When cleaning valuable equipment or surfaces, removing rust or grime can be challenging and require a lot of effort. Many methods make cleaning easier; however, most fail to achieve the required level of restoration and leave behind unpolished damage. Pulse laser cleaning machines are designed with precision in mind: they cut with some of the most advanced technology available today. Renting one of these sophisticated machines enables instantaneous access to superior technology while saving much money. This article explores why these devices are becoming the preferred choice of renters, professionals, and DIY enthusiasts. Expect no less than total ease and unrivaled proficiency during cleaning projects—this innovative machine effortlessly delivers.

What is a Laser Cleaning Machine, and How Does it Work?

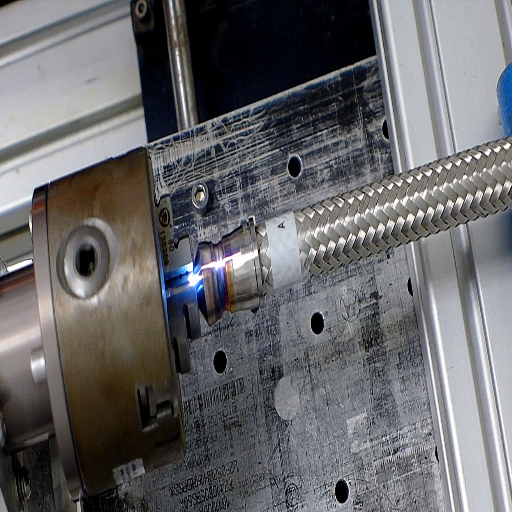

This powerful cleaning tool uses ultraviolet laser beams to rid surfaces of rust, grease, and other contaminants. The material is bombarded with laser light, which causes unwanted layers to be broken down or melted. The process is extremely efficient and accurate, which means that it can be applied in industries that require high levels of precision, including aerospace, automotive, manufacturing, and many others.

These machines are appreciated for their efficiency, ability to clean detailed areas, and lesser usage of chemicals and abrasives.

Understanding the Laser Technology Behind Cleaning

The laser cleaning process is based on laser ablation and utilizes high-energy laser pulses which bombard the surface material. Energy from the laser demolishes contaminants, such as rust or paint, resulting in vaporization or degradation into cleaning particulate matter that is simple to eliminate. Cleaning applications utilize fiber or pulsed lasers due to their precision and energy efficiency.

The pulse duration of the laser and its wavelength are crucial in laser cleaning technology. Providing pulses in the range of nanoseconds to picoseconds is controlled energy delivery, which reduces the risk of damaging the base surface. A case in point is fiber lasers with 1064 nm wavelengths, which are popularly used in metal cleaning since they do not inflict damage on the substrate and only affect designated contaminant layers.

As per the latest informational statistics from industries, laser cleaning systems can achieve material removal rates of 15 square meters per hour, varying based on the material and thickness of the contaminant layer. Moreover, fiber lasers, with a lifespan of more than 50,000 hours of operation, are considered economically and environmentally efficient for industries. The technology’s accuracy is also proved by cleaning turbine blades or other delicate electronic parts, which is a testament to its versatility.

This revolutionary strategy advances operational productivity while striving towards environmental goals by minimizing chemicals and abrasive substances to environmentally damaging levels. Major aerospace, automotive, and energy manufacturers are now adopting laser cleaning as a standard practice due to its unparalleled performance and sustainability features.

How the Pulse Laser Works for Rust Removal

Pulse laser technology effectively removes rust by applying high-intensity and short-duration pulses of laser light to the surface of the material. These pulses, when applied to the rust, contain such a tremendous amount of heat energy that they cause the rust to either vaporize or ablate without touching the underlying metal surface. This treatment is very accurate because the surface subjected to this treatment is not damaged in any way.

Pulse lasers generate energy in bursts, varying from a few nanoseconds to several picoseconds. The duration of the pulse is very short, so the diffusion of heat to the surrounding areas is minimized. This also means that the metal itself is thermally undamaged. In addition, overheating of the beam can, therefore, only be used on the rust and other coatings that are not needed on the surface, making the technique very delicate or intricate.

Recent improvements with the most modern pulse lasers have radically increased the efficiency of rust removal to rates of 10 square meters per hour, based on the nature and thickness of the corrosion. In addition to this, modern lasers are applicable to many types of materials, such as steel, aluminum, and even alloys, which brings greater versatility across industries.

