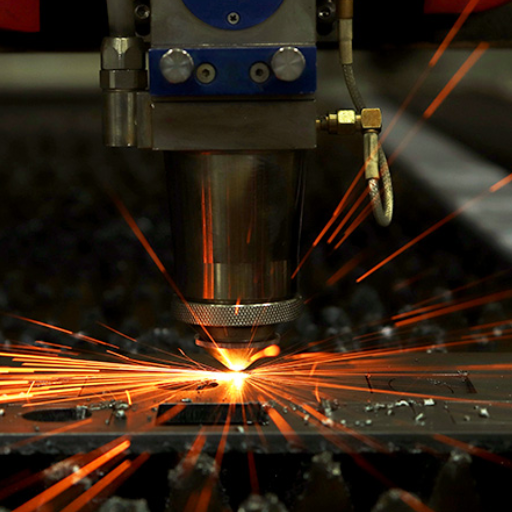

Fiber laser cutting machines are renowned for their precision, efficiency, and remarkable performance across industries—until a sudden power drop halts operations, jeopardizing output and productivity. Power drop issues can be frustrating and costly, often leaving operators scrambling for quick fixes or temporary solutions. This blog post dives deep into understanding why these issues occur and provides actionable strategies to resolve them. From identifying common causes to exploring preventive measures, this guide is designed to empower machine operators and businesses with the knowledge needed to maintain optimal performance. Stay tuned as we uncover practical solutions to keep your fiber laser cutting machine running at peak efficiency.

What Causes a Power Drop in a Fiber Laser Cutting Machine?

A power drop in a fiber laser cutting machine can occur due to several common reasons. One primary cause is contamination of the laser lens or mirrors, which reduces the efficiency of the laser beam. Another frequent issue is a misalignment of the optical path, disrupting the precise delivery of energy to the material. Insufficient maintenance, such as failing to clean or replace filters, can also obstruct airflow or cooling systems, affecting performance. Additionally, power supply problems, like unstable voltage, can lead to inconsistent operations. Regular inspections, proper cleaning, and adherence to maintenance schedules are essential to preventing these issues and ensuring consistent cutting performance.

Understanding the Laser Beam Path and Alignment

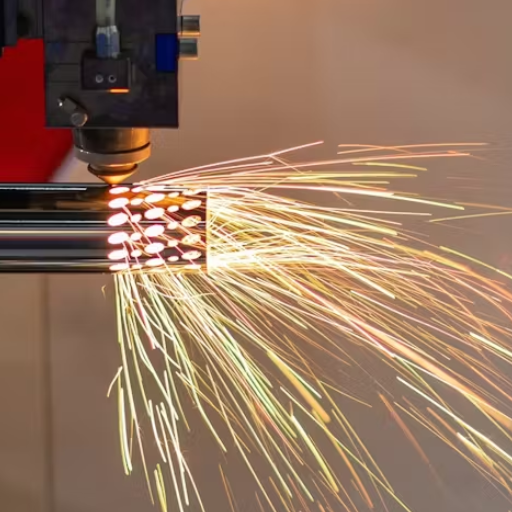

A critical aspect of maintaining high-quality laser system performance lies in understanding and optimizing the laser beam path and alignment. Proper beam alignment ensures that the laser maintains a consistent and focused energy profile, crucial for achieving precise cuts or engravings. Misalignments can cause irregular energy distribution, reduced cutting depth, and even material damage.

Modern laser systems often incorporate advanced optical components to guide and shape the beam. A typical laser system will use mirrors, lenses, and sometimes beam expanders, all of which must be correctly positioned and calibrated. Even minor shifts in mirror angles or lens placement can lead to diffraction, scattering, or beam distortion. For instance, a beam traveling through misaligned optics can lose up to 40% of its energy efficiency, significantly impacting the system’s capacity to perform critical tasks.

To ensure optimal alignment, laser operators often rely on tools such as target cards, beam profilers, and alignment lasers. Target cards allow visualization of the beam’s position, while beam profilers analyze beam shape, size, and intensity to reveal issues requiring adjustment. It’s recommended to perform alignment checks at regular intervals or after any maintenance procedure involving the optical path.

