The surface cleaning industry could be changed forever by the marvelous new invention of lasers. They offer unrivaled effectiveness and precision with their cleaning capabilities. However, their use does come with responsibility–especially in the safety department. The cleaning of surfaces with the use of lasers can be dangerous to the operators if mishandled–causing burns and damage to the user’s eyesight. From common protective equipment to habitual mistakes laser cleaner users make, this guide will cover every detailed step towards successful and safe operating of laser cleaning. The astonishing cleaning technique can be very beneficial to users, but must be handled with care. Prepare to enhance your safety along with new technologies by using this revolutionary cleaning technique.

What is Laser Surface Cleaning and How Does it Work?

As the name inplies, laser surface cleaning makes use of a laser to remove coatings or residues from surfaces without damaging the material beneath. As the unwanted layer is zapped with the laser, it is broken down or completely vaporized. This method of cleaning captures energy, in a controlled fashion, which makes the process safe and gentler on surfaces requiring cleaning. Unlike many abrasive forms of cleaning, surface laser cleaning does not require chemicals, solvents or other harmful materials, which makes it much cleaner and safer for the environment. This means it is safe for use in manufacturing and restoration industries.

Why is Laser Cleaning Most Preferred?

As is evident, laser cleaning makes use of the lowest possible energy settings for cleaning purposes. This means the surface of the artifact or area being cleaned cannot be damaged. In fact, experts note that clean surfaces are a problem is dealt with using more modern instruments. This works particularly well when cleaning delicate materials is mixed with age-old artifacts. Control over the essence of cleaning required is provided in the intensity and the time while the laser is on. This means an operator can set the duration of a laser pulse and the wavelength making surface cleaning easier and more controlled.

Research further indicates that laser cleaning is a greener alternative. Compared to traditional methods such as abrasive blasting or chemical treatments, one laser cleaning system can greatly minimize waste. For example, studies show the complete cessation of hazardous chemicals employed for cleaning, thereby lessening the environmental footprint and improving safety at the workplace. The only byproduct, which is dust or vaporized particles, is minuscule in amount and can be captured by industrial suction systems.

In addition, enhanced appeal is provided by the speed of laser cleaning, with contemporary systems having a capability of up to 15 square feet per minute, depending on the material and type of contamination. This level of efficiency is most prominent in the automotive, aerospace and shipbuilding industries, which often require large-scale cleaning. For instance, more than 40% reduction in cleaning time as reported by aerospace maintenance is attributed to the use of laser-based solutions as compared to traditional methods.

Finally, no physical contact with the surface during cleaning eliminates any chance of mechanical wear and tear. As a result, the laser system and the material being cleaned will both have an extended lifespan. The cumulative advantages noted above justify the wider acceptance of laser cleaning in industry and applied research.

How Focused Laser Beams Remove Contaminants from Surfaces

Laser cleaning works by applying focused laser beams to contaminants, using light energy to remove or evaporate unwanted layers from any surface. The process is exceedingly effective as the accumulated laser energy can clear away such materials as rust, paint, or grease without harming the underlying surface. For example, the latest developments in high power pulsed fiber lasers have provided consistent results in the cleaning of metal surfaces, achieving an astonishing cleaning rate of 50 square centimeters per second.

Along with this, new laser cleaning systems have real-time performance feedback that improves cleaning efficiency. Evidence from a study done in 2023 showcased the remarkable feat adaptive laser systems achieved, boosting energy efficiency by 20 percent while reducing power expenditure without loss in productivity. Moreover, many industries, specifically automotive manufacturing, report tangible savings from the lowered spending on providing logistics due to the reduced use of chemical solvents or abrasives. These innovations are laser cleaning as a revolutionary technology for surface preparation continue to strengthen.