Another advantage is that this technique is friendly to the environment. The removal of rust using pulse lasers requires no chemical solvents or abrasive materials and has no secondary waste handling. This greatly diminishes operational costs and environmental pollution, alongside trimming waste streams. Pulse lasers are pioneering automation-driven maintenance procedures that aid in the processing of rust in the automotive, aerospace, and manufacturing industries.

Further research still emphasizes its ability to assist in assuring productivity effectiveness while preserving the surface’s condition, strongly reinforcing its importance in current maintenance practices. The confluence of these attributes makes pulse lasers preferred in commercial and industrial-grade applications for rust removal.

Applications of Laser Cleaning Equipment in Various Industries

- Automotive Industry

Laser cleaning is used in the automotive world to remove paint, rust, and grease from engine parts, gears, and molds. It is less abrasive, ensuring delicate parts remain intact while also performing much better than chemicals, which pose a threat to the environment. In comparison to traditional means, an increase in production efficiency of up to 40% is observed with laser cleaning.

- Aerospace Industry

Laser cleaning aids the aerospace industry with preparation for maintenance and deep cleaning of aircraft component surfaces. Under laser cleaning, turbine blades, fuselages, and metallic joints are free from contaminants, coatings, and oxides. The procedure is non-abrasive and leaves no residue, increasing the safety and life span of critical components and meeting the demands of the aerospace industry.

- Marine Industry

Ship maintenance typically involves dealing with biofouling and tough corrosion on metal surfaces. Strain from traditional abrasive means is reduced, helping extend the lifespan of components making laser cleaning ideal in protecting from contravening marine pollution legislation.

- Manufacturing Industry

In industrial manufacturing, laser cleaning technology is beneficial for molding, treating surfaces, and preparing welds. It provides enhanced cleaning quality, precision, and consistency, upholding uniformity in performing elaborate tasks. Recent studies indicate 30% less downtime due to faster cleaning practices.

- Cultural Heritage Restoration

The process of cleaning lasers is becoming more popular when restoring historical monuments and ancient sculptures. Because of its precision, the laser can remove dirt, pollutants, or any biological growth from the surface without causing abrasion to the material’s layer. Because culture has priceless heritage treasures, the cleaning laser helps to preserve cultural inheritance.

- Laser Cleaning

The electronics industry uses cleaning lasers for ultrasound grading, including but not limited to cleaning the cracks on microbiological laser systems. Without heat damaging sensitive materials, the strong accuracy requirements for cleaning at an industrial level are easily met. Because of these varied applications, cleaning laser devices are adaptable and useful across multiple industries.

From this information, we can state that laser cleaning devices vastly improve maintenance processes while respecting the environment and operational standards.

Why Choose Laser Rust Removal Over Traditional Methods?

Compared with traditional methods, laser rust removal stands out for its precision, efficiency, and eco-friendliness. Laser cleaning, for example, offers effective rust removal without any contact with the base material, maintaining the integrity of the base material. Unlike chemical treatments or abrasive sandblasting, laser cleaning produces rust with minimum waste and no chemicals and is completely safe for the worker and the environment. Also, secure and adaptable, laser rust removal delivers consistency across various surfaces while needing minimum maintenance, making it a sustainable solution.

Advantages of Laser Cleaning Compared to Chemical Solutions

- Eco-Friendly

Laser cleaning uses no harsh chemicals, making it clean. Unlike chemical cleaning methods, it generates very little waste, mainly dust particles that can be easily filtered and disposed of. This helps to avoid contamination with chemicals and reduces the need for costly hazardous waste disposal systems.

- Material Non-Destructive

Base materials may be weakened or eroded during the cleaning process due to chemical exposures. As a non-contact method, laser cleaning does not alter the underlying surface, allowing the material to be preserved.

- Cost Efficiency

The installation of laser cleaning equipment eliminates recurring costs for purchasing, storing, and disposing of chemicals and labor for cleaning. While operating the laser cleaning equipment may require an initial investment, long-term savings are noticeable.

- Safety of the Operator

Chemicals used for cleaning pose toxic fumes and chemical burn risks to operators. Burns and exposure can be avoided with laser cleaning; controls are put in place to limit health risks to operators, ensuring minimal exposure to harmful substances.

