Laser cutters have become a game-changer for hobbyists, small business owners, and creative professionals alike, offering precision and versatility for a range of projects. However, investing in this technology can often come with a hefty price tag, leading many to consider budget-friendly options. But are cheap laser cutters worth the cost? This article dives deep into the advantages and disadvantages of budget laser machines, helping you weigh affordability against performance and long-term value. Whether you’re a DIY enthusiast or launching your own craft business, understanding the trade-offs will empower you to make an informed decision. Let’s explore the key factors to consider when buying a cheap laser cutter!

What Are the Pros and Cons of Cheap Laser Cutters?

Pros of Cheap Laser Cutters

Affordability: These budget laser cutters are more accessible alongside high-end models. This is owing to their low price, hence favorable for beginners and hobbyists.

Beginner-Friendly: Cheap laser cutters often have user-friendly interfaces tailored for novices, such as those new to using laser cutting tools.

Compact Design: Budget laser cutters are also lightweight which allows for easy transportation.

Decent Functionality: Other than simple cutting and engraving, these budget laser cutters can also accomplish other basic tasks.

Cons of Cheap Laser cutters

Limited Power and Speeds: Budget laser cutter brands tend to use lower power features, making it impossible to work on thicker materials.

Reduced Durability: These machines are made with cheaper components, which can lead to a short lifespan alongside maintenance issues.

Lower Precision: Professional grade models will outperform these machines as they lack detail and precision in cuts.

Limited Features: Complicated functions, such as the ability to engrave deeply and work with many other materials are limited on cheap models.

Understanding the Advantages and Disadvantages

When examining the advantages and disadvantages of budget-friendly cutting or engraving machines, it is vital to contextualize them with current market trends and data. For instance, many affordable models now incorporate features such as pre-installed software and user-friendly interfaces, making them highly accessible to beginners. According to recent findings, entry-level machines dominate the market segment catering to hobbyists, with over 60% of users favoring devices under $500 for personal and small-scale use.

However, their limitations remain significant. A noteworthy drawback is the restriction in material compatibility; most budget machines work effectively only with softer materials like acrylic, wood, or thin metals. Additionally, data reveals that around 40% of users express dissatisfaction with the durability of affordable models, pointing to hardware components that degrade faster than high-end alternatives. These factors underscore the necessity of balancing immediate affordability with long-term value when making an informed purchasing decision.

Exploring Laser Cutting Capabilities

Modern laser cutting technology has evolved significantly, offering unparalleled precision and versatility across various industries. High-power laser cutters now support a broad spectrum of materials, including steel, titanium, glass, and even textiles, making them indispensable for applications ranging from industrial manufacturing to intricate artistic designs. Current advancements in fiber laser systems, for instance, boast cutting speeds up to 20% faster than traditional CO2 lasers, coupled with enhanced energy efficiency.

Statistical insights highlight the growing utilization of laser cutting in manufacturing, with the global market for laser processing expected to reach $6.5 billion by 2025, driven by its capacity for faster production cycles and reduced material wastage. Furthermore, enhanced software integration allows for greater accuracy, with some systems achieving tolerances as tight as ±0.001 inches for highly detailed projects. This level of precision has propelled industries such as aerospace, automotive, and medical devices to adopt laser cutting extensively.

Emerging trends also include hybrid technologies that combine laser cutting with additive manufacturing, enabling complex geometries and custom designs. These advancements continue to redefine the possibilities, ensuring that laser cutting remains both an innovative and efficient solution for modern manufacturing needs.

Assessing the Build Quality of Budget Lasers

When evaluating the build quality of budget laser systems, it is essential to consider several critical factors to ensure performance, durability, and safety standards are met. The chassis material and structural integrity are often the first indicators of quality. Budget lasers made with aluminum alloy or reinforced steel frames tend to offer better longevity and resistance to vibration compared to those with plastic or lightweight materials that can feel less robust and may wear faster over time.

Another aspect to scrutinize is the quality of the laser tube or laser diode, depending on the type of laser. For CO2 lasers, reputable glass tubes typically have a lifespan of 1,000 to 2,500 hours of use, while diode lasers boast extended service lives, sometimes exceeding 10,000 hours. However, cheaper alternatives may fail prematurely, compromising both efficiency and long-term usability. Checking the supplier’s warranty terms and availability of replacement parts can provide further insight into the build reliability.

