Grasping the importance of melting points throughout the various phases of any soldering project is key to achieving a reliable finish. A seasoned electronics expert or a DIY hobbyist are bound to face some challenges while picking out the appropriate solder. Soldering is not a straightforward task since there are numerous variations of solder; all having a melting point along with other unique characteristics. This guide has everything you need for a productive project by covering factors influencing the decision, optimal output with specific parameters, and the reasons behind solder’s melting point. Keep this information in mind to discover the best tips and unwavering advice from professionals to boost your soldering skills.

What Is the solder Melting Point?

The temperature at which a solder’s solid turns into liquid is known as the solder melting point, and at this temperature, a solder can securely fuse between two materials. As an example of common solder types, lead-based solders melt at roughly 361°F (183°C). For environmental or health concerns, solders with no lead are preferred, but they tend to have a slightly higher melting point between 428-446°F (220-230°C). A solder’s composition will determine its exact melting point, so checking the material specifications is crucial.

Understanding the Melting Point of Solder

For electronics and plumbing, understanding the melting point of solder is critical, as it dictates with what strength the solder will bond the materials. Generally, solders come in two types: lead-based and lead-free, each with a defined range of melting points based on their composition. More recently, lead-based solder, which historically consisted of a blend of tin (Sn) and lead (Pb), is noted to have a melting point of about 361°F (183°C) which is quite low. This solder type is user friendly and reliable.

Due to legislative and regulatory measures, especially in adherence to the Restriction of Hazardous Substances (RoHS) Directive, health, and environmental concerns have made lead-free solders a common substitute. Tin and its compounds with silver (Ag) or copper (Cu) are used in modern lead-free solders. This increases their melting point to 428–446°F (220–230°C). A typical lead-free solder alloy with 96.5% tin, 3% silver, and 0.5% copper (Sn96.5/Ag3.0/Cu0.5) has a melting point of 419°F (215°C).

There are also specialized solders for specific purposes, like high or low temperature solders. Temperature sensitive components can benefit from low-temperature bismuth (Bi) based solders with melting points of 275°F (135°C). These can also be used in extreme situations like aerospace applications, high-temperature solders, which have significant quantities of gold (Au), can exceed 650°F (343°C).

Choosing the most suitable solder for a specific task requires understanding the task’s requirements, as well as the precise melting point of the solder. Always check the manufacturer’s datasheet for specific information and requirements for your application to guarantee optimal performance.

Factors Affecting the Melting Temperature

- Alloy Composition: The melting temperature range of certain solders is influenced by certain metal combinations such as tin-doctor Pb (Sn-Pb) alloys or lead-free alternatives like Sn-Ag-Cu solder.

- Presence of Impurities: Performance can be affected by residues within the solder which can change the melting point thus introducing contamination.

- Application Environment: Some conditions may require certain materials that operate under higher temperatures such as those in aerospace or automotive sectors.

- Type of Solder: Lower temperature suited materials, also known as Soft solders, are opposed to higher temperature welded materials termed hard solders or brazing materials.

How alloy composition Influences solder melting

Solder alloyed with metals has a certain range of melting temperature. Combination of metals results in the solder having a melting range based on the specific components. For instance, tin-lead solders, in general, reached a specific temperature prior to melting the same with silver or copper increases the melting temperature. The alloy composition besides influencing the average resource provides gives during heating influences how the solder reacts with temperature changes. Solder selection requires understanding the need of the application rather equilibria for better match requirements.

How to Melt Solder Properly?

