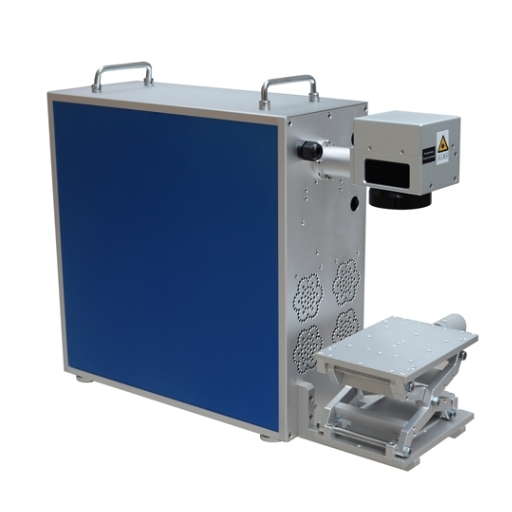

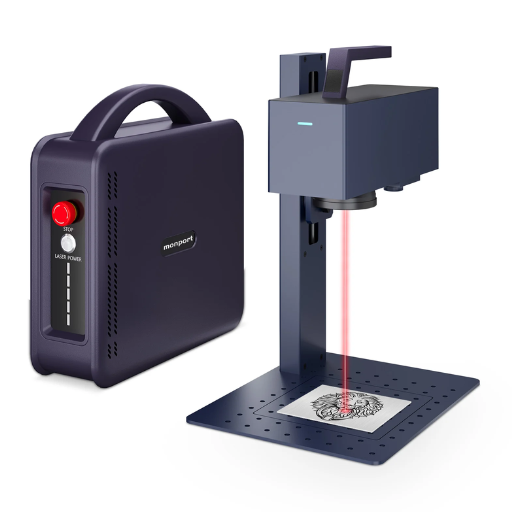

Are you searching for a cutting-edge, versatile solution to meet your marking and engraving needs? Portable fiber laser marking machines are revolutionizing industries with their precision, efficiency, and portability. Whether you’re working with metals, plastics, or other materials, these advanced tools offer unmatched flexibility and performance, making them an essential asset for businesses of all sizes. This guide dives deep into everything you need to know about portable fiber laser marking machines — from their core features and benefits to practical applications across various industries. Get ready to uncover how these innovative devices can transform your workflow and take your marking projects to the next level.

What is a Portable Handheld Fiber Laser and How Does It Work?

A portable handheld fiber laser is a compact, lightweight device designed to mark, engrave, or etch materials like metals, plastics, and ceramics with precision and speed. It operates by emitting a focused beam of light, which interacts with the surface of the material to produce permanent marks. The fiber laser technology uses optical fibers doped with rare-earth elements to generate high-quality laser beams, ensuring accuracy and minimal maintenance. These devices are highly efficient, requiring low power consumption, and are known for their durability and adaptability, making them ideal for on-site and industrial applications.

Understanding the Basics of Fiber Laser Marking Machines

Fiber laser marking machines have gained prominence in various industries due to their advanced capabilities and efficiency. They operate by employing a focused laser beam to perform precise marking, etching, or engraving on a wide range of materials, such as metals, plastics, ceramics, and even some non-metallic surfaces. The technology exhibits exceptional accuracy, enabling markings down to microscopic levels, with a typical wavelength of around 1,060 nanometers ensuring precision and clarity.

One of the standout features of fiber laser technology is its high-speed marking, capable of reaching speeds up to 7,000 mm/s under optimal conditions, which significantly enhances production efficiency. Despite their speed, these machines deliver exceptional energy efficiency, consuming significantly less power compared to other laser technologies such as CO2 or YAG lasers. For instance, fiber lasers typically require less than 500 watts for operations, making them cost-effective for long-term use.

Additionally, these machines boast a long lifespan, with fiber laser modules often exceeding 100,000 hours of operation, reducing the need for frequent replacements or maintenance. The versatility of fiber laser marking machines also ensures compatibility with different industries, ranging from automotive and electronics manufacturing to medical device labeling, thanks to their ability to produce highly durable and resistant engravings that endure extreme conditions like heat, friction, and corrosion.

