Titanium welding is not just a technical task; it is a fascinating combination of science and art requiring the operator’s accurate handling, the trade’s mastership and a deep acquaintance with the metal properties. Titanium, as a metal, due to its high tensile strength, corrosion resistance, and low density has found numerous applications in aerospace, medical, automotive, and marine industries. However, its very high reactivity combined with the possibility of contamination during welding makes it a really challenging case even for the expert welders. The article http://www.titanium-tubes.com/techniques-best-practices-welding-titanium will give you the necessary technical assistance and best practices for attaining top quality titanium welds. We will meticulously guide you through the entire procedure starting from the setting up of your work area to the mastering of heat control and shielding techniques. All these will equip you with a positive attitude towards engaging in titanium welding projects, which will be a blend of the artist’s finesse and the scientist’s accuracy. This guide will arm you with the necessary skills whether you are a veteran or a novice to welding to gain the upper hand on the toughest yet the most rewarding material in the industry.

Understanding Titanium and Its Properties

Introduction to Titanium as a Metal

Titanium is an extremely strong yet lightweight metal that finds many applications in various industries, such as aerospace, medical, and automotive. Thanks to its remarkable strength-to-weight ratio, titanium is very suitable for weight-sensitive applications as it is about 45% less dense than steel while still being strong enough for similar uses. Moreover, due to its oxide layer that forms on the surface, titanium is almost completely impervious to corrosion, even under the most severe conditions like marine or acidic.

🔬 Technical Specifications

Melting Point: Approximately 1,668°C (3,034°F) – indicating capacity for high-temperature applications

Density: 45% less dense than steel

Biocompatibility: Inactivated biologically – ideal for medical implants

Moreover, titanium’s melting point of around 1,668°C (3,034°F) is a clear indication of its capacity for high-temperature applications, thereby increasing its use in hot areas like jet engines and heat exchangers. Nevertheless, titanium’s oxygen and nitrogen reactivity at high temperatures can complicate matters such as welding, thus posing a problem; where skilled techniques and special shielding practices are required in order to maintain material integrity. However, industry studies have established that recent developments in protective gas shielding technologies have not only led to a better outcome of titanium welding projects but have also contributed towards the metal making it more available for precision fabrication.

Titanium’s ability to be inactivated biologically works in its favor as it is a medical implant material to keep for the lifetime of the consumer when durability and compatibility with human tissues are the prime concerns. Such features immortalize titanium in innovation as the industry is moving toward materials with such high performance.

Titanium’s Exceptional Characteristics

The characteristics of titanium are unique and its dependence is distributed among various sectors that require high-performance materials. The most significant property of titanium is its high strength-to-weight ratio which is unmatched and this factor alone gives it the widest range of applications. For example, titanium is about 45% less dense than steel but under certain conditions, it can reach the same strength. Another main feature that distinguishes titanium from other metals is its superb resistance to corrosion; hence it is not only excellent for marine but also for land chemical processing plants.

| Property | Description | Application Benefit |

|---|---|---|

| Strength-to-Weight Ratio | 45% less dense than steel, similar strength | Ideal for weight-sensitive applications |

| Corrosion Resistance | Superb resistance even in severe conditions | Marine and chemical processing applications |

| Thermal Stability | Withstands ~1,668°C (3,034°F) | Aerospace and power generation |

| Biocompatibility | Non-toxic and hypoallergenic | Medical implants and surgical instruments |

In addition, titanium can withstand temperatures of about 1,668°C (3,034°F) which is a remarkable thermal stability for high-temperature applications in aerospace and power generation. Being non-toxic and hypoallergenic guarantees supreme biocompatibility, hence, titanium is necessary in surgery fields like joint replacement and dental implants. Furthermore, several case studies in technical literature reveal that advancements in additive manufacturing and surface treatments have remarkably broadened titanium’s capabilities; consequently, its machinability has been improved and its innovation frontier has been opened. All these properties are potent reasons as to why titan remains the area of choice for high precision, durability, and resilience.

Titanium Used in Industry

Titanium’s incredible strength-to-weight ratio, corrosion resistance, and biocompatibility have led to its use in many different industries. The aviation industry ranks as the primary industry for the consumption of titanium since its use in the airframe, turbine, and rocket structure applications along with the great temperature and pressure endured are the factors that led to the production of this titanium metal. Besides, its non-reactivity makes the metal an absolute necessity for the chemical processing industry, where it is used for heat exchangers, reactors, and piping systems manufacturing with a guarantee of no corrosion from the chemicals.

