The way industries tackle the identification, branding, and even traceability of their products has changed dramatically with the introduction of laser marking. Because of its precision, efficiency, and versatility, almost every field uses laser marking, from manufacturing to healthcare. But did you know there are countless laser marking techniques and not one size fits all? Every method is tailored to specific applications and materials, making them more advantageous than the others. Whether you want to add product durability, achieve brand compliance, or enhance brand image, knowing different types of laser marking helps you make informed decisions. This article highlights the crucial categories of laser marking, their distinct benefits, and how to select the correct category for their intended purpose. Get prepared to learn about the transformative power of laser marking.

What are the common types of laser marking?

There are four common types of laser marking widely used across industries:

- Laser engraving involves increasing the depth of a preexisting marking by adding or removing a material. It is best suited for extreme wear conditions.

- With Annealing, the surface of a metal is heated to change color without extracting any material.

- Unlike engraving, etching is a considerably more rapid process as it merely melts the surface.

- Foaming – This process is performed on plastics and generates bubble-like features on the material’s surface after heating it.

Every method assists with specific materials and use cases, aiding in tailoring solutions to fit your needs.

Understanding laser marking technology

The evolution of high-technology laser marking and engraving systems is in tune with the requirements of modern industries. Nowadays, laser systems are more sophisticated and enable marking various materials, including metals, plastics, ceramics, and even glass. These systems can work with great precision, speed, and efficiency, sometimes achieving a marking speed of hundreds or thousands of characters per second, depending on the material used and system setup.

Introducing fiber lasers is one of the most critical changes in recent years. Fiber lasers use CO2 lasers as their core, but the beam quality and operational life greatly surpass that of CO2 and thus prove to be a superior choice. Moreover, fiber lasers possess traits such as high energy efficiency and operation with almost no maintenance over extensive periods of mass production. Research indicates that fiber lasers defeat older systems in cost and energy consumption by up to 50%, making them environmentally friendly.

Intelligent control innovative software has optimized the entire laser marking process, saving time and increasing productivity. Additional functions like intelligent calibration, real-time monitoring, and AI-based error marking increase accuracy on multiple levels and capture optimal production flows. For instance, the new intelligent software allows data marking, such as unique serial numbering, dynamic QR code marking, and barcode marking.

The growth of laser marking technology in the medical and electronics sectors, where precision is essential, is noteworthy. For example, the electronics industry performs laser marking for silicone etching on fragile components, leaving behind lasting micro-scale identifiers. Medical device manufacturers use traceable laser markings because of stringent regulatory requirements like the FDA’s UDI guidelines.

The marks engraved with lasers demonstrate the ever-growing demand for precision, durability, sustainability, and environmental care. Continuous innovations strengthen and adapt this technology for current and future industrial requirements.

Overview of common types of laser marking techniques

Each material and application has an appropriate technique for laser marking. Here is a summary of its common types:

- Annealing Marking

Metals, specifically stainless steel, titanium, and alloys, are the most common substrates for annealing marking. This technique uses a laser beam to apply heat without removing material to oxidize the surface. The markings created are smooth to the touch, corrosion-resistant, and, to some extent, unremarkable. Due to its hygiene and durability, this process is exemplary for medical devices and tools.

