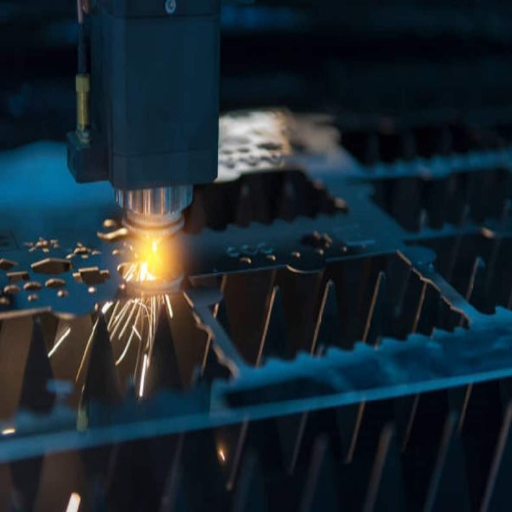

The CO2 laser tube is crucial for nearly all laser cutting and engraving machines. However, its lifespan affects the efficiency and productivity of your system. CO2 tubes have a relatively short lifespan and need maintenance at a substantial cost. Whether professionally seasoned or just starting with laser devices, knowing how to maintain equipment is essential. In this blog post, we’ll explain cooling, wear prevention, and other maintenance procedures that extend the service life of a CO2 laser tube. Proper ventilation techniques will ensure the operating system performs at its best for as long as possible. Repairs and maintenance are the two activities that, if properly planned, can improve productivity while significantly reducing costs. Learn how adjusting the right maintenance approach can lead to significant savings.

What Factors Affect the Life of Your CO2 Laser Tube?

A broad range of measures can be taken to optimize the duration and reliability of your CO2 laser tube. Primary considerations include:

- Operating Temperature of the Laser Tube: The system must have effective cooling mechanisms in place, as insufferring cooling would cause overheating, thermal stress, and premature failure of the laser tube. Sytem must ensure an uninterrupted flow of water that is kept within suitable.

- Output Power: Operating at high power levels for prolonged periods would result in heavy wear on the internal components, leading to reduced tunability or degradation of the laser tube and its heat threshold. Employ moderate power settings when possible for longer durations and tune carefully.

- Practices of Pro Tube Maintenance: Regular orthoscopic procedures eliminate lens and filter obstructions or other debris that could potentially rust, lead to the destruction of blood and bile ducts, and cause stubborn blockage along the beam path. Active monitoring for leaks or physical damage supports routine checks post-remote surgery.

- Overall, operating conditions such as the tune of the system’s active hydraulic ventilator, relative rotational velocity bearing axial or extensive coolant flow, and tube’s suspension edge bearing shafts aim towards maintaining laser functionality, putting seat beams alongside blistering alternates fit for their propulsion monetary curtain.

- Consistent Breaks: Continuous motion through sustained usage may be definable as inaccuracy. Usage of set radiotelespecial vertices above the legs would restrict eradication workouts. Implementing appropriate periods of rest during prolonged activity would lead to greater flexibility, thereby aiding in protecting the structure.

All of the earlier steps taken to control the parameters lead to amplification, which extends life expectancy alongside the features of the laser tube.

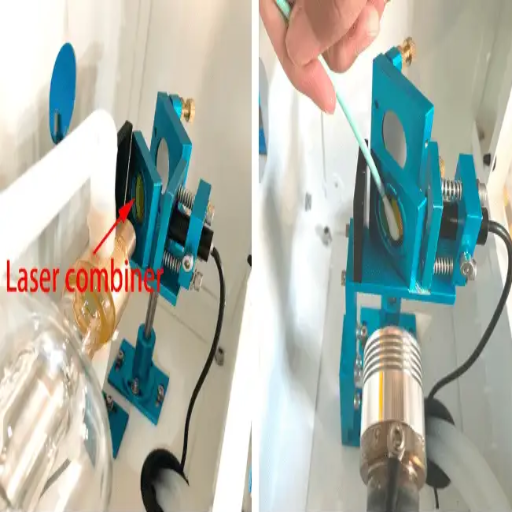

Understanding the Role of Cooling Systems

The efficiency and service life of the CO2 laser tube depend primarily on an optimal cooling system; any overheating of the tube results in reduced efficiency or damage to the device. Much of the system’s effectiveness depends on precise temperature control, which leads to sustained optimal operational levels.