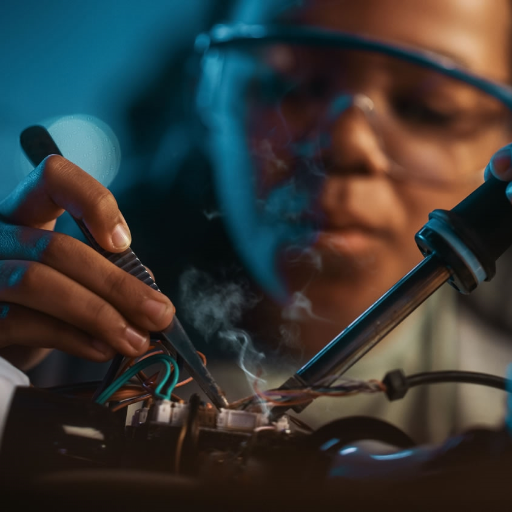

In order to melt solder accurately, you must have a soldering iron that is equipped with the right kind of solder for your work. Make sure the tip is cleaned before starting the work. Clear the surfaces that are to be joined so that the parts will stick well. Heat the joint by bringing the soldering iron over it, then bring the solder (not the soldering iron) into contact with the joint. Allow sufficient time for the solder to melt and cover the joint completely. After this, take the soldering iron off and allow the joint to cool on its own. Work in well lit spaces and follow safety protocols.

Getting the Best Out of the Soldering Iron

Optimal results can be achieved using a soldering iron if the tool is maintained clean and heated properly. The proper solder and appropriate tip should also be used. Ensure that all joints are soldered accurately without overheating by heating them uniformly before introducing solder. Maintain focus and calm to avoid uneven results. Always put the soldering iron back to its proper place after using it to prevent parts from being oxidized. Clean the tip actively to maintain proper output.

The Importance Of Flux In Soldering

Flux helps with cleaning and preparing for joining, demonstrating its importance in the soldering process. Flux helps with better adhesion between components as it removes impurities and oxides from the surface. Recent industry data suggests that proper utilization of flux can enhance joint reliability an estimated 30%, therefore reducing the risk of connection failures. While dealing with sensitive electronic parts, flux is important as it helps counter minimal oxidation during the heating phase. There are various types of flux like rosin-based, water-soluble, and no-clean flux, each designed for their specific purpose. Having the right type of flux will not only enhance the quality of solder joints but also improve the whole soldering process.

Achieving Strong Solder Joint Tips

Have clean and unblemished surfaces to achieve a strong solder joint. Ensure to have the right type of soldering flux to allow the joints to form properly without oxidation. Uniform heat should be applied to the joint so that it is allowed to flow and set a firm bond with the surface. While solder is cooling, refrain from adjusting position for parts to retain structural integrity. Proper methods along with adequate preparation are fundamental to enduring reliable and robust solder joints.

Exploring Different Types of Solder

- Lead-Based Solder: Contains tin and lead in a 60/40 ratio. Although easy to use and reliable, it is being deprecated due to health and environmental issues.

- Lead-Free Solder: With no lead in it, this solder is made of tin, silver and copper. Because of its environmental friendliness, it is now popular in modern electronics.

- Flux-Core Solder: By having a flux core within the solder wire, it preps the joint for soldering, thus improving the bond.

- Silver Solder: Has high strength and high conductivity joints due to silver content, which makes it ideal for specialized uses in jewelry or high-end electronics.

Characteristics of lead-free solder

Like other leaded solders, there is no intention of using leaded solder to replace leaded solders. At the same time, there’s no question leaded solder was used to eliminate lead from the circuit boards. Lead solder tends to be stronger than leaded versions as solder alloys do contain some tin, along with silver for added strength and soldering capabilities.

Advantages of Eutectic Solder

Eutectic solder is best known for a number of applications, because of its sharp melting point and consistent performance. The word “eutectic” specifies an alloy mixture, usually 63% tin and 37% lead (Sn63Pb37), which melts and solidifies at a temperature of 183°C (361°F). This behavior is particularly useful in sensitive electronics and surface-mount technology (SMT) because the melting is done in a very careful manner.

Eutectic solders tend to have better wettability as compared to non-eutectic solders, thus reducing the chances of voids or brittle connections to form. Eutectic solder is still instrumental in various industries such as aerospace and medical-grade electronics, owing to strict operating conditions. While environmental policies such as the RoHS directive have furthered the restriction on the use of lead solder in consumer electronics, leaded eutectic solder is still widely accepted for use in specialized and safety-critical applications due to its reliable performance. It is also noted among experts in the field that its low failure rate in thermal cycling tests (averaging <5% over 1000 cycles) makes it a preferred choice in extreme conditions.

