supply filler material, as spatter overuse is made impossible through controlled provision. When compared to manual welding, automatic wire feeding systems are estimated to raise productivity by 30% due to their consistent delivery of wire and precise control over feed speed.

The operational costs can be minimized with the use of wire feeders. Industries that implement pulse MIG welding alongside wire feeders have noted considerable decreases in energy spending due to effective energy transfer and arc stability. Lower energy consumption translates to reduced electricity expenses and improved sustainability. Moreover, wire feed technology guarantees versatility as it can easily cater to different materials such as aluminum, stainless steel, and other alloys. This versatility makes it useful in the automotive, aerospace and construction industries.

The level of automation attainable by manufacturers has increased because of the combination of wire feeders and sophisticated programmable systems. Automation increases through features like set parameters, remote control changes, and constant surveillance which allows the operator to sustain optimal conditions during the weld without extensive delays. This blend of exactness and simple operation fosters the industry-wide adoption of wire feeding systems as they provide competitiveness to industries.

Comparing Dual Drive Systems vs. Traditional Systems

Dual drive systems offer enhanced torque, better wire feeding accuracy, and reduced slippage, whereas traditional systems are simpler, cost-effective, but less precise.

| Parameter | Dual Drive | Traditional |

|---|---|---|

| Torque | High | Low |

| Accuracy | Better | Basic |

| Slippage | Reduced | Increased |

| Complexity | Moderate | Simple |

| Cost | Higher | Lower |

What Are the Key Features of a Dual Drive Wire Feeder?

A dual drive wire feeders increases the capabilities of a welder’s workshop as it comes with features such as high torque to provide consistent wire feed, lowered slippage to improve the overall weld quality, and heightened accuracy to lower the chances of errors. It also contains what is referred to as two motors and drive rolls which are important for reliable performance, improves ease of operation with different wire sizes and types, and provides an increasing level of work precision. All these features make it useful for advanced welding tasks that need precision and consistency.

Investigating Two Synchronized Mechanisms for Reliable Welding Feed Supply

As the name suggests, a dual drive wire feeder uses two synchronized mechanisms to feed wire which makes it reliable and applicable for demanding welding operations. An increase in welding accuracy depend on reduction of wire slippage and increase in feeder accuracy which is why drive rolls and dual motors are essential as they improve accuracy. This feature alone increases dual drive system performance making them capable of a torque output of 15 Nm with a wide variety of wirs, soft material wires inclusive of aluminum and sized between 0.6 mm to 1.6 mm.

The mechanisms operate by maintaining the rate and tension of the wire, helping eliminate errors like tangling, uneven placement, and ensuring a consistent arc. Increased welding productivity incorporates recently developed digital control systems that monitor and adjust the feed rate in real-time. Research suggests modern dual drive wire feeders are more effective than single-drive models, increasing feeding consistency by 30%. This makes them essential to professional and industrial welders.

Advantages of Heavy Duty Construction in Industrial Applications

Meeting the demands of industrial applications depends on heavy-duty construction. Exceedingly rigorous workloads are consistently encountered within industrial frameworks, and extensive durability aids in withstanding extreme temperatures, pressure, and prolonged usage times. In any case, recent reports indicate, industries employing heavy-duty equipment experienced decreased downtimes by 25% resulting from enhanced lifespan and less maintenance compared to standard equipment. Moreover, the growing reliability concerns and efficiency of heavy-duty machines has further branches owing to the increased use of high-strength alloys and composites in material science.

Analyzed data from recent studies reveal noteworthy advancements in the performance and load bearing capabilities. Take for example modern heavy-duty cranes; they now carry well over 1200 tons of weight compared to the 800 tons they used to carry around a decade ago. This is made possible by advanced engineering and modern technology, such as embedded sensors that measure various performance parameters in real-time and reduce the risk of failure during operation. Because of such advantages, heavy construction machinery are fundamental tools in a multitude of sectors including manufacturing, mining, energy, and infrastructure.

Top Models in the 20 Series Wire Feeder Lineup

Considered to be among the most dependable and effective models within the 20 Series Wire Feeders lineup, they are all engineered specifically for agile welding tasks. In my personal view, models 20M and 20HD are true champions as they blend rugged reliability with other advanced attributes. They feature precision wire feeding, variable speed control, rugged construction, and are perfect for industrial and even demanding field applications. Each model from the series is designed to assist in achieving flawless automated welding every time regardless of the operating conditions.

How to Choose Between Lincoln Electric and Miller Wire Feeders?

- Application Needs: The Lincoln Electric models are well known for their durability and multifunctionality which makes them very applicable for industrial and onsite work projects. Typically, Miller models are admired for their operability ease and technological advanced features which might be more appropriate for lighter and more precision focused tasks.