Types of Laser Cleaning Systems and Their Uses

Laser cutting systems are made with certain applications in mind. For example, pulsed laser systems are best suited for softer surfaces like antique pieces because they allow for careful energy management. On the other hand, continuous wave laser systems excel at more industrial applications such as rust or paint removal from tougher surfaces due to their unrelenting energy output. The automotive, aerospace, and manufacturing industries find great value in these systems because of their multifunctionality.

What Safety Risks are Associated with Laser Cleaning?

If safety measures are not strictly followed, laser cleaning poses a myriad of risks to safety. Key dangers include eye and skin injuries as a result of direct or indirect laser beams of light being inflicted, which have the potential to cause burns and permanent damage. Furthermore, the process may emit toxic particles or fumes from the material that requires cleaning, which in turn could be a risk to the lungs. To reduce these concerns, sufficient safety measures such as wearing protective clothing, appropriate ventilation, and operational rules should always be enforced.

Fumes and Respiratory Dangers of Laser Immigration

From my perspective, the dangers of laser immigration are mostly eye and skin injuries such as exposure to lasers which could lead to serious burns or permanent damage. Respiratory threats due to particles and fumes emitted during laser treatment should also be considered. If I were to address these issues, the first thing I would do would be to don the correct safety equipment, see to it that there is sufficient airflow, and adhere to every one of the safety rules.

How Laser Power Classifications Affect Safety

Lasers have different classes based on the level of danger they can cause to a human. The classification ranges from Class 1, the ‘safest’ category, to Class 4, which pose significant hazard Class 1 lasers are considered harmless under normal operational conditions because the energy emitted is way below the injury threshold. In contrast, Class 4 lasers, which are widely used in scientific and industrial activities, will cause serious eye and skin injuries, or even fire when mismanaged.

As of the latest updates, Class 4 lasers have power levels greater than 500 milliwatts and can cut, engrave or weld materials including metals, plastics, and ceramics. Such lasers need even greater care which requires the use of special laser safety glasses, complete enclosure of the workspace, and trained operators to reduce the danger overall. The ANSI Z136 sets of laser safety standards give detailed information on the proper treatment of any class of laser, protective steps for the command over high-powered lasers, and the supervision for multi-class lasers.

Knowing these classifications and following recommended safety measures are essential in minimizing the risks of accidents and injuries that can occur from laser usage, particularly in its settings, which precision and power are critical.

Risks When Cleaning Different Surface Contaminants

The level of risks associated with cleaning surface contaminants depends on the surface to be cleaned and the type of contaminant involved. Biological contaminants can pose a risk of exposure to dangerous pathogens; therefore, protective gear and disinfecting solutions are necessary. Chemical residues may also pose certain risks which are of the toxic or reactive nature. Abrasive physical contaminants like dust or debris also pose inhalation risks, requiring safety goggles and masks. Assess the situation accordingly and mitigate risks through the proper measures.

What Essential Safety Equipment is Needed for Laser Cleaning Operations?

For safe operations of the laser cleaning technique, the following listed safety precautions must be observed:

- Laser Cleaning: Safety glasses Protects the eyes from the strong light produced by the laser. Ensure the goggles have the correct specifications for the wavelength and power of the laser in use.

- Protective Clothing: Protects the skin from exposure to the laser light as well as any dust or particles that might be generated.

- Respirators: Masks or respirators protect the face against dust, fumes or vaporized matter, which may be emitted from the cleaning process.

- Gloves: Protects the hands from sharp waste and dangerous materials.

- Barriers and Shields: Encloses the area of laser cleaning to cut off the zone where the laser will not be beam.

- Emergency Stop Methods: For stopping the machine by cutting off the power in case of malfunction.

Protective Gear Advantages

Proper protective gear while performing hand-held laser cleaning highly ensures safety and reduces workplace accidents. Main guarantees include defended while exposing laser, exposure to incompatible cleaning objects after, and protections against lasting damage. Following safety regulations with proper equipment protects the person operating the machine and the environment as well.