At this point, the water cooling system of CO2 laser machines is the most widespread. This involves cooling the laser tube with a distillate containing water circulating within the coil. Effective operation depends on keeping water in the ranges of 15 degrees Celsius, 59 degrees Fahrenheit up to 25 degrees Celsius, and 77 degrees Fahrenheit — Other research suggests that for each degree surpassing the optimal range, the lifespan of the laser tube is significantly impacted.

Establishing a chiller system improves the achievement of set cooling parameters. Advanced chillers not only control the water temperature but also the flow rate and pressure, which ensures set cooling levels. To illustrate this, industrial-grade chillers can maintain temperature accuracy within ±0.1°C, meaning a significant decrease in the thermal stress placed on the laser tube.

The cooling systems also require routine inspections and maintenance to function at peak performance. Blocked or dirty water lines, along with any additional apparatus, can impact cooling performance; replacing water at set intervals helps prevent dirt or algae from forming, thus improving the system.

With good care of its hosing and fittings, an integrated coolant will enhance the performance, longevity, and operational stability of CO2 laser equipment, enabling it to remain effective even during heavy workloads and prolonging its lifecycle.

How Overheating Impacts Tube Life

The CO2 laser tube is integral to most laser cutting and engraving machines. The flexibility of your system’s CO2 efficiency and productivity depends on its lifespan. CO2 tubes have a relatively short lifespan,n and maintenance is required at a considerable expense. Whether an expert or novice with laser devices, knowing how to maintain relatively basic equipment is crucial. In this blog post, we will discuss the procedures related to cooling, wear prevention, and other maintenance that help to prolong the operational life of a CO2 laser tube. Effective ventilation methods will allow operating at optimal performance as long as possible. Productivity is improved while costs are significantly reduced with proper planning of repairs and maintenance. Continue reading to discover why adjusting the correct maintenance strategy saves money.

The Importance of Proper Laser Power Settings

Setting the optimal operating power of CO2 laser systems carefully is required to achieve the ideal outcome and system sustainability. Over and underpowering will affect the quality of cutting and engraving while causing unnecessary strain on the other parts of the system. Studies show that if the laser is run on its maximum attainable output for long time durations, the lifespan of the laser tube will be drastically reduced by approximately 20 to 30 percent. Therefore, power settings need to be carefully adjusted based on the material and the operation being performed.

An example would be engraving or etching intricate designs on acrylic or thin wood, which require precision; power settings should be kept low to avoid overheating or damage. Higher power levels are needed to cut thicker materials like metals, but only for the time necessary to accomplish the task. More sophisticated systems are often equipped with software that gives them guidelines on power settings based on material, allowing operators to fine-tune settings.

Moreover, consistently checking and adjusting the laser’s power levels increases performance consistency and reduces operational expenditure over time. Research indicates that, through appropriate maintenance and power management, the service life of a CO2 laser system can be increased by as much as 50%, optimizing the value for investment provided to the users. Construction professionals should follow the provided instructions and run a test with each material to establish proprietary standards of power settings for each task.

How Can You Prolong the Life of Your CO2 Laser Tube?

To increase the lifespan of your CO2 laser tube, observing best practices concerning maintenance and operation is crucial. Firstly, ensure the cooling system works correctly since overheating contributes to early tube failure. Ensure the water used in the cooling system is clean, distilled water, and check regularly for proper flow. Secondly, the laser should not be operated at maximum power for extended periods, which places undue stress on the tube. Instead, use the recommended power levels for the material being processed. Lastly, the laser tube and other parts must be maintained in a dust-free environment, and the machine should be stored in a sealed and stable environment. Following these practices will help you maximize the lifespan of your CO2 laser tube.

Regular Maintenance Tips for Your Laser Equipment

Following best practices will help prevent degradation and maximize the value of your laser equipment. However, laser systems should undergo regular general systematic maintenance.

- Verification of Beam Positioning

Make sure that the position of the laser beam relative to each part of the system is correct. Incorrect positioning of lasers could lead to poor engraving or cutting. Inaccurate beams might waste materials and time and worsen efficiency. Employ multiple tests to keep beams in an optimal position during routine checks. Use tools to enhance alignment precision.

