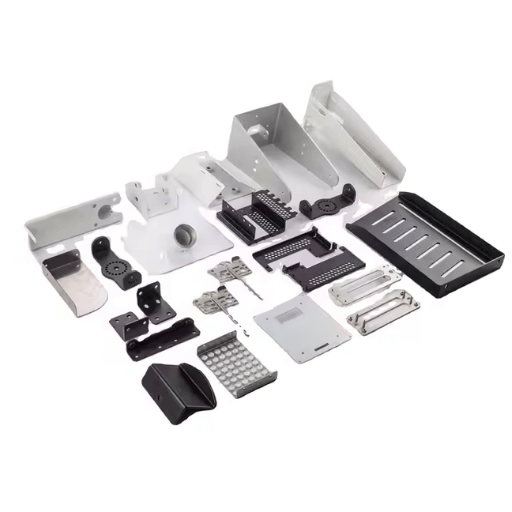

The manufacturing industry has been transformed by the use of sheet metal laser cutting due to its precise, efficient ,and versatile features. This novel innovation not only reduces production time, but also makes it possible to create complex parts for different machining centers which other devices cannot produce as effortlessly. It is of great importance to understand the capabilities of laser cutting systems in this competitive market whether you are working in automobile , aerospace, or industrial manufacturing. The purpose of this post is to explain modern techniques and procedures of manufacturing are brought out by the advancement of technology along with its major benefits, key components and underlying technology attributable to it. Understanding how this process is revolutionizing the fabrication work and why its adoption is increasing across sectors will help firms in adopting it.

What is Sheet Metal Laser Cutting?

Sheet metal laser cutting is an industrial procedure that utilizes a computer-controlled laser to carve designs into a piece of sheet metal. It focuses a high-powered laser beam on sheet metal, melting, burning, or vaporizing it along a predefined path for deft and meticulous cuts that produce little waste. In comparison to more traditional methods of cutting, laser sheet metal cutting offers great flexibility as it can be used for intricate designs, which are commonplace in many industries today. Its main benefits include remarkable precision, speed, and versatility when it comes to the types and sizes of metals and alloys used.

The Fundamentals of Laser Cutting

The principles of generating and guiding a finely focused ray of light form the bedrock of laser cutting. Within a lasing medium, which is usually gas, crystal or fiber, energy is amplified to obtain a sharp, intense light. This beam is then directed through mirrors or fiber optics and focused on the material with a lens.

A laser’s focused light melts or vaporizes different materials at extreme temperatures instantaneously. Sub-millimeter precision in guiding the laser over predetermined paths—whether for shape cutting or pattern engraving— is achieved through a CNC (Computer Numerical Control) system. For enhanced efficiency and quality, assist gas streams such as oxygen, nitrogen, or air are also utilized during cutting, helping in the removal of molten material. All forms of laser cutting juxtaposed with unparalleled thermal precision and control accomplish outstanding diverse results.

How Does a Laser Cutter Work

|

Key Point |

Parameter/Detail |

|---|---|

|

Laser Type |

CO2, Fiber, UV |

|

Power Range |

20W–10kW |

|

Material Types |

Metal, Wood, Acrylic |

|

Cutting Process |

Melting, Burning |

|

Assist Gas |

Oxygen, Nitrogen, Air |

|

Precision Level |

Sub-millimeter |

|

Speed |

Application-dependent |

|

Software Use |

CAD/CAM |

|

Thickness (Max) |

Material-specific |

The Importance of Fiber Lasers in Cutting Metals

- Increased Operational Efficiency: Unlike traditional CO2 lasers, fiber lasers offer a higher level of energy efficiency which increases productivity and reduces operating costs.

- Improved Accuracy: Placed at the laser’s output, the focusing optics eliminates the need for lens systems resulting in heat deposition and astounding cutting speed optical accuracy.

- Reduced Maintenance Rate: Fewer mechanical parts and an enclosed system boosts reliability and laser service uptime while requiring lesser care, greatly lowering maintenance costs.