Safety Features of Workspaces for Laser Cleaning Systems

To provide complete protection, modern laser cleaning systems are equipped with remarkable workspace safety features: comprehensive protection. Additional features usually include automatic shut-off systems that activate when unsafe working conditions – overheating, for instance, or breach of security – are detected. To preserve the operator’s air during the cleaning processes, toxic fumes, dust, and particles are efficiently removed by integrated high-performance exhaust systems.

Correct ventilation of enclosed workspaces is one of the most important factors of properly contained spaces and is often assisted by HEPA filters that capture microscopic contaminants. Operators’ safety is also enhanced by shielding enclosures that block escaping laser beams, which are sometimes built into the laser systems. Lasers are not allowed to function under the non-safety standards such as open enclosures or absence of the goggles being correctly worn; therefore, real-time monitoring sensors combined with interlock mechanisms ensure emission control.

These measures are critical safety precautions that aid manufacturers streamline efficient cleaning routines and health masking the precise workspace safety measures empowers operators and Manufacturers address. The importance of these measures underscoring workplace injury prevention statistics showing approximately 30% reduction in workplace incidents as laser cleaning systems compliant to international safety standards.

Sophisticated Safety Monitoring Tools

The adoption of sophisticated safety monitoring tools in laser cleaning systems is improving workplace safety standards. The tools use real-time sensors to track operational settings like the changing temperatures, ageneral lasers, and air quality. For example, modern systems use smart IoT-based technologies that can identify changes instantaneously that can lead to accident and automatically shut the machines or alert people incharge.

Recent research shows that IoT safety monitoring increases the average machine idle period for the operator by 25% leading to loss of productivity without proper human supervision. Furthermore, the use of lasers systems equipped with automated emergency stop commands and self-diagnosing AI components enhances the responsiveness to critical situations. Along with strong emergency procedures, these monitoring tools multifunctionally improve safety as well as ensuring international ISO 11553-1 and OSHA compliance. This supports a culture where employees are appreciated for the value they add while increased productivity is achieved.

How to Implement Safety Protocols When Using Laser Cleaning Solutions?

- Conduct Risk Assessment: Examine the hazards for laser cleaning solutions in relation to exposure to laser beams, fumes, and debris.

- Provide Training: Make sure all personnel know how to operate the equipment, follow safety and handle emergency procedures.

- Use Correct Protective Equipment: Provide protective equipment such as laser safety goggles and gloves to reduce exposure for workers.

- Set Up Control Area Barriers: Create restricted controlled entry zones or fences around the laser cleaning area to avoid unintentional exposure.

- Follow Lawful Measurements: Comply to relevant measures like ISO and OSHA guidelines to help maintain safety and compliance conducive to a safe working environment.

- Conduct Regular Servicing of the Laser Cleaning Equipment: Safely and optimally checked or serviced inspected laser cleaning equipment regularly.

- Prepare emergency procedures: Develop procedures on emergency stop and response plans to communicate to workers to handle incidents efficiently and quickly.

Designing Your Training Program for Laser Cleaning

To create an effective training program on laser cleaning, one must first consider the safety of the operators, efficiency of the equipment, and the legal policies in place. Employees need to be trained on laser technology, specifically on factors like frequency, pulse duration, wavelength, and how these parameters modify cleaning of the material. For example, some research indicates that employing the laser wavelength optimally increases cleaning efficiency by up to twenty percent relative to the surface material and the contaminants present.

Training should also include techniques that enhance performance, such as routine equipment maintenance and proper equipment use. Training sessions should be designed in such a way that they can prevent problematic scenarios like beam and equipment wear misalignments from becoming serious problems. Also, the training must cover the importance of some basic PPE, like the goggles marked ANSI Z136.1 for lasers, worn for eye protection in the event of injury, emphasizing that these essential tools are laser safety goggles.