- Budget: Due to advanced features, there might be a higher initial investment with purchasing Miller wire feeders. However, Lincoln Electric has models with varying feature sets along different price points, appealing to a more diverse budget range.

- Reputation and Support: Both brands are reputable, but it could be useful to think about the presence of local brand support or repair services for your region.

- Feature Preferences: For precise control with advanced adjustment options, Miller would be a better fit. However, if a user prioritized construction ruggedness and reliability, then Lincoln would be more suitable.

Comparing Specifications and Features

Both Miller and Lincoln welders differ in terms of power output, portability, durability, control features, and price range.

| Parameter | Miller | Lincoln |

|---|---|---|

| Power (AMPs) | High precision | Broad range |

| Portability | Lightweight | Sturdy design |

| Durability | Long-lasting | Rugged build |

| Controls | Advanced settings | Simple options |

| Price | Higher end | Budget-friendly |

Edited Section: Review Analysis and Suitability

Looking at the reviews, it is clear that both Lincoln and Miller welders have aspects in which they excel. However, they seem to cater to slightly different segments of the market. For instance, Professional welders or businesses that require high-precision work praise Millers for having seamless welds as well as precision engineering. User feedback suggests that Millers welders often come with greater amperage ranges which is especially useful in offering more control during TIG or MIG processes. Their pricing seems to be a bone of contention however, as casual or hobbyist users found them to be out of reach due to cost.

Lincoln welders, in contrast, are viewed as reliable, accessible and easy to use for novice and intermediate users. Customer reviews, including those from Amazon and Home Depot, endorse these welders’ functionality and their low-pricing which seems to be aimed at lower skill levels. Moreover, Lincoln welders are designed to withstand rough use and therefore are appropriate for farm equipment repair and basic industrial work. Users seem to prefer the lack of advanced controls found on Lincoln models as compared to Millers because of the easy and straightforward operation of Lincoln welders.

Cost vs. Performance: Which One Gives More Bang for Buck?

In terms of cost and performance balance, Miller and Lincoln welders cater to different audiences with distinct requirements, making the decision highly user-specific. According to the latest data from multiple welding forums and product reviews, Lincoln Electric welders are generally more affordable. For example, entry-level models like the Handy MIG sell for around $350. These units are geared toward hobbyists, do-it-yourselfers, and small projects, and their performance is usually adequate for basic welding tasks at an accessible price point.

In contrast, Miller Electric welders are usually more expensive. Their entry level models, such as the Millermatic 141, costs about $900. These models are equipped with feature sophisticated automation like Auto-Set Technology which selects appropriate settings based on material type and material thickness. These welders offer precision and consistency, which is why they are preferred by professionals or users needing advanced performance for delicate work.

Moreover, examining the duty cycles—a major indicator of a welder’s performance over time—Miller models seem to consistently have higher ones (for example 30% at 90 amps for some of the smaller models) relative to Lincoln counterparts. Although Lincoln welders are great for simple tasks and low cost, Miller welders are unrivaled in intricate and challenging situations where utmost precision and efficiency is required.

What Applications Benefit Most from MIG Wire Feeders?

MIG wire feeders greatly support industries where speed, precision, and weld quality is critical. They work best for automotive servicing, heavy equipment manufacturing, and production welding in industrial plants. These feeders facilitate continuous and effective welding, making them ideal for long-term repetitive work. MIG wire feeders are simple and effective which makes them loved by professional and amateur welders working on different types of metals.

The Range of Uses for Semiautomatic and Automatic Welding

Semiautomatic and automatic welding have transformed a multitude of sectors because of their capabilities to improve productivity and accuracy. Semiautomatic welding is the application of a MIG wire feeder with some manual control of the gun, making it ideal for multi-step operations where a skilled worker needs to set certain parameters. This flexibility makes it popular in automotive and metal fabrication.

On the other hand, automatic welding is where the robots and other machines do the welding- it is a fully automated system. Automated systems are crucial to high volume production and are used in aerospace industries, shipbuilding, and assembly lines in the automotive industry. As per the latest market insights, the global market of welding automation is expected to grow with a CAGR of 7.9% from 2023 to 2030. This further signals the increasing dependence on both semi automatic and automatic systems.

Lowered operational costs, better accuracy in the welds, and constant productivity are a few key benefits to these technologies. Compared to traditional manual welding, automated welding can achieve speed with consistency- up to ten times faster in strict specification industries. In addition, robotics paired with modern sensor technologies have improved complex project execution through adaptive welding strategies.