- Broad Application Use: Different metals such as stainless steel, aluminum, and even brass and copper are used widely across industries and fiber lasers are widely used in cutting them all.

How to Choose the Right Metal Laser Cutter?

Different Types of Lasers for Metal Cutting

When choosing the right metal laser cutter, I focus on key factors such as material compatibility, cutting thickness, and precision. Additionally, I evaluate the machine’s power, speed, and overall efficiency to ensure it meets specific project requirements. Reliable suppliers like https://ud.goldsupplier.com/ provide a wide range of options, ensuring I can select a cutter tailored to industrial needs while maintaining cost-effectiveness and performance reliability.

Key Features of a Laser Cutting Machine

|

Key Point |

Description |

|---|---|

|

Precision |

High cutting accuracy |

|

Speed |

Fast processing speeds |

|

Power |

Adjustable for materials |

|

Versatility |

Cuts diverse materials |

|

Thickness |

Handles varying depths |

|

Efficiency |

Minimizes waste output |

|

Maintenance |

Low upkeep requirements |

|

Software |

Advanced control systems |

Taking Into Account The Laser Power and Quality of the Beam

For any application of a laser, its power and quality must be evaluated ensuring all the factors below are considered:

Power Output: Quantifies the energy provided by the laser. Affects the cutting speed and the types of materials used.

Beam Diameter: Influences the beam’s focus and precision.

Beam Intensity: Affects the penetration of the material; the range of energy allotted to the beam.

Mode Quality (M² Factor): The gaussian beam deviation; affects focus and precision and describes the beam.

Wavelength: Determines a material’s absorptive and complementary qualities.

Stability: Consistency of the power output, the quality of the beam, and the duration for which they stand stable.

Thermal Effects: Surrounding the cut zone, heat’s impact on materials.

Focus Optics: With respect to the beam’s concentration, it the sliceable materials describes the accuracy and power decision directly.

Adjustability: Availability for settings customization tailored to tasks or materials for better performance.

Maximizing efficiency and precision while maintaining reliability in laser applications is paramount and can be achieved through careful analyses of these factors.

What Are the Advantages of Laser Cutting?

Speed and Precision in Laser Cutting Metal

High Precision: With laser cutting, intricate patterns can be manufactured with a tolerance of about ±0.1 mm. This facilitates advanced features and intricate geometrical shapes while minimizing the excess material effortlessly.

Speed Efficiency: Different types of metals, including steel, can be cut at a rate of 20 meters per minute, subject to the thickness of the metal and power settings.

Versatility: Other than stainless steel and aluminum, acrylic, a non-metal, too, can be used as raw material, thus increasing its adoption across different fields.

Minimal Post Processing: Construction blunders seldom occur, and if they do, they are incredibly subtle. As a result, construction finishing is needless and therefore saves time and labor.

Enhancements in Operational Efficiency with Automation in Sheet Metal Fabrication

The rise in demand from consumers has made it necessary for manufacturers to adopt modern methods of production such as CNC and automated laser cutting. Such methods of sheet metal fabrication enable precision, accuracy, and proficiency in meeting consumer expectations. Modern technologies such as CNC machines and automated laser cutters greatly enhance operational efficiency. With the provision of exact bends and cuts to the sheet metals, these machines ensure maintenance of high precision. In addition, automation reduces the requirement for manual labor, improving workplace safety and lead times. The adoption of software solutions tailored for design, workflow management, and scheduling have also streamlined operations thus reducing unnecessary delays and improving efficiency in comparison to manual methods. All together, these changes have led to an improvement in CAD workflow systems. These advancements also allow manufacturers to improve efficiency, productivity, and cost in comparison to other fabrication methods.

