Marking lasers have changed the way industries think of detailing accuracy, careful structural work, and individualization. Choosing the proper marking laser method is crucial, whether you need to engrave lovely imagery, add vital identification marks, or even meet marking compliances. This blog will take you through the most common methods of laser marking: engraving, annealing, etching, and many more while explaining their advantages and features. Such knowledge will better equip you to identify the appropriate laser paradigm for calculating operations, optimizing efficiency, and achieving productive results. Prepare to unveil laser techniques and make educated decisions for your project or business!

What are the different types of laser marking technologies?

As previously mentioned, different laser marking technologies can be segmented into four principal classes.

- Laser Engraving—This method uses lasers to remove a certain depth of material to mark the object deeply and permanently. It provides the most durable and long-lasting marks on metals, plastics, wood, and other materials.

- Laser Etching – Etching is a faster method of marking than laser cutting. It involves melting the surface of the material to produce shallow grooves. It is suitable for metals, ceramics, and polymers.

- Laser Ablation is a method for uncovering a defined surface located beneath a coating or material layer, commonly employed in manufacturing and label production.

These vary according to the type of material, depth of marking, permanence, and other factors.

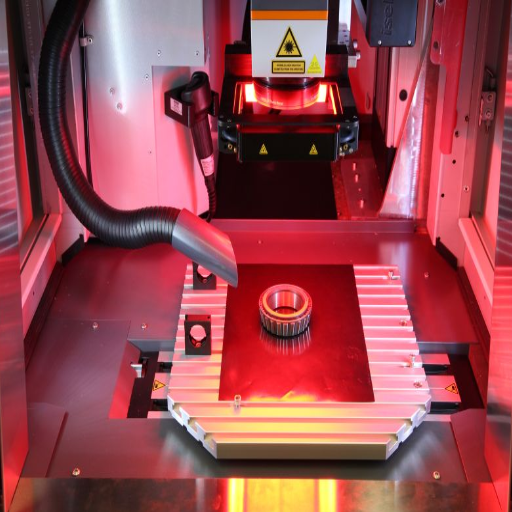

Understanding CO2 laser marking

CO2 laser marking is a marking technique applied to wood, glass, leather, paper, certain plastics, and other non-metallic materials. It involves using a CO2 gas-filled tube laser that concentrates an infrared beam to etch or engrave the surface of a material. Its versatility and precision make it suitable for industries such as manufacturing, packaging, and custom product design.

One of the key advantages of CO2 laser marking is efficiency. As with any application, there are limits to what can be done using CO2 lasers. Operating at a wavelength near 10.6 micrometers, CO2 lasers are well absorbed by many materials, leading to clear, permanent marks being made; for example, CO2 lasers can achieve marking speeds of upto 1,000 mm/s, which is beneficial in high-volume production environments.

CO2 lasering has a customizable output ranging from low to high power, which in the case of lasers would be 30W, 60W, and 100W. Such flexibility ensures that the littlest detailing and the deepest engraving requirements are covered. The marks are also highly durable as they resist wear, heat, and fading, crucial for long-term traceability and branding.

Systems for marking with CO2 lasers are economical. This is mainly because they require less maintenance than other marking technologies. Moreover, marking is done non-contact, significantly reducing tool abrasion and material damage. These advantages and the ability to perform detailed and complex engravings establish CO2 laser marking as a valuable technology applicable to numerous fields.

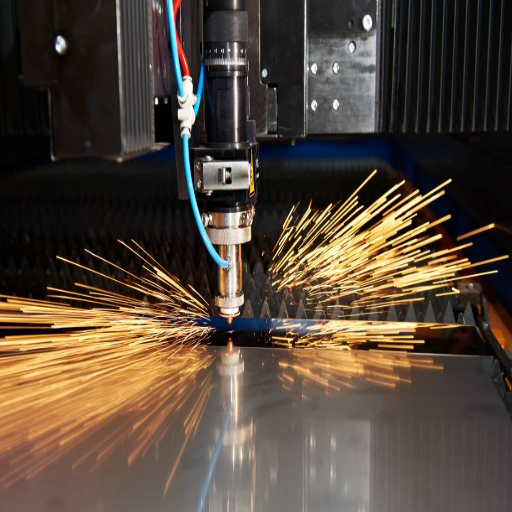

Exploring fiber laser marking

Fiber laser marking has surfaced with excellent efficiency and versatility as a modern solution for marking certain items with precision and accuracy across various materials. Fiber lasers use advanced laser technology as they generate power from high-intensity beams from optical fibers, which contain rare elements, providing upgraded marking capabilities.

