The robotic welding systems automation has brought forth a variety of new opportunities within the industrial and manufacturing sectors. Modern production requires a higher level of precision and efficiency which increases the need for automation in traditional welding processes. Because of the sophisticated welding technologies and robotics, industries face unmatched productivity, efficiency and consistency. At the same time, resolving issues such as labor scarcity and needing improved safety measures within the workplace is possible. In this article, I will examine the major constituents of robotic welding systems, their uses in different sectors, and the overall impact robotic welding has on industrial systems.

What is a Robotic Welding System and How Does It Work?

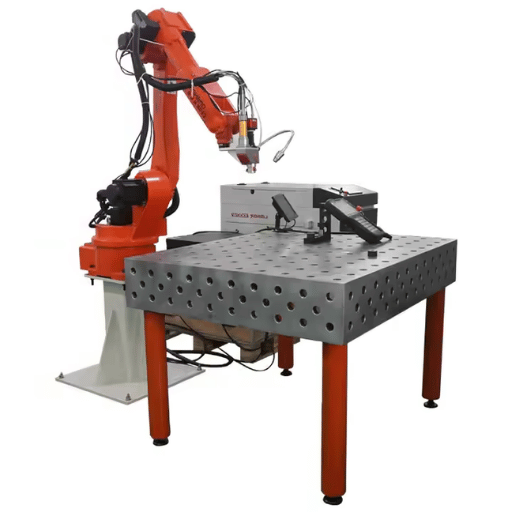

Robotic Welding Systems are a class of automated machinery that performs the welding process of a workpiece with precision. A typical system comprises a robotic arm, welding torch, power supply, and a controller. The way it functions involves programming the robotic arm for certain welding operations and controlling the timing of the steps by the controller. Fitted with sensors and advanced software, corrections can be made in real time. Modern robotic welding systems are highly reliable, eliminate maximum human error, and improve productivity in automated industrial applications due to the integration of artificial intelligence and machine vision technologies.

The Fundamentals of Robotic Welding

When robotic welding systems are compared to traditional manual welding methods, there are clear benefits. Studies suggest robotic systems achieve production throughput of up to 25% due to consistent performance and non-stop operation devoid of fatigue. Accuracy of robotic welding systems is measured in terms of repeatability, which often falls within ±0.02 mm ensuring uniform welds across numerous cycles of high-volume production. Integration of modern adopted sensors and control systems also has lower defect rates, with some systems reporting defect levels as low as 0.5%.

Another significant measurement of performance for robotic welding systems pertains to energy efficiency. Some advanced power management technologies report energy consumption reduction by as high as 30%, improving operational costs in addition to corporate social responsibility. Operational metrics indicate robotic welding systems have the potential to save industrial facilities hundreds of labor hours every year while consistently meeting quality standards. These factors are what make robotic welding crucial for integrating modern manufacturing processes in automobile, aerospace, or heavy equipment industries.

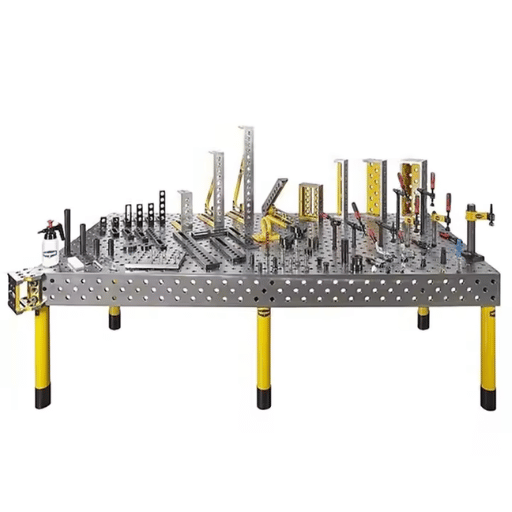

Parts of a Welding Robot

To achieve maximum effectiveness, precision, and productivity during welding processes, a welding robot consists of several vital and distinct parts. These parts include the following:

- Robotic Arm (Manipulator): This is the primary constituent which physically performs the welding action. Thanks to programmed trajectories, it has considerable flexibility, reach, and accuracy.