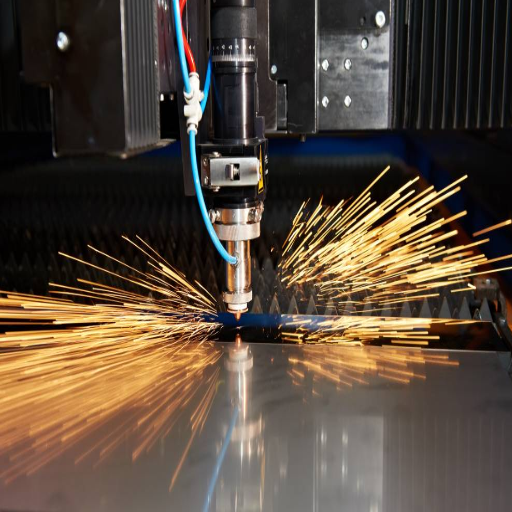

- Engraving

Engraving with a laser means removing some layers of a material’s surface to a certain depth to deepen and mark it. This is especially common for industries whose operations require engravings of high precision and extreme durability, like aerospace and automotive. For instance, laser engraving is widely used for serial numbers and barcodes because they can be read under extreme conditions. Specific CO2 and fiber lasers can engrave as deep as 0.5 mm, making this technique dependable for high-volume applications.

- Etching

Etching lasers are considered a subdivision of engravers. A laser etcher uses a laser beam to melt a given surface, resulting in markings that are moderately raised and smoother compared to engraving. This subset of engraving is more efficient than traditional engraving and can be used on various materials, such as metals, ceramics, and polymers. Clearness and clarity, as well as speed, are prioritized over depth.

- Carbonization

This marking methodology is generally applied to organic substances like wood, cloth, leather, or paper. Carbonization uses a laser to ‘burn’ the material to create high-contrast designs or text with an obvious cut outline. Its branding and decorative uses make it popular because of its unique effect.

- Foaming

This is a type of engraving that produces 3D raised marks on plastics. The change of the surface of the material caused by heating creates small bubbles, causing a lighter-colored mark. This is common in electronics and consumer products as it is not only easy to see but also attractive.

- Color Marking

This is a more advanced method of laser engraving that allows the creation of multicolor markings on metals such as titanium and stainless steel by changing the intensity of the laser. Luxury items like watches, jewelry, and prestige branding need this form of marketing.

Laser marking is experiencing rapid growth owing to its unmatched accuracy, green initiatives, and multi-aspect capabilities. Focus industries such as healthcare, electronics, and automotive manufacturing are expected to further propel growth, with the global laser marking market reaching $5.6 billion by 2028, according to a 2023 market analysis. This stunning growth–aided by advancements in fiber laser technology and sustainable practices–makes laser marking the solution of choice for quality control and traceability in many sectors.

Applications of laser marking in various industries

The innovation of laser marking technology has become increasingly important to various sectors because of its level of detail, speed, and convenience. Here are some particular use cases about different industries:

- Medical Treatment and Devices

The healthcare sector depends heavily on laser marking for accurate and indelible markings of medical instruments and devices. Guidelines like the UDI imposed by the FDA require adequate marking that is easily readable and traceable to ensure patient safety and compliance. Biocompatibility, resistance to sterilization, and even marking complex or small surfaces are some attributes that make laser marking ideal. Increasing instrument demand and better traceability will fuel future growth in the medical device laser processing market.

- Electronics Segment

Recently, laser marking technology has found use in virtually all areas of the electronics sector. With the shrinking sizes of electronic components, circuit boards, microchips, and electronic housings, precision laser marking is necessary. It guarantees the permanent marking of serial numbers, barcodes, and logos, which is critical for tracking products and eliminating counterfeit items. Thermally sensitive marking of delicate materials without heat damage has made fiber and UV laser technology popular in the electronics industry.

- Automotive Manufacturing

In the automotive industry, traceability of the sourcing and production of parts is a key requirement. Laser marking for notes and engraving on chassis, safety-critical elements, and engine components has reached significant strides in marking parts with logos, VINs, and QR codes. This practice reinforces quality control measures, maintains regulatory oversight, and assists in minimizing risks when necessary. The market data emphasizes the increased importance of laser marking devices as the automobile manufacturing industry integrates more rigid quality control policies.

- Aerospace Industry

Aerospace manufacturers apply laser marking technology for increased compliance and part traceability in critical applications. Turbine blades and other structural assemblies, which are marked with high durability codes, experience extreme environmental conditions like high temperatures and pressures. The high requirements needed in terms of precision and durability make laser marking highly necessary in the aerospace manufacturing industry.