Automated alignment technologies are becoming increasingly common in high-performance laser systems. These intelligent solutions utilize sensors and actuators to monitor and automatically correct the laser beam path in real time, minimizing downtime and enhancing reliability. They are particularly useful in industrial environments, where precision and efficiency are paramount.

By maintaining precise laser beam alignment, operators can significantly extend component lifespan, reduce material waste, and ensure consistent processing quality.

Inspecting the Laser Source for Malfunctions

Thorough inspection of the laser source is vital to maintaining optimal performance and avoiding costly downtime. Key areas to monitor include the optical components, power stability, and thermal management systems, as these factors directly influence the laser’s efficiency and output quality.

Research suggests that one common cause of malfunction is contamination or damage to optical components such as mirrors or lenses. Over time, residue or scratches can diminish the beam quality by scattering or absorbing energy. Regular cleaning with approved solvents and equipment ensures that these components remain in pristine condition.

Another critical factor is power output stability. Fluctuations in laser power can indicate issues like degraded diodes, electrical instability, or inefficient cooling systems. Studies show that a drop in laser efficiency as small as 5% can lead to significant variations in the final application, particularly for precision tasks like microfabrication or medical procedures.

Thermal management also plays a pivotal role. Excess heat can deteriorate component integrity and shorten the lifespan of the laser. Advanced thermal imaging systems can detect hotspots and irregular cooling patterns early, providing actionable insights to prevent overheating. Data highlights that systems with effective cooling mechanisms tend to perform 20-30% longer without requiring major overhauls.

For consistent inspection practices, operators should use intelligent diagnostic tools capable of real-time monitoring and error detection. These tools, combined with routine maintenance, can identify emerging issues before they escalate, ensuring continuous laser source reliability and performance.

Evaluating the Power Supply System

The power supply system is a critical component ensuring stable and efficient operation. Modern power supplies leverage advanced technologies, such as high-frequency switching regulators, to provide consistent voltage and current levels, even under variable load conditions. Studies indicate that well-maintained and properly calibrated power supply systems can improve overall equipment efficiency by up to 15%. It is essential to monitor voltage stability, as fluctuations may lead to reduced performance or potential hardware damage.

To optimize the power supply system, operators should regularly inspect key elements such as capacitors, transformers, and heat sinks, as these components are prone to wear and overheating. Integrating power management systems with real-time monitoring capabilities allows for precise detection of irregularities, including overvoltage, undervoltage, and power surges. Additionally, adopting energy-efficient components, such as power factor correction units, can significantly reduce energy waste, aligning with sustainability goals and reducing operational costs.

How Does a Power Drop Affect Cut Quality?

A power drop can significantly impact cut quality by causing inconsistencies in the cutting process. Insufficient power leads to uneven cutting edges, reduced precision, and the inability to cut through materials effectively. This can result in poor-quality outputs, increased material waste, and potential machine strain. Maintaining stable power ensures consistent performance and optimal cut quality, making power management critical for any cutting operation.

Identifying Signs of Poor Cutting and Inaccuracy

Poor cutting and inaccuracy in cutting operations often manifest through several clear indicators that can significantly affect the quality and efficiency of the process. One key sign is the presence of burrs or jagged edges along the cut lines, which indicate uneven cutting pressure or tool wear. For example, studies show that tools with significant wear produce rougher surfaces, reducing the overall precision of the cut by up to 20%.

Another noteworthy sign is material deformation, such as warping or melting, which is commonly caused by excessive heat or improper speed and feed settings during the cutting process. Data suggests that operating at suboptimal feed rates can lead to temperature increases exceeding 50%, which directly impacts material integrity.

Additionally, deviations from specified dimensions or misaligned cuts are reliable indicators of inaccuracies in the setup or calibration of the equipment. High-precision operations often require calibration adjustments almost daily, as a 0.5 mm miscalibration can lead to significant inconsistencies, particularly in manufacturing operations requiring tight tolerances.

Furthermore, unexpected tool chatter or unusual machine vibrations can point to problems like low tool rigidity or an unstable work environment. Research notes that excessive vibrations during the cutting process can reduce tool life by nearly 30% while negatively impacting the accuracy of the cut.