Marking with fiber lasers comes with many perks, including astonishing speed. It enhances productivity in industries such as automotive, electronics, and aerospace, as it processes materials faster than traditional methods. Due to fiber lasers’ exceptional power of approximately 1.06 microns, they can render fine and high-contrast markings on metals, plastics, and ceramics with extreme accuracy.

In addition, fiber laser markers are energy-efficient and highly durable. They can work for up to 100,000 operating hours, which further reduces operational and environmental costs compared to CO2 lasers. Moreover, these systems boast excellent beam quality, which allows them to render intricate patterns, micro-level engravings, serial numbers, and barcodes with utmost ease.

Fiber laser marking is also versatile in applications. It is frequently used for engraving components in fast-paced industries, marking medical devices requiring permanent labeling, and meeting stringent regulatory traces. The non-contact process also offers exceptional quality by removing the possibility of mechanical stress or damage to the substrate.

The advancement of marking with a fiber laser shows proactive thinking about efficient, precise, and green material processing technologies, making it ideal for specialists looking for durable marking solutions.

What is UV laser marking, and what are its applications?

UV Laser marking, also known as Ultraviolet Marking, is one of the most efficient technologies used to engrave materials. It works with a UV laser of short wavelength, approximately 355 nm, which allows cold marking without the application of rough heat. As a result, sensitive materials are not damaged, which is a prerequisite in UV laser marking industries and primal in quality-controlled processes.

UV lasers work best with suitable materials like glass, ceramic, heat-sensitive plastics, and thin metals. UV laser marking is commonly used in medical devices, electronics, and pharmaceuticals to mark important identifiers like logos, serial numbers, and barcodes. With higher contrast and clarity, these marks improve the products’ check traceability and quality assurance.

Growth in the semiconductor increases the need for UV laser technology because it doesn’t cause micro-cracking while performing slotting and grinding. Besides this, ki marking makes it environmentally friendly because of its lower waste disposal and the absence of ink and solvent consumables. Moreover, such UV lasers require lower maintenance, outpacing other technologies providing high-speed marking services, which makes them suitable for modern industries and recent advancements in manufacturing.

How do you choose the right laser marking technology for your needs?

While deciding on the marking laser technologies to go for, always remember the following pointers:

- Compatibility – Ensure the technology is adequate for marking your materials, which include metals, plastics, glass, and ceramics. Specialized materials require specific lasers like fiber, CO2, or UV.

- Production and Speed—Marking for high-speed production or detailed design requires specific marking technologies. This guide provides tools to efficiently meet all production marking goals.

- Sharpness and Endurance—Examine the marking’s sharpness and precision for signs of fading. Select a marking solution that meets the required standards for your application.

- Protecting Mother Earth – If there is a goal to reduce waste and use of consumables, select UV lasers.

- Regions – Ensure all maintenance charges do not exceed the budget limit while fitting outside the areas.

With these pointers in mind, ensure you can choose a system tailored to your specific needs.

Factors to consider when selecting a laser marking machine

One of the most important aspects when purchasing a laser marking machine is ensuring it will perform optimally in every relevant area concerning efficiency, performance, and value. Here is a detailed list of the most important aspects:

- Laser Type

Different types of lasers may be needed for various applications. The most common include:

- Fiber Lasers CO2 Lasers UV Lasers

– Perfect for marking metals, plastics, and other hard materials.

– High precision and fast processing speeds.

– Used for organic materials like glass, wood, leather, and acrylic

– Versatile in non-metal marking.

– For sensitive materials such as glass and ceramics.

– Provides high contrast marks with a minimum risk of heat damage to delicate surfaces.

- Material Compatibility

Make sure that the materials with which the laser system will work are compatible. For example, CO2 lasers are good for non-metals such as paper, leather, and acrylic, while fiber lasers work best for metals like brass, stainless steel, and aluminum.

- Power Requirements

Having the correct power output for the laser’s marking speed and efficiency.

– Low-power (10-20 watts) laser systems are suitable for small and precise markings.

– Mid-range (20-50 watts): For versatility and speed.

– High power (above 50 watts): For deep engraving or fast throughput.

- Marking Speed and Throughput

Selective laser marking machines come in different configurations. Choose one that can mark rapidly if your operation calls for volume. The productivity of high-speed lasers is unrivaled, and the quality is uniformly maintained.