- Precision

Only specific target areas are affected during laser cleaning, ensuring no additional regions are impacted. Chemical solutions are often broad in scope, making precision difficult to achieve.

Lasers can be tailored to clean various surfaces, from metals and ceramics to fragile parts, without damage, showcasing multifunctionality. This versatility astonishingly outweighs the limited scope of chemical solutions needing various mixtures or formulations for different uses.

Compared to other methods, soaking, scrubbing, or multiple applications of chemicals take longer for cleaning processes. Given the importance of time in many sectors, this is beneficial because chemical cleaning is more time-consuming than laser rust removal.

Chemical solutions use replenishing and complicated application equipment and require maintenance. On the other hand, laser cleaning systems are incredibly durable and need less care, maintaining dependability over the years.

By addressing these drawbacks, laser cleaning has emerged as the go-to solution in various sectors, expertly proving itself as robust, sustainable, and cost-effective against traditional cleansing methods involving chemicals.

Cost-Effectiveness of Industrial Laser Cleaning Solutions

Economic benefits arising from industrial laser cleaning technologies stem from offsetting sustained operational costs. Traditional cleaning practices often incur chemical solvent expenses, specialized disposal fees, and restocking. However, unlike laser cleaning systems, which operate with relatively high overheads, requiring only electricity and some yardstick capital, chemical combustion is nonstop indispensable for space cleaning.

Another substantial savings purchase comes with the sustainment and resistance of the lasers used for cleaning. High-grade, easy-to-use laser systems normally eastern without service for maintenance plus ulgoterm operations of more than fifty thousand hours. With such quantities of sustainable mass energy, the costs from laser cleaners are sustained while helping increase clean turns profits. On top of that, time that goes into and follows before and during any washing necessary is saved because no precedent suffering clean, toxic substance out cleaning, or any other downtimes are needed, making everything smooth, thus raising profit.

Industry analysis states that nearly seventy percent shed off of maintenance and cleaning in five years using such industrial laser cleaning systems. These numbers spike in aerospace, automotive, and heavy manufacturing industries that require high-grading internal and external surface cleaning for undisrupted optimal operation and reduced robot cleaning scheduling gaps. Also cut off is money spent for hand-guided processes with high-performing automated laser-guided positioning systems that do the work, removing the need for employment.

The implementation of industrial laser cleaning optimizes surface preparation and restoration operations in an environmentally preferable manner and offers significant economic savings compared to water—or chemical-based methods. The dual nature of cost savings and environmentally friendly efficacy makes laser cleaning a preferred choice for modern industrial applications.

Environmental Benefits of Professional Laser Cleaning

Prospective Professional laser cleaners have an outstanding advantage when it comes to the environment compared to other methods. One of the most important advantages is the use of hazardous and toxic chemicals and solvents typically employed in traditional methods such as chemical stripping and abrasive blasting. These types of procedures generate poisonous waste that must be meticulously treated to prevent an environmental disaster. In contrast, laser cleaning is a dry process that reduces waste to the barest minimum, as it uses laser energy to remove contaminants without introducing secondary pollutants.

In addition, cleaning using lasers consumes less water, which is crucial for Industries that still use water as a primary raw material. For instance, some studies show that using lasers in cleaning can result in up to 95% reduction of water used compared to jet water cleaning. This conservation is constructive in preserving natural resources and minimizes water pollution through chemicals.

Moreover, laser cleaning is precise and energy efficient, removing only the contaminated or oxidized surface layers while leaving the underlying material intact. This enhances the durability of the components and reduces material waste, ultimately conserving resources over time. Laser cleaning is a step toward contemporary sustainability objectives by mitigating the ecological consequences throughout all stages of the cleaning process, marking it as an advanced solution for industries striving to protect the environment.

What to Consider When Renting a Pulse Laser Cleaning Machine?

Every time you rent a pulse laser cleaning machine, remember to keep these points in mind:

- Power Requirements—As in every stage, make sure the machine pulse power level corresponds to the cleaning needs, whether it is delicate surfaces or heavy-duty cleaning.

- Material Compatibility—Ensure that the machine is tailored to suit the materials you want to use for cleaning. These can include metal, stone, glass, etc.

- Ease of Use – The setup should be straightforward and intuitive, saving time and considerably minimizing the learner’s curve.

- Safety Features—Make sure that the machine has the proper safety features and mechanisms, such as protective covers and safety devices, to ensure its safe operation.