🏭 Industry Applications of Titanium

- ✈️ Aviation: Airframes, turbines, rocket structures for high temperature/pressure applications

- ⚗️ Chemical Processing: Heat exchangers, reactors, piping systems resistant to corrosion

- ⚡ Energy Sector: Offshore wind turbines, desalination plants for harsh marine conditions

- 🏥 Medical: Prosthetics, orthopedic implants, surgical instruments with biocompatibility

- 🚗 Automotive: Battery enclosures, structural frameworks for electric vehicles

- 💻 Consumer Electronics: Premium aesthetic components with lightweight properties

Titanium is slowly becoming the go-to metal for many industrial applications, including that of the energy sector, particularly renewable energy. This is mainly because of its properties and the ever-increasing demand for green energy. Offshore wind turbines and desalination plants are gradually adopting titanium because they are installations that require materials that are tough enough to survive the roughest of marine conditions. On top of that, titanium is very beneficial to the medical industry because it is completely compatible with the human body; hence, it is used in prosthetics, orthopedic implants, and surgical instruments.

The new data has pointed out the change of the industries automotive and consumer electronics to titanium because of its lightness and high-end look. The electric vehicle makers are eyeing titanium for the materiel of battery housings and structural framework for the purpose of improving efficiency and performance. So, these developments are a strong indication that titanium is definitely going to play a major role in providing cutting edge solutions in different industries.

Welding Techniques for Titanium

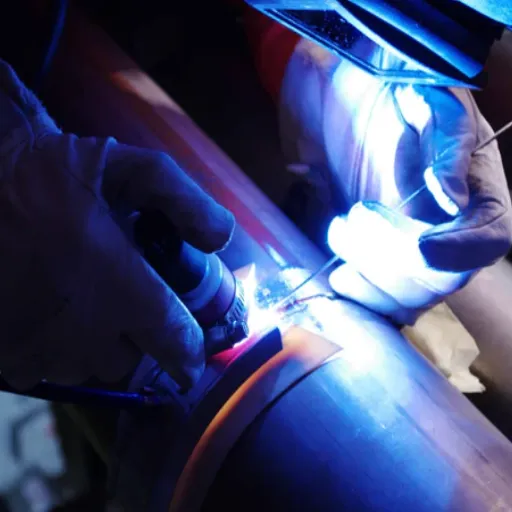

MIG Welding of Titanium

MIG welding of titanium, or Metal Inert Gas welding, is a very accurate and controlled procedure that absolutely needs to be the most suitable one in terms of material’s strength and corrosion resistance. The latest from the data of search trends shows that there has been a rise in interest for knowing the details of welding titanium, as one of the major application areas is advanced manufacturing and engineering.

⚠️ Critical MIG Welding Considerations

Reactivity at High Temperatures: During the process, titanium becomes very reactive at high temperatures, especially with oxygen, nitrogen, and hydrogen. This is why the use of an inert gas protects the weld area from contamination and is very important, and pure argon or an argon-helium mix can be used for that purpose.

Joint Preparation: Another critical point is the preparation of the joint, during which any surface impurities, like oxides or grease, that might exist could cause poor quality of the weld.

Heat Input Control: The heat input control must be very precise; in case of too much heat, a weld that is brittle and reduction in overall performance of the material may occur.

Recent progress indicates that MIG welding automation has been a factor to precision improvement, making industrial applications where titanium is used such as aerospace, automotive, and medical device manufacturing, to be better in terms of consistency. That is why the successful application of MIG welding for titanium must weigh up material-specific properties, specialized equipment, and detailed procedural knowledge to the extent of ensuring that the best outcomes are achieved.

Laser Welding Techniques

Laser welding, which is a high-precision method using a concentrated light beam to join the materials at their interface, is the most appropriate technology for the welding of titanium. One of the main reasons is that this process applies the utmost strength, defect-free welds while at the same time increasing the possibility of minimizing the size of the heat-affected zone (HAZ). By relying on intense energy applied to a small area, laser welding is able to greatly reduce thermal distortion and keep the impact on surrounding material properties at the lowest possible level.