To modern lead-free options, innovations are being made to use combinations like tin-silver-copper (SAC) alloys which provide eutectic-like properties. These tend to have a higher working temperature along with higher production prices.

When to Apply High-Temperature Solder

High-temperature solder is important in areas where the components face severe attack, especially with regard to high temperatures, physical strain, or harsh chemical environments. This solder is extensively applied in aerospace, automotive and electronics manufacturing industries that need long-term reliability and durability.

Recent work emphasizes the effectiveness of high-temperature solders such as those made from lead containing high lead alloys and lead-free substitutes like tin-antimony compounds. These solders perform well above 300°C. An example is high-lead solders which are Pb-90Sn that has a melting range of 275°C to 310°C. On the contrary, high stress thermal applications SAC305, a lead free option performed between 217°C and 250°C, does also need some tuning of the reflow temperature for consistent strength.

In addition, recent research has aimed to increase the thermal fatigue resistance of lead-free solders. Industry research suggests that microalloying with bismuth, for example, can increase the reliability of joints by as much as 30% during thermal cycling. This increase mitigates the problem of escalating manufacturing costs by offering enhanced durability and sustainability, and efficiency at lower supply costs.

In trans-temporal power systems, higher concentrated power electronics are specialized in slow heat dissipation resistance customer application. A subcategory of those are automotive under hood appliances, where hot exposure of above 200°C for long durations is routine. In these extreme environments, right materials can maximize assembly lifespan and ensure structural safety.

How to Choose the Right Solder for Your Project?

- Operating Temperature: As with any solder, make sure it withstands the temperature extremes of your particular application. Automotive and power electronics require specialized formulations of solder with higher working temperatures.

- Material Compatibility: Corrosion protection and adequate bonding depend on the joining materials; therefore, use appropriate solder alloy which matches composition of materials being joined.

- Strength and Longevity: For the application, there needs to be enough mechanical strength and solder joint durability with time.

- Application Type: Make a decision whether the solder needed is for electrical, mechanical, or high heat applications, and select one accordingly.

Understanding Solder Types and Their Uses

Solder types include lead-based, lead-free, flux-core, silver-bearing, and high-temperature variants.

| Type | Key Material | Use Case | Strength | Heat Level |

|---|---|---|---|---|

| Lead-based | Lead-tin | General electronics | Moderate | Low |

| Lead-free | Tin-copper | Eco-friendly uses | High | Moderate |

| Flux-core | Tin-lead + flux | Simplified soldering | Moderate | Low |

| Silver-bearing | Tin-silver | Precision connections | High | Moderate |

| High-temp | Tin-antimony | High-heat environments | Very high | High |

Determining An Alloy’s Composition For Specific Requirements

- Application Type: Select a lead-free solder for health-conscious applications and flux-core solder for convenience in electrical and plumbing work.

- Melting Point: Use a solder alloy with a melting point that fits the temperature limits of your components.

- Strength Requirements: Use alloyed silver or copper if you need stronger solder joints with enhanced durability.

- Compatibility: Corrosion or weak electrical connections can be avoided by selecting an alloy that matches the materials being joined.

Taking Use into Account with Melting Range

The range of possible temperatures for a solder alloy to melt is always critical for the ease of application as well as the strength of the joint. Common solder alloys, such as 60/40 (tin/lead), have a melting range around 183-190°C. This works well for many general-purpose electronics. However, lead-free solder alloys are known to have a higher melting point. SAC305, which consists of 96.5% tin, 3.0% silver, and 0.5% copper, is known to have a melting point around 217-220°C. This requires more care when soldering to avoid damaging sensitive components.

As with any procedures, the type of solder used is also dictated by the particular usage. For aerospace or automotive applications, where extreme reliability is crucial, higher numbered solders that contain silver are used due to their increased thermal cycle resistance and high tensile strength. Recent industry insights suggest that adoption of lead free solder has increased significantly due to regulatory requirements like , RoHS (Restriction of Hazardous Substances), even with the solder cost being higher and more difficult to process.