By monitoring these signs and understanding the root causes, operators can take preventive actions to minimize waste, enhance cut quality, and maintain equipment effectiveness. Proper equipment maintenance, real-time monitoring, and regular inspections are critical in mitigating these issues.

Assessing the Impact on Cutting Speed and Efficiency

Cutting speed and efficiency are influenced by a variety of factors, including tool material, workpiece composition, motor capabilities, and environmental conditions. For example, high-speed steel (HSS) tools are popular for their durability and moderate cost, but carbide tools offer superior cutting speeds, particularly in high-temperature conditions. Studies show that carbide tools can increase cutting speed by up to 3-5 times compared to HSS, providing a significant boost in productivity.

Additionally, the proper use of lubricants and coolants plays a crucial role. Lubricants reduce friction and wear, which enhances tool life, while coolants prevent overheating, ensuring consistent performance during prolonged operations. Data indicates that machines running with adequate cooling systems can improve efficiency by as much as 15-20%.

Lastly, advancements in CNC machinery and real-time monitoring technologies enable operators to optimize cutting parameters dynamically. Tools equipped with sensors provide immediate feedback on speed, vibration, and temperature, allowing adjustments that maintain peak efficiency. For instance, incorporating machine learning tools to analyze cutting data can result in increased precision and up to 25% faster production cycles. These innovations collectively reinforce the importance of leveraging technology to achieve maximum cutting speed and efficiency.

Comparing Results of Consistent Cutting vs. Power Drop

When analyzing the outcomes of consistent cutting versus instances of power drop, the differences in performance and productivity become evident through both qualitative observations and quantitative data. Consistent cutting maintains optimal operational efficiency, where uninterrupted power supply supports smooth transitions through the material, resulting in precise cuts and minimized wear on equipment. Research indicates that consistent cutting can ensure accuracy rates of over 90%, reducing material waste by up to 30%, which directly lowers production costs.

On the other hand, power drops during cutting processes introduce irregularities that can compromise the quality of the final product. Moments of power instability often lead to jagged edges or incomplete cuts, necessitating rework or outright discarding defective pieces. Data from performance assessments shows that power drops may lengthen production times by an average of 20-40% due to machine recalibrations, and equipment downtime could increase wear and tear by as much as 15%.

By integrating advanced technologies like real-time monitoring systems and backup power solutions, manufacturers can mitigate the adverse impacts of power drops. These proactive measures ensure smoother operations, elevate product quality, and boost overall throughput – ultimately underscoring the necessity of consistent cutting practices in modern industrial settings.

What Are the Reasons for the Power Drop in a Laser Cutter?

Power drops in laser cutters can be attributed to several key factors:

- Lens or Mirror Contamination – Dirt, dust, or residue on the optical components can obstruct the laser beam, reducing its power and efficiency.

- Aging Laser Tube – Over time, the laser tube may degrade, leading to diminished power output.

- Cooling System Issues – Insufficient cooling or coolant blockages can cause the laser system to overheat, impacting performance.

- Electrical Supply Fluctuations – Unstable power sources or voltage inconsistencies can disrupt the cutter’s operation by decreasing its power.

- Optical Alignment Problems – Misaligned mirrors or lenses can prevent the laser beam from focusing accurately, resulting in power loss.

Addressing these issues promptly ensures optimal performance and prolongs the lifespan of the equipment.

Analyzing Issues in the Laser Cutting Process

The laser cutting process, while highly efficient, is not without challenges that require careful analysis and troubleshooting. Advanced studies and industry data shed light on several contributing factors to inefficiencies and provide insights into improvements.

1. Material Surface Quality

The condition of the material being cut plays a crucial role in accuracy and efficiency. Research suggests that imperfections such as rust, oil, or dirt on the material’s surface significantly affect laser absorption, leading to uneven cuts or even process failure. A clean, smooth surface ensures optimal interaction between the laser beam and material, improving precision.