Additionally, focus should be placed on the mechanical components, such as rails, motors, and belts. Smooth linear motion systems with precise stepper motors indicate higher accuracy in cutting or engraving tasks. Conversely, substandard parts may yield inconsistent results, requiring frequent recalibrations or repairs. Furthermore, the integration of safety features, like emergency stop buttons, interlocks, or enclosure systems, is pivotal. While higher-end machines often prioritize safety advancements, budget lasers might include less reliable or absent protective systems, which can pose risks during operation.

Recent data indicates that some manufacturers are successfully bridging the gap between affordability and quality by adopting innovative manufacturing processes, like using modular assembly and sourcing high-performance parts at scale. These efforts have resulted in budget lasers that rival mid-tier offerings in certain applications, delivering decent output while maintaining cost-effectiveness. Prospective buyers should weigh these considerations against their specific project requirements to identify models that provide an optimal balance between price and long-term value.

What Should You Consider When Buying a Laser Cutter?

When buying a laser cutter, consider the following key factors:

- Cutting Power and Speed – Match the machine’s wattage to the materials and thicknesses you plan to cut. Higher wattage typically allows for faster and deeper cuts.

- Material Compatibility – Ensure the laser cutter supports the range of materials you intend to work with, such as wood, acrylic, metal, or fabric.

- Bed Size – Choose a machine with a bed size large enough to handle your typical project dimensions without frequent repositioning.

- Ease of Use – Look for user-friendly software, clear controls, and features like autofocus to simplify operation.

- Maintenance and Durability – Research the machine’s reliability and ease of maintenance, focusing on models with good reputations for longevity.

- Budget – Balance your budget with long-term value, including the cost of operation, replacement parts, and warranties.

Overall, prioritize a laser cutter that aligns with your project needs and offers dependable performance with minimal downtime.

Evaluating Laser Power and Laser Tube Options

When assessing laser power, it’s essential to consider both the material types you intend to process and the desired precision. Lower-powered laser cutters, typically between 30W to 50W, are ideal for delicate engraving projects or thinner materials such as wood, acrylic, and fabric. For cutting thicker materials like metals and dense woods, higher-powered lasers—ranging from 100W to 150W or more—are recommended, as they offer greater penetration capability and faster processing speeds.

The choice of laser tube is equally crucial for ensuring consistent performance. CO2 laser tubes are popular for their versatility, cost-effectiveness, and ability to handle a wide range of materials. However, fiber laser tubes outperform CO2 in metal cutting applications due to their higher energy efficiency and longer lifespan, often exceeding 20,000 operation hours compared to the 8,000-10,000 hours typical of CO2 tubes. For high-precision tasks, RF (radio frequency) laser tubes are preferred because they produce a finer beam quality with superior control.

Industry data shows that machines with adjustable power settings offer greater flexibility, enabling operators to switch seamlessly between engraving and cutting tasks. Additionally, advanced cooling systems in modern laser tubes ensure durability and reduced wear over extensive operations, which is critical for commercial or large-scale use. Selecting the optimal combination of power and tube type will directly influence not only the quality of your work but also operational efficiency and long-term cost management.

Comparing Fiber Laser vs. CO2 Laser Machines

When choosing between fiber laser and CO2 laser machines, understanding their distinct capabilities, strengths, and applications is essential. Both technologies offer advantages, but their suitability depends on your specific requirements.

1. Wavelength and Material Compatibility

Fiber lasers operate at a shorter wavelength (typically around 1.064 microns) compared to CO2 lasers, which have a wavelength of 10.6 microns. This difference significantly impacts material compatibility. Fiber lasers excel at cutting and engraving metals, including stainless steel, aluminum, brass, and copper, as their shorter wavelength is better absorbed by reflective materials. On the other hand, CO2 lasers are better suited for cutting non-metal materials like wood, acrylic, glass, and leather, making them more versatile for non-metal projects.