- Accuracy and Resolution

Laser marking machines are best suited for detailed work such as marking, engraving, or etching. Order high-res machines if you require precision, such as in electronics or medical devices for detailed designs, barcodes, and intricate patterns.

- Cooling Systems

Inquire if the system employs air or water cooling. Air-cooled systems are smaller and more efficient, while water-cooled systems can cool better than air for high-power lasers.

- Software Features and Integration

Find out if the machine has customizable software tools for creating barcodes, QR codes, and logos. Also, check if the software will integrate with your systems and workflows.

- Environmental Impact

Laser systems with low consumables and less energy usage are ideal for the eco-conscious buyer. UV lasers, for instance, are marketed as environmentally friendly because they operate with low material destruction and waste.

- Durability and Maintenance Requirements

Look for systems with long lifespan components combined to have minimal maintenance. For example, fiber lasers are believed to have long service lives and little maintenance needed compared to other technologies.

- Cost Efficiency

Choose solutions that strike the right balance between up-front expenditure and operating costs. Even though fiber lasers might cost more to acquire, their long life and minimal maintenance usually make them more economical in the long run.

- Safety Standards and Certifications

Ensure that the machine follows relevant safety standards, such as ISO 11553 or FDA registration in the USA, to ensure the operator’s safety.

By considering and analyzing the goals and use case before selecting a laser marking machine, it is possible to fully take advantage of its functionality while ensuring a worthwhile investment.

Comparing fiber laser and CO2 laser markers

I look at their advantages and applications for both Fiber and CO2 laser markers before making comparisons. For instance, the subdivisions of mechanics and electronics require detailed markings on various parts. Fiber lasers ‘ longer wavelength makes marking metals and some plastics easier. CO2 lasers do a better job with organic materials like wood, glass, and acrylic; non-metal projects offer greater versatility. For my purposes, the deciding factor is mainly the central material that needs markings done, making fiber lasers ideal for industrial applications. CO2 lasers are better suited for creative work done on organic materials.

What are the applications of laser engraving in various industries?

Laser engraving is used in various fields because it is both precise and versatile:

- Manufacturing and Electronics: Portioning industrial pieces and electronic devices requires engraving logos, serial numbers, and barcodes for branding and identification purposes.

- Jewelry and Fashion: Intricate designs and customizations, along with personalized engravings, are done on metals and leather fashions.

- Medical Industry: Engraved surgical tools and medical devices for traceability and compliance with regulatory standards are subjected to marking.

- Automotive Sector: Various tools and parts are subjected to engraving for tracking, quality control, and ensuring authenticity.

- Creative and Artisanal Work: Wood, glass, and acrylic art pieces, decor, and gifts are custom-made with detailed designs through laser engraving.

- Aerospace and Defense: Components that require harsh environmental customization undergo marking to ensure durability and resistance.

These examples demonstrate the creative and industrial applications of laser engraving.

Typical uses of laser marking in manufacturing

Laser marking is an inseparable part of modern manufacturing processes across different industries. It is mainly used for marking products and traceability, which includes tagging essential features such as serial number, barcode, QR code, batch number, etc., which are permanently inscribed on parts. This improves clarity across the supply chain and helps meet regulatory requirements in the automotive, aerospace, and medical devices industries.

Branding and labeling are other important uses of laser marking. They help mark logos, trademarks, and product information onto a surface without damaging the material. This creates a unique, high-standard, high-quality result that is scratch-resistant.

Consumer goods also have a variety of applications for laser marking for customization and personalization. Electronics, jewelry, and even packaging can be marked with very delicate designs to increase value and customer satisfaction. Recent market analysis shows that there is a growing desire for personalized goods, which propels advancement in laser marking technology.

In the medical and pharmaceutical industry, laser marking is used for marking UDI engravings on tools, implants, and their packaging. This helps ensure safety and better supervision throughout the device’s lifecycle. The accuracy of laser marking is essential for these industries because there are high standards for sanitation and safety.

Lastly, marking materials for durability and wear resistance is one of the key industrial requirements. Laser marking is performed on complex surfaces like plastics, metals, and ceramics, providing deep and long-lasting markings. This is particularly useful within strict manufacturing settings where marked parts are subjected to severe stress like heating, moistening, and rubbing.

The global economy is expected to develop in the next few years. This is due to the speed and accuracy of laser marking, as well as other environmentally friendly attributes. These features make it an indispensable technology in modern-day manufacturing processes. These functions underline laser marking as a vital component striving for precision and quality control in contemporary manufacturing systems.