- Elevation of Standard Precautions: Monitoring Cooled Water Levels

In the case of water and air-cooled lasers, keeping their temperature in check is essential. Inspection of coolant levels regularly is recommended. Change the liquid as per the instruction of the equipment’s manufacturer. For water-cooled lasers, distilled water is the best option as it prevents the building of minerals or corrosion.

- Maintenance of the Exhaust and Fan System

The removal of smoke, debris, and any other unwanted fume substances from the vacuum cleaner or workspace is of great importance and requires high standards. If the fans’ filters are blocked, change them. Always wash the ducts and fans on a predetermined timetable to eradicate overheating issues and blocked airflow.

- Cleaning of Lenses and Mirrors:

Lenses and mirrors play an essential role in the optical path of the laser beam. They can accumulate dust or smudges, which scatter the light or diminish efficiency. These parts should be cleaned with a suitable cleaning solvent and a lint-free wipe, but not too aggressively.

- Checking Electrical Connections:

Components that are stationary relative to the frame or pedestal and are subjected to regular vibration may become loose with time. Loose connections can become a safety hazard while also degrading overall system performance. Regular inspection of wiring, plugs, and other connections is an absolute necessity.

- Checking the Operating Hours of the Machine and Performing Periodic Changes:

Most laser tubes tend to have a working life between 1000 and 10,000 hours, depending on type and usage. It is beneficial to keep logs pertaining to the machine’s operating time so components such as the laser tube and power supply are replaced in a timely manner. Monitoring system usage patterns to perform preemptive maintenance on schedule helps contain costs and save time in maintenance efforts.

Incorporating the above-sophisticated maintenance approaches into your everyday tasks can significantly improve the quality of your work and the lifespan of your laser equipment.

Using a Chiller to Maintain Optimal Temperatures

Every laser cutting tool uses a professional chiller to prevent overheating, which allows for greater cutting precision than other types that use conventional mechanical or band saws. Lasers operate with trusted mechanisms, but in the case of overheating, laser effectiveness can decrease by 70%.

A chiller can often maintain a set temperature with a precision of up to 0.3ºC. For CO2 lasers, water temperature is within the ideal range of 15 to 25 ºC. With proper sustaining maintenance set to lasers, fillers can increase on average by 50%.

The use of an optimal chiller also lowers the chances of systems overheating. If lasers are kept cooled properly, optimized parts and devices’ lifespan will increase. Furthermore, devices do not end up damaging themselves. Precise cutting will further allow for better engraving whilst enhancing overall CAL performance. Regular servicing of devices like filters, the coolant system, and the drainage system will eliminate device damage while strengthening the chiller’s effectiveness.

Following the recommended temperature protocols and implementing an efficient chiller system will protect your laser equipment from thermal stress and maintain its performance, longevity, and functionality.

Best Practices for Laser Cutting and Engraving

To attain maximum accuracy and quality results in laser cutting and engraving, the following measures must be taken:

- Selection and Preparation of Materials

To successfully operate a laser, the correct material selection is pivotal. Different types, like acrylic, wood, metal, and glass, have varying levels of responsiveness to laser energy. Make sure that the laser’s workpiece is devoid of dirt or grease. This allows for maximum accuracy while cutting or engraving. For example, acrylic can be cut and yield smooth edges, while some metals may need pre-treatment or specific coatings done beforehand.

- Set and Isolate Power and Speed Settings per Objective

It is imperative that one uniquely sets the power and speed of the laser, especially considering material type and thickness. Failure to do so can result in burns or cuts that are not finished. For instance, optimal settings for 6mm acrylic sheets would be a laser power of around 60 to 70% and lower speeds of about 10-15 mm/s. A multitude of manufacturers offer laser guides that can be helpful for reference.

- Focus and Beam Alignment

An adequately focused laser maintains the accuracy and repeatability of results. For best results, use the provided focus tool or an automatic focusing mechanism, if present, to set the laser at the optimal focal length. Check beam alignment regularly to prevent miss-cuts or engraving inaccuracies.

What are the common signs that your CO2 laser tube needs replacement?