2. Cutting Speed and Efficiency

Fiber lasers generally deliver faster cutting speeds, particularly for thin metals, due to their higher energy absorption and efficient energy transfer. For instance, a fiber laser can cut a 1mm stainless steel sheet approximately 2–3 times faster than a CO2 laser of similar power. However, for thicker materials, CO2 lasers can sometimes match or exceed fiber laser performance depending on the specific setup and material type.

3. Maintenance and Operating Costs

Fiber lasers are renowned for their low maintenance requirements and high durability. The absence of mirrors and the solid-state design reduce wear and tear, resulting in minimal upkeep. CO2 lasers, in contrast, feature optics and mirrors that require periodic replacement and alignment, contributing to higher maintenance costs. Additionally, fiber lasers are more energy-efficient, typically consuming 50% less power than CO2 lasers, offering long-term cost savings for high-volume operations.

4. Initial Investment and Lifespan

CO2 laser machines often have a lower initial cost compared to fiber lasers, making them more accessible for small businesses or those new to laser cutting technology. However, fiber lasers tend to have a significantly longer lifespan, with an average operating life of 100,000 hours compared to less than 20,000 hours for CO2 lasers. This longevity further validates the higher upfront investment in fiber lasers for industrial-scale applications.

5. Beam Quality and Precision

Fiber lasers provide superior beam quality with smaller focal diameters, allowing for more precise cuts on intricate designs and thin materials. CO2 lasers, while precise for many applications, cannot achieve the same level of detail in fine cutting due to their larger focal spot size.

6. Applications in Industry

Fiber lasers dominate industries such as automotive, aerospace, and metal fabrication, where speed, precision, and metal processing capabilities are critical. CO2 lasers, however, remain the top choice for signage, woodworking, and other creative applications that require versatility in non-metals.

By understanding these factors, you can better assess which laser technology aligns with your project needs, budget, and long-term operational goals. Whether prioritizing speed, precision, or material flexibility, selecting the right machine type can maximize productivity and ensure a return on investment.

Importance of Work Area and Ventilation

With laser cutting and engraving machines, the arrangement and upkeep of your workplace is essential for safety, productivity, and performance. A well organized area attends to functionality and regulatory requirements. As an example, the workspace layout must have an area for materials, tools, and equipment to be stored in an orderly fashion to minimize the chances of accidents.

During laser cutting or engraving, the quality of air and the dangerous particles created are removed by the ventilation system. There are regulations in the industry that state that machines must be equipped with a good exhaust system, or air filtration equipment for handling debris created from different substances like wood, acrylic, or plastics. These fumes, when breathed in over a long period of time, can result in dire medical complications, especially respiratory ones. To maintain a cleaner working environment, advanced ventilation systems like HEPA filters or activated carbon modules that help trap these unhealthy airborne particles, can improve the situation.

Furthermore, preserving the laser airflow balance prevents the buildup of dirt on delicate parts of the machine, thus increasing the life of the laser equipment. Moreover, airflow is known to affect the consistency of cut quality and the frequency of malfunctions. A clean, well-ventilated workspace promotes better health, improves productivity, and increases the longevity of equipment.

How Does Laser Cutting Work with Different Materials?

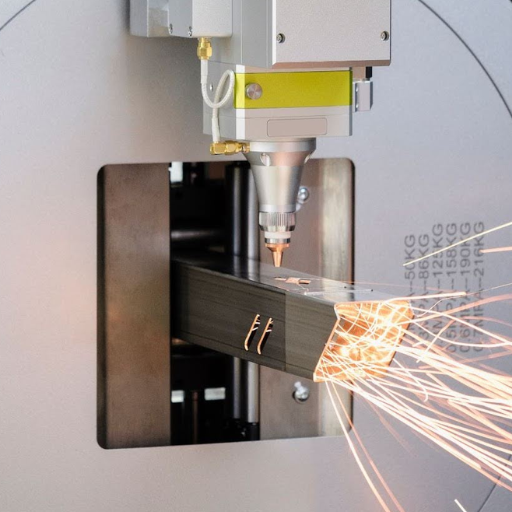

Laser cutting works by directing a concentrated beam of light onto the surface of a material, melting, burning, or vaporizing it to achieve a precise cut. The process can vary depending on the material being cut. For metals like steel or aluminum, the high intensity of the laser melts the surface, while assist gases like oxygen or nitrogen help remove molten material. For non-metals such as wood, acrylic, or textiles, the laser typically burns or vaporizes the surface to create clean edges. Each material requires specific laser power and speed settings to ensure accuracy and minimize waste or damage, making proper calibration essential for achieving the best results.