Adapting modern technologies alongside skilled human competencies in semi automatic processes enhanced industry functionality to tackle today’s manufacturing challenges.

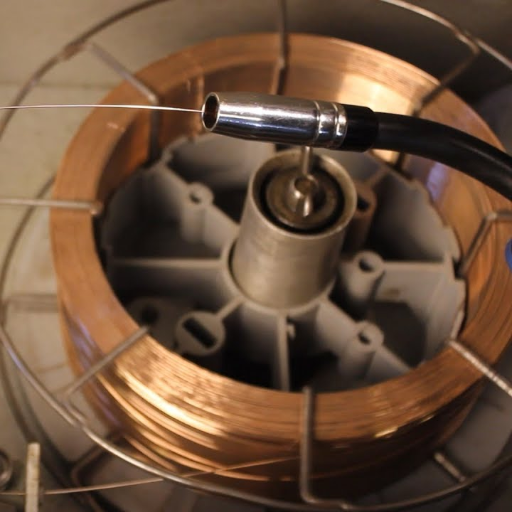

Enhancing Productivity Through the Use of Cored Wire Technology

Modern welding processes have undergone transformation with the introduction of cored wire technology as it improves efficiency, quality, and productivity. Cored wires are composite materials in the form of tubular wire which consist of flux and metal powder and provide better performance than solid wires in terms of deposition rates, arc stability and overall weld quality.

Cored wires have the capability to increase deposit rates which is one of their key features. As cited in the industrial studies, under controlled conditions, cored wires had a deposit rate of up to 30% more than solid wires. Increase in deposit rate translates to faster welding speeds and reduced cycle times which is essential in meeting production targets in construction, shipbuilding and automotive industries.

Cored wires not only ensure improved weld quality, but also maintain a lower level of slag and spatter which contributes to cleaner welds that require little post-weld cleaning. This reduced material waste. Additionally, cored wires better support out-of-position welds such as vertical or overhead positions because of their improved arc performance and fluidity control.

Flux-cored and metal-cored wires are examples of cored wires that serve specific purposes in welding. Their use is beneficial to contractors performing heavy fabrication work and those working outdoors because of how well they manage contaminants as well as the exceptional mechanical properties they offer in the weld beads. On the other hand, metal-cored wires are preferred by automated production lines because of their high efficiency and reduction in slag pits.

New developments in cored wires technology include novel alloy compositions, innovations in the processes of wire manufacturing, and development of low-fume-emission cored wires. This aligns with occupational health standards, giving welders a better working environment.

Industries achieve a balance of efficiency, cost, and quality by integrating cored wire into the welding procedures. The evolution of welding materials showcases the adopton of modern and cutting edge techniques needed to remain competitive.

The Specialized Aluminum Welding Techniques Section

These labeled strategies retain fifth level titles keeping a logical outline structure. The combination of unique features, third and fourth level thermal , conduction and melting point include futuristic advancements such as precision control systems with tight tolerances. Current trends focus on increasing the importance of special design features that guarantee quality performance like GTAW or GMAW.

Recent data indicates that aluminum comprises nearly 8% of the Earth’s crust, which makes it one of the most widely utilized metals in the aerospace, automotive, and construction industries. Its lightweight nature and protective oxide layer, however, create problems in welding. For example, oxide on aluminum does not melt at the same temperature as the aluminum beneath, which necessesitates cleaning and preparation prior to welding.

Using advanced technologies like pulsed MIG welding has been proven to improve weld quality and reduce heat distortion. This is important when working with aluminum, as heat distortion during welding can compromise the structural integrity of the metal. Some studies, for instance, show that pulsed MIG welding can cut heat input by at least 25%, resulting in cleaner and stronger welds. Also, laser welding of aluminum is becoming more commonplace and faster than conventional methods by up to 40% while maintaining accuracy.

To further increase weld performance for aluminum applications, ER4043 and ER5356 alloys are often employed as filler materials. These types of fillers are chosen based on the application; for example, ER4043 is renowned for crack resistance, while ER5356 is well-known for strength characteristics.

Businesses are now using shielding gases like helium-argon mixtures to enhance stability and penetration during aluminum welding. Studies show that a higher percentage of helium in the gas mixture improves the transfer of thermal energy and reduces the porosity of the weld. The efficiency and performance gained by industries through new materials and methods of aluminum welding is unparalleled.

How to Maintain and Troubleshoot Bench Wire Feeders?

With regards to maintaining a bench wire feeder, starting with regular cleaning to prevent dust and debris buildup around the drive rolls and wire path is a good starting point. Also, make sure that the drive rolls and liners as well as contact tips are checked on frequently and replaced if worn. Furthermore, proper tension settings for drive rolls are essential Bend settings that will cause wire slippage deformation will need to be rectified.