- Consumer Goods

For marking logos, product details, and even decorative designs, laser marking has proven to be highly attractive for branding and personalizing goods in the consumer sector. The application of high-speed and precision laser technologies offers additional customization on various products ranging from everyday household appliances to high-end luxury goods while ensuring a professionally finished look.

- Food and Packaging Industry

The environmentally friendly process of laser marking can be used on all types of packaging, such as plastics, glasses, and cardboard. It offers an economical and efficient way of marking expiration dates, batch numbers, and barcodes because there is no direct contact with the packaging and zero ink waste.

Because of innovations and advancements tailor-made to specific industries, the versatility and usefulness of laser marking technology continue to grow across various fields where accuracy, robust markings, and identification details are required.

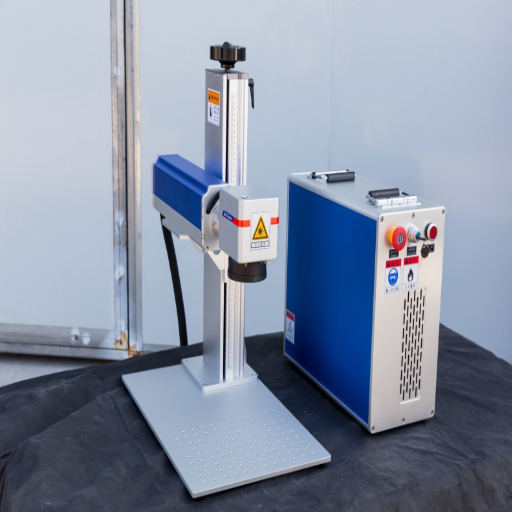

How do you choose the right laser marking machine?

While selecting a cnc laser marking machine, consider the following tips:

- The machine should be stopped for metals, glass, ceramic, or plastics.

- Also, consider the engraving accuracy, depth, and the required resolution.

- The machine’s marking speed must match your production capability.

- This is a very flexible budget estimate tailored around specific requirements.

- Unlike my emphasis on software, the dependability of machine aid is equally important.

- You are free to ask for further verification and assistance when and if you find trouble with mark precision and production for any reason.

Following instructions makes handling perplexing tasks simple, ensuring they are to specifications while optimizing machine control software.

Factors to consider when selecting a laser engraving machine

- Material Compatibility

Confirm that the machine can work with the materials you intend to engrave, including wood, glass, plastic, metal, and leather. Different engraving machines work best on specific materials, and versatility can be a crucial factor if your work involves multiple substrates.

- Power and Speed

When comparing machines for a versatile piece of equipment, pay attention to the options available in power (watts) and speed. In high-demand and/or heavy-duty tasks, faster and deeper engravings are essential, which are usually offered by high-wattage machines.

- Engraving Area (Workspace Size)

Pick a machine that best suits the size of the pieces you intend to engrave. For bigger pieces or batch processing, larger engraving areas would be more suitable, while smaller ones would accommodate intricate, detailed designs.

As with the rest of the machine parts, it’s also wise to consider the rest of the machine features; in this case, the rest of the machine tools are used alongside laser engraver machines.

- Resolution and Precision

The quality of engraving highly depends on the resolution of the machine, which is usually referred to as DPI (dots per inch). Higher resolution translates to increased precision for engravings with intricate and complex designs.

- Cooling System

Because laser engravers tend to generate heat, check whether they have efficient cooling systems, such as air—or water-cooled ones, that provide stable performance without the risk of overheating.

- Software Compatibility

Identify a machine that is easy to operate and runs on multiple types of software. It is essential that design applications like CorelDraw, Adobe Illustrator, or AutoCAD can be interfaced with and files can be operated on without issues.

- Connectivity Options

Thanks to modern additions of laser engravers that enable USB, Ethernet, or Wi-Fi functionalities, files can be uploaded, and devices can be controlled remotely.