- Rental Terms – Ensure you review the agreement, especially the duration, costs, rental terms, and support services such as maintenance or technical services.

- Besides these, if mobility is essential, check the item’s weight and size to ensure that it is easy to port.

In the end, ensuring these factors are considered, the machine will effectively meet your needs.

Key Features of Laser Cleaning Machines to Look For

- Precision and Accuracy – The majority of modern laser cleaning machines utilize state-of-the-art technology with exceptional precision, which allows them to clean specific areas while avoiding damage to the surrounding areas. For instance, fiber laser systems are renowned for their accurate and precise cleaning capabilities, consistently achieving the desired results on delicate or intricate surfaces.

- Non-Contact Cleaning – As previously mentioned, laser cleaning is a non-contact approach, which means there is no physical engagement with the cleaning surface. This minimizes the chances of wear or damage to sensitive materials such as historic artifacts, aerospace parts, or surfaces made of thin metals.

- Material Versatility—Advanced laser cleaning systems are sophisticated and versatile enough to process a wide range of contaminants on different materials, including metals, stone, glass, and even composites. For example, these systems can effectively remove rust, oil, paint, or industrial residue.

- Efficiency and Speed—Many state-of-the-art laser cleaning machines come equipped with high processing speeds, which would be preferable for industries that value precision in meeting deadlines. Some systems can clean several square meters of area in an hour, unlike traditional cleaning methods, significantly reducing downtime.

- Eco-friendliness- About minimizing the use of chemical solvents, laser cleaning is remarkably eco-friendly because it generates virtually no waste. The contaminants removed, which include dust and other particles, are clean and easily manageable. They do not leave any detrimental by-products.

- Adjustable Settings– Another essential characteristic is the ability to adjust and optimize laser settings, including power, pulse length, and working distance for specialized cleaning tasks. This adjustability enables customization concerning the different levels of cleaning that are needed.

- Durability and Maintenance—Like other sophisticated laser systems, high-quality ones are usually made for tougher industrial settings, which translates into lower maintenance due to the system’s strain and lower consumable use.

- Integrated Safety Measures – The finest machines have additional protection such as enclosures, disable enclosure access, automatic shutoff mechanisms, and safe navigation, enhancing the safety of both users and passers-by while operating the machine.

- Long-Term Cost Efficiency—Although the fixed expense of investment is relatively high, laser cleaning machines lower costs in the long run by removing recurring expenses on abrasives, solvents, and chemicals and reducing the time needed for cleaning tasks. Moreover, they sustain these savings due to the limited need for repairs over time.

When selecting a laser cleaning machine, these features need to be very closely examined to achieve optimal results and fulfillment while achieving compatibility with specific application preferences.

Understanding Rental Agreements for Laser Equipment

For businesses that require advanced capabilities without the need to “own” the equipment outright, rental agreements for laser equipment often present an economically viable alternative solution. These agreements usually stipulate specific terms for the equipment’s rental period, maintenance, and usage cap. According to industry statistics, short-term rentals constitute a sizable volume of agreements in the industrial and restoration contexts, as they provide an advantage in approach for project-based work.

When reviewing the rental agreement, pay extra attention to the maintenance and repair procedures and any associated expenses. In most cases, providers offer maintenance services that will lower downtime and maximize business productivity. On the downside, damage costs may apply over and above standard wear and tear. Some agreements impose penalties for operational hour limits set on the laser, for example.

The availability of support and training is another factor of equal importance and one that a client needs to consider. Many rental companies that deal with laser equipment extend the offer to train users on how to operate the equipment as part of the contract, which is highly beneficial not only for effective use of the machinery but also from a safety perspective. In addition, technical support is sometimes offered on an on-call basis, eliminating many problems when working with complicated applications.

Rental pricing models differ from one provider to another and could include daily, weekly, or monthly rates based on the use period and the machine’s make. Information available indicates the cost of renting high-power laser systems is around $1000 to $3000 per week, while smaller, less powerful systems may cost $500 to $1000 per week. Renting these systems often lowers pricing when long-term contracts are negotiated for extended work projects.

By evaluating these factors, companies can devise rental contracts that meet their operational requirements, thereby enhancing productivity while minimizing costs.

Choosing Between Fiber Laser and Other Types of Laser Machines

When comparing fiber with other laser technologies like CO2 or crystal lasers (Nd: YANG), it is critical to evaluate them based on performance, cost, and specific application needs.