Lastly, advancements in user-friendly interfaces and software ensure ease of operation, allowing customization of marking patterns, barcodes, serial numbers, or logos. Combined with environmentally friendly processes—since no toxic chemicals or consumables like ink are required—fiber laser marking machines remain a top choice for sustainable and efficient industrial applications.

How Does a Handheld Laser Marking Machine Differ from Traditional Methods?

Handheld laser marking machines bring a significant shift in technology compared to traditional marking methods such as engraving or mechanical stamping. One of the most notable advantages is their portability and flexibility. Unlike fixed machinery, handheld devices are lightweight, compact, and allow operators to mark objects directly on-site, regardless of shape or size. This is particularly beneficial for large or immovable equipment used in industries like aerospace or manufacturing.

From a precision standpoint, handheld laser markers achieve unparalleled accuracy. Traditional methods often result in wear and tear over time, leading to inconsistent marks. However, laser technology ensures clean, precise, and permanent markings without physically touching the surface. For instance, fiber laser marking has a tolerance of up to 10 microns, making it an excellent choice for complex details such as QR codes or microtext often required in electronics and metal components.

Furthermore, efficiency is another area where handheld laser marking machines vastly outperform traditional tools. These devices operate at incredible speeds, with some capable of marking up to 7000 mm/s, significantly reducing production time. They are also practically maintenance-free, as there are no moving parts or consumable materials like ink or etching solutions. This contributes to lower long-term costs and a greener footprint for businesses.

Lastly, handheld laser marking machines excel in material versatility. They can mark a wide range of surfaces, including metals, plastics, ceramics, and even reflective materials, something that traditional methods may struggle with. This adaptability, combined with advanced software, allows for customized designs, logos, or identification systems, making these devices indispensable in modern industrial applications.

The Advantages of Using a Handheld Laser Engraver

Handheld laser engravers provide unparalleled precision in marking and engraving, with an accuracy level often reaching up to 0.01 mm. This ensures even the most intricate designs are replicated flawlessly across different materials, enabling businesses to maintain consistent quality. The compact size and portability of these machines are other key advantages, allowing operators to easily transport and use them for on-site projects, whether on a factory floor or in remote locations.

Another significant advantage is their efficiency. Many contemporary handheld laser engravers utilize fiber laser technology, which is not only energy-efficient—reducing energy consumption by up to 50% compared to traditional engraving setup—but also offers a lifespan of around 100,000 hours. This translates to reduced downtime and lower maintenance costs, making them a cost-effective investment for industries.

Furthermore, these machines can operate without the need for chemicals, inks, or additional fast-wearing components, making them an eco-friendly solution. For industries prioritizing environmental sustainability, handheld laser engravers provide a clean, waste-free marking alternative that aligns with greener practices.

Finally, laser engravers are equipped with robust software integrations, allowing users to load designs or data directly onto the machine. Many models support barcodes, QR codes, and dynamic numbering systems, streamlining inventory tracking and product identification processes. With increasing demands for traceability in sectors like aerospace, healthcare, and electronics, this functionality has become more critical than ever.

Why Choose a 20W Fiber Laser for Your Projects?

A 20W fiber laser is an excellent choice for projects that require precision, efficiency, and durability. It delivers high-quality engraving and marking with exceptional accuracy, making it ideal for detailed work on materials like metals, plastics, and ceramics. Its power level strikes a perfect balance, offering efficient performance while minimizing the risk of material damage. Additionally, 20W fiber lasers are highly energy-efficient and designed for long-term use, ensuring reliability and low maintenance costs. This combination of precision, versatility, and cost-effectiveness makes the 20W fiber laser a practical solution for a variety of industries.

Exploring the Power of a 20W Fiber Laser

The 20W fiber laser stands out due to its remarkable precision, efficiency, and adaptability across numerous industrial applications. With a wavelength typically around 1064nm, it delivers exceptional accuracy, making it particularly effective for detailed engraving, marking, and cutting tasks on materials such as stainless steel, aluminum, copper, and even non-metals like plastics. It operates with a beam quality that ensures seamless and clean results, reducing the need for post-processing.