- Welding Torch: This element is placed on the robotic arm and is responsible for meeting the heat and welding materials supply requirements; this includes the provision of gases, electrodes, or filler as per the required process.

- Control System: A unit consisting of a programmable robotic controller that directs the movements and performance of all processes to meet the required standards. Instructions may be provided in the form of parameters, which can be changed in real time, ensuring flexibility.

- Teach Pendant: This device allows users to set up, control, and observe processes performed by the robot that can be done remotely from the workbench. They are necessary for the robot’s configuration and for carrying out operational adjustments.

- Power Source: This unit provides electrical energy for the purposes of producing the heat required for welding. It must also be suitable for other welding processes such as MIG, TIG, or even plasma arc welding.

- Wire Feeder: This works in MIG welding where operational consumable wire is continually advanced to the weld zone.

- Sensors: Supplied a range of passive feedback about the position, seam tracking, and quality of control welding. They ensure exact alignment of the furnace nozzle with the weld joint.

- Safety Equipment: This incorporates barriers and curtains alongside other devices, for example, emergency stop buttons which can enclose an area and block out all access, dangerous to the workers.

- Base or Mounting Platform: This is the part of the robot which acts as a stabilizing structure, allowing the robot to be fixed or placed in a movable position.

- Cooling System: This keeps the welding equipment and the robotic system from overheating during high workloads or heavy and unrelieved work duties on the equipment.

In achieving high productivity and consistency in the level of welding as well as repeatable automated robotic welding cycles, each of the components listed above are instrumental and significantly important.

The Role of Automation in Welding

- With the automation of welds comes numerous advantages that enhance their efficiency as well as the entire industrial operations within the business. As stated by the reports from specific industries, automated welding systems help boost productivity by forty percent when compared to manual welding. This is so because of the effectiveness of robotic systems in performing welds, they indeed dramatically cut back on the welds performed incorrectly as well as waste materials.

- Furthermore, unlike human welders, automated systems could conduct continuous welding operations without exhaustion. This allows for the equipment to operate on average between 16 and 24 hours each day with appropriate maintenance. When properly set, these systems can achieve guaranteed consistency and precision in results, making sure that every weld produced is compliant to strict quality assurance standards set by the industry.

- The automation of processes in robotic arms or mechanized welding has two noteworthy results such as lowering costs of production and workplace injuries. Employees are exposed to dangerous elements like heavy smoke, extreme heat, and physical labor to fumes, smoke, and physically intensive work (due to automation) which in turn is resulting in the saving of production costs. Do note that automation has also decreased the human error and is optimizing through the usage of resources.

The benefits that are perceived through the implementation of automation surpasses the accuracy and the productivity goals that are possible in conventional welding procedures. Furthermore, automation assists providers keep pace with growing industry needs while achieving unparalleled safety and reliability performance standards.

Why Choose Robotic Welding Over Manual Welding?

Benefits of Welding Automation

When measuring important factors like accuracy, efficiency, and scope, robotic welding surpasses manual welding. One of its key benefits is the elimination of human variability, allowing for uniform robot welds that are accurate and of a set quality benchmark. Welded would be of uppermost standards with slight variation achievable only with advanced robotic systems which are fitted with AI and sensor technology capable of registering and reacting to changes in the welding surroundings.

Another huge benefit is speed. Robotic welders can work without rest, enabling a continuous weld throughout a shift. These factors simultaneously increases production capacity while enhancing workplace safety by reducing human exposure to dangerous situations e.g. extreme heat, radiator, UV light, and toxic smoke. Furthermore, worrying about materials needed for production becomes unnecessary due to accurate and repeatable operations leading to cost reductions associated with high material waste.

Workplace needs not only precision but also flexibility with the ability to perform multiple complex tasks. Modern robotic welding is built for multiple functions, enabling businesses to surpass intricate and high volume production requirements.

Assessing Weld Quality of Automation and Manual Process

The weld produced by robotic welding systems is more precise and consistent than that produced manually. Defect rates also differ significantly, since robots can follow programmed paths and parameters without deviation. Studies show that the defect rate in robotic welding is typically as low as 0.5% while manual welding may see up to a 10% defect rate depending on the complexity and skill involved.