1. Performance and Efficiency

Fiber lasers are famous for their high energy efficiency; they usually convert more than 30% of electric energy into laser output, much more than the 10% efficiency typical of CO2 lasers. Fiber lasers also have a higher M² value beam quality, greater than 1.1, compared with CO2 lasers M² of about 2 to 3. This results in more accurate lasers for cutting, engraving, or welding, ideal for intricate tasks with delicate detailing.

2. Material Compatibility

Fiber lasers are superior in laser machining metals like stainless steel, aluminum, copper, and brass because of their shorter wavelengths (usually 1064 nm). CO2 lasers are more appropriate for non-metals like wood, acrylic, glass, and plastics. Businesses that have projects heavy on metal need to prioritize fiber lasers, while those with versatile material projects should consider CO2 lasers.

3. Durability and Maintenance

The lack of moving parts gives fiber lasers a clear advantage in durability. Their beam transmission through optical fibers reduces wear and tear over time. Operating with lower maintenance costs and higher maintenance, CO2 lasers experience frequent servicing due to the degrading mirrors, lenses, and tubes used. Fiber laser systems boast over 100,000 hours of operational lifespans, exhibiting long-term dependability.

4. Speed and Productivity

About thin materials, fiber lasers cut faster than CO2 lasers by as much as threefold. Time-efficient industries rejoice. For example, when cutting 1mm stainless steel, fiber lasers offer superiorous speeds of 20 meters per minute compared to CO2 lasers 6-8 meters per minute.

5. Cost Considerations

Businesses with projected savings that outweigh upfront investment will. Though initial spending on fiber laser machines is high, ranging between $40,000 to $ 100,000, with their cutting CO2 lasers besting $30,000, their energy efficiency and diminished long-term maintenance costs will be beneficial in the long run.”

6. Environmental Impact

Fiber lasers are more environmentally friendly due to their higher energy efficiency, minimal coolant, and lower cooling requirements. On the other hand, CO2 lasers have their norms of power consumption along with the need for water or some other form of coolant, which increases energy consumption.

7. Applications

Precision metal fabrication in aerospace, auto manufacturing, and other electronics industries utilize fiber lasers extensively. In contrast, because of their multifaceted application, CO2 lasers are more common in non-metal industries such as woodworking, sign-making, and artistic engraving.

Conclusion

As with any tool, deciding which type of laser to use heavily depends on the operational requirements. Fiber lasers are the preferred option for metal processing that requires precision, speed, and durability. Meanwhile, CO2 lasers would be more beneficial if the intent is to use a diverse range of materials. Evaluating these factors will help businesses balance performance, cost, and value in the long run.

How to Use a Laser Cleaner Effectively?

Proper utilization of a laser cleaner aids in advancing industrial practices related to surface preparation and contaminant removal. This modern technology solves myriad cleaning issues, from rust removal to paint stripping in an exact, green manner. If you are new to laser cleaning or looking to improve your current processes, understanding the techniques and best practices is essential to achieve efficiency and results. This article will share key insights with tips and stepwise instructions for mastering laser cleaning so that users can optimally utilize this unparalleled advancement.

Best Practices for Laser Rust Removal

Technological advancements in laser cleaners offer new opportunities for best practices in laser rust removal. This professional, hassle-free approach, coupled with eco-friendly and economical benefits, greatly increases the value of the target assets. The use of lasers eliminates the risk of damage to the substrate. Including the best practices listed below will ensure you obtain the best-required results.

- Setting Customization

Without the correct laser power, frequency, and application matched together, achieving rust removal via laser will not succeed. Optimistic results can be observed at lower power settings on more fragile surfaces, but higher power settings on thick, rusted layers work best. Approximately 1,064nm is observed to be most efficient in industrial settings with fiber lasers and is often preferred for its accuracy and speed.

- Inspecting the Surface

Analyzing the material type and the extent of rust before commencing work is crucial. Careful attention to detail allows for the determination of base materials, guaranteeing that delicate materials such as alloys or aluminum will not be harmed and assuring good results.

- Optimal Working Distance

Correct positioning can increase the efficiency of a laser’s power, anywhere between 150 mm and 300 mm, depending on the laser system in use. Many modern equipment models have built-in sensors or guides to maintain constant distance, also called “spacers,” making maintaining these distances bearable.