Understanding Laser Beam Interaction with Acrylic and Plastic

The interaction between a laser beam and materials like acrylic or plastic is heavily influenced by the material’s optical properties, thickness, and composition. Acrylic is highly receptive to laser cutting due to its excellent light transmission and low melting point. When exposed to the focused laser beam, the heat energy melts and evaporates the material, resulting in smooth, polished edges that require little to no post-processing. Clear acrylic, in particular, achieves optimal cut quality because it absorbs the laser’s wavelength efficiently, leading to precise, clean designs.

On the other hand, plastics present a more varied response depending on their chemical makeup. For example, polycarbonate reacts differently compared to polypropylene due to variations in heat resistance and reflectivity. High-speed settings combined with appropriate power levels are essential for preventing thermal deformation, burning, or discoloration in plastic materials. Multiple studies suggest that a CO2 laser with a wavelength of 10.6 µm is ideal for cutting and engraving most plastics, as it provides the necessary energy absorption for effective processing.

Modern laser systems allow precise optimization of parameters like power, speed, and pulse frequency, accommodating the distinct behaviors of both acrylic and plastic. Data indicates that cutting speeds can range between 200 to 500 mm/s for 3 mm acrylic with a 50-watt laser, while the same speed applied to denser plastics may require higher energy input. Heat management during the process is also critical, as overheating can lead to warping or toxic byproducts, especially with certain thermoplastics.

By aligning laser settings with material characteristics, manufacturers and designers can achieve unparalleled efficiency and versatility in working with acrylic and plastic for intricate designs, industrial components, or artistic applications. This precision ensures that laser cutting continues to be a key technology in industries ranging from signage to automotive production.

Utilizing Diode Laser for Cutting and Engraving

From my experience, utilizing a diode laser for cutting and engraving offers a highly precise and efficient solution for both intricate and large-scale projects. Diode lasers excel in handling a variety of materials, including wood, acrylic, and certain plastics, while maintaining exceptional accuracy in every cut or etching. Their compact size, energy efficiency, and user-friendly operation make them an ideal choice for applications ranging from creative designs to industrial components. By adjusting the power and speed settings, I can tailor the laser’s performance to achieve precise results consistently.

Application of Laser Engraving on Various Surfaces

Laser engraving has transformed how materials are customized across numerous industries by offering precision and versatility. Below are some details about its application on different surfaces and the potential it unlocks:

- Wood: Laser engraving on wood is widely used in creating intricate designs, furniture detailing, and custom artworks. Materials like plywood, hardwood, and MDF are suitable for achieving sharp engravings. Modern laser engravers can engrave fine details as small as 0.1mm, making them perfect for high-resolution patterns or logos. Wood’s organic texture enhances the contrast of the engraving, creating visually appealing results.

- Metal: Metals such as stainless steel, aluminum, and brass are ideal substrates for laser marking and engraving. This technique is commonly utilized in the medical, automotive, and jewelry industries to mark serial numbers, QR codes, or decorative patterns. Fiber lasers are particularly effective for metals, with engraving speeds of up to 7,000mm/s, which ensures efficiency for large-scale production.

- Acrylic and Plastics: Laser engraving on acrylic sheets produces smooth, polished edges without the need for additional processing. This capability is popular in signage, trophies, and display design. Materials such as cast acrylic respond exceptionally well due to their homogeneous structure, providing crisp and vibrant engraving results. Engraving depth can also be customized, ranging from shallow etches to deeply engraved designs.

- Glass: Laser engraving on glass renders frosted designs, which are commonly applied to decorative pieces, mirrors, and drinkware. With CO2 laser systems, high-power beams ensure precision without cracking or damaging the surface. Delicate patterns as fine as 0.5mm can be achieved, offering a refined touch to decorative items.