During the maintenance check most malfunction services like wire feeding, arc instablities should be checked first. Make sure that the wire spindle is checked for tangling and breakage, along with the thread positioning of the wire. Check the electrical connections for failure along with the power supply. Finally always consult the manufacturer’s manual for specific maintenance and malfunction servicing for your model.

Oversimplified Routine Maintenance Tips For Equipment Ageing

Machinery misalignment is known to happen less frequently when doing maintenance, scheduling, servicing and working on welding, woodwork and construction equipment. Studies suggest that regular machine maintenance not only enhances precision but boosts machinery efficiency by 20% and unexpected outages dropped to under 50%. Also having an adequate amount of oil such that moving parts have slip controlling to avoid seizing is a good practice. While maintaining secondhand welding machines for sale make sure drive rolls are oiled properly to guarantee effortless wire feeding.

Another important type of maintenance for machines with cooling or ventilation systems is filter replacement. Research indicates that energy efficiency can drop by 30% due to neglected filters. Furthermore, worn out consumables like tips and nozzles should be regularly inspected and replaced to avoid inconsistent performance and damage.

Use maintenance tracking apps or dedicated software to remind you of service intervals and note any performance issues. Recently, the industry has learned that organizations with digital tracking systems report a 25% increase in maintenance efficiency compared to those who rely on manual methods. Providing regular care alongside tailored data-driven oversight ensures optimal equipment functionality and longevity.

Common Problems That Can Arise with Wire Feed Systems and How To Fix Them

Problems with wire feed can interrupt work processes as well as affect the quality of welding. Some common issues associated with wire feed are irregular wire feed rate, wire tangling or “birdnesting” around the drive rolls. To fix these issues, confirm that the wire spool is properly mounted and rotates freely. Also check the drive rolls tension, and balance so that the wire is firmly held but not crushed. Furthermore, clear or change the contact tip regularly, as worn or clogged contacts can slow down the smooth wire feeding. Optimal performance and efficiency during work requires proactive maintenance and consistent monitoring for the system related to wire feeds.

Adjusting the Rate of the Wire Feed for Different Welding Applications

While seeking to make wire feed adjustment for a specific welding task, it is critical to note that the wire diameter, material type and wire speed are interrelated as is the required amperage for each task. A commonly accepted principle is that an increase in wire diameter necessitates a proportional increase in amperage. For example, 0.030 inch wires are often used at 40 to 145 amps while thinner materials like automotive parts are paired with 0.045 inch wires, where 75 to 250 amps are required to weld thicker materials such as structural steel.

Recent advancements in technology have made precise calibrations effortless. Modern welding machines use digital interfaces that estimate the ampere and wire feed speed needed for the given materials and joints within an ergonomic range. Thus, they save a great deal of time during setup and reduce trial-and-error. As an example, welding mild steel with a 0.035 inch wire requires feeding at a rate between 90 to 130 inches per minute (IPM), as most applications would perform best.

Besides setup parameters, shielding gas mixture also affects wire feed speed. A mixture containing 75% Argon and 25% CO2 is often preferred as it achieves a balanced penetration, lower spatter, as well as atraightforward and clean welds. When used with the previously noted wire feed speed, this gas mixture guarantees welds with high integrity and consistency.

Reference sources

- Study on Welding Characteristics and Parameters of Gas Metal Arc Welding for A516 Grade 70 Steel with ER70S-6 and ER308LSi Filler Materials(Chong et al., 2024)

- Publication Date: 2024-11-01

- Key Findings: This study investigated the impact of different filler materials (ER70S-6 and ER308LSi) and variations in wire feeder speed (WFS) and shielding gas flow rate (GFR) on the Gas Metal Arc Welding (GMAW) of ASTM A516 G70 steel plates. The highest ultimate tensile strength and hardness were achieved with specific combinations of WFS and GFR for each filler material. ER308LSi showed superior mechanical properties compared to ER70S-6. Microstructural analysis revealed that finer, more compact grain structures correlated with higher hardness.

- Methodology: The study used visual inspection, liquid penetrant testing, tensile testing, hardness testing, and optical microscopy to characterize the weld joints. Nine combinations of WFS and GFR were tested for each filler material.

- Pulsed dynamic wire feeding with low insertion angle in GTAW process: a metal transfer characterization(Pigozzo et al., 2022, pp. 2107–2118)

- Publication Date: 2022-07-25

- Key Findings: This research characterized metal transfer in the Gas Tungsten Arc Welding (GTAW) process using pulsed dynamic wire feeding with a low insertion angle. While the specific findings aren’t detailed in the abstract, the focus is on understanding the metal transfer mechanism under these specific welding conditions.