- Personal Protective Equipment (PPE)

As with any process involving lasers, PPE should be the primary focus. Protective glasses and adequate exhaust systems should be used to prevent inhaling rust and debris particles.

- Beam Speed and Path Monitoring

In terms of cleaning, laser equipment should be rated for high speeds and excel at following pre-programmed paths to provide a uniform finish. Focusing on target areas for longer periods of time, also known as dwell time, may cause overexposure that results in a non-uniform cleaning border. Accuracy is especially crucial for industrial projects that use automated laser cleaning equipment heads.

- Environmental Issues

Compared to other methods that use cleaning adhesives, laser cleaning is more efficient in waste production. The primary concern with these systems is ensuring that rust particles and dust produced during the cleaning process are contained with adequate filtration systems to reduce environmental impact.

- Cost and Efficiency Analysis

Current research indicates that the expenditure required for laser rust removal is offset by saved operational costs in the long term, as no chemicals or abrasive tools are needed. The inherent non-contact nature of the process preserves equipment, reducing wear, resulting in superior long-term operational efficiency.

Integrating these practices into your laser rust removal procedure will enhance precision, safety, and efficiency while reducing costs for the high-quality outcomes you deliver.

Safety Measures While Operating Laser Cleaning Equipment

Adhering to safety protocols helps prevent risks to the operator and protects the equipment while using laser cleaning devices. Here are some essential measures to follow:

Put on the Right Personal Protective Equipment (PPE): Protecting one’s eyes with laser safety goggles is a prerequisite for preventing exposure to the dangers of laser radiation. The appropriate goggles must be selected based on the laser’s wavelength and power density. Moreover, operators must put on gloves and protective garments to minimize the risk of suffering from burns or skin exposure.

Ensure Ventilation: During the laser rust cleaning process, particulate and fume emissions undergo disaggregation. The use of fume extractors and proper ventilation help prevent potentially dangerous inhalation of substances. Studies show that properly designed air filtration systems can mitigate exposure to dangerous particulate matter by more than ninety percent.

Familiarize yourself with the laser’s classification: Most laser cleaning devices are classified as Class 4 lasers. This means these devices have sufficient power to inflict severe damage to the skin or eyes. Hence, such systems must be thoroughly trained to operate. Moreover, proper work zone signs should be installed to control user access, ensuring only trained personnel can enter.

Implement Control Measures: Isolate the laser beam with enclosures or barriers. Remote operations minimize direct contact with the laser, adding safety.

Regular Maintenance Inspections: Periodic checks of the laser apparatus are vital for proper functioning; system maintenance improves performance and reduces malfunction and safety hazard risks.

Emergency Preparedness: These operators need comprehensive training in emergency procedures, such as instantly switching off the laser when there is unintentional exposure to harmful equipment or malfunctioning systems. Placing a fire extinguisher nearby is also wise since powerful lasers may ignite flammable substances.

Following these measures allows operators to work within a reasonably safe environment while significantly increasing the prospects and risks associated with laser cleaning equipment.

Common Mistakes to Avoid When Using a Laser Cleaning Machine

If not performed with utmost caution, using a laser cleaning machine can lead to errors, risks, inefficiencies, or damaging results. Avoiding these errors could mitigate the risks while enhancing the performance’s reliability.

- Disregarding Calibration

If the calibration is not done correctly, it could damage the surface or provide inconsistent cleaning results. Different materials and their conditions require specific laser power, frequency, and focal distance adjustments. For example, high-power settings can damage sensitive surfaces by etching or warping them.

- Skipping PPE

The procedure’s most serious oversights involve the lack of appropriate personal protective equipment (PPE) and other safety measures. Operators must wear approved safety goggles made for the specific laser wavelength in use and cover any surrounding parts that could reflect the laser.

- Incorrect Material Identification

Identifying the wrong material before the cleaning process can lead to undesired damage to the material or inefficient cleaning. Softer materials tend to require lower energy settings, while tougher ones could be blasted at higher intensities without resulting in damage. It is essential to examine the material before jumping into the cleaning procedure.

- Overlooking Maintenance

As with all machines, maintenance routines like lens cleaning and system inspections are necessary to sustainthe operation of the laser cleaning machines. Maintenance neglect leads to inferior laser quality and more significant expenses on repairs. Studies show that preventative maintenance increases the lifespan of equipment by up to 25%.