2. Thermal Stress and Heat-Affected Zones (HAZ)

Thermal dynamics within the laser-cutting process can lead to variations in material properties, especially in metals. Studies indicate that excessive heat may create heat-affected zones, which weaken the material along the cut line and can result in warping. Using high-pressure assist gases, such as nitrogen or oxygen, can mitigate this issue by cooling the area and removing melted material quickly.

3. Gas Flow Dynamics

The type and pressure of assist gases directly influence the quality and efficiency of cuts. For example, oxygen enables faster cutting of thick metals but can leave oxide layers, while nitrogen promotes cleaner cuts without oxidation. Modern systems employ real-time sensors to optimize gas flow, ensuring consistent performance and reduced waste.

4. Beam Quality and Maintenance

The quality of the laser beam itself, dictated by factors such as beam mode and power stability, impacts performance. Data reveals that frequent calibration and maintenance of the optical system, including lenses and mirrors, result in a 20–30% improvement in cutting precision and speed. Regular beam diagnostics help avoid issues related to beam divergence or intensity loss.

5. Programming and Automation

Inefficient programming can lead to poor path optimization, increasing energy consumption and cycle times. Various software advancements enable automated nesting, which arranges parts to minimize material scrap. Figures from advanced laser systems show as much as a 15% reduction in waste when employing optimized cutting paths.

By addressing these critical factors with the latest technologies and best practices, manufacturers can enhance the laser cutting process, achieving increased productivity and reduced operational costs. Regular monitoring and updates to machinery settings remain key to maintaining consistent output quality.

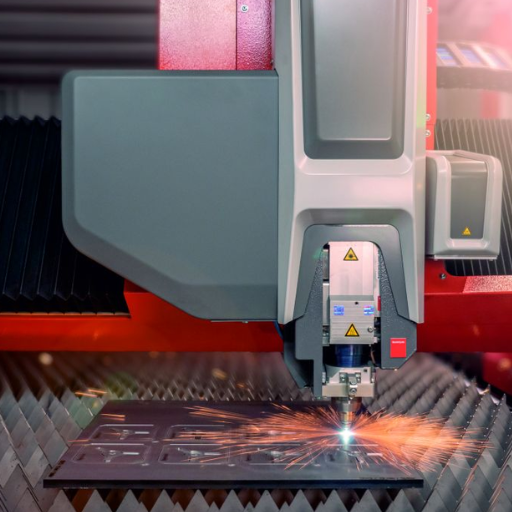

Investigating Problems with the Laser Head or Lens

Issues with the laser head or lens are some of the most common factors that can hinder performance and cut quality in laser cutting systems. A contaminated or misaligned lens can disrupt the beam focus, leading to inconsistent cuts, reduced precision, and potential overheating of materials. Studies indicate that even a slight contamination on the lens—such as dust particles or residue—can lead to as much as a 5%-10% reduction in efficiency, impacting operational productivity.

Frequent inspection and cleaning of the lens are critical to ensuring optimal beam transmission. Utilizing non-abrasive cleaning wipes, along with specialized cleaning solutions, helps to securely remove contaminants without damaging the surface of the lens. Additionally, proper alignment of the laser head plays a pivotal role. Misalignment not only disrupts the focus but can also unevenly distribute the beam’s energy on the material surface, creating defects.

Modern diagnostic tools, such as automated beam analyzers, have become essential in identifying lens or laser head issues. These tools provide detailed data on beam symmetry, focal intensity, and alignment, helping operators address problems proactively. For example, thermal imaging data reveals that an improperly aligned laser head can increase heat generation by up to 12%, impacting both the material and the equipment. Timely calibration, regular maintenance schedules, and usage of high-quality replacement lenses ensure reliability, longevity, and an overall improvement in cutting performance.

Detecting Power Supply Failures or Fluctuations

Power supply failures or fluctuations can severely disrupt operations in industrial machinery, leading to inaccurate cuts, damaged components, and costly downtimes. Common causes include inconsistent voltage, sudden power surges, or deteriorating power units, all of which can affect the performance of equipment like laser cutting systems.