- Durability and Build Quality

Consider the materials used to build the machine. Reliable and robust constructions tend to minimize vibrations during operation, improving precision and maintaining reliability over time.

- Cost of Maintenance

Research the availability and pricing of ancillary items like replacement parts and maintenance kits to determine whether the machine is cost-effective in the long run.

- Safety Features

Measures such as automatic shut-off, protective cages, and shield lasers should be used to protect users and the environment when operating laser-cutting tools.

- Budget and ROI

Calculate the return on investment (ROI) alongside your financial plan. It is prudent to ignore cheaper machines that offer a lower upfront cost to maximize performance and durability.

Through analysis of these factors, you can select a laser engraving machine style or feature that fulfills your technological and production requirements while simultaneously guaranteeing the utmost efficiency, dependability, and worth for your business or personal use.

Comparing types of laser marking machines

- CO2 Laser Marking Machines

CO2 laser marking machines are popular for non-metal materials like wood, acrylic, glass, leather, and plastics. They operate at a wavelength of 10.6 microns and are, therefore, efficient when engraving and cutting organic materials. Due to their versatility and affordability, CO2 systems remain a favorite across many sectors, including packaging, signage, and textiles. They have limitations compared to Fiber Laser Marking Machines, as they cannot mark metals unless specially coated. Typical CO2 lasers operated with power ranging from 10W to 150W depending on the precision, depth, and detail required.

- Fiber Laser Marking Machines

Fiber laser marking machines are optimized for marking metals and some plastics, operating at a wavelength of 1.06 microns. This allows marks such as barcodes, serial numbers, and logos commonly used in electronics, automotive, and medical devices to be etched in a detailed and durable manner. Fiber lasers are highly efficient with low maintenance and often feature longer lifespans of up to 100,000 operating hours. Their speed and precision also make them ideal for high-volume production environments. Depending on the material and application, power options usually range from 20W to 100W.

- Machines for Marking with UV Laser

The use of UV laser marking machines in ‘cold marking’ is indicated by a wavelength of 355 nanometers. In addition to reducing the risk of thermal damage (thermal stress), cold marking is ideal for delicate materials such as glass, certain ceramics, and specific types of plastics because it does not scratch, deform, or destroy the surface. These machines are often used in the electronics and medical device industries, where marks must have fine detail and high contrast. Additionally, ultraviolet lasers produce more minor beam spots, making the engraving more detailed and precise; however, these lasers are more expensive, unlike CO2 and fiber lasers.

- Machines for Marking with Green Laser

Like fiber lasers, green laser marking machines have a wavelength of 532 nanometers and fall in between UV and fiber lasers. As such, they are perfect for engraving gold, silver, and copper, which are highly reflective materials. The green laser tracer does not create significant heat-affected zones (HAZ), allowing these surfaces to be marked precisely. However, marking green laser machines are not widely used and are only valid for specific applications.

- Considering options of a laser engraver based on material

When choosing a laser engraver’s material options, I consider the project’s particular requirements. For metals such as gold or silver that have a high reflectiveness, green lasers are my choice due to their accuracy and low heat-affected zones. In contrast, wood and acrylic perform best with CO2 lasers. I use fiber lasers for my metalwork because of their speed and engraving depth efficiency. By matching the material with the correct laser type, I achieve accurate results that are reliable and of high quality.

What are the different types of laser engravers available?

These three categories can be used to classify laser engravers:

- CO2 Laser Engraving Machines

They are multifunctional and extensively used for engraving non-metal items such as wood, acrylic, glass, cloth, and fabric. They suit a broad spectrum of applications, including crafting and engraving signs.

- Fiber Laser Engravers

The most effective for engraving metals, including stainless steel, aluminum, and gold. Engravers of this type are highly productive and engraved profoundly and accurately.

