Laser light has transformed various sectors including health care, communication, entertainment, and manufacturing. But what makes laser light so important? What component of modern technology depends on it? In this blog, we will look into the world of laser light: its types, working mechanisms and practical uses. Whether you are a mere enthusiast or a professional looking for more, this write up will describe the astounding flexibility of lasers which affect us in so many different ways. Join us as we discuss the science and demonstrate the effects of these forms of concentrated energy.

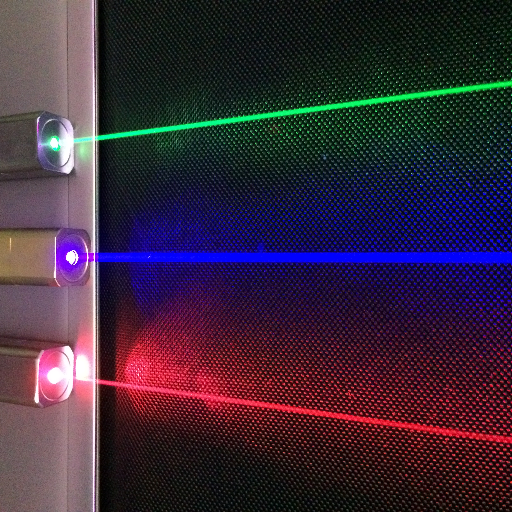

What Are the Main Types of Lasers?

- Gas Lasers: Utilizes gas mixtures of helium-neon or carbon dioxide to produce light. Commonly used in barcode scanners or for medical procedures.

- Solid-State Lasers: Uses a solid medium such as glass or crystals doped with rare earth or transition metal ions. Used for cutting, welding, and in laser pointers.

- Semiconductor Lasers (Diode Lasers): These small form factor lasers are made from semiconductor materials and are found in DVD players, as well as in fiber optic communication devices.

- Liquid Lasers (Dye Lasers): Make use of liquid solutions that contain organic dyes as the medium. Their main application is in scientific research due to the wavelengths being tunable.

Considerations of Solid-State Lasers

Solid-state lasers integrate a solid gain medium which is a host material doped with rare earth or transition metal ions. They are highly efficient, durable, and versatile in their application. Common host materials include crystallized ruby or glass. The doping ions such as neodymium or erbium generates the specific wavelengths of the laser.

Solid-state lasers find application in several areas like industrial cutting and welding, laser procedures in medicine, and scientific work that requires stable and precise laser beams. Their construction and ability to provide high power beams makes them a required tool in many technological and scientific progress. Knowing how these lasers work and what makes them different is important in order to use them properly in practice.

Looking at Applications of Gas Lasers

Electric current through the gas medium helium-neon, CO2, or argon powers gas lasers. I find them very interesting because of how widely used they are in many different fields and industries. For example, they cut and engrave materials with great precision, so they are widely used in material processing. Gas lasers are also widely used in medicine, such as in laser skin therapy. Other uses include holography and spectroscopy, as they provide lasers of fine quality needed for complicated scientific work. Their capability to give unceasing or pulsed outputs makes them highly useful in different industries.

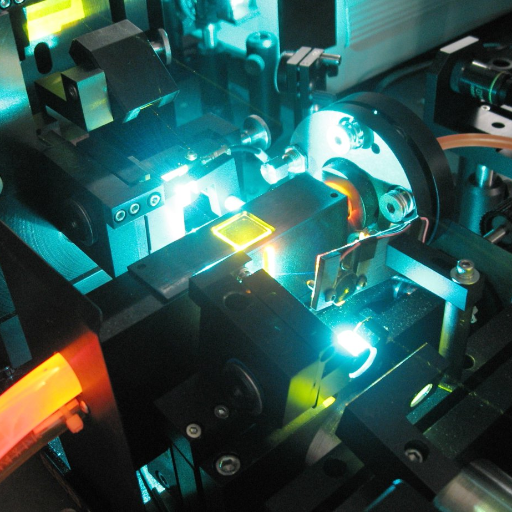

How Fiber Lasers Work and Their Uses

The basics of fiber lasers is that an optical fiber, usually doped with some rare earth element like ytterbium or erbium, serves as the gain medium. Their design enables them to achieve high power levels while maintaining an exceptional level of beam quality and operational efficiency. When measured against traditional gas or crystal lasers, fiber lasers are much more compact, robust, and, due to their solid-state nature, require less maintenance.

One of the most notable benefits offered by fiber lasers is the wide variety of options available to users, making these lasers incredibly versatile. These lasers are used extensively for marking, cutting, welding, and engraving. In marking applications, for example, fiber lasers have a distinct advantage because they have high-speed scanning capabilities. As research indicates, fiber lasers can reach marking speeds of over 7,000 mm/s, depending on the material and specific application. This efficiency makes fiber lasers vital for high-demand industries such as automotive, aerospace, and electronics manufacturing.