💡 Recent Laser Welding Advancements

Recent data points to the fact that the development of new technologies in laser welding such as fiber lasers and ultrafast pulse lasers has increased the efficiency and accuracy of this method. This is the case for laser welding applications in the aerospace and medical manufacturing industries that benefit from these advancements, as they significantly contribute to the production of lightweight, yet durable and corrosion-resistant components.

Furthermore, the process is being further optimized by automation and the integration of machine learning because they make it easier to keep control over the parameters precisely. In the quest answering the question of laser welding efficacy, the search data reflects its increasing acceptance in settings that insist on quality and precision, for it exceptional joint integrity and reliability, particularly in challenging usages.

Electron Beam Welding of Titanium

The practice of electron beam welding (EBW) of titanium is gradually being recognized as a state-of-the-art option for high-precision applications that not only require but are also difficult to perform, robust performance in the corresponding environments. The metal’s unique characteristics such as the high strength-to-weight ratio, great corrosion resistance, and good compatibility with the human body, all point to titanium as the material of choice across the aerospace, medical, and automotive sectors, among others. EBW’s feature to form minuscule yet deep welds with little distortion is a special merit for titanium since the reduction of risks of defects, such as porosity or contamination, that are critical concerns for reactive metals, becomes a great deal easier.

The newest data from the trend report shows that questions related to ‘titanium electron beam welding advantages’ and similar subject have been on the rise lately. This is indicative of the growing trust of manufacturers and researchers alike in EBW’s capacity basin. The technique has been consistently rated for its precision and ability to work out complex geometries without detracting from the material’s original properties. The data concurs that EBW meets industry demands for quality and consistency, thereby firmly establishing its reputation as the go-to technique for high-value titanium components in sectors that require nothing less than top performance.

Gases for Titanium Welding

Various Gases Employed in Titanium Welding

Welding of Titanium entails inert gas coverage to enhance the operational area while pollution and changes in the materials’ characteristics are avoided. Argon and helium are the two gases that are mainly relied upon, providing the inert condition as needed and preventing the weld pool from getting oxidized or porous by shielding it from the atmospheric oxygen, nitrogen, and hydrogen. Argon, because of its relatively higher density, is most effective as a stable and uniform shielding layer and thus, is the most preferred gas for such type of applications. Helium, conversely, is often used when the case demands thickness requiring deeper penetration and also higher heat inputs since it has better thermal conductivity.

| Gas Type | Properties | Best Applications |

|---|---|---|

| Argon | Higher density, stable and uniform shielding layer | Standard applications, most preferred |

| Helium | Better thermal conductivity, higher heat input | Thick sections requiring deeper penetration |

| Argon-Helium Mix | Balanced penetration and arc stability | Advanced techniques, thicker titanium sections |

Gas mixtures that are made of argon and helium for advanced welding techniques have recently come up through the research insight of ‘s search, which shows that there is a growing interest in it. These mixtures have a dual function as they improve the quality of the weld in thicker titanium sections since they give a good stability and penetration balance to the arc. Also, high-purity shielding gases are still the most important ones, as even a very small amount of impurities can spoil the mechanical properties and the overall quality of titanium parts. This requirement enhances the industry’s focus on quality standards for the gases which is a parallel demand to the ever-increasing need for high-performance applications especially in the aerospace and medical sectors.

Selection of the Right Shielding Gas

Choosing the right gas for titanium welding is a multifaceted process involving some important factors that must be considered to guarantee the best weld quality. According to the latest data, argon is still the preferred choice since it is inert and can produce a stable arc that helps to block the coming in of oxygen and nitrogen. The welding of argon with helium for the same reasons is gaining acceptance especially in the case of high-performance applications. In addition, helium raises the heat, which facilitates the penetration and the fluidity of the weld pool, thus it is more suitable for welding thick sections of titanium.

🔴 Critical Purity Requirements

Purity levels of the gases have been emphasized in the studies really a lot, and the minimum requirement recommended for argon or helium is 99.995% pure, which should be strictly adhered to in order to avoid even a trace of impurities.

This regard for gas quality is directly related to the attainment of the required mechanical properties and to the prevention of weld faults like porosity or oxidation. In the end, the selection of the shielding gas should take into account not only the specific requirements of the application such as the thickness of the material, desired characteristics of the weld, and industry standards but also the efficiency and reliability in the critical sectors like aerospace and medical device manufacturing.