- Diode Laser Engravers

These features are affordable and compact in design and increase their popularity among novice engravers. They perform exceptionally well with wood, plastic, and leather materials.

Introduction to fiber laser engravers

Fiber lasers are perfect for marking, engraving, and etching metals such as stainless steel, aluminum, brass, and even gold and silver due to their capability to emit lasers at around 1.064 micrometers wavelength. This tool uses a powerfully reliable laser beam to enable high precision and efficient engraving, specifically on metals.

Fiber laser engravers are well regarded for being reliable tools that can run for over 100,000 hours with minimal maintenance. They achieve unparalleled precision marking as fine as 0.001 inches while boasting engraving speeds up to 7,000 millimeters per second. The modern technology consumes significantly less electricity than other laser types, increasing efficiency.

The automotive, electronics, medical device, and jewelry sectors utilize fiber laser engravers. These devices are also environmentally friendly because they do not need inks or chemical additives, which lowers overall operational costs. Thanks to advancements in software and technology, integrating digital design instruments into fiber lasers has increased customization and detailing capabilities.

Understanding the CO2 laser engraver

CO2 laser engravers are highly flexible devices that employ gas as the laser medium. They work by blasting a ring of infrared light that can finely cut, engrave, or mark a diverse list of materials such as wood, paper, leather, and acrylic. Additionally, they can be used on nonmetallic materials, including glass and ceramics. CO2 lasers are very popular in non-metal applications because of their efficiency, primarily in sign-making, packaging, and arts and crafts.

CO2 laser engravers can have broad power outputs ranging from 30 to 150 watts and high engraving speeds depending on the material and design complexity. For example, a 60-watt CO2 laser can engrave acrylic at speeds up to 500 mm/s, which is ideal for commercial use. Surgeons have increased precision to allow engravings with an astonishing DPI of over 1000.

Furthermore, CO2 laser engravers stand out to individuals and businesses alike as being more economically friendly than other lasers like fiber lasers. Small companies and hobbyists eager to personalize items or carve beautiful designs readily have CO2 lasers within reach. Moreover, modern CO2 laser machines incorporate safety features that guarantee the user’s protection and compliance with industry standards and modern software interfaces that promote ease of use.

The disadvantages of CO2 lasers include lesser efficacy when dealing with uncoated metals, unprepared substrates, and engines without proper pre-treatment. However, specific CO2 lasers with proper attachments can engrave metal surfaces, broadening their applicable markets. To summarize, engravers and cutters of all kinds will find CO2 laser engravers suitable for their various projects.

Exploring UV laser marking technology

Typically, UV laser marking is performed using UV light with a very short wavelength (like 355nm), which usually allows for very controlled and precise marking. Unlike traditional laser systems that use heat to process materials, UV lasers use a “cold marking” technique. This technique is useful because it reduces thermal stress for lasers that need to be used on plastic and glass components like rigid medical components.

One key advantage of a UV laser is its ultra-fine beam, which can create deep etching and engraving with high contrast at the micron level while preserving the material surrounding the engraving, meaning no damage is done to it. This opens the doors for a number of economic sectors, including aerospace electronics and medical device manufacturing, that rely on precision customization. For instance, circuit boards are commonly marked with UV lasers because they do not compromise the board’s structural integrity.

UV lasers are very stable and legible on challenging materials like ceramics and silicon, which other laser types usually struggle with. Furthermore, earlier models had high operating costs, but newer versions have improved energy efficiency and operational lifespan, reducing costs.

Statistical insights highlight that UV laser systems possess a three times smaller wavelength than fiber lasers, resulting in an almost 50% increase in precision for intricate designs. Moreover, the photochemical reaction employed in UV marking improves contrast to achieve better readability under different lighting conditions. These features have made UV laser systems a go-to solution for industries needing non-invasive and permanent markings.

In summary, UV laser marking technology’s distinguishing aspect lies in the precision of the results produced on delicate and difficult materials while upholding the demands of modern industrial applications.