Moreover, fiber lasers have gained popularity due to their high power efficiency that is greater than 30-50% of electrical power with an operational cost reduction. The near-infrared radiation provided by fiber lasers for cutting metals, plastics, and other reflective materials increases the efficiency to reflect these materials. This precision is advantageous for multiple applications like micro-machining, 3D printing, and others.

These new developments are now enabling innovations to be made to improve power scaling without reduced beam quality. Other uses for modern fiber lasers include industrial manufacturing where the power output is vital, after all it does exceed 10kW which is optimal for cutting thick metals and deep engraving.

How Do Solid-State Lasers Operate?

A solid gain medium like a glass or a crystal containing rare-earth ions is used to amplify light in solid-state lasers. Supplied energy from a diode or flash lamp, for instance, leads to the excitation of atoms in the medium. Photons are emitted, which are further amplified through the bouncing off mirrors within the laser cavity. This results in achieving a focused coherent beam of light. The reliable and efficient design of solid-state lasers makes them suitable for numerous tasks like surgical cutting or other medical treatments.

The Role of Ruby Lasers in Solid-State Technology

Ruby lasers became one of the first solid-state lasers ever crafted. Their creation weaved the fabric of laser technology advancement as we know today. The gain medium relies on a synthetic ruby crystal that is doped with chromium ions to achieve adequate optical characteristics required for light amplification. Flash lamps deliver intense energy in pulses, resulting in the chromic ions of fast-amplifying ruby crystals capturing energy, sending them into exciting new configurations. As a result, red light is emitted at 694.3 nanometers and is amplified into a coherent laser beam.

Ruby lasers, one of the oldest types of lasers, possess historical and technological significance in solid-state tech for their simplicity. Their applications range from holography and scientific research to laser ranging as well as dermatology. Even though newer solid-state laser systems are more efficient and multi-functional, ruby lasers are still a critical part of the history of laser development.

Uses of Diode Lasers in the Manufacturing Sector

Diode lasers are accurate, efficient, and flexible making them essential to industrial work. They can be used for material processing such as welding, cutting, and engraving. Because of their compact designs, diodes lasers are high energy efficient and can significantly reduce operational costs while retaining unparalleled precision.

More recently, there have been additional refinements that strengthen their role in manufacturing. For example, in laser welding, deep penetration and high-speed welding are achieved simultaneously which is especially useful in automotive and electronics sectors. Single-mode diode lasers that are capable of producing more than 6kW power can deliver exceptionally strong welds on Aluminum and Stainless Steel metals. This ensures enhanced product longevity and minimal production time.

Diode lasers have found extensive application in the field of additive manufacturing. They precisely melt and solidify powdered materials in processes like selective laser melting (SLM). Diode laser systems are able to manufacture very intricate and detailed 3D-printed parts with resolution between 10 to 50 microns, especially for the aerospace, medical and prototyping industries.

Their importance in microelectronics is also remarkable. Diode lasers facilitate micro-machining operations, such as drilling and patterning, with unparalleled accuracy. They can achieve feature sizes below 10 microns when operating at shorter wavelengths, supporting the miniaturization of electronic devices.

The global market for high-power diode lasers is estimated to grow at a rate of nearly 8% annually from 2023 to 2030, suggesting an increasing adoption in the industry. Their affordability, efficiency, and flexibility make them crucial for elevating industrial capabilities.

What Are the Characteristics of Gas Lasers?

Gas lasers are a class of laser that incorporate electronically stimulated gases as the gain medium. They have unique capabilities such as producing coherent and stable beams, making them optimal for intense precision tasks. Examples include the helium-neon lasers which are commonly used lasers in alignment and measurement, and CO2 lasers which are often employed for high power cutting and engraving. Ongoing innovations with gas lasers improve their reliability and efficiency for continuously or pulsed laser light.

What Needs to be Known about CO2 Lasers

Carbon dioxide (CO2) lasers are a subtype of gas lasers that use a combination of carbon dioxide, nitrogen, and helium as their active medium. Because industrials greatly benefit from devices capable of high-power output, these lasers are well-suited since they offer high-power continuously-with great efficiency. They are primarily used at 10.6 microns, excelling in laser material processing—cutting, welding, and engraving. CO2 lasers become essential in production and medical manufacturing due to high energetic precision output.

An Overview of He-Ne Lasers and Their Applications

Gas lasers like the helium-neon (He-Ne) laser are easily recognizable because of their reliable performance, and He-Ne gas lasers happen to be the most world renowned. He-Ne lasers emit at a fundamental wavelength of 632.8 nanometers, which is in the visible red region of the spectrum. They are highly coherent with excellent beam quality. All of these advantages allow them to be used in activities such as precision alignment, holography, interferometry, and scientific work.