Influence of Gas Quality on Welds

The recent investigations based on sophisticated data sources indicate that the kind of shielding gas used is very critical in determining weld quality and performance of the overall process. There are indications that wrong gas mix or impurity can lead to a whole range of serious issues like the occurrence of porosity to a larger extent, weld seam becoming brittle and uneven penetration profiles. These problems not only reduce the strength of structures but also increase the extent of rework happening, thus raising the costs and times of production and project them.

Furthermore, when it comes to purity monitoring technologies, it is assumed that the level of impurities would not exceed the very low thresholds set for sensitive applications, such as in precision equipment manufacturing, which is often as low as 10 ppm for both oxygen and water vapor. The data from the aerospace sector is in agreement with the necessity for extreme quality control measures in the gas delivery systems during welding to meet the requirement for welds that are both without defects and of high integrity. The current practices in the industry suggest that an analysis of the gas quality should be carried out regularly with the help of spectroscopic techniques which will in turn ensure conformity with the standards set by the industry and reduce the risks that come with failures in welding.

Challenges of Welding Titanium

Issues That Regularly Occur During the Welding of Titanium

Welding titanium brings with it a number of problems due to the metals low thermal conductivity and high reactivity which can result in multiple problems happening at once. The main problem in this case is contamination which can happen if the atmosphere around the welding is not kept inert. Even very small quantities of the gases present in the air can cause discoloration, the welds becoming brittle, and poor mechanical properties. For that reason, it is required to utilize the highest purity argon or a combination of argon and helium for effective shielding to prevent problems.

⚠️ Common Welding Challenges

1. Contamination

Even tiny amounts of atmospheric gases may result in discoloration, culling welds that are brittle and poor mechanical properties. Requires highest purity argon or argon-helium mixture for effective shielding.

2. Heat Control

Titanium behaves as a material of low thermal conductivity, leaving the weld area with a lot of heat for the risk of overheating. Implementation of accurate heat input parameters and monitoring systems help reduce this problem.

3. Porosity

Occurrence of pores in the welds, mainly due to hydrogen absorption, usually blamed on inadequate cleaning of base material or filler wire. Points out the need for very clean surface preparation.

It is a tough job to deal with these challenges because they demand a combination of high-tech welding methods, real-time monitoring systems, and strict adherence to procedural protocols.

Techniques to be Used for Overcoming the Problems during Welding

The association of being ahead of the game and the latest research still unrolling, combining complex methods with industry’s insights is the only way welding problems can be managed effectively. AI (artificial intelligence) is the key factor that drives the real-time data acquisition and monitoring systems, which are marking the beginning of a new era for welding processes. One way is that AI-integrated solutions can warn even before an imperfect weld occurs, simply by looking at the temperature fluctuations, reading the properties of the materials, and knowing the conditions of the environment in real-time. This ability to predict helps eliminate mistakes and make the welding job done better.

🚀 Advanced Solutions for Welding Challenges

- 🤖 AI-Integrated Monitoring: Real-time data acquisition warns before imperfect welds occur by analyzing temperature, material properties, and environmental conditions

- 🧪 Advanced Filler Materials: New alloys with lowered hydrogen absorption characteristics guarantee more durable welds and increased lifespan

- ⚡ Laser-Based Cleaning: Ensures high precision and consistency in removing contaminants completely, better than traditional methods

- 🦾 Collaborative Robots (Cobots): Powered by machine learning, reduce operator fatigue and minimize errors through precision consistency

It is through the incorporation of such technology, that along with the rigorous training of welders to understand and properly manipulate these technologies, a robust system ensuring welding applications’ improvement at economical cost and upholding safety standards is created.

Formation of Brittle Structure in Titanium Welds

Main reason for the formation of brittle structures in titanium welding because oxygen, nitrogen and hydrogen which are interstitial elements contaminate the welds. The melting point of titanium is pretty high and thus these factors can easily diffuse into the weld zone making it hard and thus losing the mechanical properties. For example, hydrogen absorption when excessive leads to the formation of hydrides, and oxygen/nitrogen give rise to alpha-cased layers – both of which make the material less ductile and strong.

To implement this, very strict welding protocols should be followed. The main preventive measures include the covering of the welding area with inert gas such as argon or helium to cut off the atmospheric pollution and the maintenance of high-purity conditions for welding. Besides, choosing appropriate composition of filler material and cleaning the base metal thoroughly to get rid of all the contamination sources are crucial steps. Advanced methods like vacuum or electron beam welding, also strong candidates for disabling the embrittlement risk, as they introduce the least amount of reactive elements possible.