What is the laser marking process?

The laser marking begins with directing a highly focused beam of light to engrave or mark a material’s surface. Marking a material, particularly a given substrate, does not necessitate contact with it because it can be done using a laser, which will engrave deeply accepted marks. The technology is stable, which makes it possible to create designs of letters and patterns. Each material and industry may employ a different method: engraving, discoloration, or surface annealing. Laser marking technology is more straightforward, accurate, and better at maintaining the material’s properties than other approaches.

Step-by-step breakdown of the marking process

- Steps for Preparing the Material

Before performing deep cleaning, the material being worked on is inspected to ensure there are no leftover particles of dust, oil, or unwanted residue that may affect the laser’s operation. The material must also be aligned precisely and may be kept in place using support fixtures.

- Set-Up of Laser System

Depending on the material’s features and expected outcome, the type of laser (fiber, CO2, UV) used, as well as the power, speed, focus, and frequency settings, need to be adjusted. For example, metals are commonly cut using fiber lasers since they are exact and efficient. Configuring the laser parameters properly prevents up to 30 percent of energy waste.

- Etching, Engraving, or marking

Various techniques are used based on the application at hand, and in this case, the laser beam is focused on the surface of the material once the system is ready. The following will require working and, at the same time, removing portions of material:

– Creating deep engravings, also known as deep and permanent marks

Surface layer alterations known as discoloration can also occur by altering the color of the material,which is most effective when working with stainless steel.

– Producing oxidation marks known as annealing, which is often the case with medical devices as they maintain the smoothness of the surface.

- Marking Quality Control and Inspection

After marking, the material is checked for clarity and correctness. Most modern systems include a camera or scanner that can achieve up to 0.001-inch accuracy, including precision error checking on serial numbers, barcodes, and other designs.

- Final Steps

If these coatings enhance the marking’s appearance and increase its durability, cleaning or protective coating application is required. Research shows that post-processing can increase the longevity of markings by up to 50%, particularly in industrial settings.

With these systematic approaches, laser marking attains unmatched accuracy, consistency, and effectiveness across multiple sectors.

Key elements of the laser marking system

- Laser Source

The **laser source** is arguably the most essential part of a laser marking system since it generates the laser beams that engrave or mark the surface of a material. The most common types include Fiber Lasers, CO2 Lasers, and UV Lasers. For instance, fiber lasers are very efficient and tend to last over 100,000 hours of use. The laser source selection is based on the type of material and marking requirements to achieve maximum precision and speed.

- Optical Delivery System

This system transports the beam from the source to the surface at which work will be performed. Mirrors, lenses, and beam expanders are all parts of this system that focus and control the laser path. High-speed scanning galvanometers are commonplace in advanced systems, allowing marking speeds of 7,000 mm/s.

- Control Software

As with any CNC machine, the control software is the central point of interaction used to configure laser power, design templates, and marking parameters. More sophisticated software can perform complex designs, operate batch processes, and change configurations on the go. Some systems allow the integration of artificial intelligence to improve output quality and consistency.

- Marking Field or Workspace

The marking field defines the area within which the marking laser operates. The size of this field is determined by the geometry of the lens used, which differs for systems designed for lower precision, such as industrial systems, and for high-focus precision marking areas. For example, marking fields of up to 300 x 300 mm can be achieved with excellent detail using long focal lenses.

- Cooling System

Effective cooling systems are incorporated to avoid disruption of operations, especially during high-power operations. Critical components are protected from overheating, extending their operational life due to the air and water-cooled systems. In production environments, high-end cooling technologies have reduced heat-related downtime by an estimated 20%.

- Power Supply

As noted before, the power supply provides the stable and reliable energy required by the laser source and the other components in the system. These modern power systems have been built with economy of power in their design, which reduces system power consumption by 30% compared to older models.

Modern laser systems use these essential components to achieve remarkable durability and precision while augmenting the work output encompassing the automotive, aerospace, medical, and electronics sectors.