Speed and Efficiency: These lasers are capable of marking speeds up to 7,000mm/s, significantly increasing productivity in high-demand manufacturing settings. This speed couples with their high optical conversion efficiency, often exceeding 30%, leading to reduced power consumption compared to older technology.

Durability and Longevity: Designed for continuous use, a 20W fiber laser typically has a lifespan exceeding 100,000 working hours. The robust build and lack of moving parts enhance reliability and minimize the risk of mechanical failure, making them a cost-effective solution over time.

Applications Across Industries: From automotive and electronics to jewelry and medical devices, this laser technology has become a preferred choice due to its ability to deliver detailed, permanent marks such as barcodes, serial numbers, logos, and intricate designs. For example, in the electronics industry, its controlled heat output ensures precise markings on delicate components without causing undue damage.

Eco-Friendly Operation: Another notable feature is its energy efficiency. Consuming less power not only reduces operational costs but also minimizes its environmental impact, aligning with the growing demand for sustainable manufacturing practices.

Whether it’s for small-scale artisanal projects or large-scale industrial production, the 20W fiber laser continues to redefine precision and efficiency in material processing. Its combination of advanced performance and cutting-edge technology leads to unparalleled results across diverse applications.

Comparing Fiber Laser Engravers to Other Types of Engravers

|

Feature |

Fiber Laser Engravers |

CO2 Laser Engravers |

Diode Laser Engravers |

Mechanical Engravers |

|---|---|---|---|---|

|

Material Compatibility |

Metals, plastics, ceramics |

Non-metals, some coated metals |

Wood, plastics, light metals |

Metals, wood, plastics |

|

Engraving Speed |

Very fast |

Moderate |

Moderate |

Slow |

|

Precision |

High |

Moderate |

Low to moderate |

High |

|

Lifespan |

100,000+ hours |

20,000+ hours |

10,000+ hours |

Dependent on wear & tear |

|

Maintenance Requirements |

Low |

High |

Moderate |

High |

|

Initial Cost |

High |

Moderate to high |

Low |

Moderate |

|

Operating Cost |

Low |

Moderate |

Low |

Moderate to high |

|

Power Efficiency |

High |

Moderate |

High |

Low |

|

Suitable Uses |

Industrial, detailed marking |

General cutting, engraving |

Hobbyist projects, small-scale |

Carving, deep engraving |

|

Portability |

Compact design |

Bulky |

Compact |

Varies |

Benefits of Using a Fiber Laser Engraving Machine

- Exceptional Precision and Accuracy

Fiber laser engraving machines boast unparalleled precision, capable of creating intricate and detailed engravings on a variety of materials. The narrow laser beam allows for minute designs, ensuring clean edges and reducing the likelihood of material deformation. This makes it ideal for industries like jewelry-making, electronics, and medical device manufacturing.

- Durability and Reliability

These machines are designed for long-term performance, with most fiber lasers having a service life of over 100,000 hours. Their robust construction and minimal required maintenance ensure consistent results over time, making them a cost-effective choice for businesses.

- Versatility Across Materials

Fiber laser engravers can process a wide range of materials, including metals like stainless steel, aluminum, brass, and titanium, as well as certain plastics and ceramics. This versatility allows them to be used in various industries, from automotive to aerospace and beyond.

- Energy Efficiency

Compared to traditional engraving technologies, fiber lasers are significantly more energy-efficient. They convert a higher percentage of input energy into laser output, consuming less power during operation. This translates to reduced operational costs and a smaller environmental footprint.

- High Engraving Speed

Fiber laser machines offer rapid engraving speeds, enabling faster production cycles. On average, these machines can work up to 10 times faster than traditional engravers, making them suitable for high-volume manufacturing environments.

- Low Operating Costs

With no requirement for consumables like inks, chemicals, or replacement parts, fiber laser engravers reduce ongoing operating expenses. Additionally, their efficient design minimizes maintenance costs.

- Eco-Friendly Technology

Fiber laser engraving is a clean and environmentally friendly process. It generates minimal waste, operates without harmful chemicals, and reduces energy consumption, aligning with sustainable manufacturing trends.

- Non-Contact Process

The laser engraving process is entirely non-contact, meaning there is no physical wear-and-tear on the machine. This ensures the longevity of the equipment while preserving the integrity of delicate materials.