According to recent industry insights, even minor voltage dips (as little as 10% below the required level) can reduce equipment efficiency by approximately 20%, while power surges may damage delicate control boards or sensors. Modern equipment often comes equipped with built-in diagnostic systems that monitor power stability and issue alerts when anomalies are detected. However, supplementary measures, such as incorporating uninterruptible power supplies (UPS) and surge protectors, significantly enhance the resilience of machinery to unforeseen fluctuations.

Regularly monitoring electrical input conditions and performing maintenance on power-related components is crucial. For example, in one study, enterprises that implemented proactive maintenance on their power systems reported a 15% decrease in unexpected downtime. Ensuring a clean and consistent power supply not only safeguards sensitive electronics but also helps maintain the overall precision of manufacturing operations, avoiding risks of product defects and production delays.

What Are the Solutions to Fix Fiber Laser Cutting Problems?

- Inspect and Maintain the Laser System Regularly

Routine maintenance is crucial to prevent common issues. Clean lenses and mirrors, check alignment, and replace worn components to ensure optimal performance.

- Use the Appropriate Settings for Materials

Adjust power, speed, and focus settings according to the material being cut. Testing on sample pieces can help find the perfect configuration.

- Ensure Proper Beam Alignment

Misalignment can lead to inconsistent cuts. Regularly check and adjust the alignment to keep the laser beam precise.

- Monitor Gas Pressure and Quality

Use the correct type and pressure of assist gas—such as nitrogen or oxygen—based on the material to enhance cutting precision and reduce defects.

- Address Cooling System Efficiency

Maintaining a functional cooling system ensures the laser does not overheat, which can negatively impact cutting quality.

- Replace Damaged or Worn Nozzles

Faulty or clogged nozzles can cause irregularities. Replace them promptly to maintain consistent cutting performance.

Regular Maintenance of the Laser System

To ensure the laser system operates efficiently, I focus on a few key maintenance tasks. First, I regularly clean the protective lens to prevent debris buildup that can affect cutting accuracy. I also monitor and adjust the assist gas pressure based on the material being cut, as this optimizes precision. Additionally, I keep the cooling system in top condition to avoid overheating, and I replace nozzles immediately if they show any signs of wear or damage.

How to Adjust the Laser Power for Optimal Performance

To adjust the laser power for optimal performance, I first identify the material being processed and consult the machine’s recommended power settings. Then, I fine-tune the power through the control panel, ensuring it matches the material thickness and desired cut depth. By running a quick test cut, I confirm the adjustments deliver clean, precise results. If needed, I make minor tweaks based on the output to ensure accuracy and efficiency.

Implementing a Consistent Cutting Procedure

To implement a consistent cutting procedure, I start by ensuring the material is properly secured to prevent movement during the process. Next, I verify that the laser focus is accurately aligned and double-check the cutting parameters, including speed and power, against the material specifications. I run a test cut on a scrap piece to validate these settings and make any necessary adjustments. Once everything is fine-tuned, I proceed with the actual cut, monitoring the process closely to maintain precision and consistency.

How to Maintain the Power of Fiber Laser Cutting?

To maintain the power of fiber laser cutting, it is essential to follow these key practices:

- Clean and Inspect Optical Components Regularly – Ensure lenses and mirrors are free from dirt or debris, which can affect beam quality and cutting efficiency. Use proper cleaning tools and techniques recommended by the manufacturer.

- Monitor Cooling Systems – Keep the cooling system in optimal condition to prevent overheating, which can degrade performance. Check coolant levels and replace as needed.

- Perform Software and Firmware Updates – Regularly update the system software and firmware to incorporate improvements and maintain compatibility with newer technologies.

- Schedule Routine Maintenance – Follow the manufacturer’s recommended maintenance schedule to address wear and tear, replace consumables, and prevent potential faults.

- Ensure Proper Machine Calibration – Periodically calibrate the machine to maintain cutting precision and consistent power output.

Adhering to these practices will enhance the system’s longevity and ensure reliable and precise performance over time.