Common challenges in the laser marking process

While there is progress in laser marking technology, inefficiency, and quality issues still exist. One of the significant challenges is material relations with laser devices. Different metals, plastics, ceramics, composites, etc., respond to laser wavelengths and intensity differently, which leads to poor marking quality or low contrast. For example, strong marks on aluminum, a highly reflective material, need specialized wavelength settings and modulation precision.

Another high-precision requirement problem is working at higher speeds. With high-speed laser marking, overheating, distorted marks, or even substrate damage can occur. Industry research claims that poor heat management in systems that rely heavily on high-speed marking solutions can lead to as much as fifteen percent defect rates.

System maintenance and calibration pose problems as well. Over long periods, lens alignment, laser diodes, and beam-delivering systems can deteriorate or drift, causing subpar performance. Because of the miscalibration, efficiency loss can reach twenty percent, which is highly detrimental to production deadlines and budgets. Therefore, proper monitoring and frequent maintenance are required to ensure systems continue performing consistently.

Lastly, dust, vibration, and temperature changes can affect the accuracy of laser markers. For example, dust in industrial environments can degrade the quality of the laser beam, diminishing the overall accuracy of laser marking. To meet such challenges, modern laser systems utilize more protective casings and more sophisticated filtration systems.

What are the applications of laser engraving?

The versatility and precision of laser engraving give it a wide variety of applications in multiple industries. Its typical applications include making permanent engravings for branding, identification, and traceability in manufacturing and electronics. It is also popular for engraving customized jewelry, awards, and promotional items. Furthermore, laser engraving is essential for making detailed industrial artwork, components, and signage. This technology is increasingly popular because it can engrave or cut various materials like metals, plastics, glass, and wood, essential for industrial and artistic works.

Industrial applications of laser marking

Having a cross-industry impact, laser marking provides an affordable and permanent method of identifying components. Product identification and traceability are areas that benefit greatly from this technology. Parts used in the automotive and aerospace industries have high-quality serial numbers, barcodes, and QR codes engraved. This helps manage the stringent requirements of the industries and improves the supply chain’s efficiency.

Another industry in which laser marking assists is the medical field. Surgical tools and medical devices need to be marked with the patient’s details for identification purposes, and this technology assists in that. The marks for identifying the patients are made from materials that can withstand sterilization, so they are safe, and these marks meet the FDA guidelines for safety. Moreover, the ability to engrave on stainless steel and titanium dramatically increases the durability of these components.

The electronics industry also benefits from laser marking. Various electronic components including the printed circuit boards (PCBs) need to be marked non-destructively and with a high degree of accuracy. This granularity is possible with laser marking, which is not harmful to the most minor parts of the printed circuit. This greatly helps in quality control and makes it easy to repair or replace parts during the product’s life cycle.

Data from laser marking system manufacturers suggests that the value of the global laser marking market reached approximately $2.8 billion in 2022. It is expected to grow at a compound annual growth rate of 8% from 2023 to 2030. The growth in laser marking systems is mainly driven by the rising adoption of traceable products and harsh regulatory requirements for several industries. Furthermore, progress in fiber, CO2, and UV lasers continues to mark an expansion in the material and industrial sectors benefiting from laser marking.

Laser marking is versatile, precise, and compliant with industrial requirements, making it an essential tool in modern manufacturing and logistics frameworks.

Personalized products and laser engraving

Owing to laser engraving technology, individuals and businesses can create customized and refined products with unmatched accuracy. The technology can be used to engrave wood, glass, metal, leather, and acrylic, making it useful for many industries. In 2023, the market for personalized gifts is expected to grow by 8.4% annually until 2030. Growth is fueled by new technology like laser engraving and increases in consumer spending and demand for customized gifts.