- Customizable Automation Options

Fiber laser engravers can be easily integrated into automated production lines. Custom software and advanced programming options allow precise control, increasing productivity and reducing human error.

- Superior Marking Quality

Whether creating deep engravings or surface-level markings, fiber laser machines deliver unmatched quality. They ensure legible, high-contrast markings that are resistant to abrasion, heat, and corrosion, which is critical in industries like medical and aerospace.

By combining these benefits, fiber laser engraving machines provide an advanced, high-performance solution for modern manufacturing needs.

Applications of a Laser Engraving Machine in Various Industries

Laser engraving machines are utilized across a wide range of industries due to their precision and versatility. In the automotive industry, they are used to mark components with serial numbers and barcodes for traceability. The medical sector benefits from their ability to create high-contrast, durable markings on surgical tools and medical devices, ensuring compliance and safety standards. Similarly, in electronics, laser engraving is crucial for labeling circuit boards and components without causing damage. The jewelry industry relies on these machines for intricate designs and personalization, while manufacturers of promotional items use them to create custom branding on various products. These applications highlight the adaptability of laser engraving technology in meeting diverse industry needs.

How Can a Portable Laser Engraver Benefit the Metal Industry?

A portable laser engraver provides unparalleled precision and efficiency for the metal industry, making it an essential tool for both small-scale artisans and large-scale manufacturers. These devices are versatile, capable of engraving detailed patterns, serial numbers, logos, and barcodes on various metal surfaces such as stainless steel, aluminum, and titanium. This ensures compliance with industry standards and traceability requirements, which are vital in sectors like aerospace, automotive, and medical equipment manufacturing.

One of the major advantages of portable laser engravers is their ability to operate on-site. For instance, maintenance teams and repair technicians can use these devices to mark or engrave replacement parts directly, reducing downtime and enhancing overall productivity. Furthermore, advances in fiber laser technology have improved the durability and precision of portable engravers. According to industry standards, fiber lasers can last over 100,000 hours and are energy-efficient, making them a cost-effective choice for metal marking.

Additionally, portable laser engravers minimize waste by offering non-contact marking. Unlike traditional engraving methods, which may generate chips or shavings, laser engraving ensures a clean process without physically altering the material’s integrity. This is particularly beneficial for high-value components where maintaining surface quality is critical. Industries have also reported a reduction in production costs thanks to the minimal maintenance required for these devices and their ability to perform consistent, high-speed engraving across various types of metals.

The metal industry continues to integrate portable laser engravers as a long-term solution for efficient, durable marking, whether for practical applications or aesthetic purposes. By leveraging these innovations, businesses can future-proof their operations while ensuring quality and compliance in their metalworking processes.

Using a Laser Machine for Wood and Metal Projects

Laser machines are versatile tools that provide unmatched precision, efficiency, and reliability for both wood and metal projects. By using highly focused beams of light, these machines can cut, engrave, and etch materials with extraordinary detail and consistency. For wood projects, laser machines can create intricate designs for furniture, decorations, or custom craftwork, while maintaining clean edges and reducing material waste. On the other hand, in metalworking, laser machines excel in engraving durable markings such as serial numbers, logos, or intricate patterns, even on hard alloys like stainless steel or titanium.

Recent advancements in laser technology have also led to higher efficiency and productivity. For example, modern fiber laser machines can achieve engraving speeds of up to 7,000 millimeters per second while maintaining resolutions of 4,000 DPI (dots per inch). This level of precision ensures superior quality outputs, even in demanding industrial settings. Additionally, CO2 lasers are ideal for organic materials like wood and acrylic, providing versatility for mixed-material projects.

From hobbyists to large-scale manufacturers, laser machines now come equipped with user-friendly software compatible with a wide range of design files, making them accessible for individuals of all skill levels. Furthermore, these machines often feature energy-efficient designs, cutting down operating costs and contributing to sustainable practices—an increasingly important factor for businesses worldwide. Whether working on detailed wooden ornaments or marking intricate identifiers on metal tools, laser machines continue to revolutionize artisanal and industrial projects alike.