- Methodology: The methodology involved characterizing the metal transfer behavior using pulsed dynamic wire feeding and a low insertion angle in the GTAW process. The abstract indicates that the research used a metal transfer characterization approach.

- Effect of Orbital Welding Parameters on the Weld Geometry(Tran et al., 2022, pp. 41–46)

- Publication Date: 2022-07-13

- Key Findings: This review-type paper discusses the challenges of manual orbital welding and the advantages of an automated system incorporating a filler wire feeder. It highlights the improved weld quality and reduced welding time achieved with automation. The paper references the American National Standard AWS D18.1/D18.1M: 2009 for weld result review.

- Methodology: The study involved experimentation with an automatic orbital welding device integrated with a filler wire feeder. The results were reviewed against the AWS standard.

Frequently Asked Questions (FAQs)

Q: What is an arcreach suitcase welder, and how does it benefit industrial welding applications?

A: An arcreach suitcase welder is an industrial welder placeholder or suitcase that comes with a portable wire feeder designed to enable set remote adjustments by the user giving improved efficiency as well as safety in industrial applications. With this functionality, the need to spool back and forth to the power source is mitigated, enabling time savings and productivity boosts.

Q: How does activ8x wire drive manage the welding procedure?

A: Activ8x wire drive provides positive speed control that responds properly to the changing loads of different welding wires including aluminum wire. Consistency in feeding is guaranteed by the advanced design as stated which has impact on feeding reliability which determines the overall quality of the weld in any industrial or fabrication work.

Q: Why is there an advantage when using feeders made exclusively to handle aluminum wires?

A: Feeder made for aluminum wire specifically falls into the category of class work tools which improves the speed and efficiency of spool along with reducing errors linked with wire feed systems bettering precision affecting the weld quality and reducing unnecessary downtimes for high reliable precise engineered applications.

Q: What is the importance of magnum pro curve 300 in welding?

A: magnum pro curve 300 is an accessory for welding that adds ergonomics and control for the user. It helps reduce fatigue while enhancing the quality of the welds which makes the magnum pro curve 300 important for semiautomatic wire and submerged arc welding.

Q: How does the ln-25 portable wire feeder increase portability of welding?

A: ln-25 is a rugged and versatile portable wire feeder. Welders are able to walk to different locations within the job site without being restricted to a single location because of the portable wire feeder. This increases productivity in offshore and other difficult areas.

Q: What are the reasons for wire feeders to have a four drive reel system?

A: A four drive reel system guarantees precision with regard to wire feeding as it augments wire feeding accuracy and consistency, both critical in achieving quality welds. This configuration enhances reliability in feeding the wire, decreasing weld problems caused by inconsistent feeding.

Q: What factors should be thought of when choosing a gas type for welding with a portable feeder?

A: When choosing a type of gas for welding along with a portable gas feeder, the portable gas feeder’s welding and working technique, thermal refinement of the welded materials, and the position of the weld must all be put into consideration. The selection offers the possibility to a wide variety of gas types.

Q: What are the productivity and cost consequences of using obsolete welding machinery?

A: Outdated welding equipment can increase costs through chronic outages, inconsistent fail rates of repetitions, and a high need for servicing. There is an opportunity this model designation offers such as adopting a new structure with the heavy duty roll wire feeder’s a new roll frame.

Q: Which elements does the one-pak wire feeder solution contain?

A: The one-pak wire feeder solution has completed and functional welding kits as well as the wire feeders, the connection to the power sources, and the accessories that fulfil the unit purpose. This bundling enhances the setting up process through removal of errors.

Q: In What Ways Does A Spool Gun Assist In Welding Applications?

A: A Spool Gun helps with feeding the wire from a small spool that is mounted on the gun itself wire feeder. This is easier for aluminum welding since it reduces wire feeding problems and improves control for both semiautomatic and industrial use.

- Everything You Need to Know About Laser Cut Acrylic Sheets

- The Unmatched Tungsten: Exploring the Melting Point of the Metal with the Highest Melting Point

- Pulsed vs Continuous Wave Lasers: What’s the Difference?

- Unlocking the Power: How Does Laser Cleaning Technology Function?

- The Art of Precision: Mastering the Wood Laser Engraving Machine

- The Ultimate Guide to 3D Laser Cutting and Printing: Unleashing the Power of the Best Laser Technology

- Mastering Fiber Optic Laser Technology: The Ultimate Guide to Fiber Laser Cutting and Beyond

- Unlocking the Power of Fiber Laser Marking Machine: Your Ultimate Guide