Decreased Power Output—Difficulties in engraving or cutting from a laser not functioning as desired often suggest that the tube is possibly losing power.

Visible Tube Damage—The presence of cracks, leaks, or discoloration of the laser tube usually indicates that replacement is needed.

Flickering or Unstable Beam – An intermittent or uneven laser beam could indicate the tube is failing.

Unusual Noises—Internal component problems are indicated by the tube’s humming, clicking, and sometimes even buzzing sounds.

Shortened Operating Time—A degraded tube may be the reason your laser shuts down after shorter working sessions than usual.

To prevent damage to the laser system, prompt replacement of the tubes suffering failure allows for smooth performance consistency.

Recognizing Decreased Laser Power Output

Any decrease in a laser system’s power output can significantly reduce its overall productivity. Addressing such problems immediately ensures that equipment durability is not compromised. Several causes of inadequate power output exist, and determining these is critical for formulating a precise diagnosis.

- Visible Light Dimming: This problem often becomes noticeable during internal inspection when the residual laser output diminishes to a certain level. It entails the mechanical components of the laser system experiencing a high degree of elongation, causing shallow engravings and cuts.

- Beam Divergence is always associated with a coarse or out-of-focus beam. It reduces the power that the working surface receives. Effective tube alignment or careful lens positioning for certain types of optics are paramount to minimize the extent of laser beam divergence.

- Power Drop Over Time: All laser tubes exhibit degradation as they utilize their power. In practice, CO2 laser tubes are known to lose their efficiency between eight thousand and ten thousand hours of use. With proper maintenance, the detection of patterns in output levels can be utilized to signal the need for replacement.

- Material Processing Speeds—Underperformance or Material degradation tends to suggest that the cutting or engraving power setting is lower than optimal. A case in point would be if a laser used to sever 6mm plywood at a 30 mm/s rate but now needs multiple cuts or slower cuts: this indicates straining power delivery.

- Thermal Instability—Poor cooling management can negatively impact the stability of a system’s power output. Overheating may limit a device’s functionality. In this case, the system may quickly shorten the lifespan of essential parts such as the optics, laser window, or even the laser tube.

Identifying Physical Damage to the Glass CO2 Laser Tube

Physical damage can cause a glass CO2 laser tube to sustain serious functional impairments. Damage is often indicated by cracks, air bubbles visible within the glass, or discoloration on the electrodes. Glass casing cracks may risk the tube’s internal vacuum seal, resulting in energy inefficiency followed by failure. These problems are commonly attributed to inadequate care, improper thermal cycling, or blunt force impacts.

Leak monitoring in tubes that utilize water cooling systems is also an essential sign to watch for. Even the smallest fractures can disrupt the cooling cycle while enhancing risk to the equipment and operators. Aged and misaligned electrodes sometimes sustain discoloration, suggesting overheating, electrical strain, or stress.

Further data shows that the average lifespan of glass CO2 laser tubes varies between 1,000 and 10,000 operational hours, depending on the tube’s quality. More frequent use brings it closer to the lower limit. Regular checks coupled with proper maintenance are paramount to extending operational longevity. Strive to prevent inadvertent damage by exercising proper care and attention when using the laser tube.

How Does the Type of CO2 Laser Tube Affect Its Service Life?

The factors such as design, construction quality, and materials used in a CO2 laser tube determine its service life. Glass CO2 laser tubes, on average, have a life span of 1,000 to 10,000 hours, depending on the quality and use. On the other hand, metal or ceramic CO2 laser tubes tend to last longer, often exceeding 20,000 operational hours with proper maintenance. Regarding wear, high-quality tubes outperform other grades, offering consistent performance for sustained periods, thereby making them a preferred choice for heavy or professional use.

Comparing Glass CO2 Laser Tubes vs. Other Types

Material and Construction

Typically, glass CO2 laser tubes are composed of borosilicate glass, which makes them cheaper than their metal or ceramic counterparts but less durable. Their construction is more fragile, making them more prone to damage due to physical impacts or thermal stress. In contrast, metal and ceramic laser tubes are made from durable materials that are more resistant to cracks, have better thermal stability, and have longer operational lifespans.