As an example, in automotive industry, robotic systems have shown 95% improvement in accuracy and uniformity for spot welding. This improvement leads to reduced rework and scrap rates. Further to this, robots maintain constant speeds at which welding is performed as well as the temperature during welding, weld penetration and bonding of materials becomes uniform. On the other, human welders tend to inadvertently introduce variations over time, especially during high demand periods.

Impact on Productivity and Efficiency

The implementation of robotic systems helps achieve greater accuracy and offers numerous benefits pertaining to productivity and efficiency. These benefits include:

Reduction of Cycle time: Robotic welders can reduce cycle times by 40% or more which allows for much faster production than manual welding.

Operational Uptime: Scheduled downtime along with efficient programming and maintenance enables robots to run continuously at 90-95% uptime.

Error Reduction: Defects are reduced by over 80% with automated systems which decreases rework costs along with material waste.

Energy Efficiency: Well programmed robotic systems can lead to 20-30% reduction in energy consumption thus aiding sustainable practices.

Scalability: The systems can be easily adjusted to increased production demands without any decline in quality.

Reduction of Labor Cost: Robots can complete repetitive manual tasks and lower labor expenditures by 25-35% while allowing human employees to be shifted to more meaningful work.

The improved operational reliability and productivity is greatly impacted by the incorporation of robotic systems into a manufacturing process.

How Does Arc Welding Robots Enhance the Welding Process?

Highlighted Qualities Of Arc Welding Robots

Arc welding robots enable welding procedures to be executed with the utmost ease and effectiveness as they come with sophisticated features that greatly improve productivity. Here are some of the features accompanied by relevant statistics:

Accuracy and Consistency: Unlike most industrial robots that operate in fixed welding conditions, arc welding robots work under carefully controlled robots that maximize precision and repeatability. Customers benefit from the vast amounts of identical parts reinforced with welds that are highly precise and repeatable handicapped only by tolerances of approximately ±0.1 millimeters.

Maximum Welding Speed: Not only are arc welding robots far more productive than manual operators, they can also operate faster. For instance, robotic arc welding can perform at speeds that are 20% to 30% more efficient than traditional methods, which shortens the production sequence.

Seam Tracking Technology: With the aid of lasers or efficient cameras, modern-day arc welding robots have the capability to track seams as they undergo work on welds and adjust extemporaneously, ensuring financial savings through reduced raw material waste due to bones being placed accurately on poorly executed welds.

Reduction Of Energy Consumption: The majority of the robots lean on more advanced welding systems. More efficient welding systems and the robots themselves cut total energy use by 15%-20% against arc welding setups. The rationalization shrinks operation prices as well as encouraging ecofriendly manufacturing.

Improved Safety: With welding being carried out by robots, manufacturers mitigate hazards related to worker contact with excessive heat, ultraviolet rays, smoke, and molten metal. This improved safety encompasses general industry standards and regulations.

Insight through Data: Certain advanced arc welding robots have been incorporated with IoT systems that allow for the monitoring and analyzing of production parameters in real time. Such information can be utilized to improve processes, detect lags in productivity, and create models for planned upkeep, which aids in reduced downtime.

By integrating such technologies, these arc welding robots solve the most pressing problems of the welding process while also advancing productivity and safety standards alongside cost efficiency.

The Importance of Robot Welding in Heavy Industries

Consistent weld accuracy within a tolerance of 0.1 mm.

Reduced welding defects by 75% compared to manual processes.

Depending on the application, can average 25-30 welds per minute.

Requires minimal human intervention, enabling 24/7 operation and effectively doubling production.

Up to 30% reduction in material waste due to more precise welding.

Implementation of predictive maintenance can reduce unplanned downtime by 20-40%.

Less exposure to hazardous fumes and high temperature environments.

Over 50% reduction in welding related accidents.

Easily integrated into existing manufacturing lines due to modular design.

Supports multiple types of welding, including MIG, TIG, and spot welding.

Marking industries with an opportunity for sustainable growth without the need of relaxing safety standards, alongside stringent regulations, and mounting competition becomes possible when aligning with industry data responsibly.