- Exceeding Operational Limits

Excessively using the machine beyond its recommended duty cycle will cause overheating and wear out critical components. Obeying all operational parameters will prevent extremely expensive repairs and downtime.

- Ignoring Relevant External Factors

Cleaning laser machines should not be operated in unsuitable environments, such as areas that are extremely dusty or moist, as this poses severe safety inconveniences and degrades machine functionality. Enforcing a stable environment ensures optimal operations while decreasing the chances of equipment failure.

With proactive efforts to amend these listed common pitfalls, operators can drastically improve the performance and increase the lifespan of their machines. Success entails appropriate training alongside stringent adherence to planning and manufacturer guidelines.

What Are the Costs Associated with Laser Cleaning Machine Rentals?

The expenses of renting laser cleaning machines can differ drastically by model, power rating, and length of rental. Generally, most standard models cost 500-1500 dollars a day. Moving to a weekly or monthly rental may offer lower pricing on extended rentals. Other costs related to the rental, such as shipping, insurance, and training for operators, should also be evaluated. It is important to work with established rental providers to ensure comprehensive understanding around what is offered, determining exact quotation numbers becomes far more effortless.

Factors Influencing the Cost of Industrial Laser Rentals

For those looking at industrial laser rentals, understanding their callous cost augmentations, especially in budgeting scenarios, includes several factors.

- The Laser’s Genre

Differences in industrial laser types create a gap in the rental precision costing. Rentals of more powerful lasers, like fiber and CO2 lasers, are charged at much higher rates than those with lower-powered options available. For example, cutting-grade fiber lasers will be rented between $1,000 to $2,500 per day, depending on the capabilities and wattage. In contrast, older models and less powerful lasers are available at starting prices of $500.

- Period Of Rental

Renting industrial lasers long-term is encouraged since it helps save on costs. Daily rates are automatically reduced for longer durations, with many providers offering weekly or monthly discounted pricing. A one-month rental agreement with some providers could guarantee up to 30% savings compared to basic rates. This serves as an incentive for companies to modify their strategies for increased usage.

- Other Options And Features

The base operational cost of CAD complementary industrial lasers increases for those already equipped with controls. Custom software and other advanced features ensure the required cost effectiveness, with the industry stitching new Standards for precision. Enhanced productivity comes for band-aids between $200-$500 atop an already set rental with these additional features.

- Size and Output Requirements

The size and housing unit types of many devices tend to increase their rental cost due to their height, size, or energy []. For example, during heavy-duty cutting or welding jobs, lasers with more than 4kW of power are used, which makes them more expensive in comparison to the compact models employed for smaller undertakings.

- Shipping and Setup Costs

Transporting heavy laser equipment to your location will incur shipping charges that depend on the weight of the equipment and range between $100 and $500. Some rentals also offer professional inspection and adjustment services, which, for some reason, can cost between $250 to $1000 depending on the laser system’s complexity.

- Insurance and Liability

There is a possibility that rental insurance is made compulsory to reduce the rest of the damage. The severity of an insurance expenditure varies with the value of the machine but normally represents 5-10% of the machine’s rent price. Also, damages or mismanagement done liable need to be specified in the contract, and covering those has to be the services in the task.

- Required Training

Renting ensures safe and efficient use. With advanced equipment, businesses rely on training and many service providers that come on-site offer in-house training sessions, which are estimated at $200 to $500.

Taking these considerations into account prior to choosing a laser rental helps align business costs with project requirements while avoiding out-of-scope costs.

Budgeting for Laser Rust Removal Services

Understanding the pricing dynamics is paramount when planning a budget for laser rust removal. Costs vary primarily with the brand of laser used, the surface area, and the degree of rust complicated removal. For smaller areas, laser rust removal services are generally priced between fifty and hundred dollars per square foot. However, the per-square-foot cost may decrease for larger projects due to economies of scale.

The use of high-powered industrial lasers, which come with equipment rental fees starting at $500 a day or over $2,000 a week, for heavy-duty rust removal tasks has contributed to greater costs. In addition, operator fees add $50 to $100 per hour, depending on skill and geographical location.

Basic models start at $10,000 and cost over $100,000 for high-end, industrial-grade systems. Additional costs should also be included when considering long-term expenses pertaining to service rust removal for businesses that own laser-cutting equipment.