- Leather: Leather laser engraving is a favored technique in crafting personalized products such as wallets, bags, and belts. Whether synthetic or genuine, leather engraves deeply, producing clear contrast that highlights patterns and text. This application is particularly popular in the fashion and accessory industries, where high customization is highly valued.

These capabilities have made laser engraving indispensable across countless industries, ensuring unmatched quality, efficiency, and scalability when working with diverse materials. Modern advancements continue to enhance versatility, broadening the horizons for creativity and innovation.

Which Are the Best Laser Cutters for Budget Buyers?

For budget-conscious buyers, here are some of the best laser cutters that combine affordability, reliability, and performance:

- Ortur Laser Master 2

A compact and user-friendly option, it provides excellent precision and is ideal for beginners or hobbyists working with wood and acrylic.

- NEJE Master 2S Plus

Known for its simplicity, portability, and affordability, this model is perfect for small-scale cutting and engraving projects.

- Atomstack A5 Pro

This laser cutter offers strong performance at a competitive price, handling a variety of materials with ease—great for craft projects.

- xTool D1

Featuring a sturdy design and impressive cutting ability for its price range, this is a versatile tool for users looking to experiment with different materials.

Each of these models strikes a balance between cost-efficiency and functionality, making them excellent choices for budget buyers without compromising on quality.

Exploring 40w Laser Options for Hobbyists

When considering 40W laser options for hobbyists, it’s essential to evaluate key aspects such as power, material compatibility, precision, and usability. Here are some popular and high-performing models in this category:

- OMTech 40W CO2 Laser Engraver

The OMTech 40W is a robust option for hobbyists seeking professional-level capabilities at an accessible price point. It features a 12″x8″ engraving area and works effectively with a variety of materials, including wood, acrylic, leather, and fabrics. The machine boasts a high precision rate of ±0.01mm, ensuring detailed and consistent results. Its water cooling system ensures stable performance during prolonged use, while the intuitive software interface makes it easy to operate, even for beginners.

- Aeon Mira 5 40W Laser Cutter

Known for its premium build and exceptional accuracy, the Aeon Mira 5 offers high-quality CO2 laser cutting and engraving to creative enthusiasts. With a cutting area of 19.7″ x 11.8″ and a cutting speed of up to 600mm/s, it provides hobbyists with versatility and efficiency. Materials such as wood, cardboard, acrylic, and even stainless steel (with special coatings) can be processed effortlessly. Built-in features like an air assist system and autofocus improve cutting quality while reducing user effort.

- K40 Chinese Laser Engraver

The K40 model is a widely recognized affordable entry-level laser cutter and engraver. It offers a reasonable working area of approximately 300mm x 200mm, ideal for small-scale projects. Supported materials include wood, plastic, and paper. While it lacks some advanced features like integrated ventilation or touchscreen controls, its budget-friendly price tag makes it an attractive choice for hobbyists starting their laser-cutting journeys.

- GWEIKE Cloud 40W Laser Engraver

This machine is designed with convenience and innovation in mind, featuring Wi-Fi connectivity and a user-friendly app interface that allows operations directly from a smartphone. It supports a variety of materials, including glass, bamboo, leather, and anodized metal. Its compact yet sturdy design fits well in small workshops or home workspaces, making it a practical option for hobbyists who prioritize efficiency and functionality.

Each of these 40W laser options offers unique features tailored to different needs, making it easier for hobbyists to find a machine aligning with their specific projects and creativity while staying within budget.

Reviewing Affordable Laser Cutters and Engraving Machines

When selecting a laser cutter or engraving machine, several factors come into play, ensuring that the machine suits both your needs and budget. Key considerations include power output, supported materials, and software capabilities.

Power Output

For hobbyists and small businesses, machines with a power rating ranging from 20W to 50W are typically ideal. A 40W laser, for example, offers enough power to cut materials such as wood, acrylic, and leather, while also excelling in detailed engraving work. Machines with higher wattage, such as 50W, provide faster cutting speeds, making them perfect for thicker materials, though they may come at an added cost.

Material Compatibility

Versatility in material types is essential for ensuring creativity in projects. Affordable models, like the OMTech 40W, can handle wood, paper, plastics, and even coated metals. Similarly, the longer Ray5 10W, priced competitively, supports engraving on harder surfaces like stone and stainless steel. Always review a machine’s supported materials to align with your specific project needs.