The operational simplicity and low costs are great benefits of He-Ne lasers since they do not need advanced cooling systems. Despite their low operational power, typically limited to the miliwatt range, they are widely used in industry for distance measurement on lasers used in metrology, optical equipment calibration, as well as in lower-grade education for safe research experiments. Because of their stable output and safe parameters, these lasers make good teaching resources.

He-Ne lasers are very efficient in optics scanning systems as well as in barcode readers, making them irreplaceable in modern engineering. Not only are they excellent for academic and industrial pursuits, but there is no doubt these lasers have become a staple with a vast variety of accessible technologies.

How Do Semiconductor Lasers Differ from Other Types?

Semiconductors lasers are different than any other type of laser due to its even more compact and modulated construction. Compared to other gas and solid-state lasers, semiconductor lasers are produced with semiconductor materials as the mediator to light generation. With such construction, semiconductor lasers may be applied in telecommunications, optical storage, laser pointers due to their unrivaled efficiency and energy economy. While other types of lasers are more expensive, semiconductor lasers are cheaper owing to their simple design and capabilities for mass production.

Some Important Information About Laser Diodes

One laser diode is often known as a semiconductor laser. Most other modern technologies incorporate them as they perform the critical function of transforming electrical energy into coherent light via the electroluminescence process. In simple terms, when electrons and holes in the semiconductor recombine, energy is released in the form of photons. With a p-n junction in place, current flow will also add some light-exanding excitation to the diode. In comparison to other types of diodes, laser diodes have buffers in the form of size and adaptable performance. Which makes them vital for communication, data storage, and sensing.

Benefits of Semiconductor Lasers in Communication

One of the greatest advantages of semiconductor lasers in communication is their reliability and high efficiency. Modern telecommunication systems benefit from these lasers as semiconductor lasers operate within a low power range while providing optimal functionality. Their small size assists in the deployment of highly compact and densely integrated optical networks, which further accelerates the growth of broadband technologies and 5G infrastructure.

Also, the wavelength stability of lasers permits long distance data transmission with minimum signal attenuation. Semiconductor lasers, for instance, are used in Dense Wavelength Division Multiplexing (DWDM) systems because their emission characteristics make it possible to transmit multiple signals simultaneously over one optical fiber, which drastically increases the bandwidth capacity. As per recent trends in the industry, DWDM technology is expected to support up to 50 Tbps per fiber, which is made possible by advancements in laser diode technologies.

Semiconductor lasers are critical in optical interconnects which improve multifunction data center performance by enabling high speed data transfer with low latency. Average estimates suggest that the typical optical interconnects made with semiconductor lasers exceed data transfer rates of 400 Gbps which address the rising demand caused by cloud computing and AI workloads.

These features highlight why semiconductor lasers are essential for building the future of worldwide communication networks.

What Are Dye Lasers and How Are They Used?

Dye ptyv lasers issuing organic dye solutions as the gain medium are a type of laser. Its versatility stems from its ability to produce a broad array of colors which makes it tunable to different parts of the light spectrum. Spectroscopy, scientific research, and medical applications are fields where precise control of laser wavelengths is needed and therefore dye lasers are often incorporated.

The Science Behind Liquid Lasers

Light amplification in liquid lasers such as dye lasers uses organic dye solutions as a gain medium. Organic dye is made up of complex carbon molecules that is commonly found in solvents such as alcohol and water. These dye molecules require some form energy to be provided, usually in the form of an external light source like a flash lamp or a different laser. Excited molecules release energy in the form of light in the form of photons which possess specific wavelengths in a process called normal return, thereby yielding laser light.

One of the distinguishing characteristics of liquid lasers is their tunability. Researchers can achieve light emission at different wavelengths by changing the dye solution or modifying the optical configuration of the laser cavity. For instance, some common dyes such as Rhodamine 6G have an emission range of approximately 570-610 nanometers while other dyes span both above and below this range. This adaptability of liquid lasers is important in fluorescence spectroscopy and medical imaging, both of which require high precision.

A 2022 study by the Journal of Applied Physics showcased how efficiently dye lasers provide ultra-short pulses needed in biomedical engineering. Additionally, dye lasers are instrumental in fast chemical process studies and nonlinear optics for issuing bursts of light with speed and precision at selected wavelengths. Research is also advancing the efficiency and operational lifetime of dye lasers by increasing the stability of the dye molecules and decreasing photodegradation during use.

Liquid lasers remain an important asset in science and technology due to their tunability and advances in their chemical and optical design.