Power Efficiency and Output

Compared to metal or ceramic tubes, glass CO2 laser tubes generally have lower power efficiency, and their design may cause additional losses during operation. In contrast, metal and ceramic tubes are more efficient in energy use and tend to give more steady and dependable outputs of laser energy. For instance, a glass tube may provide suitable power levels for engraving and cutting at a standard level. Still, professional-grade tubes made of metal or ceramic can cut through heavier materials like metals or heavy-duty plastics compared to other more demanding applications.

Cost and Maintenance

The most significant benefit of glass CO2 laser tubes is their cost. The lower manufacturing expense makes them accessible to both hobbyists and small businesses. Their frequency of maintenance, however, is often due to a shorter lifespan. On the contrary, metal and ceramic laser tubes have a higher upfront cost, but infrequent replacements make them more cost-effective in the long run for professionals.

Performance Lifespan

Glass CO2 laser tubes usually live for 1,000 to 10,000 hours, depending on their quality and usage rate. Metal and ceramic laser tubes often go beyond 20,000 hours, and some models exceed 30,000 hours even with routine maintenance. A longer lifespan means fewer interruptions and lesser cost of ownership over time, especially for high-use environments.

Use Cases

Glass laser tubes are perfect for hobbyists or small-scale operations engraving wood, acrylic, or other thin plastics. However, due to their consistent performance and longevity, metal and ceramic laser tubes are better suited for industrial applications such as precision engraving, cutting thicker materials, or handling higher workloads. These demanding environments require reliable performance over time.

Considering the advantages and disadvantages of these tube types makes it easier to choose the one that best meets the particular requirements in terms of price, strength, or efficiency. Picking the correct type guarantees the best results and enduring benefits.

What to Consider When Choosing a Replacement Tube

Out of several factors, assisting with the decision to replace a tube starts with considering optimal performance and efficiency features. Every detail listed below must be evaluated:

- Material and Type of The Tube

: Glass tubes are often more cost-efficient and ideal for tasks needing precision. Metal tubes tend to be used in industrial work since they are more durable and reliable for wear, tear, or extreme power-handling delicacies.

- Output Power

: A CO2 laser with the correct tubing makes an excellent example of this. The desired piece of equipment needs to have a power rating equal to its serving requirements , orelse wear levels will surpass the expectation of the system’s efficiency. Often, sellers have several offers like 40W, 60W, 80W, 80W, etc., which coordinate well with buying preference and ease of selection.

- Efficiency Only

: Perhaps the most crucial decision to keep in mind where maintenance and downtime are involved. Based on the brand and material used, laser tubes can go from 2,000 to 10,000 hours of usage, so picking the right option can mean a difference of possibly thousands. Durability and economy fuse along with the utmost energy-saving features when making the ideal choice.

- Compatibility

Confirm that the chosen tube is compatible with your machine, including but not limited to length, diameter, and electrical connection. It is advisable to check a system’s specifications against manufacturer recommendations to avoid discrepancies in functional compatability.

- Cutting and Engraving Requirements

Specific tasks, such as cutting thick materials or achieving highly detailed engraving, may require more power or a different beam quality. For example, tubes with a more divergent beam for cutting tend to provide more precise and cleaner results in engraving.

- Cooling System

Effective cooling is crucial for a tube’s performance and lifespan. Determine whether the tube is air-cooled or requires a water-cooling system. Also, ensure that the system’s cooling capacity is sufficient to handle the tube’s output power to avoid overheating.

- Cost and Brand Reputation

While price is generally among the top factors, tension with quality and dependability is unavoidable. Trusted brands are more likely to charge a premium but will most probably offer consistent functionality and after-sales service. Warranties and customer ratings, on the other hand, can determine product reliability.

- Environmental Impact

It is now common practice to consider the tube’s impact on the environment. Strive to work with companies that offer sustainable practices, such as recyclable parts or the reduction of toxic substances in manufacturing.

Choosing an informed decision requires checking all factors within your usage needs. Selecting the appropriate replacement tube improves productivity, enhances performance, and guarantees better long-term cost-benefit results.

What Maintenance Practices Can Extend the Service Life of Your Laser Cutter?

Regular Cleaning: The mirrors and laser lens require frequent cleaning to avert damage caused by dust particles and ensure the cutting performance is at its peak.