Cost Efficiency Overview of Laser Cutting Services

The adoption of laser cutting tools has brought forth new and unparalleled methods for fabricating sheet metals. Such methods have made it possible for custom designs to be created at a lower cost while precision is maintained. Unlike traditional methods, laser cutters reduce the amount of raw materials wasted as they are more adaptive and precise to complex cuts with lesser kerf. Furthermore, traditional cutting methods with no automation demand a professional operator which drastically increases the operational cost. The innovations introduced with the cutting machinery provide greater accuracy at a lower price with increased efficiency as there is no need for manual intervention.

Moreover, the efficiency of laser cutting helps in significantly reducing production time, allowing manufacturers to fulfill tight deadlines without incurring additional operational costs. Research indicates that companies utilizing these services tend to realize savings over time because of reduced material scrappage and labor costs. In conjunction with the ability to work with various materials such as metals, plastics, and composites, laser cutting services remain an economical choice for high-volume production as well as tailor-made small-batch orders. This flexibility helps maximize ROI (Return on Investment) for companies aiming for precision fabrication at a low cost.

What Applications Use Sheet Metal Laser Cutting?

Industries Utilizing Parts With Laser Cut Precision

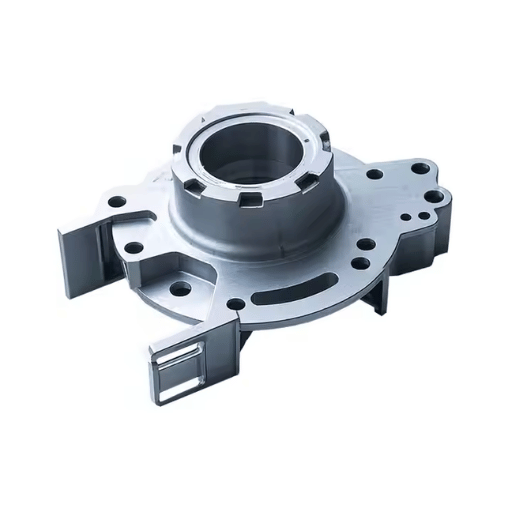

Automotive Industry: In the automotive sector, laser-cut sheet metal is used for such components as body panels, brackets, and even complex engine parts. This fuels consistency improvements and decreases time spent in assembly.

Aerospace Sector: Because of the stringent requirements of accuracy, laser cutting is well-suited for manufacturing light structural components as well as reliable and complex engine parts used in turbines for aircraft engineering.

Construction: Laser cutting offers exceptional precision which greatly enhances architectural creativity. Thus, frameworks for ornamental panels, bespoke metal fittings, and structural supports are executed with laser precision, ensuring clean borders.

Electronics Industry: For electronic devices, laser cutting plays an invaluable role in the manufacturing of enclosures, connectors, as well as other precision components. It enables intricate circuitry to be used with tight tolerances and compatibility.

Familiar Metal Materials for Laser Cutting

Steel, aluminum, and stainless steel remain the most widely laser cut metals, each providing specific benefits for accurate and effective manufacturing. Mild steel is often a favorite due to its low price and wide range of applications. On the other hand, aluminum is valued due to its low weight and resistance to corrosion. Stainless steel is a favorite for applications where strength, durability, and a smooth or polished finish are needed, both structurally and aesthetically. Exotic metals such as titanium and copper are becoming more popular for specialized laser cutting during recent years, especially for use in aerospace and medical applications due to high precision and specific material properties.req

Advancement in Cutting Technology

Analyzing recent search queries from Google alongside advancements in cutting technologies reveals new trends in industry focus. Studies show that focus, expenses, material based productivity, and brand laser cutting tools have a high demand. The need for 5-axis laser cutting and micro-milling suggests growing need for intricate attention in aerospace and electronic engineering. Moreover, the use of sustainable manufacturing and energy efficient practices indicates growing eco-outlook towards business. These findings indicate that the market direct attention towards eco-friendliness, multi-purpose use, and advanced technology.

How to Maintain a Laser Cutting Machine?