Uses and Advantages of Tunable Lasers

Tunable lasers are versatile lasers, particularly dye lasers and other liquid lased systems, used in various industriebecause because of their exceptional versatility of wavelengths. Spectroscopy is one such area and involves using lasers with precise and adjustable wavelengths to analyze the molecular structure of a specime and recognize the chemicals that make up it. Recently, tunable laser absorption spectroscopy or TLAS was developed and proven to be ultra-sensitive which makes it possible to detect gas concentrations as little as parts per trillion, making this technology useful for environmental monitoring as well as medical diagnostics.

Another important example is in the medical fields, especially with ophthalmology, in laser photocoagulation and other retinal therapies where specially tuned laser wavelengths increase the accuracy of treatment and laser-aimed damage to healthier tissues. Moreover, tunable lasers are also used in the telecommunication industry and are very important in wavelength division multiplexing WDM as a means for increasing the speed of data transmission and improving the accuracy of channeling the signals sent. Newer data indicates that such progress have enhanced the network’s efficiency by around 30% which is a testament to the advancement of modern day connections.

The advantages of tunable lasers also include material science and quantum technologies. Proving that researchers manipulate the atoms using high powered, monochromatic beams of lasers which help them examine the atomic interactions and alter their quantum states with unimaginable precision. The above examples prove that indentureable laser offers an unmatched service in almost all sophisticated science and industry.

Reference sources

- Laser Technology in Mechanical and Machine Manufacturing:

- Key Findings: This study highlights the applications of laser technology in manufacturing, emphasizing its precision in cutting, engraving, and welding. It discusses the advantages of laser cutting for metals and other materials, including high speed, smooth surfaces, and reduced manpower.

- Methodology: The paper provides an overview of laser types (solid, gas, liquid) and their industrial applications, supported by theoretical principles and practical examples.

- Laser Applications in Dentistry:

- Key Findings: Lasers are increasingly used in dentistry for both hard and soft tissue applications, such as caries prevention, cavity preparation, and wound healing. They offer precision and reduced patient discomfort.

- Methodology: The review categorizes lasers by wavelength and application, detailing their interaction with biological tissues and their advantages over traditional methods.

- Medical Lasers: Fundamentals and Applications:

- Key Findings: This paper reviews the use of lasers in medical fields like dermatology, cancer therapy, and ophthalmology. It emphasizes the role of diode lasers in soft tissue cutting and photothermal therapy.

- Methodology: The study explains laser-tissue interactions, penetration depths, and the principles of photothermal and photodynamic therapies.

Frequently Asked Questions (FAQs)

Q: What are the five main types of laser light?

A: The five main types of laser light include solid state lasers, gas lasers, dye lasers, semiconductor lasers, and fiber lasers. Each type is used for different applications such as laser cutting, laser entertainment, and laser surgery.

Q: What is a solid state laser and where is it commonly used?

A: A solid state laser utilizes a solid substance as the laser medium. It is frequently employed in processes such as laser cutting and laser engraving because of its effectiveness and dependability.

Q: How are lasers classified?

A: Lasers are classified according to the type of laser material or medium they use to create laser light. This classification embraces gas lasers, solid state lasers, dye lasers, and others; each fulfills distinct functions like printing or tattoo erasing.

Q: What is a special type of laser used in medicine?

A: Quantum cascade lasers are a special type of laser used in medical applications especially in laser surgery for procedures such as birthmark and hair removal.

Q: How are fiber lasers different from other lasers?

A: Fiber lasers have optical fibers for their active mediums. They have a high level of efficiency and are commonly employed in the processes of laser cleaning and laser cutting.

Q: Which types of pulsed lasers exist?

A: Q-switched lasers are a type of pulsed laser. They are widely used for the procedures of tattoo removal and laser engraving. Another type is mode-locked lasers; they have applications in scientific research.

Q: What is the purpose of dye lasers in a laser show?

A: Dye lasers have a special function in a laser show: they can generate an extensive range of different colors which are necessary to capture the attention of the audience.

Q: How is safety incorporated in the design of lasers is available on the market?

A: Safety standards that govern the construction and the use of lasers available on the market enforce their safety. Those help avoid undesirable incidents and ensure safe employment of such devices as laser printers and laser cutters.

Q: What are the applications of infrared lasers?

A: Infrared lasers give off radiation within the infrared spectrum; this type of laser is used in science, communication technology, and medicine as a non-invasive surgical instrument.

Q: What is a laser system and how is it utilized in various sectors?

A: A laser system refers to a configuration of a laser and its parts. It is used for processes within laser engraving, laser medicine, and industrial laser cutting and many more.

- Understand the Benefits of Laser Fabric Cutting: The Optimum Machine for Processing Textiles

- Unlocking the Power: How Does Laser Cleaning Technology Function?

- Unlocking the Secrets of the 3D Laser Marking Machine: A Comprehensive Guide

- Understanding CNC Routers: The Ultimate Guide to CNC Routing vs Mill Technology