In the accuracy-enhancing training of operators, simulation-based training models are seen as particularly beneficial. Such models enable the practitioner to train on virtual systems, and as a result, the risks while dealing with actual systems is minimized. Industry research indicates companies that utilize complete training programs for laser cleaning show a reduction in equipment downtime by 25%-30%, proportionate to increased operational productivity. This clearly indicates value of education.

Roles and Responsibilities of a Laser Safety Officer

A Laser Safety Officer (LSO) performs an critical role in protecting the workplace and ensuring compliance with the standards for safety using lasers. Important activities entails formulation and implementation of safety policies, evaluation of possible risks, and refresher training for operators and other employees using laser machines. Studies of the impact of LSOs in manufacturing and medical facilities claim there is a 40 percent decrease in accidents associated with lasers, which articulates the importance of LSOs.

LSOs are also tasked with performing periodic audits to check the accuracy of the laser systems, as well as helping to put in place any needed corrective action. Their skills are most useful concerning hazard assessment, mainly in areas which contain Class 3B and Class 4 laser systems which are more dangerous from the point of view of injury. In addition, they work with engineering design groups to incorporate other necessary features such as interlock systems, beam shielding, and caution signs to other safety features in accordance with sets like ANSI Z136.1 or its other equivalents. Safety standards set by DPI USA state that total productivity increases by around 20 percent in the presence of defined LSOs at a workstation compared to without him due to reduced interruptions.

Latest Advancements in Laser Technology and Safety

New developments in industrial, medical, and military-grade lasers have broadened the range and capabilities of such devices, driving up the demand for accuracy, precision, and safety. The inclusion of high-speed galvo scanning heads and fiber laser sources have elevated the marking speeds by up to 30 percent alongside meeting production requirements as noted from the 2023 study on industrial laser systems. Advanced digital monitoring systems are also in place to maintain beam quality and control overheating risks.

Ensuring safety is the top priority in environments with laser equipment. Studies show that the use of automated laser safety shutters and remote monitoring systems has decreased accidents in industrial environments by 15% in the last five years. For instance, closed-loop control systems now have “safety interlocks” that prevent emission of dangerous levels of power by controlling the laser’s output. This complies with international regulations, such as the IEC 60825-1, which ensures the thorough evaluation of lasers as products for the safety of consumers and operators.

The analysis from the laser manufacturing plants also shows that instructor-led classes alongside the use of specially-designed, laser-specific personal protective equipment (PPE) have greatly reduced incidents of laser-related eye injuries. Data from a 2022 study shows that facilities with stricter safety protocols reduced overall workplace injuries by 25% in comparison to those without mandatory safety training. These results emphasize the need to appreciate and properly utilize technological advancements while upholding safety regulations to enhance workplace safety.

How Does Laser Cleaning Compare to Traditional Cleaning Methods in Terms of Safety?

Cleaning with lasers, whenever proper safety protocols are obeyed, is usually safer than traditional methods. This is because, unlike cleaning techniques that are abrasive and generate dust, laser cleaning is a contact-free process that has little waste. Also, the process is laser-based eliminates the chances of exposure to chemicals and pollutants, therefore making it cleaner and more green. But, working with lasers involves strict safety precautions, such as protection from injuries to the eyes or skin. Cleaning with rays of light is safer than traditional techniques, but still requires appropriate training and equipment.

Cost Efficiency of Laser Cleaning

The usefulness of laser cleaning technology economically has been evident in industries, especially with reduction in operational and maintenance costs, it is laser cleaning that is cost-effective. In contrast, traditional chemical cleaning techniques often incur multiple costs for purchase of chemical solutions and even for waste disposal. Furthermore, operational costs of cleaning laser systems in comparison to spending and abrasive techniques, are by up to 60% in five years.

Also, laser systems are very durable, often exceeding 50,000 hours of operation with proper servicing. This lifespan enhances ROI for businesses further. The decrease in operational downtime coupled with lowered servicing costs results in substantial financial savings. Laser cleaning becomes cost effective in addition to being environmentally helpful for sectors such as automotive, aerospace, and heritage restoration cleaning.