Periodic Maintenance Suggestions for Laser Systems

Regularly Maintain Optical Components:

Take care of and maintain the protective cover, lenses, mirrors, and other optical elements integral to laser systems. Dirty or damaged optics may induce a reduction of up to 40% in cutting and precision machining efficiency alongside increasing energy requirements.

Check the Filter for Tissues:

As is the case with air and exhaust filters, they should be checked periodically and replaced as deemed fit. Filters that are dirty may limit airflow, hamper performance, and lead to defects in the parts produced by the equipment.

Supervise Cooling Systems:

The control of temperature should be consistent, and coolant levels checked, especially in the chillers, accompanied with regular interval checks of the chiller performance. According to one study, a failure in the cooling system may lead to a reduction in the operational lifespan by around 20%.

Alignment and calibration of the laser beam:

Cutting effectiveness and overall system efficiency is achieved by addressing issues with the focus lens and periodically performing laser alignment. Unfocused and misaligned beams lead to reduced quality, increased component wear, and consequently, a 15% increase in maintenance cost over time.

Resolving Issues Relating to Your Laser Cutting Processes

Deficient Cutting Quality

A common culprit of poor cutting quality is the malfunction of focus lenses alongside damaged nozzles. Ensure the focus lens is clean and not off balance – if so, readjust; and replace damaged nozzles. Finally, check if the working pressure and type of gas are suited for the material being executed.

Burn Marks on the Material

Burn markings, as well as discolorations covering the surface of a material, often result from a laser gas flow that is too low, insufficient gas pressure, or contamination in the optics. Inspect gas nozzles for blockages, confirm that mirrors and lenses are clean, and set the gas pressure to an optimal value according to the needs of the material.

Incomplete Cuts or Uncut Sections

This problem can arise due to insufficient laser power, an incorrect cutting speed, or inadequate support for the material. Make sure the laser is set to the correct power, match the cutting speed to the material thickness, and provide adequate support to the workpiece to avoid vibration.

Excessive Dross Formation

Dross that accumulates under the cut more than what is normal could indicate inappropriate settings, too slow of a cutting speed, or insufficient gas pressure. Adjust these settings to improve the cut quality while reducing the need for further processing.

Laser Not Firing

Electrical or hardware failures could also result in a laser not firing. Inspect the system components for hardware or electrical failures starting at the power supply, checking connections, and looking for faults within the control software. These, along with routine diagnostics, can identify and resolve many issues promptly.

Improving the common issues would improve the dependability of the system as well as lower the downtime and boost the efficiency of the system as a whole.

Extending the lifespan of metal laser cutters

Scheduled Maintenance Monitoring: Avoiding the chronic lack of maintenance and the damaging effects from missing critical systems maintenance is achieved by regularly scheduled maintenance of lenses, mirrors and drive systems.

- Optimal Calibration: To achieve the best results, the laser machine should sustain cutting accuracy for different materials of varying thicknesses, so optimal performance requires frequent calibration.

- Management of Coolant System: Internal components may be damaged due to overheating therefore cooling systems must be properly monitored.

- Utilization of Premium Grade Materials: Operational expenses are reduced by using high-grade consumables such as gas and cutting plates which results in reduced residue build-up and increased lifespan of the laser cutter.

Reference Sources

- Optimization Method of Sheet Metal Laser Cutting Process Parameters under Heat Influence (Wang et al., 2024)

- Publication Year: 2024

- Key Findings: This paper addresses workpiece distortion and excessive material melting during laser cutting of thin-walled sheet metal. It proposes a segmented optimization method for process parameters, considering thermal effects. A temperature prediction model is developed, and a multi-objective optimization model is created using PSO-BP and NSGA II algorithms. The TOPSIS method is then used to select optimal parameter combinations, controlling heat accumulation during the cutting process. The method’s effectiveness is validated through experiments.

- Methodology: The study uses a combination of modeling (temperature prediction, multi-objective optimization), algorithmic approaches (PSO-BP, NSGA II, TOPSIS), and experimental validation.