Routine Checks and Calibration of Equipment

Regular routine checks and proper calibration are fundamental aspects of maintaining equipment efficiency and ensuring operational accuracy. For instance, performing daily visual inspections can help identify signs of wear, such as loose components, misaligned parts, or fluid leaks, which could escalate into significant malfunctions if left unnoticed. Additionally, conducting weekly inspections using diagnostic tools can pinpoint internal issues, such as electrical anomalies or software irregularities, ensuring that minor problems are addressed before they impact performance.

Calibration plays a particularly vital role in industries reliant on precision machinery, such as manufacturing or medical technology. Studies indicate that inadequate calibration may cause errors in measurements, reducing accuracy by as much as 30%. To counteract this, prioritize scheduled calibration cycles, aligning with industry standards or equipment-specific guidelines. Modern technologies, such as automated calibration systems, now enable faster and more reliable adjustments, reducing downtime while ensuring consistent performance. By combining thorough routine checks with proactive calibration measures, organizations can extend equipment lifespan, lower repair costs, and improve overall productivity.

Ensuring Stable Power Levels for Laser Cutting Machines

Maintaining stable power levels is a critical aspect of optimizing the performance and precision of laser cutting machines. Fluctuations in power can lead to uneven cuts, reduced material integrity, and increased operational inefficiency. Studies have shown that even minor inconsistencies in power output—often as little as 5%—can significantly impact edge quality and lead to material waste. To avoid such issues, many manufacturers recommend power monitoring systems that offer real-time data tracking and automated adjustments.

For instance, advanced power control solutions integrate sensors that continuously measure and balance the laser’s power output across cutting sessions, ensuring reliable performance. Additionally, these systems often provide detailed diagnostic feedback, enabling operators to promptly address potential power supply problems or identify components in need of maintenance. Research suggests that incorporating such systems can increase cutting accuracy by up to 20% while reducing energy consumption by approximately 15%.

Overall, investing in robust power stabilization mechanisms not only enhances the quality of cuts but also contributes to the equipment’s long-term durability, translating into lower operational costs and a more sustainable workflow.

Training Operators to Manage Laser Cutting Systems Efficiently

Properly training operators to manage laser cutting systems is crucial for optimizing performance, minimizing downtime, and ensuring safety. A well-structured training program should combine theoretical knowledge with hands-on experience, enabling operators to comprehend both the principles of laser technology and the practical skills required to maintain precision.

1. Understanding System Components and Operation

Operators should first gain a comprehensive understanding of the laser cutting system’s core components, such as the laser source, cutting head, motion control system, and power stabilization technology. Familiarity with how these parts interact allows operators to troubleshoot and address minor issues efficiently. For instance, when operators can identify and recalibrate misaligned optics, production interruptions may be reduced by up to 30%.

2. Importance of Maintenance Protocols

Training should emphasize the significance of routine maintenance to extend the machine’s lifespan and reduce equipment failure rates. A well-maintained laser system can operate at peak efficiency for extended periods. Studies indicate that implementing guided maintenance protocols can decrease unplanned downtime by 25% and improve overall productivity.

3. Skill Development in Material Handling

Material type, thickness, and reflectivity heavily influence the precision of laser cutting. Operators must be trained to adapt parameters such as laser power, speed, and focus based on the material being processed. For example, adjusting the focus when cutting reflective metals has been shown to improve cut accuracy and reduce material waste by nearly 15%.

4. Safety Education and Compliance

Laser cutting systems involve high-powered beams and complex machinery, making safety a paramount concern. Operators should be trained on proper safety procedures, including the use of personal protective equipment (PPE), system interlock functions, and emergency shutdown protocols. Comprehensive safety training has the potential to decrease workplace accidents by up to 40%, fostering a safer working environment.

5. Utilizing Digital Tools and Monitoring

Operators should also be familiar with software tools designed for monitoring and diagnostics. Many modern systems incorporate real-time data collection, allowing operators to track performance metrics like beam intensity, cutting speed, and gas usage. Harnessing this data effectively can lead to a 20% increase in cutting efficiency while lowering overall energy costs.

By investing in a structured training program that addresses these areas, operators can maximize the capabilities of laser cutting systems, ensuring high-quality output, lower operational costs, and a safer work environment.