The Role of Laser Marking Machines in Product Identification

Laser marking machines have become indispensable in the realm of product identification, combining precision, efficiency, and durability to meet the needs of modern industries. These machines employ a focused beam of light to create permanent marks on a wide variety of materials, including metals, plastics, ceramics, and even glass. One major advantage is their ability to produce high-resolution markings that remain intact despite exposure to extreme environmental conditions, such as high temperatures or chemicals.

Industries such as automotive, electronics, and medical manufacturing leverage laser marking for applications like serial numbers, barcodes, and regulatory codes. For instance, in the automotive sector, laser marking ensures the traceability of parts, which is essential for quality control and compliance with safety standards. A study from industry reports highlights that the global laser marking market is anticipated to reach over $3 billion by 2025, driven by increased demand for non-contact and precise marking solutions.

Additionally, laser marking machines support sustainable practices by eliminating the need for consumables such as inks or chemicals, reducing waste and lowering operational costs. The integration of advanced features, like automated data input and cloud-based tracking systems, has further boosted their appeal. This ensures that every product is uniquely identifiable while enhancing efficiency across mass production and supply chains.

With advancements in fiber, CO2, and UV laser technology, these machines continue to evolve, offering greater customization options and faster processing speeds. Whether for branding purposes or compliance with stringent industry regulations, laser marking machines serve as a critical tool for ensuring well-documented and traceable products in today’s fast-paced global market.

How to Use and Maintain a Handheld Fiber Laser Marking Machine

- Prepare the Workspace

Ensure the workspace is clean and free of obstructions. Place the machine on a sturdy surface and confirm proper ventilation.

- Power On the Machine

Connect the machine to a reliable power source and switch it on. Follow the manufacturer’s startup instructions displayed on the interface.

- Set the Marking Parameters

Adjust settings like laser power, speed, and frequency based on the material being marked. Refer to the machine’s user guide for recommended settings for specific materials.

- Position the Material

Secure the material to be marked in the machine’s work area, ensuring it is aligned properly with the guidance system to achieve accurate results.

- Execute the Marking Process

Use the control interface to begin marking. Monitor the process closely to ensure precision and quality.

- Inspect the Marking

Once completed, check the result to ensure the marking is clear and meets required specifications.

Step-by-Step Guide to Operating a Fiber Laser Engraving

Prepare the Equipment

-

- Ensure the fiber laser engraving machine is clean and free of dust or debris to prevent interference with the engraving process.

- Power on the machine and allow it to initialize fully before proceeding.

- Confirm all components, such as the lens and focus adjustments, are in optimal working condition.

Set Up the Engraving Parameters

-

- Input the specific parameters for your project, such as laser power, speed, and frequency, based on the material you are engraving.

- Common parameter ranges for fiber lasers include:

- Power: 10W-100W (depending on material type and engraving depth).

- Speed: Typically measured in mm/s, recommended values usually range between 50 mm/s to 800 mm/s.

- Frequency: Adjust between 20 kHz and 80 kHz for optimal energy distribution.

- Refer to the material’s engraving settings chart, if available, for precise values.

Position the Material

-

- Secure the material firmly in the machine’s work area using clamps or screws if needed to prevent movement during operation.

- Use the machine’s guide or grid system to ensure proper alignment.

- Adjust the laser’s focus using the focus calibration tool provided with the machine. Misalignment can lead to errors or incomplete markings.

Execute a Test Engraving

-

- Run a test engraving on a sample or scrap piece to verify the current settings.

- Examine the test result for accuracy, depth, and clarity.

- Fine-tune parameters if the output does not meet the desired standards.

Start the Production Process

-

- Once satisfied with the settings, initiate the full engraving operation.

- Observe the laser process through the protective glass or monitor, following safety protocols to avoid exposure to the laser’s beam.

- Ensure the workspace remains clutter-free to prevent disruptions.

Inspect the Final Output

-

- After engraving is complete, carefully inspect the material for quality and precision.

- Look for sharp edges, even engraving depth, and consistent coloring depending on the design requirements.

- Perform any post-processing, such as cleaning the engraved surface, to enhance the final product.

Complete Shutdown and Maintenance

-

- Turn off the machine and allow it to cool down if necessary.

- Clean the machine’s lens, work table, and other relevant parts to prepare it for future use.