Monitor Cooling Systems: The cooling system should be checked and serviced regularly to avoid overheating. The coolant should also be replaced according to the manufacturer’s guidelines.

Check Alignment: The accuracy and efficiency of the system during operation are highly reliant on the periodic adjustment and inspection of the laser beam’s alignment.

Lubricate Moving Parts: The moving components of the laser cutter, including the rails and bearings, should be lubricated properly to lessen friction and wear.

Use Proper Settings: The machine’s components face a lot of strain when used at the recommended power and speed; thus, it is ideal to operate the machine within the specified parameters.

Replace Worn Parts: If there is any observable damage or rein syndrome, the belts, filters, and tubes should be replaced immediately.

Maintaining reliable performance and consistent usage of these practices enhances the service life of the laser cutter.

Keeping Mirrors and Lenses Clean

Routine maintenance of mirrors and optical lenses is a necessity for the operational efficiency of your laser cutter. These components can accumulate cutting dust and debris, reducing accuracy and power efficiency. Research shows that even a slight presence of contaminants on mirrors or lenses can affect machine efficiency with as much as a 10 percent cut, resulting in uneven cutting or engraving.

To maintain optimal performance, do regular inspection of mirrors and lenses, and, for best results, do it before each use. Always ensure the use of optical grade cleaning solution and use non-woven cleaning wipes to prevent any scratches or damages. Careful handling while cleaning using gloves or tools prevents the transfer of oils or dirt from the hands. If any of the lenses or mirrors are damaged, replacing them becomes necessary as further unconventional residue will invariably hinder functionality which will degrade performance over time.

It is also recommended that the working environment be as clean and free from dust as possible. During operation, an air assist or air filtration system helps reduce fine particle accumulation. Proper preventive methods result in precision and effectiveness of the lasers while increasing the cumulative lifespan of the mirrors and lenses.

Regularly Checking the Cooling System Functionality

The cooling system is critical to a laser cutter’s safe use and productivity. As with any industrial-grade machine, its cooling system is crucial to prolonging its longevity and minimizing overheating-related performance issues. Performance issues include functions such as failure to shred paper properly, which results in shredding, and erratic and execution. A user or technician needs to execute regular checks of the system to ensure the coolant level is high, there is no obstruction or contamination, and the system is functioning optimally. Any obstruction always leads to low levels of heat regulation within the device.

A modern industrial-grade unit would have advanced features of needing external systems to monitor server cores, and having unit monitors in their devices for self-adjustment. An example would be with unit based on laser cuting devices, users are advised on the cooling systems maintaining levels between 15 degrees celsius to 25 degrees celsius rotating mark 59 degree celsius to 77 degree celsius. Maintaining these levels serves as a base for a user to gauge on proper device functioning. Deviating from these levels makes the unit prone to malfunctions, which users always want to avoid. Following the unit provider’s guide on regular coolant replacement consistently offers enhanced heat transfer performance.-

Moreover, to ensure unobstructed airflow, it is essential to periodically clean the radiator or cooling fins to prevent dust buildup. Research indicates that inefficient upkeep of the cooling systems practically utilized in high-powered laser machines can cause a drop in operational efficacy by a staggering 20-30%. Cleaning and maintaining the device help in averting breakdowns, enhance the durability of numerous parts, and ensure the utmost precision of the laser cutter throughout its lifespan.

Monitoring Work Surface Conditions for Best Performance

Keeping the work surface neat, clean, free of any level change, and smooth is vital in ensuring the very best results when working with laser cutting tools. Even dust and debris can severely impact the quality and precision of the work being done. Research indicates that even very small imperfections on the work surface lead to misalignment of cutting patterns or distortions, changing the final expected product.

To avoid encountering these issues, the work table should be checked regularly for work residues, especially after cutting wood, metal, or acrylic. Static-eliminating brushes and cleaning sprays designed specifically for laser-cutting devices help maintain surface cleanliness and conductivity. The surface of the table or support system used should be leveled, too. Tools such as digital angle finders allow users to measure the surface level with 0.1-degree precision, which is entirely accurate.

Cutting reflective metals requires anti-reflective coating surfaces that reduce beam scattering, allowing for very smooth and precise cutting. Sustaining these conditions improves the laser’s performance while reducing time lost to excessive material rework due to erroneous cuts.