Reference Sources

-

Energy Efficiency and Cut-Quality Improvement During Fiber Laser Cutting (2022)1:

- Focus: Investigated the impact of processing parameters on energy efficiency and cut quality for aluminum alloys.

- Key Findings: High thermal conductivity of aluminum alloys leads to energy loss and degraded cut quality. Optimizing parameters like laser power, cutting speed, and assist gas pressure improved energy efficiency by up to 200% and reduced surface roughness.

- Methodology: Used grey relational analysis (GRA) to optimize parameters and analyzed the effects on mechanical properties and surface quality.

-

Optical Cutting Interruption Sensor for Fiber Lasers (2015)2:

- Focus: Developed a sensor system to detect cutting interruptions in fiber laser machines.

- Key Findings: The system successfully identified cutting interruptions caused by power drops or parameter changes with a high detection rate (96.4% accuracy). It highlighted the importance of monitoring systems for maintaining cutting quality.

- Methodology: Combined Si and InGaAs diodes to monitor thermal radiation and used signal processing to detect interruptions.

-

Innovations in High Power Fiber Laser Applications (2012)3:

- Focus: Explored advancements in high-power fiber lasers for cutting and welding applications.

- Key Findings: High beam quality and optimized feedback mechanisms are critical for maintaining cutting efficiency and preventing power-related issues.

- Methodology: Discussed the integration of scanner-based remote cutting systems and their impact on cutting speed and quality.

- Top Fiber Laser Marking Machine Supplier and Manufacturers in China

Frequently Asked Questions (FAQs)

Q: What are the common reasons for power drop of a cutting machine?

A: Common reasons for power drop of a cutting machine include misalignment of laser optics, contamination of optical components, degradation of the laser source, and incorrect machine settings. Regular maintenance and proper calibration can help in mitigating these issues.

Q: How can the power drop of a fiber laser cutter affect the cutting quality and efficiency?

A: The power drop of a fiber laser cutter can lead to poor cutting quality and efficiency, resulting in rough or incomplete cuts. This can also increase production time and material wastage, impacting overall operational efficiency.

Q: What are some effective solutions to address the power reduction of the fiber laser?

A: Effective solutions to address power reduction of the fiber laser involve regular maintenance of laser optics, ensuring clean and aligned optical components, updating machine settings, and checking for any damage to the laser source.

Q: How does the power and cutting speed relate to the output power of the laser?

A: The power and cutting speed are directly related to the output power of the laser. Higher power allows for faster cutting speeds and better quality cuts, while a reduction in power can slow down the process and degrade the cut quality.

Q: What maintenance practices can prevent power drop in modern fiber laser cutting machines?

A: Regular cleaning of optical components, proper machine calibration, timely replacement of worn-out parts, and routine inspections can prevent power drop in modern fiber laser cutting machines, maintaining optimal performance.

Q: How can machine settings contribute to the cutter power drop?

A: Incorrect machine settings can lead to inefficient power usage, causing a cutter power drop. Ensuring that the settings are optimized for the specific material and thickness can help maintain consistent power levels and cutting efficiency.

Q: Can damage to the laser cause a reduction of the fiber laser power?

A: Yes, damage to the laser can cause a reduction of the fiber laser power. Physical damage, overheating, or electrical issues can degrade the laser’s performance, leading to a drop in output power.

Q: Why is it important to monitor the power drop of a fiber laser cutter regularly?

A: Monitoring the power drop of a fiber laser cutter is crucial to maintain cutting quality and efficiency. Early detection of power issues allows for timely interventions, preventing prolonged downtime and potential damage to the equipment.

Q: What role do laser optics play in preventing the power drop of cutting machines?

A: Laser optics play a crucial role in focusing and directing the laser beam. Clean and properly aligned optics ensure maximum transmission of the laser power, preventing power drop and maintaining cutting accuracy.

- Unlocking the Power:Advantages of Pulsed Laser Technology

- CNC Router vs CNC Mill: Understanding the Key Differences Between These Popular CNC Machines

- Laser Marking vs. Engraving vs. Etching: Understanding the Key Differences and Applications

- Waterjet Vs. Laser Cutting: The Ultimate Guide to Metal Cutting Services