- Store any tools or materials properly to maintain an organized workspace.

By following these comprehensive steps, you can ensure a precise, efficient, and safe fiber laser engraving process.

Maintenance Tips for Prolonging the Life of Your Laser Engravers

- Regular Cleaning of Parts

Cleaning the laser engraver is a crucial step to ensure its optimal performance. Residues, dust, and debris can accumulate on the laser’s lens, mirrors, and work table, hindering precision and cutting quality. It is recommended to clean the lens daily or after each extended use with a lint-free cloth and appropriate cleaning solution. For high-use environments, replacing the lens every 6 to 12 months can prevent performance degradation.

- Lubrication of Moving Components

The moving parts of the engraver, such as rails and bearings, require regular lubrication to reduce friction and wear. Using a high-quality lubricant designed for machinery helps maintain smooth operation and minimizes the risk of mechanical failure. Check lubrication schedules provided in the user manual for specific intervals and products recommended by the manufacturer.

- Monitoring Cooling Systems

Overheating can severely damage your laser’s components. For machines equipped with water or air-cooling systems, ensure they are functioning correctly. Regularly check the coolant levels, and replace or clean the filters as needed to maintain proper airflow and cooling efficiency.

- Alignment and Calibration

Misalignment of the laser beam can impact cutting precision and reduce efficiency. Regularly calibrate the laser to ensure the beam is centered and aligned properly. Modern laser engravers often include alignment tools or software to simplify the process.

- Dust and Ventilation Management

The engraving process generates fine dust particles and fumes that can clog ventilation systems. Install a reliable exhaust system or air purifier to remove these particles from the workspace. Additionally, clean or replace exhaust filters every few months to avoid system blockages.

- Routine Software Updates

Outdated software can introduce inefficiencies or errors in your engraving operations. Regularly update the firmware and design software to access the latest features, security patches, and performance improvements. This helps keep the machine running smoothly and extends its overall usability.

Common Troubleshooting Tips for Portable Laser Marking Machines

- Laser Does Not Engrave Properly

-

- Possible Cause: The focal distance may not be set correctly.

- Solution: Adjust the laser head’s focus using the machine’s focus gauge or marker guidelines until the laser precisely aligns with the material’s surface.

- Possible Cause: Insufficient power settings.

- Solution: Increase the laser power in the machine’s software settings gradually, testing on scrap material until desired engraving quality is achieved.

- Possible Cause: Dirty lens.

- Solution: Gently clean the laser lens with a microfiber cloth or special lens cleaning solution to remove dust or debris.

- Irregular Line Patterns or Blurred Marking

-

- Possible Cause: Material is moving during the marking process.

- Solution: Ensure the material is firmly secured to the workspace using clamps or grips.

- Possible Cause: Misalignment of the laser beam.

- Solution: Calibrate the laser head to ensure proper alignment with the material surface. Regular calibration is recommended for consistent results.

- Machine Does Not Turn On

-

- Possible Cause: Faulty power connection.

- Solution: Check the power cord for loose connections or damage. Replace if necessary and ensure a stable power supply.

- Possible Cause: Internal circuit or hardware issue.

- Solution: Consult the user manual for diagnostic checks or contact the manufacturer for technical support.

- Overheating During Operation

-

- Possible Cause: Prolonged usage without breaks.

- Solution: Turn off the machine and allow it to cool down before resuming work to avoid damaging internal components.

- Possible Cause: Blocked air vents.

- Solution: Clear any obstructions around the vent and ensure proper air circulation. Regularly check for dust accumulation and clean the areas around the vents.

- Software Crashes or Freezing

-

- Possible Cause: Overloaded system resources on the connected computer.

- Solution: Close unnecessary applications and ensure the computer meets the software’s minimum specifications.

- Possible Cause: Corrupted software installation.

- Solution: Reinstall the marking software or update to the latest version from the official website.

- Engraving Depth Is Too Shallow or Deep

-

- Possible Cause: Incorrect power or speed settings.

- Solution: Adjust the power and speed settings appropriately based on the material being used. Refer to the machine’s recommended settings chart for guidance.

- Possible Cause: Material is unsuitable for depth adjustments.