Ultimately, performance requirements for specific components and the operative surroundings dictate the choice of alloy and environmental regulations alongside cost consideration, mechanical strength, and the range for melting ensure optimal balance.

Common Issues with Solder and Their Solutions

One of the most noticeable problems when using solder is the poor quality of the joints, often resulting from insufficient heating or solder surface contamination. Proper cleaning of the components, application of flux, and correct soldering temperature provide better results. Yet another issue is the formation of voids, which could weaken joints. Improved soldering methods along with proper reflow profiles may help reduce this problem. Finally, electrochemical migration or corrosion might occur under humid environments, which can be mitigated using protective coatings or selecting solders with greater environmental resistance.

Working with Greater Alloy Solders

Alloys with higher melting points are more difficult to solder, like those which contain silver or other stronger metals. These alloys paraphrase expand during the bonding process as they require much higher temperatures for their melting points. An example of such high temp solders is Sn95.5-Ag3.8-Cu0.7 (SAC387) which melts and solders at 217-221°C, a degree less than or twice the melting point of traditional leaded alloys.Alloys with higher melting points require specialized tools and techniques for processing. A high-performance soldering station that can maintain a steady temperature is essential to prevent thermal shock to the workpiece. Moreover, preheating the assembly is also recommended to reduce the difference between room temperature and the soldering temperature to minimize mechanical stress.

Recent studies have been conducted on the formulation of fluxes designed for higher melting alloys. It has been shown that fluxes designed specifically for higher temperature use improves wetting and reduces void formation, which aids in reliable connections. In addition, uniform heat distribution is equally important during the reflow stage; for example, sustaining a reflow peak temperature approximately 20 – 30 degrees above the melting temperature of the alloy being used optimizes solder joint formation without excessive overheating.

Last but not least, the thermal compatibility of materials should not be ignored. Shrink-sensitive hybrid parts may be affected due to elevated temperatures, therefore using high-temperature solder and robust materials for the solder mask is advisable. Employing these methods will provide greater processes yield while working with high temperature alloys.

Avoiding Cold Solder Joints

In my case, I avoid producing cold solder joints by ensuring the right amount of heat is applied so that solder is molten and flows freely to fuse to the components completely. Also, ensuring surfaces are clean and devoid of oxidation or contaminants is critical. Selecting proper solder alloys with adequate profiles of reflow also guarantee the reliability and robustness of the solder joints.

Improving Techniques For Solder Flow

Use of adequate techniques and other soldering materials are critical towards optimal solder flow. One of the most effective methods is to preheat the components to promote even distribution of heat. The reduction of thermal shock makes soldering quite consistent, especially when dealing with bigger or high mass components.

Appropriate levels of flux activation have been shown to be instrumental in improving wetting and void reduction. It has been shown that no-clean flux formulas have managed to wet up to 95 percent efficiency on metal surfaces. It is important to note that adhering to the prescribed temperature range for the specified solder alloy strongly affects the quality of solder joints; thus needs to be respected. Sn-Ag-Cu alloys which are lead free have a higher temperature overhead of 240-250 °C for optimal reflow.

Adjustments to wave height in wave soldering is advantageous as it guarantees proper component coverage without spillage. A wave height of 2/3 of the component’s height is optimal as it minimizes bridging while producing consistent joints.

Lastly, calibrating environmental factors like the workspace’s airflow or humidity can greatly impact solder effectiveness. Moisture control is essential and, when applied, enhances efficiency for solder joints while reinforcing reliability by preventing moisture-related defects. These practices not only ensure smoother flow during soldering but also improve the performance of solder joints over the long term.

Reference sources

- Mechanical Bonding Properties of Solderable Anisotropic Polymer Composite containing Low-Melting-Point and High-Melting-Point Solder Fillers (2024)(Ha et al., 2024)

- Methodology: Synthesized two types of low-melting-point solder and high-melting-point solder mixed filler filled SAPCs (LH-SAPCs) with different mixing ratios (0 and 50 vol%) of high-melting-point solder. Conducted a bonding test using QFP.