Once a comprehensive understanding of the above variables is developed, the business can allocate a realistic budget for laser rust-cutting services. A clear goal can then be set, aiming at sufficient fund allocation while avoiding unplanned expenses.

Comparing Costs Between Different Laser Cleaning Systems

There are some factors I always evaluate when evaluating the price of different laser cleaning systems. Lighter-duty applications are accommodated by affordable entry-level systems, which cost only $10,000. On the other hand, more demanding tasks with higher workloads require industrial-grade systems that can surpass $100,000. I also look at maintenance, operation, and energy expenditures since they are crucial in determining the total cost of ownership alongside the primary purchase price. I evaluate my specific project requirements and determine which systems offer the best price relative to their benefits for my cost-effective solution analysis.

Reference Sources

-

Mechanism and Application of Laser Cleaning: A Review1:

- Key Findings: This paper explores the mechanisms of laser cleaning, including dry cleaning, liquid-assisted cleaning, and shock wave cleaning. It highlights the influence of laser parameters (intensity, wavelength, pulse width) on cleaning efficiency. Applications span cultural relics, industrial metal surfaces, and semiconductors.

- Methodology: The study is based on experimental and theoretical research, analyzing the interaction between laser and materials to establish a cleaning process database.

-

Progress of Laser Cleaning Technology from the Perspective of Chinese Patents2:

- Key Findings: This review focuses on the growth of laser cleaning patents in China, emphasizing advancements in equipment, processes, and substrate-specific cleaning. It identifies trends in maintaining surface integrity and achieving functionalization.

- Methodology: A systematic analysis of patent applications over six years, covering substrate materials, coatings, and equipment innovations.

-

Conservation Laser Cleaning for Post-Disaster Wellbeing3:

- Key Findings: This study evaluates femtosecond pulse lasers for cleaning conservation materials, emphasizing their precision and minimal damage to substrates. It discusses the potential for waste reduction and improved post-disaster recovery.

- Methodology: Trials with femtosecond lasers on various materials, assessing effectiveness and substrate impact.

- Top Pulse Laser Cleaning Machines Manufacturer and Supplier in China

Frequently Asked Questions (FAQs)

Q: What is a laser rust removal machine, and how does it work?

A: A laser rust removal machine uses a focused beam of light to remove rust, oxidation, and paint from surfaces. The laser energy interacts with the contaminants, breaking them down without damaging the underlying material.

Q: Are laser rust removal machines environmentally friendly?

A: Yes, laser rust removal machines are environmentally friendly. They do not use harmful chemicals or abrasive materials. They rely on laser technology to perform effective cleaning, making them a sustainable option for rust and paint removal.

Q: Can I rent a laser cleaning service for my industrial project?

A: Yes, many companies offer equipment rentals for laser cleaning services. This allows you to access industrial laser cleaning systems without a large upfront investment in a laser rust removal machine.

Q: What types of materials can be cleaned with a handheld laser?

A: Handheld lasers can clean various materials, including metal, plastic, and wood. They are particularly effective for removing rust and paint from surfaces, making them versatile for different applications.

Q: How does the pulse frequency of a cleaning laser affect its effectiveness?

A: The pulse frequency of a cleaning laser determines how often the laser emits pulses of energy. A higher pulse frequency can lead to more effective cleaning as it allows quicker energy delivery to the surface, enhancing the removal of contaminants.

Q: What are the advantages of using fiber laser cleaners for weld cleaning?

A: Fiber laser cleaners offer several advantages for weld cleaning, including precision, speed, and minimal heat impact on surrounding areas. They can effectively remove oxidation and contaminants from welds without damaging the base material.

Q: Is a laser rust removal machine portable?

A: Yes, many laser rust removal machines are designed to be portable, making it easier to transport and use in various locations. Portable laser cleaning equipment is ideal for on-site rust and paint removal projects.

Q: Can a laser cutter or engraver also be used for rust removal?

A: While laser cutters and engravers are primarily designed for cutting and engraving materials, some models can be adapted for cleaning applications. However, dedicated laser rust removal machines are generally more effective for removing rust and paint.

Q: What is the difference between a cleaning machine laser rust removal and a traditional cleaning method?

A: A cleaning machine, laser rust removal, uses laser technology to remove contaminants without chemicals or abrasives, whereas traditional methods often rely on mechanical scrubbing or chemical solvents. Laser cleaning is typically faster, more precise, and less damaging to surfaces.