- Solution: Test alternative materials or coatings compatible with the intended engraving requirements.

- Error Messages on the Display Panel

-

- Possible Cause: Incorrect file format or corrupted files.

- Solution: Verify that the uploaded files are in the correct format and not damaged. Use compatible design software to export new files if required.

- Possible Cause: Firmware issues.

- Solution: Perform a system reset or update the firmware to the latest version provided by the manufacturer.

By addressing these common issues with proper troubleshooting techniques, operators can significantly improve the efficiency, lifespan, and reliability of their portable laser marking machines. Regular maintenance and adhering to manufacturer guidelines are essential practices for optimal performance.

What to Look for When Buying a Portable Laser Marking System?

- Type of Laser: Choose the appropriate laser type based on your material needs (e.g., fiber lasers for metals or CO2 lasers for non-metals).

- Power Output: Ensure the laser has sufficient power to efficiently mark your materials while maintaining precision.

- Portability: Opt for a compact and lightweight system that is easy to transport without compromising functionality.

- Software Compatibility: Verify that the system’s software is user-friendly and compatible with your existing devices or design platforms.

- Durability and Build Quality: Look for a robust design to ensure long-term reliability, especially in industrial or demanding environments.

- Warranty and Support: Choose a system with a solid warranty and responsive customer support for troubleshooting and maintenance.

By focusing on these factors, you can select a system that meets your operational needs while ensuring high-quality marking performance.

Key Features to Consider in a Portable Handheld Laser

When selecting a portable handheld laser, it’s important to evaluate its features thoroughly to ensure it aligns with your specific requirements. Here are the key features to consider, along with detailed insights:

- Laser Power and Wavelength

Choose a laser with appropriate power levels (measured in watts) suitable for your intended applications. Lower power may suffice for soft materials like plastic, while higher power is necessary for engraving metals or achieving deeper marks. Additionally, the laser’s wavelength impacts its compatibility with various materials.

- Portability and Weight

One of the main advantages of a handheld laser is its portability. Check the weight and ergonomic design to ensure it remains comfortable for prolonged use, especially in fieldwork or mobile environments.

- Precision and Beam Quality

High beam quality results in accurate and intricate markings or cuts. Look for features like consistent focal points and low divergence rates to achieve superior precision and detailed outputs.

- Battery Life and Power Options

A reliable power source is crucial for portable lasers. Check the battery life to ensure uninterrupted operation, and consider systems with easily replaceable or rechargeable batteries for added convenience.

- Marking Speed

Evaluate the laser’s marking or engraving speed, especially if efficiency and fast turnaround times are priorities. Look for a balance between speed and accuracy to meet production needs.

- Material Compatibility

Consider the range of materials the laser can handle—such as metal, plastic, wood, or glass. A versatile laser will expand your application possibilities and offer greater overall value.

- Software and Connectivity

Modern handheld lasers often come with integrated software to streamline operations. Ensure the software is user-friendly, supports the file formats you need, and allows seamless connectivity via USB or Wi-Fi for transferring designs.

- Cooling System

Effective thermal management ensures consistent performance and prolongs the life of the laser. Look for built-in cooling mechanisms, such as air or water cooling, to maintain optimal functionality during extended use.

- Safety Features

Safety is paramount when handling high-powered lasers. Choose a device with robust safety features, such as protective housings, interlocks, and warning systems to prevent accidents.

- Cost and Value for Money

While evaluating the price, consider the overall value the device provides. Features, durability, and long-term performance should justify the investment.

With these factors in mind, you can effectively evaluate and choose a portable handheld laser that meets your operational demands while ensuring reliability and superior performance.

Understanding the Cost and Efficiency of a Laser Cutter

When evaluating the cost and efficiency of a laser cutter, I focus on three key aspects: the initial purchase price, operating costs, and performance efficiency. It’s essential to consider how energy consumption, maintenance requirements, and material compatibility align with my production needs. A laser cutter that offers consistent precision and faster cutting speeds can lead to significant long-term savings, justifying a higher upfront investment if it minimizes operational expenses and downtime over time.