Integrating Advanced Welding Technology

Advanced automated welding systems have resulted in improved cycle times by up to 30%-50%. This reduction in manual processes not only lowers production bottlenecks, but improves overall efficiency and throughput.

With high-precision command of welding processes, defect rates have plummeted to 0.5% in automated systems, compared to 3%-5% in manual operations. This substantially improves product quality while minimizing rework costs.

Modern welding equipment features energy-efficient innovations that decrease power usage by 20%-35%. This functionality contributes to cost savings, as well as other environmentally responsible objectives.

With robotic welding units, productivity is reported to increase by 40% per operator allowing skilled employees to supervise multiple processes or attend to more valuable tasks, increasing optimal resource utilization.

Automated systems record unmatched weld seam uniformity with real-time adjustments, achieving a joint strength increase of up to 25% compared to older methods.

IoT-enabled advanced systems paired with AI diagnostics ensure reliability, reducing unscheduled downtimes by 15%-20% while prolonging equipment lifespan.

These measurable advancements reflect the importance of modern welding technologies in advancing efficiency and adapting to the needs of today’s manufacturing systems.

What Are the Welding Applications for Robotic Welding Cells?

Industries That Can Implement Robotic Welding Solutions

Robotic welding cells are employed from numerous industries. This is done to improve productivity, precision, and fulfill the production volume requirements. Following is the list of industries and their corresponding cases for use of robotic welding solutions.

- Welding involves the assembly of car frames, chassis, and exhaust systems.

- Manufacture of components for vehicles is done in bulk and with a uniform standard of weld quality.

- Welding of aircraft parts such as fuselage sections and engine mounts, heavy precision.

- Compliance with safety and performance criteria, stricter than on commercial aircrafts.

- Welding of steel beams, trusses, and other structural parts.

- Assembly of heavy construction machinery and equipment.

- Welding of ship hulls, bulkheads, and pipes for large vessels designed for operation in difficult marine environments.

- Production of large structures which are corrosion resistant.

- Manufacturing pipelines, pressure vessels, and storage tanks.

- Deterioration resistant and well sealed components enduring extreme pressure and temperatures.

- Welding of components for machines used in agriculture, mining, and industrial processes.

- Welding that ensures highest of strength is achieved and able to endure severe load and continuous operation.

- Welding of small components of appliances, transformers, and battery packs.

- Mass production is automated and makes use of electrical goods.

- Welding of rail tracks, train carriages, and other related parts of that for trains.

- Improves the durability and safety of the entire system of transportation.

Industries utilize robotic welding technologies to resolve issues such as lack of labor, poor welding standards, and the need for faster production cycles. Effective adoption of these technologies leads to increased productivity and cost efficiency without compromise on quality.

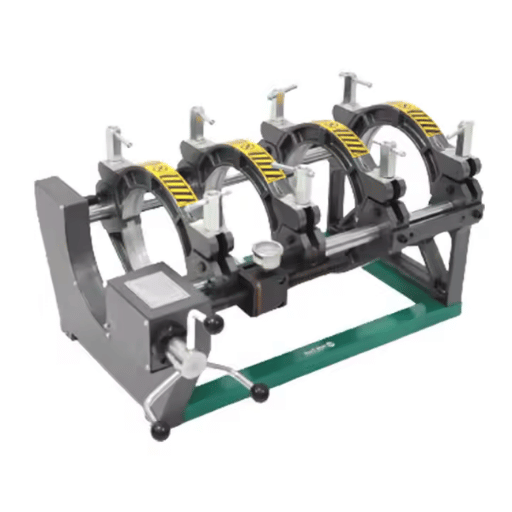

Different Automation For Specific Tasks In Welding

Automated welding systems offer different industries enhanced precision, productivity, and consistency of the above measurable benefits. A classic example would be the increase of up to 30% production efficiency of automotive assembly lines owing to the introduction of robotic welding, as reported in various industry reports. This extensi and surge is credited to robotic arms precision at high speed which further reduces cycle times achievement of industry standards.

Further, robotic welding in the aerospace sector has achieved near 40% reduction in defect rate of critical components enabling greater safety and compliance with strict regulatory requirements. Also, the railway industry has been able to streamline the manufacture of large steel structures with automated welding systems thereby reducing overall manufacturing time by 25%.