Applications in medical devices and electronics

Applications in Medical Devices

Laser marking is now one of the most essential techniques in medicine because it can produce clear, detailed, and permanent markings on delicate machines and devices. Surgical instruments, medical tools, and implants must often include specific identification codes, serial numbers, or barcodes for traceability and compliance with pertinent legislative requirements such as the FDA’s UDI. Because of the elevated risk in medical surroundings, laser marking is preferred over other alternatives due to its non-contact nature, which reduces contamination risks. In addition, it can also mark devices made out of stainless steel, titanium, some ceramics, and specific polymers, further accentuating its relevance to the industry. The growth of the medical sector and changes in regulations also contribute to the anticipated growth of the laser marking industry for medical devices. Recent market analyses show that the medical device laser marking segment is set to grow substantially in the upcoming years.

Comprehending the Marking Applications in Electronics

Consider a scenario where you attended an event only to discover that it has already been marked as an ‘exclusive by the management’. Marked laser applications are proliferating, mainly in participated user life sectors such as IoT devices and wearables, helping wear devices via smartphone, tagging a wearable calculator with smart glasses, etc. Tools such as PCBs, integrated circuitry, and shut connectors are brutally fused. Markers scratched on costume goggles, registers, and marks customizing instructions. All tears require consideration marking that is renowned for ensuring compliance and themes. Manufacturing devices using laser clearer compasses and sturdotiated aging devices did not eliminate chances of color fading: crushing, chipping, or wear and marker blasting marks. Semiconductor Equipment and Technology noted the laser and marking electronics market is sharply growing due to rapidly blooming hobbies transforming ultra few electronic instrumentation signaling over last year as addiction related to virtual worlds, newer 5G, and PC before transforming their regular editor, visually creating graphs.

How is laser engraving used in art and design?

The introduction of lasers into engraving has increased the artistic and design opportunities available to artists within these domains. With lasers, a designer can engrave patterns, images, and custom illustrations on wood, glass, metal, leather, stone, and acrylic much faster, easier, and even more creatively than before. In recent years, the technology has become more popular due to its ability to create and engrave custom-made jewelry, artwork, and home decor items with laser precision.

On top of that, laser engraving allows individual creators and large companies to enjoy an efficient production process. According to recent studies, the global market for laser engraving will increase in the years to come due to greater consumer demand for personalized goods and advancements in laser technologies. For example, CO2 laser engravers are widely used for crafting intricate designs on organic materials, while fiber lasers are more popular for engraving robust materials like stainless steel.

Many professionals in the creative industries use CAD software to combine laser engraving with digital design, which gives them unmatched precision in translating digital ideas into physical items. Compared to traditional methods, designers using laser engraving technology can create prototypes and finalize products much faster and with less material waste. The integration of technology and craftsmanship means that laser engraving continues to be a core implement for modern creators, allowing them to redefine the limits of innovation in art and design.

What is the laser marking process, and how does it work?

Laser marking consists of using a focused beam of light to etch accurate, indelible marks on the surface of the material being worked on. The laser applies tto ext, logos, or patterns as markings onto the material’s surface without physically removing any outline by changing the material’s properties. This is achieved by aiming the laser beam at the material’s surface, and the energy supplied brings about changes like heating, discoloration, or oxidation. In laser marking, common types include annealing, etching, and engraving, which differ depending on the intended outcome. It is popular because of its precision, resistance to wear and tear, and adaptability to different materials, including metals, plastics, and glass.

The steps involved in the laser marking process

- Surface Treatment

Cleaning the target surface is a critical step in preparation for laser marking. It should be devoid of any form of contamination, such as dust, oil, or oxidation. Wiping or compressed air blasting is usually used to remove these contaminants. Proper cleaning improves the quality and accuracy of the laser marking.

- Choice of Materials and Machine Settings

Plastics, glasses, ceramics, and metals all require a specific type of laser to be used with their characterizing parameter settings. Fiber lasers, for example, are frequently employed in working with metals, while CO2 lasers are ideal for organic materials like wood and leather. Marking users must set parameters like laser power, frequency, and speed to the best suitable values for marking the material.

- Design Configuration

The design or text to be marked can be created in the corresponding software or uploaded directly. Users can manipulate the marking design and adjust it to the target surface by scaling, positioning, or customizing it. More advanced systems often employ preview styles that simulate the final outcome before commencing the marking process.