Software Integration

Modern machines often come equipped with user-friendly software compatible with operating systems like Windows and macOS. Entry-level systems typically include basic engraving tools, while advanced software allows for greater customization and control. Machines such as the xTool D1 Pro 10W also support popular design software like LightBurn, extending functionality for professional users.

By carefully evaluating these factors, users can make informed decisions when investing in a laser cutting or engraving machine, ensuring their purchase aligns perfectly with their creative aspirations. Technologies in this realm continue to improve, bringing precision and innovation to creators worldwide, no matter their budget.

Comparing Used Laser Machines: Cost vs. Performance

When evaluating used laser machines, achieving the right balance between cost and performance is essential. The price range for used laser cutters and engravers can vary widely, often spanning from $1,000 to $10,000, depending on factors such as the brand, model, condition, and capabilities. Buyers should carefully assess technical specifications, including wattage, cutting speed, engraving resolution, and supported materials. For instance, higher wattage machines (e.g., 60W or 100W) typically offer faster cutting speeds and the ability to handle thicker materials, but they may come at a higher price point.

Another critical factor is the machine’s operating hours. Equipment with extensive use may suffer from wear and tear, particularly in essential components like the laser tube, mirrors, and lenses. Replacing these parts can add significant costs, so it’s crucial to inquire about the machine’s maintenance history. Additionally, older models may not support newer software features, limiting their functionality compared to more recent designs.

When it comes to performance, precision is a key metric. Look for machines offering high-resolution capabilities, typically measured in dots per inch (DPI). A machine capable of achieving 1,000 DPI or higher is well-suited for detailed engraving projects, whereas lower resolutions may suffice for simpler cutting tasks. Popular brands like Epilog, Trotec, and Thunder Laser tend to hold their value well due to their durable builds and advanced features.

Lastly, compatibility with upgraded software and accessories, such as rotary attachments or enhanced ventilation systems, can maximize a machine’s versatility. With careful evaluation, buyers can strike the ideal harmony between affordability and efficiency, ensuring the chosen machine meets both current and future project demands.

What Are the Key Features of a Cheap Laser Cutter?

- Affordability: Cheap laser cutters are budget-friendly options, making them accessible for beginners or small-scale projects.

- Basic Functionality: They typically offer essential cutting and engraving capabilities, suitable for materials like wood, acrylic, leather, and paper.

- Compact Design: Many inexpensive models are space-efficient, ideal for hobbyists or workshops with limited room.

- Lower Power Output: These machines generally have lower wattage, limiting their ability to cut through thicker or more demanding materials.

- User-Friendly Operation: Basic models often feature simple interfaces, allowing for quick setup and easy use.

Cheap laser cutters are best for light-duty work and are a great starting point for those exploring laser cutting without a significant investment.

Importance of Air Assist and Rotary Attachments

The use of Air Assist and Rotary Attachments in laser cutting can significantly enhance both the performance and versatility of your machine. These features are essential for improving cutting precision, reducing material damage, and expanding the range of materials that can be worked on.

Air Assist

Air Assist works by directing a constant stream of compressed air toward the cutting area during operation. This simple yet effective mechanism has several benefits:

- Improved Cutting Quality: The airflow helps to blow away smoke and debris from the laser path, ensuring cleaner and sharper edges.

- Thermal Protection: By reducing the accumulation of heat around the cutting zone, it minimizes the risk of burns or scorching on sensitive materials.

- Longer Lifespan for Lenses: Keeping the cutting area clear of debris prevents particles from depositing on the laser lens, reducing wear and maintenance costs.

- Enhanced Speed: Tests have shown that using Air Assist can increase cutting efficiency, speeding up production by up to 25% in certain materials, like acrylic or wood.

Rotary Attachments

Rotary Attachments expand the capabilities of a laser cutter by enabling the engraving or cutting of cylindrical objects such as glasses, bottles, and tumblers. This is especially valuable for businesses that want to offer customized products. Key advantages include:

- 3D Versatility: With this attachment, your laser cutter can handle curved or tubular surfaces seamlessly, providing precise and uniform results.