Further to this, research suggests that automated welding can achieve as much as 70% savings in costs related to material waste and rework attributed to inaccurate and repetitive welding processes. This serves as an indication on how the automation of welding helps resolve specific impediments within an industry, allowing for the refinement of industrial practices.

Use Cases of Robotic Welding Systems

In addition to these metrics, robotic welding systems provide multiple other benefits like improved accuracy, speed and consistency, all of which strengthen the production process. Reduction of material waste and rework are also accomplished through precise welding being done repetitively, saving costs by up to 70%. Moreover, robotic welding increases safety at the workplace as humans are no longer required in dangerous positions during the welding process, enabling faster production. These features make robotic welding essential in the current industrial ecosystem.

How Do Cobots and Robot Systems Integrate into Welding Automation?

The Use of a Collaborative Robots in Welding Automation

Collaborative robots (cobots) augment welding automation processes by cooperating with human operators and scaffolding automation processes. Unlike traditional industrial robots, cobots are equipped with force safety mechanisms such as sensors that prevent accidents during operation—these robots are safe. With human operators freed from monotonous production tasks, these robots facilitate relentless repetitive welding operations. In addition, the new programming interfaces make it easier and cheaper to deploy cobots than traditional robotic systems. As a result, these retractable systems are suitable for small and medium enterprises that strive to refine their welding processes and modernize business activities without losing flexibility and safety.

The Future Development of Robot Technology in Welding

Robots are capable of operating nonstop, yielding 20-30% higher productivity than manual welding operations.

Automated welding systems work with minimal downtime and variation for consistent output.

Weld robotic systems attain an average precision of ±0.2mm which is precise compared to any other standards.

Welds that are consistent in composition and structure reinforce build quality and diminish the possibility for reworks.

The initial investment put into collaborative robots (cobots) is recoverable in 25% operating cost savings long term.

Lower material allowance on defected items coupled with lesser material wastage translates to improved cost efficiency.

Robotic welding takes care of occupational hazards like exposure to welding fumes and high heat.

Drastic improvements in injury rates are predicted in workplaces with robotic systems, with one prediction estimating a 50% decrease.

Collaborative robots (cobots) are multifunctional and can be programmed to do spot welding, arc welding, and material handling.

Smaller footprint designs enable cobots to work in tight areas, making it possible to incorporate them into various production environments.

Easier scalability for small and medium enterprises (SMEs).

Deployment time has improved with the addition of more intuitive designs, cutting it by 60%.

Robotic systems enable regional SMEs to increase production without a proportional increase in labor.

The use of robotic technology has emerged as a game-changer for the welding industry with powerful evidence of improvement in productivity, safety, and operational efficiency.

Global Advances in the Processes and Innovations of Robotic Welding

The processes of robotic welding have greatly evolved with the addition of more technologies to meet industry needs. A good example is the introduction of AI-powered vision systems which has improved welding accuracy by 25%, eliminating the need for numerous inspections and corrections. Even more, adaptive programming software permits real-time adjustments to weld joints, making efficiency 40% better than traditional processes.

The results were remarkable with the incorporation of collaborative robots (cobots) into welding processes. Research indicates that collaboration robots approximately triple throughput of welding operations with worker safety maintained via sophisticated sensing and stoppage systems. In addition, the predictive maintenance systems incorporated in modern robotic welders has slashed downtime on average by 20% thereby allowing for uninterrupted production schedules.

This information reveals the technological advancements in robotic welding, proving distinctly their capability to sustain demanding quality standards and enhance performance in a myriad of economic sectors.

Reference Sources

1. Welding Penetration Monitoring for Ship Robotic GMAW Using Arc Sound Sensing Based on Improved Wavelet Denoising

- Authors: Ziquan Jiao et al.

- Published In: Machines

- Publication Date: September 16, 2023

- Citation Token: (Jiao et al., 2023)

- Summary:

- This paper discusses a method for monitoring welding penetration in robotic Gas Metal Arc Welding (GMAW) by analyzing arc sound signals. The authors propose an improved wavelet threshold denoising method to eliminate noise interference from the arc sound signal.