- Implant Module Laser Marking Procedure

After systems calibration and design file completion, the laser could be turned on for marking. A laser beam is guided through mirrors or using galvanometer scanners, which achieves high precision and speed. Depending upon the chosen marking technique, either annealing, etching, or engraving, surface modification due to heat, oxidation, or removal of material takes place.

- Calibration Process Inspection and Quality Inspection

Thorough inspections are conducted after the implant module is laser marked to guarantee that the marking has been completed to the required standard. Some of the criteria used for measuring this standard include clarity, depth, legibility, and overall specification compliance. Automated cameras and sensor systems have been found to offer efficiency and high levels of accuracy during inspections.

Post-processing work or steps are usually optional steps that perfect the marking. These steps range from cleaning engraving aids, debris removal, and the application of protective coatings to increase durability. Polishing is also done for engraved surfaces to smooth out rough edges that are sometimes left behind.

Laser marking has become a key pillar of many industries, such as automotive and electronics manufacturing and medical devices. Due to the unmatched precision of modern systems, laser marking can achieve speeds of over 7000mm/s. These systems have a longer lifespan due to being non-contact operated, which puts less wear and tear on the marking head.

How laser beams interact with materials

How a laser interacts with a material’s surface depends on the properties of the laser beam and the material itself. These properties may include wavelength, energy, pulse duration, and thermal properties. The most common interactions include absorption, reflection, and transmission.

Absorption enables cutting, engraving, or welding by exerting energy on the material, resulting in localized heating, melting, or vaporization. For example, metals remain highly reflective at specific wavelengths; however, the absorption of energy increases when treated with short or ultra-short laser pulses. Non-metallic materials, such as polymers and ceramics, often exhibit strong absorption at specific infrared or ultraviolet wavelengths, facilitating precise cutting, marking, or engraving.

Femtosecond lasers, for instance, can attain multidimensional accuracies of sub-micron levels owing to the absence of a heat disturbance area. This precise accuracy is critical in the medical field, where lasers are used to form microstructures on implants or surgical tools with tolerances of less than 10 microns.

Also, metals like aluminum or copper can create problems because of their strong reflectivity at visible and near-infrared wavelengths. Processing efficiency has dramatically improved with the development of laser technology, including using fiber lasers with higher beam quality and power density. Laser Industry reports state energy consumption with modern fiber lasers has increased to 45%, which makes them ideal for these applications.

The use of lasers for material interaction provides industries, from electronics to aerospace, with advanced options for precision processing that are at a whole new level of versatility and efficiency.

What are the common types of laser marking machines available?

Due to their speed, longevity, and flexibility, fiber laser marking machines are specialized for a variety of applications. They mark all classes of materials, such as metals, plastics, ceramics, and certain organic materials, with a highly focused fiber laser beam. The technology surpasses 100,000 hours of operation and requires significantly less maintenance than other systems.

The most crucial benefit of fiber laser marking machines is their unparalleled precision and speed. These machines perform at high speeds, with markings done at a staggering 7,000 mm/s, which is optimal for mass-production environments. Markings done on these machines are permanent, wear-resistant, and capable of intricate details such as barcodes and serial numbers.

These machines are widely used in aerospace, automotive, electronics, and medical manufacturing, where precision and clarity are critical. Other lasers, such as CO2 and green lasers, are less efficient, making fiber laser marking machines more energy efficient, operating at around 30%. Their lack of spare parts also allows them to be maintenance-free, further decreasing operational costs.

Innovations include the development of MOPA (Master Oscillator Power Amplifier) fiber lasers, which enhance control over pulse duration. This control makes it possible to mark colored patterns on stainless steel or create sharp marks on fragile materials. Advances like this are expanding the capabilities of fiber laser marking and meeting changing demands from different sectors.

Features of CO2 laser marking machines

CO2 laser marking machines are well-known for their effectiveness and versatility. They offer many features which help them perform better in different sectors. These machines employ a gas laser medium, mainly CO2, for gas-based lasers, which produces powerful laser beams that mark, engrave, and cut a variety of nonmetal items, including wood, glass, paper, plastics, and ceramics.

- Wide Wavelength Range

With 10.6-micrometer wavelength CO2 lasers, this kind of cutter interacts supremely with metallic or nonorganic material. This wavelength is perfect for minimal thermal distortion with precision deep cutting or marking.