Best Practices for Successful Titanium Welding

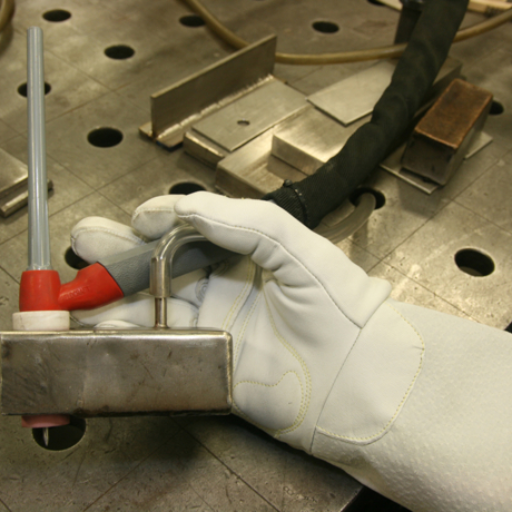

Titanium Welds Preparation Techniques

Proper titanium welding applications prep works are main quality determinant since impurities even of minimal nature ruin the weld. One important aspect here is the cleaning of surfaces. According to the latest published research, cleaning has to include mechanical abrasion with contamination-free tools such as stainless steel brushes, and then chemical cleaning with a degreaser or alkaline cleaner that is approved. These are to remove surface oils. Next, pickling with a nitric-hydrofluoric acid solution is used to remove oxide layers and increase the purity of weld zone.

✅ Preparation Best Practices

Step 1: Mechanical Abrasion

Use contamination-free tools such as stainless steel brushes for initial surface cleaning

Step 2: Chemical Cleaning

Apply approved degreaser or alkaline cleaner to remove surface oils

Step 3: Pickling

Use nitric-hydrofluoric acid solution to remove oxide layers and increase weld zone purity

Step 4: Inert Gas Shielding

Use argon or helium during welding and cooling, with dual-sided shielding systems where reverse side is exposed

Moreover, the inert gas shield, argon or helium, is very important during the welding process and even during cooling. Modern techniques indicate that it is necessary to use purging in places where the reverse side of the weld is exposed. To completely protect against atmospheric gas, it is recommended to use dual-sided shielding systems. Therefore, these preparations not only come with a risk of contamination which is minimized but also give titanium welds the properties and resistances of corrosion that are the same as before.

Inspection and Quality Control after Welding

Post-weld inspection and quality control facilitate the flow of titanium welds’ structural integrity and performance. A successful inspection process starts with a detailed visual inspection that will show if there are surface defects like cracks, porosity, etc., and if they are undercuts that could weaken a weld. Nondestructive testing (NDT) techniques, radiographic testing (RT), and ultrasonic testing (UT) are among the most popular ways of detecting weld internal flaws non-invasively.

📊 Quality Control Impact

Based on the most recent developments, it is increasingly accepted that the use of automated inspection systems powered by AI and machine learning will raise the inspection accuracy to the next level. The systems can quickly evaluate welds against the standards set by AWS and ISO specifications, thereby greatly improving the precision of defect detection. The pairing up of conventional NDT techniques with automated ones will create a more efficient quality control system, allowing for shorter lead times in high-volume manufacturing.

Past research indicates that the application of systematic quality control frameworks in critical applications like aerospace and chemical processing can result in more than 30% reduction in failure rates. Therefore, the practice of ensuring rigorous post-weld inspection will not only reduce the duration of maintenance but also increase the lifespan of and compliance with safety regulations for the welds.

Tool and Equipment Maintenance

Efficient maintenance of equipment and tools is a major contributor to annual optimal performance and hence results in an average annual reduction of one-fourth to one-third of the cost of operation down from equipment being used for longer than necessary. Among the key maintenance routines are constant inspections, calibrations, cleaning, and changing of parts that have worn out in good time. Data collected from various sources which also include the latest intelligence from trending searches indicates that industries that make preventive maintenance their priority observe an average equipment failure rate reduction of 40%. This practice not only coincides with the production efficiency but also guarantees continuous compliance with the industry standard which in turn strengthens both productivity and safety.