- Key Findings:

- The study establishes a nonlinear mapping model for penetration state identification using various pattern classifiers, achieving higher accuracy in feature extraction and classification.

- The effectiveness of the proposed denoising method is validated through simulations and statistical analysis, demonstrating its adaptability in real-world applications.

2. Fault Correction of Algorithm Implementation for Intelligentized Robotic Multipass Welding Process Based on Finite State Machines

- Authors: Yinshui He et al.

- Published In: Robotics Comput. Integr. Manuf.

- Publication Date: October 1, 2019

- Citation Token: (He et al., 2019, pp. 28–35)

- Summary:

- This study focuses on improving the stability of robotic welding processes through the implementation of finite state machines for fault correction in multipass welding.

- Key Findings:

- The proposed method enhances the stability of the welding process and achieves over 95% success in weld profile extraction, indicating significant improvements in robotic welding efficiency.

3. Digital Tools as Part of a Robotic System for Adaptive Manipulation and Welding of Objects

- Authors: Zuzana Kovaríková et al.

- Published In: ACTA IMEKO

- Publication Date: August 19, 2022

- Citation Token: (Kovaríkova et al., 2022)

- Summary:

- This paper describes the design and verification of digital tools that facilitate information sharing within a robotic system for adaptive manipulation and welding.

- Key Findings:

- The study emphasizes the integration of intelligent sensors and control systems to enhance the efficiency of robotic welding operations, minimizing human effort and improving production quality.

Frequently Asked Questions (FAQs)

Q: How do advanced robotic welding systems optimize welding task efficiency?

A: The welding process is made more effective by advanced robotic systems because these technologies automate the various welding tasks which eliminate human error and increases precision. Laser welding and tig welding are examples of welding processes that are satisfactorily executed by these systems.

Q: What is the contribution of cobots to the robotic welding cycle?

A: During the robotic welding cycle, cobots work directly with human welders, maximizing productivity. Due to their ease of programming, cobots can be set to many different activities which enhances efficiency in a versatile production system where fast adaptation is critical.

Q: When compared to a conventional welding machine, what advantages does it bring to the production line?

A: Welding machines improve the execution of tasks in the production line as they assist in observing set standards and minimizing time spent on manual processes. Furthermore, these machines when integrated with robotic automation can operate non-stop serving the workflow and, in turn, high demand production.

Q: Why is Fanuc considered a leader in welding robotics?

A: Fanuc’s leadership in welding robotics is attributed to the advanced systems technology and automation innovations as well as dependable robotic welding systems. Tools such as the Fanuc Arc Mate boast tremendous accuracy, longevity, and the capability to perform multi-dimensional and intricate welding functions paramount for industries which require versatile, economical and high standard welding automation solutions.

Q: How can offline programming benefit the robotic welding process?

A: Welding programs can now be built and tested while the production line is ongoing with the use of Offline programming. This helps make sure that time is kept to a minimum and processes are thoroughly prepared for testing prior to execution guaranteeing efficiency.

Q: What are some of the benefits of having a positioner on welding robots?

A: A positioner enables precise control of workpiece rotation in welding robotics which enhances both the quality of welding and accessibility. A positioner is especially helpful for performance of advanced welding sequences because it permits optimal conditions for every weld.

Q: In what way does robotic automation solve the problem of the lack of skilled welders?

A: The lack of skilled welders is mitigated with robotic automation because welders no longer need to perform mundane and repetitive welding processes. This technology resolves employment issues while ensuring there is no compromise on quality needed in production.

Q: How do welding robotics affect cost-effectiveness?

A: Cost-effectiveness is improved through welding robotics because they lower labor expenses, reduce material waste, and enhance production speed and quality. These systems provide long-term cost effectiveness by decreasing operational costs while increasing productivity, offering a faster return on investment.

Q: Is it possible to use a motoman welding machine for different welding techniques?

A: A Motoman welding machine can be set up for numerous welding techniques such as arc welding as well as gtaw making it applicable on various sectors. It can be utilized in different industries due to its versatility and adaptability, affording excellent welding quality on numerous workpieces.