- High-Speed Marking

CO2 laser machines possess galvo systems, which enable them to mark up to 7,000 millimeters a second. This makes them suitable for high-volume production lines without compromising on quality.

- Non-Contact Process

These processes cannot bend or stress materials, giving them repeatability while making sure that the delicate surfaces kept unharmed are preserved.

- Adjust Power Levels

These types of lasers are usually set with power levels between 10 and 200W for light etching on paper and deep engraving on wood and leather, making them suitable for a broader range of functions.

- High Precision and Fine Detailing

With enormous detail, CO2 laser marking machines offer spot sizes as small as 200 microns, providing intricate detailing or engraving fine text.

- Low Maintenance and Long Lifespan

Depending on the model and usage of the laser tube on modern CO2 lasers, designed to be durable and low-maintenance, it can last anywhere from 10,000 to 30,000 hours.

- Compatibility with Automation

Numerous machines are equipped with software that integrates smoothly into automated systems, making them ideal for large-scale industrial manufacturing environments.

- Eco-Friendly Operation

Because CO2 laser marking uses nonchemical means, hazardous materials are reduced during production, aiding sustainable manufacturing practices. Furthermore, waste production is minimal.

Considered to be ideal for the packaging, advertising, automotive, and consumer electronics sectors, CO2 laser marking machines are unparalleled in agility, precision, and speed, enabling them to exceed modern industrial demands with unmatched efficiency.

Reference Sources

-

Laser Marking Methods1:

- Focus: Systematization of various laser marking methods for different materials and shapes.

- Key Findings: The study highlights the importance of selecting specific laser marking methods based on material type, production needs, and geometry. It emphasizes the need for a database to streamline the selection process for manufacturers.

- Methodology: The research involved analyzing different laser marking techniques and their applications across various materials.

-

Laser Marking as an Environmental Technology2:

- Focus: Investigating laser marking as an eco-friendly alternative to traditional marking methods.

- Key Findings: Laser marking minimizes waste compared to conventional methods like painting or etching. The study explored how laser parameters (pulse frequency, energy, and speed) affect aluminum materials’ surface texture and color changes.

- Methodology: Experiments were conducted using the TruMark 6020 laser machine. Surface morphology was analyzed via scanning electron microscopy (SEM), and roughness was measured using standardized methods.

- Top Handheld Laser Marking Machine Manufacturer And Supplier In China

Frequently Asked Questions (FAQs)

Q: What types of laser machines are commonly used in marking and engraving?

A: The most common types of laser machines used in marking and engraving include CO2 laser technology, YAG laser, MOPA laser, fiber laser machines, and UV laser markers. Each type has its specific applications and advantages.

Q: What is the difference between a laser engraving machine and a laser marking system?

A: A laser engraving machine is designed explicitly for creating deep and permanent engravings, while a laser marking system is typically used for more superficial markings, such as logos or text, on various materials.

Q: How does a YAG laser differ from a MOPA laser in engraving applications?

A: YAG lasers are solid-state lasers often used for deeper engravings. MOPA lasers allow for more control over pulse duration, making them ideal for colorations and finer detail in marking and engraving.

Q: What are the advantages of laser marking and engraving over traditional methods?

A: Laser marking and engraving offer advantages such as precision, speed, versatility of materials, minimal equipment wear, and the ability to produce high-quality, permanent marks without the need for inks or other consumables.

Q: What is coloration laser marking, and where is it used?

A: Coloration laser marking is a process that uses specific laser parameters to change the color of a material’s surface without removing any material. This technique is commonly used in branding and decorative engraving on metals.

Q: Can you explain what annealing laser marking is?

A: Annealing laser marking involves heating the surface of a metal without burning it, creating a color change that results in a permanent mark. This method is especially suitable for marking metals like stainless steel and titanium.

Q: What materials are suitable for engraving with a laser engraving machine?

A: Laser marking and engraving can be used on a wide range of materials, including metals, plastics, wood, glass, and leather. The laser source and settings choice will depend on the material being processed.

Q: How do fiber laser machines compare to CO2 laser technology in engraving?

A: Fiber laser machines are generally better for marking and engraving metals and have a longer lifespan, while CO2 laser technology is more effective for non-metal materials like wood, acrylic, and glass.

Q: What should I consider when choosing a laser engraving machine for my business?

A: When choosing a laser engraving machine, consider factors such as the types of materials you will be working with, the desired speed and precision of the engravings, the machine’s power and flexibility, as well as the specific applications you plan to use it for.