- Packing layout added value in sheet metal laser cutting operations considering raw material reuse (Francescatto et al., 2025)

- Publication Year: 2025

- Key Findings: This research tackles the two-dimensional strip packing problem in sheet metal laser cutting, aiming to maximize material utilization and reuse. A modified Best Fit Decreasing Height heuristic is used to generate packing layouts, considering practical constraints. The modified heuristic outperforms other methods in terms of sheet metal utilization and raw material reuse. The study highlights the added value of raw material reuse while cautioning against over-prioritizing it, as it can lead to other manufacturing wastes.

- Methodology: The study uses a modified heuristic algorithm (Best Fit Decreasing Height) and compares its performance against other heuristics using a set of literature and generated instances.

- Applicability of a laser pre-treatment for a robust subsequent bending of thin sheet metal (Valentino et al., 2023)

- Publication Year: 2023

- Key Findings: This paper investigates the use of laser pre-treatment to improve the subsequent bending of thin sheet metal. While not directly about the cutting process itself, the laser pre-treatment is applied after the sheet metal is cut to a specific shape. The research explores how laser pre-treatment affects the robustness of the bending process.

- Methodology: The study likely involves experimental testing of laser pre-treatment on sheet metal samples followed by bending tests to evaluate the impact on bending robustness. Specific details on the methodology are not provided in the abstract.

Frequently Asked Questions (FAQs)

Q: What is the process of sheet metal laser cutting?

A: Sheet metal laser cutting is a process that has a metal beam specifically constructed to slice through sheet metals precisely and skillfully. There is low material wastage, and precision fabrication is advanced because of the systems efficiency.

Q: How does a laser machine cut out shapes from sheets of metal?

A: A schematic representation of the operation of laser cutting equipment includes a laser machine which has its own cutting head. Laser machines have fiber lasers or s olid-state lasers lenses which emits stronger calibrated light rays. The light beam gets concentrated on the metal plate and sues specific cutting heads that focus on a narrow area to penetrate the solid piece gently.

Q: What can be cut with laser technology?

A: With laser cutting technology, carbon and stainless steel, as well as aluminum sheets and other metal sheets, can be easily cut out. The technology especially excels in cutting through metals of different thicknesses.

Q: What are the practical benefits of utilizing laser cut components?

A: Parts that are cut with lasers are precise, time efficient and lose no materials, having the contours, clean edges, and more advanced shapes when compared to their traditional counterparts which use needles or lasers.

Q: How does a fiber laser machine assist in the process of cutting metal?

A: A fiber laser machine assists in cutting metal parts with efficiency and low wear-and-tear maintenance. It excels in cutting reflective metal materials because of its focused refinement, which minimizes reflection losses.

Q: Are aluminum and stainless steel effectively cut using industrial laser systems?

A: Indeed, aluminum and stainless steel are effectively cut using industrial laser systems. These systems can accommodate different metal thicknesses while attaining a clean accurate cut edge which is advantageous in high precision sheet metal parts manufacturing.

Q: What are the common applications for industrial cutting lasers?

A: The application of lasers for industrial cutting encompasses production of metal parts, automotive industry components manufacturing, and detailed parts in sheet metal machining. In industrial manufacturing, laser cutters are indispensable as they offer precision and speed for cutting various materials.

Q: In what ways is laser cutting different from traditional methods of cutting?

A: Compared to other methods of cutting like plasma and flame cutting, laser cutting is more precise, provides clearer cuts, allows for more complex designs, and also saves time and money by eliminating secondary processes.

Q: What criteria are relevant in selecting a laser for cutting sheet metal?

A: The criteria that are relevant in selecting a laser for cutting sheet metal include: type of laser source, material to be cut, level of precision desired, and volume of production. Also, solid-state and fiber lasers have differing impacts on efficiency and quality, and the machine must accommodate the material’s thickness and type.