- Material Compatibility: Rotary Attachments work effectively with glass, metal, plastic, and more, making them essential for diverse product offerings.

- Scalability for Businesses: For small business owners, rotary functions allow for the creation of personalized merchandise, such as branded drinkware or bespoke gifts, which can drive revenue growth. Current reports suggest that consumer interest in customized goods has increased by nearly 20% over the past few years.

To make the most of a laser cutting system, integrating both Air Assist and Rotary Attachments creates a dynamic setup. Air Assist ensures pristine cuts, while Rotary Attachments open doors to new designs and product options, making these features indispensable for professional-grade results.

Evaluating Lightburn Software Compatibility

Lightburn software is renowned for its versatility and robust functionality, making it a popular choice for laser cutting and engraving projects. It supports a wide range of laser systems, including CO2, diode, and fiber lasers, ensuring seamless compatibility with many industry-standard machines. Its intuitive interface makes it accessible for beginners while offering advanced features for seasoned professionals.

One key aspect of Lightburn’s compatibility is its ability to connect with controllers using common standards like Ruida, Trocen, and GRBL. The software allows for direct communication with these devices, streamlining design-to-production workflows. It is noted for its cross-platform functionality, operating smoothly on Windows, macOS, and Linux systems, providing users on various platforms consistent performance.

Additionally, Lightburn’s regular updates keep the software modern and aligned with advancements in laser technology. Users have reported a significant reduction in time spent preparing files for cutting or engraving due to Lightburn’s ability to handle vector and raster files, thereby achieving precise and efficient project outputs. Furthermore, its support for advanced settings, such as multiple layer controls and offset adjustments, enhances compatibility with different materials and projects.

This level of flexibility allows companies or hobbyists to optimize their laser usage for diverse applications, ranging from simple engraving to detailed custom cuts, making Lightburn a central tool in today’s laser crafting innovations.

Understanding Laser System Maintenance Needs

Proper maintenance of a laser system ensures consistent performance, prolongs its lifespan, and reduces the risk of costly downtime. To achieve these benefits, adhering to a regular maintenance schedule and paying close attention to key system components is critical.

Cleaning the Optics

Laser optics, including lenses and mirrors, require routine cleaning to remove dust, debris, and residue caused by prolonged use. Contaminants on these surfaces can degrade beam quality and reduce cutting efficiency. Using recommended cleaning materials and techniques—such as lint-free wipes and appropriate solvents—can prevent accidental damage.

Cooling System Checks

Whether using water- or air-cooled laser systems, it’s essential to monitor and maintain the cooling mechanism. Insufficient cooling can cause overheating, which can lead to permanent damage to laser components. Regularly check coolant levels, ensure proper airflow, and replace water in closed-loop systems to prevent blockages and contamination.

Alignment of the Laser Beam

Misaligned laser beams can hinder precision and compromise output quality. Regularly inspecting and adjusting beam alignment ensures accurate performance in cutting or engraving applications. Many manufacturers provide alignment tools to simplify this process.

Monitoring and Replacing Consumable Parts

Components such as laser tubes, filters, and belts naturally degrade over time. Monitoring these consumables and replacing them at recommended intervals can prevent sudden failures. For instance, an average CO2 laser tube typically has a lifespan of 1,500 to 2,500 hours, depending on usage conditions, while fiber lasers generally last much longer, often exceeding 50,000 hours.

Software and Firmware Updates

Keeping the control software and firmware up to date is crucial for compatibility and the system’s optimal performance. Updates often include bug fixes, performance enhancements, and additional features.

Environmental Controls

The surrounding environment also plays a critical role in system health. A dust-free workspace with stable temperature and humidity levels can prevent hardware clogs and reduce strain on temperature-sensitive components.

Regular attention to these aspects, alongside manufacturer-recommended guidelines, can maintain high productivity levels and ensure your laser system remains reliable for years to come.

Reference Sources

-

Design and Testing of Components for a Low-Cost Laser Cutter (MIT)1:

- Focus: Explores the design and testing of components for a low-cost laser cutter aimed at hobbyists and recreational users.

- Key Findings: Laser diodes in low-cost systems struggle to cut materials of structural thickness (0.125 to 0.25 inches). While potentiometer feedback for positioning showed promise, mechanical designs lacked precision, requiring further refinement.