Such gifts include engraved jewelry, commemorative plaques, and bespoke phone cases. Precision, high speed, and accuracy ensure that fine details, logos, and even intricate designs are reproduced exactly as they are on the original. Thanks to the accuracy of laser systems, businesses can cut down on operational expenses and production waste. The growing personalization trend is best achieved using laser engraving, showing the device’s growing market potential and the ability to merge technology and creativity.

Reference Sources

-

Laser Marking Methods1:

- Focus: Systematization of laser marking methods for various materials and shapes.

- Key Findings: Different materials require specific laser marking techniques based on their properties and production needs. The study emphasizes the importance of a database for laser parameters to meet diverse customer requirements.

- Methodology: Analysis of laser marking methods and their applications across industries, highlighting the adaptability of laser systems.

-

Laser Marking as Environment Technology2:

- Focus: Environmental benefits of laser marking compared to traditional methods.

- Key Findings: Laser marking minimizes waste, eliminates the need for consumables like paints, and reduces energy consumption. The study also explored how laser parameters (pulse frequency, energy, and speed) affect aluminum’s surface texture and color changes.

- Methodology: Experimental analysis using a TruMark 6020 laser system, with surface characterization via scanning electron microscopy (SEM) and roughness evaluation.

-

Aesthetic Laser Marking Assessment3:

- Focus: Evaluating the aesthetic quality of laser markings on various materials.

- Key Findings: The study used the CIE color difference formula to assess color changes on anodized aluminum, stainless steel, and plastics under different illumination conditions. Marking speed significantly influenced color contrast and aesthetic quality.

- Methodology: Spectrophotometric analysis of marked surfaces, comparing materials and lighting conditions.

- Top Co2 Laser Marking Machine Manufacturer And Supplier In China

Frequently Asked Questions (FAQs)

Q: What are the different types of laser marking technologies available?

A: Different laser marking technologies include fiber laser markers, CO2 laser markers, and UV laser markers. Each type is suitable for marking various materials and applications, such as metal marking or marking plastics.

Q: How do I choose the right laser marking technology for my project?

A: To choose the right laser marking technology, consider the type of material you will be working with, the desired marking method, and the specific requirements of your project. Understanding the advantages of laser marking can help you make a decision.

Q: What are the advantages of laser marking over other marking methods?

A: Laser marking’s advantages include high precision, permanence of marks, minimal material damage, and the ability to mark a wide range of materials. Laser marking is a non-contact process that reduces wear and tear on tools.

Q: Can you explain what carbon migration laser marking is?

A: Carbon migration laser marking is a specific marking method used primarily on metals. A laser induces changes in the material’s surface, resulting in a dark mark due to the migration of carbon. This method is ideal for creating durable and visible marks.

Q: What is coloration laser marking, and how does it work?

A: Coloration laser marking is achieved by using a laser to create different colors on the material’s surface through controlled heating. This method is typically used on metals and plastics to produce visually appealing designs without altering the material’s surface integrity.

Q: What types of laser engraving machines are available for various applications?

A: There are several laser engraving machines, including fiber laser machines, CO2 laser machines, and solid-state lasers. Each type is optimized for different applications, such as engraving on wood, glass, metal, or plastics.

Q: What is the role of annealing laser marking in industrial applications?

A: Annealing laser marking is a process that uses laser energy to create a color change or mark on metal surfaces without removing material. This method is often used in industrial applications because it produces high-contrast, durable marks while preserving the integrity of the material.

Q: How does the type of material affect the choice of laser marking machine?

A: The type of material significantly affects the choice of laser marking machine. For example, fiber laser machines are ideal for marking metals, while CO2 laser markers are more suitable for organic materials like wood and acrylic. Understanding the material properties is essential to select the best laser marking solution.

Q: What should I consider when looking for the best laser marking solution for my business?

A: When looking for the best laser marking solution, consider factors such as the types of materials you will be marking, the required marking speed, the size and complexity of the marks, and your budget. Additionally, researching the different types of laser machines available can help you make an informed decision.