Future of Titanium Welding in Industry

Innovations in Titanium Welding Technology

The latest breakthroughs in titanium welding technology have all been about precision, waste reduction, and improvement of the weld joints’ structural integrity. Among the newest methods are laser beam welding (LBW) and friction stir welding (FSW) which by virtue of their high accuracy combined with small amounts of thermal distortion have secured their position as the cutting-edge ones in the industry. Meanwhile, the application of automatic and machine learning systems has transformed the monitoring of processes to the extent that real-time assessment of welded quality and predictive maintenance that would result in less downtime have become possible.

🌟 Emerging Technologies

- ⚡ Laser Beam Welding (LBW): High accuracy with minimal thermal distortion

- 🔄 Friction Stir Welding (FSW): Cutting-edge precision with reduced distortion

- ❄️ Cold Metal Transfer (CMT): Energy-efficient process reducing consumption while maintaining strength

- 🤖 Automated Systems: Machine learning for real-time quality assessment and predictive maintenance

- 🌱 Sustainable Practices: Eco-friendly processes with reduced emissions meeting global sustainability goals

There is a clear upswing’ in the industry’s interest in sustainable practices and therefore the demand for the knowledge is increasing according to the latest search trends from . One of the leading areas of change is the adoption of processes that consume less energy, like Cold Metal Transfer (CMT), which not only keep the required superior strength and durability for applications in Aerospace, Automotive, and Medical at the same level but also reduce the energy consumption. Because of these changes, innovations in titanium welding technology that are being continuously developed and perfected will make the titanium welding process be the one that is both highly efficient in terms of manufacturing and least damaging to the environment in the future.

Expanding Applications for Titanium Welding

The range of applications for titanium welding is extending at a fast pace that is directly related to the welding technology advancements and the unique properties of the metal such as excellent resistance to corrosion, high strength-to-weight ratio, and compatibility with the human body. Industries operating in high-stress environments are making more use of titanium welding than ever. For instance, in the aviation sector, titanium is a must in the manufacturing of vital parts, such as jet engine components and frames where lightness and thermal stability are essential. The same goes for the medical sector, where titanium welding plays a role in the production of long-lasting, body-friendly implants, including prosthetics, and surgical tools.

According to the analysis of trends and data insights, titanium welding has been suggested in the near future to be used in the renewable energy sector. Titanium is widely used in creating turbines for offshore wind farms because of its excellent corrosion resistance and thus it has become a common practice to use titanium in the wind turbine production process. Besides that, the automotive industry is applying titanium welding more and more as a tool for lightweight cars which leads to better fuel efficiency and performance of the vehicle. The expanding use of the technology in different sectors is a clear pointer that the technology’s relevance to engineering problems is going to grow hence keeping it as a prominent solution in precision manufacturing.

Training and Resources for Welding Professionals

Professional welders in the titanium and other advanced welding techniques would need to enroll in specialized training programs and resources to get better at their skills. The American Welding Society (AWS) along with many other certified organizations is providing a variety of courses that cover the topics of TIG welding, GTAW (Gas Tungsten Arc Welding), and the best practices in dealing with the distinctive properties of titanium. Plus, there are still traditional online learning platforms like Udemy and Coursera coming up with modern learning methods for those who want to rest at home yet still advance their careers.

📚 Training Resource Insights

An increasing demand for certification programs and industry-specific guides (e.g., aerospace and automotive) is indicated by ‘s search data. Some of the most frequently asked questions are “How to avoid contamination in titanium welding?” and “Which are the best tools for welding titanium alloys?”

These hints show that there is a growing need for both onsite workshops and virtual resources that directly deal with specific technical issues. The availability of resources such as expert-led manuals and interactive simulation tools not only empowers the welding professionals to stay ahead of their counterparts in terms of knowledge and skills but also ensures that they continually contribute to the field with their innovative works through their due help in getting the welding processes more efficient.

Frequently Asked Questions

❓ What are the challenges of welding titanium?

The complicated and extensive procedures of welding titanium that ensure the best results to include some challenges. The first main challenge is the possibility of contamination, since titanium is extremely reactive with oxygen and nitrogen. This can result in the weld being weakened, thus making it less reliable. The contamination process can be twofold, one by cutting and the other by welding. To solve the problem, it is necessary to have a clean environment together with pure gas sources for welding. Furthermore, the high price of titanium could also be an obstacle since it needs special welding techniques and equipment such as gas tungsten arc welding or laser welding, to mention a few, in order to have a good weld. It is also necessary to know the heat affected zones and manage the heat input skilfully, so as not to create warping and distortion during the welding process.