Evaluating Risks Involving Pulsed Laser Cleaning Versus Abrasive Techniques

Pulsed laser cleaning is well known for its accuracy as well as being environmentally friendly compared to traditional techniques. Unlike abrasive methods that generate secondary waste and create micro-scratches on the surface, laser cleaning is contactless and surface wear is minimal, making it perfect for fragile or high-value items. For instance, in aerospace applications, laser cleaning protects component integrity by removing contaminants without the risk of microfractures induced by abrasive techniques.

The latest industry research indicates that, compared to abrasive techniques, pulsed laser cleaning minimizes the generation of hazardous waste by almost 90%. Moreover, laser systems deliver uniform results at lower energy levels. For example, a standard pulsed laser system takes about 0.1 to 1 kW of power for each operation. In contrast, some abrasive techniques use much more energy as a result of routine servicing of the machinery and continual material feeding. This difference also emphasizes the economic advantage of laser cleaning over time.

Safety considerations of using pulsed lasers are also noted in the data. Through abrasive cleaning, for example, sandblasting creates noxious airborne particles and poses a long-term health risk, often related to the respiratory system. Laser cleaning avoids this risk because it contains no particulate waste; instead, it uses a light beam confined to a small area with low energy. With these benefits, pulsed laser cleaning stands out as an advantageous and innovative answer for numerous businesses.

Reference sources

- Hazard Analysis and Risk Assessment on Laser Cleaning Workstations1:

- Key Findings: This study identified hazards associated with laser cleaning workstations, emphasizing the importance of risk assessments and safety measures. It proposed technical and organizational solutions to minimize risks, such as proper equipment, protective gear, and training.

- Methodology: A five-step risk assessment method was used to evaluate occupational risks, focusing on laser cleaning of metal surfaces.

- Laser Cleaning for Historical Paper Preservation2:

- Key Findings: The study explored safe laser cleaning methods for historical documents, ensuring no damage to paper properties like reflectance, acidity, and fracture resistance. It highlighted optimal laser parameters for effective and safe cleaning.

- Methodology: Experiments were conducted using pulsed lasers with high-speed scanning to clean contaminants from paper while preserving its integrity.

- Femtosecond Laser Cleaning for Historic Monuments3:

- Key Findings: This research demonstrated the safety and effectiveness of femtosecond lasers in cleaning materials like stone and steel used in historic monuments. It showed that this method minimizes thermal damage and preserves substrate integrity.

- Methodology: Case studies included cleaning contaminants like biofilm and rust from various materials, with evaluations using microscopy and spectroscopy.

- Top Handheld Laser Cleaning Machine Manufacturer And Supplier In China

Frequently Asked Questions (FAQs)

Q: What are the key precautions when using a laser cleaning machine?

A: Working with a laser cleaning machine necessitates several important precautions: the use of relevant PPE like laser safety glasses tailored for the system’s wavelength; adequate ventilation for the removal of fumes produced during laser ablation; restricted access to the cleaning area; and adequate operator training. Every operator must know the emergency shutdowns as well as the organizational safety rules regarding lasers. In addition, special engineering safety features must be constructed such as interlocks and beam guard windows to prevent unintentional exposure. Keep in mind that various systems (hand-held laser cleaning systems, laser cleaning workstations or conveyor laser cleaning machines) may have different safety features that must be attended to.

Q: What are the primary advantages of laser cleaning over conventional techniques?