- Key Findings: LH-SAPCs containing high-melting-point solder formed wider and more stable conduction paths due to the interaction between molten low-melting-point and solid-state high-melting-point solder fillers. Mechanical bonding properties were enhanced compared to LH-SAPCs with only low-melting-point solder, attributed to precipitation hardening and dispersion strengthening effects.

- Enhanced Hydrogen Generation from Magnesium–Aluminum Scrap Ball Milled with Low Melting Point Solder Alloy (2023)(Buryakovskaya et al., 2023)

- Methodology: Manufactured composite materials by ball milling Mg-based alloys and a low melting point Sn–Pb eutectic. Tested hydrogen generation performance in NaCl solution. Investigated the effects of ball milling duration and additive content on microstructure and reactivity using SEM and XRD.

- Key Findings: Ball milling induced structural transformations and the formation of new intermetallic phases (Mg2Sn and Mg2Pb), enhancing galvanic corrosion and hydrogen generation. Reactivity showed a non-monotonic dependence on activation time and additive content, with optimal hydrogen generation at 1-hour milling and 5 wt.% Sn–Pb alloy.

- Mechanisms for the formation of conduction paths in a solderable epoxy composite with a mixed low- and high-melting-point solder filler (2023)(Ha et al., 2023, pp. 1–13)

- Methodology: The research paper investigates the mechanisms of conduction path formation in solderable epoxy composites using a mixed low- and high-melting-point solder filler. Specific methodologies are not detailed in the provided abstract.

- Key Findings: The abstract does not provide specific key findings beyond the focus on the mechanisms of conduction path formation.

Frequently Asked Questions (FAQs)

Q: What is the typical melting point of solder?

A: Different types and alloys of solder have distinct melting points; for instance, lead solder has a melting point of approximately 183°C, while lead-free solder is considerably higher with a melting temperature of 217°C to 227°C.

Q: Why are lower temperature solders used?

A: For the purpose of protecting delicate components or materials that could be damaged by heat during soldering, lower temperature solders are made.

Q: What is the melting point of indium-based solder?

A: Indium-based solders tend to have a melting point between 118 and 166 degrees Celsius which makes both easy to use and highly effective in situations that require low temperature soldering.

Q: How does leaded solder compare to lead-free solder?

A: Lead solder not only has a lower melt temperature around 183°C but also possesses better wettability than other solders. Although more expensive, lead-free solders are preferred as they are environmentally mandated, especially in electronics assembly.

Q: What is a solder preform?

A: A solder preform is a piece of solder cut out ahead of time for a specific application where is will be melted and placed so as to need solder in a specific amount and area to ensure the correct amount on assembly. Electronics is one of the areas where they are applied, while they can be made from a variety of solders, indium based solder is one of the solder used.

Q: Why is high temperature solder important?

A: High temperature solder is important in automotive and aerospace industries due to extreme automotive or aerospace applications high heat usage. Solders that have melting points of 280°C or even 327°C are available in the market.

Q: Where is plumbing solder typically used?

A: Plumbing solder is used to join copper pipes and fittings used in plumbing. Plumbing solders are expected to form strong and leak proof joints to ensure reliability. They can be made from lead or lead free materials to meet safety standards.

Q: What is the role of electrical solder in circuit board assembly?

A: Electrical solder is used in the assembly of the circuit board to form electrical joints of the components inserted into the board. They ensure proper conductivity and mechanical strength which is important for the functioning of any electronic device.

Q: What advantages does indium provide in a solder?

A: With solder type indium, it is possible to achieve better wetting, lower melting points, and less thermal expansion. Indium-based solder is perfect for delicate electronic components.

Q: What is the specific ideal temperature for reflow or wave soldering?

A: It depends on the solder type, but for standard lead-free solder, the reflow temperature is set to 240 and 250 degrees C so that it can be melted and bonded without damaging the components.