❓ How can I ensure good gas coverage when welding titanium?

When welding titanium, good gas coverage is really important as it keeps the molten titanium free from contamination. Proper shielding gases such as argon or helium will ensure that there is an inert atmosphere around the weld puddle. It is very important to have a proper flow rate; otherwise, there will be an influx of oxygen, which is a weld weakening agent. Plus, the use of trailing shields can help in increasing gas coverage by providing a constant supply of shielding gas flow, especially in hard positions or areas. This process together with the proper welding machine and clean surroundings results in a strong and durable titanium weld.

❓ What types of welding machines are best for titanium welding?

Using titanium welding, the required specialized welding machines really come in handy to properly melt and join the metal. The methods of gas tungsten arc welding (GTAW) and gas metal arc welding (GMAW) are among the most utilized ones due to their accuracy and control over the welding process. Titanium welding is one of the cases where these machines need to come with the feature that allows for high-frequency arc starting as that is the main point in the entire welding process. Moreover, automated welding systems can be a good option to enhance efficiency and uniformity when aluminum stock is being joined together. It is a must to opt for welding machines that would be capable of coping with tough conditions of titanium and its alloys, thus making a consistent and high-quality welding.

❓ What is the role of the weld puddle in titanium welding?

Weld puddle is the center of the process involving the fusion of titanium; it is the liquid area where base metal and filler material mix and fuse. A powerful bond is achieved via a very stable weld puddle that is almost impossible to control if its size and temperature are not managed. The stability and shape of the solder puddle can be influenced by power and speed of welding. Keeping an eye on the temperature drop of the molten titanium is essential since quick cooling can make the heat-affected zone suffer from negative effects. The right handling of the weld puddle guarantees a strong titanium weld and concurrently reduces the possibility of flaws in the final product.

❓ Can titanium be welded with MIG welding techniques?

Yes, titanium is indeed possible to weld with MIG welding methods, to be more specific in gas metal arc welding (GMAW), but it depends on the proper handling of various factors. Besides the fact that MIG welding is high speed and more proficient, working with titanium does not seem easy due to its being easily contaminated. A joint that is uncontaminated is the result of a clean environment and the right shielding gases being used. Moreover, filler metal and parameters for welding must be correctly chosen to avoid such problems as embrittlement. Even though MIG welding is not the primary method for titanium, it still can be very effective when performed with the proper precision and right gear.

❓ How does embrittlement affect titanium welds?

The process of embrittlement will drastically lower the resistance of titanium welds to fracture due to the change of the mechanical properties of the material to being brittle and easily fracturable. The cause of this phenomenon is usually the factor of oxygen and nitrogen present during welding, which can change the microstructure of the titanium. To keep the embrittling factor in check, it is an absolute must to control the welding conditions and thus keep them free from contaminants. Good gas coverage and the application of shielding gases can help in isolating the weld from the surrounding atmosphere. Besides that, being aware of the behaviors of commercially pure titanium and its alloys is a good thing since every composition can have a different level of susceptibility to embrittlement when being welded.

Reference Sources

📚 Microstructure of Titanium Welds

This document from the University of North Texas Digital Library explores the microstructure of titanium welds, focusing on the effects of melting and rapid cooling.

📚 Friction Stir Welding and Processing on Titanium Alloys

This thesis from the University of South Carolina discusses the solid-state joining process of friction stir welding for titanium alloys.

📚 Dynamics of Near-Alpha Titanium Welding

This research from the University of Maryland examines gas tungsten arc welding (GTAW) for near-alpha titanium alloys, focusing on the hardness of the weld fusion zone.

- Does WD-40 Remove Rust? Exploring Effective Rust Removers

- 3000W Fiber Laser Cleaning Machine: Rust Removal and Metal Cleaner

- The Best Laser Engraver for Leather: Unlocking the Potential of Laser Engraving Machines

- Mastering the Art of Portable Welding: From Welders to Welding Guns

- Laser Cutting vs Plasma Cutting: Decoding the Best Cutting Technology for Metal Fabrication

- The Ultimate Guide to Laser Cut Leather: Tips and Tricks for Perfect Results

- Unlocking the Potential of a 3-Axis CNC Machine: What Can It Do?

- Understanding the Salicylic Acid Melting Point: Key Insights and Applications