A: There is a broad range of benefits from laser cleaning when compared to traditional methods. Laser cleaning is non-contact and non-abrasive, thus avoiding mechanical damage to the substrate surface. The method is “green” as it does not require the use of any chemicals or solvents, meaning there is no environmentally dangerous waste disposal associated with laser cleaning. Compared to other methods, laser cleaning is remarkable for its accuracy and precision; cleaning can be done with selective contamination while preserving the base material. Cleaning with lasers can be done with a great level of control and custom settings tailored to different surfaces, achieving the desired outcome. Use of lasers in cleaning results in cost savings over time due to low consumption costs and waste management expenses. This method of cleaning is particularly useful for surfaces, as well as complicated shaped delicate parts. It can also be used for surface finishing prior to laser welding and other joining operations.

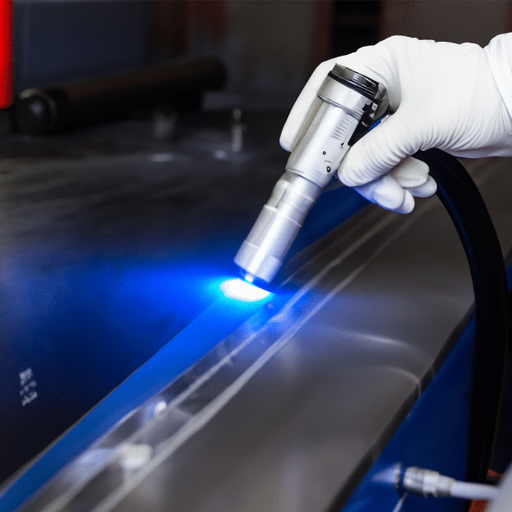

Q: What is the difference in safety considerations for handheld laser cleaning systems and fixed installations of laser cleaning systems?

A: Handheld cleaning lasers have distinct safety issues that fixed systems do not have. The use of hand-held lasers creates a larger possibility of inadvertent exposure because the aim of the beam is rotary. Hand-held operators must be fully trained and highly attuned to their surroundings. Additional safety measures such as dead-man controls and beam shutters should be integrated. Fixed installations incorporates class 1 laser safety enclosures that adequately contain laser radiation during use, which limits exposure risk and hazard significantly. Stationary systems usually have automated interlocks that disable the laser at the opening if the set enclosure is opened. All these systems abide by regulations but hand-held systems are more complex requiring more per last-minute equipment due to vulnerability to mistake. Fixed systems usually have stricter protective measures because of user error risk.

Q: What are the risks with laser cleaning and how can these be addressed?

A: The risks with laser cleaning include eye and skin injuries due to exposure to the beam or its reflections, the inhalation of hazardous particles generated during the laser ablation process, fire risks posed by heated materials, and electrical risks from the use of high-powered equipment. Appropriate engineering measures such as adequate beam enclosures and extraction systems should be implemented to eliminate these risks. Administratively, the organization should incorporate training sessions, SOPs, restricted access to laser areas, and well-defined organizational procedures. The PPE section should indicate adequate protective eyewear matched to the used laser wavelength. The operational servicing of the equipment, emergency measures, and adherence to applicable frameworks (ANSI Z136.1 for the US) are mandatory. Identifying the risks involved prior to starting any laser cleaning operations is important in addressing the issues concerning the materials being cleaned.

Q: How does a laser cleaning machine work for cleaning and texturing surfaces?

A: The focused laser cleaning machine blasts surfaces with high-powered light pulses to remove contaminants via a process called laser ablation. The energy from the laser will vaporize away contaminants like rust, paint, and oxide layers without damaging the underlying material. In order to achieve a textured surface, the laser settings are modified (such as power, pulse duration, frequency, and scan pattern) to control the surface characteristics on a microscopic level, which allows specific patterns or roughness to be made. These features enhance adhesive properties of coatings, wettability, and optical features. The beam is usually directed to scan over the workpiece while fume extraction systems capture remaining vapors during the laser cleaning. Modern fiber laser cleaning systems have precise measurements of power and other parameters to allow tailored surface treatments.

Q: What are the safety measures for handheld laser cleaning equipment?