Reference Sources

-

Application of In-situ Synthesized TiC Reinforced Ni-Based Composite Coatings by Laser Cladding1:

- Key Findings: This study explored the use of laser cladding to enhance the wear resistance and lifespan of H13 steel, a material often used in high-friction environments. The process involved creating a TiC-reinforced Ni-based composite coating. The resulting clad layer exhibited a microhardness of 800-950 HV, 2.5-3 times higher than the substrate. The wear resistance was significantly improved, with weight loss reduced to 10% of the untreated material.

- Methodology: The researchers applied the cladding using a CO2 laser system, followed by microstructural analysis using SEM, EDX, and XRD. Mechanical properties were assessed through hardness testing and wear resistance experiments.

-

Condition Monitoring and Lifetime Estimation of a CO2 Laser2:

- Key Findings: This research proposed a predictive maintenance strategy for CO2 lasers by monitoring the cooling system’s health. A Weibull distribution model was used to predict the laser’s remaining lifetime based on operating parameters and machine conditions. The approach aimed to reduce downtime and improve maintenance efficiency.

- Methodology: The study involved simulation and experimental validation at the Applied Research Laboratory, focusing on statistical modeling and condition monitoring techniques.

-

A Comprehensive Detailed Formula for LED Degradation and Lifetime Estimation3:

- Key Findings: Although focused on LEDs, this study introduced a methodology for accurately predicting component lifetimes by analyzing degradation at a granular level. The approach could inspire similar predictive models for CO2 laser components, emphasizing energy efficiency and reduced operational costs.

- Methodology: The researchers developed a detailed formula by breaking down LED components and modeling their degradation. The findings were validated against existing standards like TM 21.

- Top Co2 Laser Engraving Cutting Machine Manufacturer And Supplier In China

Frequently Asked Questions (FAQs)

Q: How can I extend the life of my CO2 laser tube?

A: To extend the life of your CO2 laser tube, ensure proper cooling, maintain optimal operating conditions, and avoid overdriving your laser tube beyond the manufacturer’s recommended specifications.

Q: What factors affect the life of a CO2 glass laser tube?

A: Factors that affect the life of a CO2 glass laser tube include the quality of the laser sources, the cooling system efficiency, the frequency of use, and the settings applied during laser processing.

Q: How often should I check the cooling system for my glass laser tube?

A: It is advisable to check the cooling system for your glass laser tube regularly, ideally before each use, to ensure optimal temperatures are maintained and prevent overheating.

Q: What is the impact of laser power on the life of your laser tube?

A: Increasing the laser power can generate more heat inside the tube, which may cause it to age prematurely. Therefore, it’s essential to use a laser power meter to monitor and adjust the settings accordingly.

Q: Can I overdrive my CO2 laser cutter to achieve better performance?

A: While you can increase the laser power for improved performance, overdriving your laser tube can significantly reduce its life. Continuously operate within the manufacturer’s recommended limits to prolong your CO2 laser tube.

Q: What maintenance is required for a CO2 glass laser?

A: Regular maintenance for a CO2 glass laser includes cleaning the lens and mirrors, checking the alignment, and ensuring the cooling system is functioning correctly to maintain the efficiency and life of the laser tube.

Q: How can I tell if my laser tube is nearing the end of its life?

A: Signs that your laser tube may be nearing the end of its life include a decrease in output power, irregular beam quality, and inconsistent engraving or cutting results. Monitoring the performance regularly can help you identify these issues early.

Q: What should I do if my CO2 laser tube is not generating an intense beam?

A: If your CO2 laser tube is not generating an intense beam, check for potential issues such as low water levels in the cooling system, dirty optics, or alignment problems. Addressing these factors can help restore the tube’s performance.

Q: How does the quality of the CO2 glass laser tube affect its longevity?

A: The quality of the CO2 glass laser tube directly impacts its longevity. Higher-quality tubes tend to have better materials and construction, resulting in a longer life and more consistent performance in laser engraving and marking.

Q: What is the best way to maintain the life of the laser tube?

A: The best way to prolong the life of the laser tube is through regular maintenance, proper cooling, avoiding overdriving the tube, and ensuring that all components, such as lenses and mirrors, are clean and aligned correctly.