- Methodology: Experimental tests were conducted on various materials using a test rig, and a low-cost positioning system was evaluated for accuracy.

-

Ultrafast Laser Applications in Manufacturing Processes (2020)3:

- Focus: Reviews advancements in ultrafast laser technology and its applications in manufacturing, including cost-effective solutions.

- Key Findings: Highlights the precision and efficiency of ultrafast lasers in micro/nanomachining and additive manufacturing. However, the high initial cost of advanced systems remains a barrier for budget-conscious users.

- Methodology: Combines theoretical insights and process development reviews to evaluate the impact of ultrafast lasers on manufacturing.

- Top Co2 Laser Engraving Cutting Machine Manufacturer And Supplier In China

Frequently Asked Questions (FAQs)

Q: What are the pros of buying a cheap laser cutting machine?

A: Buying a cheap laser cutting machine can be a cost-effective option for beginners or hobbyists looking to explore laser cutting and engraving. These machines often provide clean cuts and high accuracy on thinner materials like 3mm wood or acrylic. They can serve as a great introduction to the world of laser cutters without a significant financial investment.

Q: What are the cons of buying a cheap laser engraver?

A: Cheap laser engravers might have limitations in terms of power and durability. They might not be suitable for cutting thick materials or achieving high-quality results on more robust projects. Additionally, customer support and troubleshooting options might be limited, and cheaper models may require multiple passes to achieve desired cuts, impacting overall efficiency.

Q: What factors should I consider when buying a cheap laser cutter?

A: When buying a cheap laser cutter, consider factors such as the thickness of the material you plan to cut, the types of laser cutters available (like CO2 or fiber laser cutters), the focal length, and the level of customer support provided by the manufacturer. Also, evaluate the machine’s power, such as a 10w laser, and ensure it meets your project requirements.

Q: How does a CO2 laser cutter compare to other types of laser cutters?

A: A CO2 laser cutter is often more versatile and can cut a wide variety of materials, including wood, acrylic, and some plastics. Compared to fiber laser cutters, which are typically used for metals, CO2 lasers are better suited for non-metal materials. They are also generally more affordable, making them a popular choice for budget-conscious buyers.

Q: Is the xTool P2 a good option for beginners?

A: The xTool P2 is considered a good option for beginners due to its user-friendly interface and relatively low cost. It provides decent power for hobby projects and is capable of producing clean cuts on thin materials. However, as with many laser cutters and engravers in this price range, it may have limitations when working with thick materials.

Q: Can a Glowforge be considered a budget laser engraver?

A: While the Glowforge is not the cheapest option available, it offers a balanced mix of performance and ease of use, making it a popular choice among hobbyists and small business owners. Its enclosed laser design ensures safety, and it offers reliable customer support, which can be beneficial for troubleshooting issues.

Q: What is the advantage of using a 10w laser in budget laser machines?

A: A 10w laser in budget laser machines provides a good balance between power and affordability. It is capable of cutting and engraving thin to medium materials with high accuracy. This power level is often sufficient for hobby projects and small-scale production, making it a practical choice for users seeking cost-effective solutions.

Q: How does focal length affect the performance of a laser cutter?

A: Focal length is crucial in determining the precision and quality of the cuts. A properly focused laser can achieve high-quality results and clean cuts. In budget laser cutters, maintaining the correct focal length is essential to maximize the machine’s effectiveness, especially when dealing with intricate designs or thinner materials.

Q: Are there any specific troubleshooting tips for budget laser machines?

A: For troubleshooting budget laser machines, check the alignment and cleanliness of the laser lens, ensure the correct focal length, and verify that the software settings match the material being used. Regular maintenance, such as cleaning the machine and checking for loose parts, can also help prevent common issues and ensure consistent performance.

- Waterjet Vs. Laser Cutting: The Ultimate Guide to Metal Cutting Services

- How Accurate is Laser Cutting: Understanding Laser Cutting Tolerances

- Understanding the Crucial Differences Between Laser Engraving vs Laser Marking: A Complete Guide

- Exploring the 5 Different Types of CNC Machines: A Comprehensive Guide