A: Handheld laser cleaning equipment must be accompanied by proper protective gear. Laser safety glasses are the top priority. Protective clothing must also be flame-resistant, and must include full skin coverage. The appropriate gloves must protect the operator from laser radiation, heat, and must be easy to take off. Depending on the materials getting cleaned, the ablation process might produce toxic particles and gases; therefore, respiratory guard might be needed. Some high-power equipment might need hearing protection as well. All crew members must check each other for protective equipment every so often to prevent injuries. Lastly, not normal glasses must be worn because they do not help against laser attacks.

Q: How should facility layouts be designed to maximize laser cleaning safety?

A: When designing a facility to accommodate cleaning operations with lasers, the layout should also consider isolating the workspace with restricted access signage, as well as proper warning indicators. Protective measures include non-reflective matte walls to contain beam reflections as well as implementing class-1 laser enclosures configured with safety interlocks which deactivate the unit upon opened access or drawing the system out of zone. The unit requires proper baffled ventilation and fume cleanout to prevent buildup of hazardous particles from the cutting head. Emergency controls must be remote from the equipment but activate emergency cut-off immediately. The charge console must separate the operate area more than possible for the lasers themselves. For facilities that use handheld lasers, designate participant-permission zones marked with curtains and containment. Within reason make the handler comply with servowind access zones for maintenance hot of curl guides and compliance for sector mark installation safety having infrared set safety.

Q: What training is necessary prior to using the laser cleaning technology?

A: There are pre requisites every operator must complete in order to safely utilize laser cleaning technology, such as understanding the biological impacts of laser exposure, knowing the dangers that can arise during the cleaning process, and the advantages of using personal protective gear, among other things. Operators should complete practical training on the specific machines they will engage with, embracing tasks like transitioning the machine on and off, and emergency procedures from start to finish. The training should also cover the capability to modify laser parameters for varying materials, troubleshoot equipment failures, and carry out maintenence. In addition, operators should be versed in facility regulations and safety measures concerning national policies. Many locals necessitate an established Laser Safety Officer who supervises the work. To enhance safety best practice knowledge, refresher session interviews are scheduled.

Q: How does laser cleaning metal and non-metal surfaces differ in terms of safety measures?

A: Cleaning of different materials uses different safety measures mostly because of their reflectivity and potential hazardous emissions. For highly reflective metal surfaces, the risk of reflected laser beams poses a greater danger. This increases the need for additional beam blocks, enclosures, and more restrictive controlled areas. Moreover, cleaning metals will generate fumes that will require further ventilation. For non-metals such as plastics, rubber, or composites, the main issue is the potential release of toxic vapors during ablation along with stagnant filtered air requiring specialized filtration systems designed to remove these contaminants. Fire hazards are also a concern as non-metals usually absorb more laser energy than metals. While total safety will be needed for both material types, the extraction and filtration systems tailored for the contaminants need to be removed are central. Prior to any laser cleaning operations, material-related risk assessments are a necessity.

Q: What are the safety considerations while integrating laser cleaning with laser welding or any other processing?

A: While combining laser cleaning with laser welding or other techniques, specific important integrative safety issues must be considered. First of all, make sure that all systems are checked for common safety boundaries and control mechanisms. Combining different laser technologies can pose new risks, thus all systems must have compatible control measures. Integrated systems need adequate risk evaluation covering the whole process. Automated systems require coordinated safety mechanisms with interlocked emergency controls that disable all lasers simultaneously. Ventilation should be improved because integrated processes are likely to be accompanied by more advanced fumes and particulates. Teaching all integrated technologies, as well as instructor-learner hazards, is essential for operator training. Make provisions for safety zones with appropriate barriers between the different process areas. Where different laser wavelengths are employed, appropriate eye protective devices that block all present wavelengths must be supplied. Lastly, ensure maintained clear safety documentation within the integrated system and conduct ongoing audits during set intervals to confirm compliance with preset standards.