Where to Find Reliable Laser Marking Systems

Finding reliable laser marking systems requires evaluating trusted manufacturers, industry reviews, and technical specifications to ensure optimal performance for your specific applications. Some of the leading providers in this industry include Trotec, Epilog Laser, and Datalogic, all of which are known for their innovative designs and dependable systems.

For instance, Trotec offers advanced laser marking systems such as the SpeedMarker series, tailored for industrial use with cutting-edge software compatibility and high-speed precision. Epilog Laser’s products, like the Fusion Edge series, are favored for their user-friendly interfaces and exceptional versatility, catering to a variety of materials including metal, plastic, and glass. Similarly, Datalogic provides robust solutions such as the AREX series, which features fiber laser technology ideal for fast, high-quality marking even in demanding production lines.

When selecting a laser marking system, it’s crucial to consider not only the technical features but also customer case studies and warranty offerings. Companies that provide comprehensive technical support and after-sales services can ensure a seamless integration into your existing processes. Additionally, value-added features such as automated workflow integration, energy-efficient operation, and compatibility with advanced marking software can further enhance productivity and longevity. By thoroughly researching well-established brands and available options, you’ll be able to invest in a laser marking system that meets both your current and future operational needs.

Reference Sources

-

Portable Handheld Laser Small Area Supplemental Coatings Removal System – This study demonstrates the use of portable handheld laser systems for coatings removal, showcasing their efficiency and application in various scenarios.

-

Item Unique Identification Capability Expansion: Established Process Analysis, Cost Benefit Analysis, and Optimal Marking Procedures – A detailed analysis from the Naval Postgraduate School discussing laser etching and portable laser equipment for marking.

-

Design and Fabrication of Laser Engraving Machine – This paper explores the design and fabrication of a portable laser engraving machine, emphasizing its compact and efficient design.

- Top Fiber Laser Marking Machine Supplier and Manufacturers in China

Frequently Asked Questions (FAQs)

Q: What is a portable fiber laser marking machine?

A: A portable fiber laser marking machine is a compact and mobile device designed for laser etching and engraving on various materials, including metal and non-metal surfaces. It combines the power of a fiber laser with the convenience of portability, making it suitable for on-site applications.

Q: Can a portable fiber laser engraver be used for metal engraving?

A: Yes, a portable fiber laser engraver is highly effective for metal engraving. It can precisely mark and engrave on various metal parts, making it ideal for industries that require detailed and durable markings on metal surfaces.

Q: How does a handheld fiber laser engraver differ from a desktop model?

A: A handheld fiber laser engraver offers the flexibility of mobility and ease of use in various environments, whereas a desktop model is typically stationary and used in a fixed workspace. Handheld models are designed for quick and convenient marking tasks on the go.

Q: What materials can a 20w fiber laser engraver work on?

A: A 20w fiber laser engraver can work on a wide range of materials, including metals like stainless steel, aluminum, and brass, as well as some plastics. It’s versatile enough for both metal and non-metal applications, making it a popular choice for various industries.

Q: Is color marking possible with a portable fiber laser marker?

A: Yes, color marking is possible with certain types of portable fiber laser markers, particularly those equipped with MOPA fiber laser technology. This capability allows for the creation of colored markings on metal surfaces, adding aesthetic value to the engraved items.

Q: What are the advantages of using a fiber laser engraver machine?

A: A fiber laser engraver machine offers several advantages, including high precision, fast engraving speeds, low maintenance, and a long lifespan. It is suitable for intricate designs on both small and large metal parts, making it a reliable choice for industrial applications.

Q: How does a portable laser engraving machine handle wood metal applications?

A: A portable laser engraving machine can effectively handle wood metal applications by providing precise and clean engravings on both wood and metal surfaces. It is versatile enough to switch between different materials without compromising on quality.

Q: What is the difference between a CO2 laser and a fiber laser marker?

A: A CO2 laser is typically used for engraving non-metal materials like wood, acrylic, and glass, while a fiber laser marker is more suited for marking and engraving metals. Fiber lasers generally offer higher precision and efficiency for metal applications.

Q: Can a portable handheld laser marking machine be used for industrial purposes?

A: Yes, a portable handheld laser marking machine is well-suited for industrial purposes due to its ability to deliver precise and durable markings on metal parts. Its portability allows for easy integration into various industrial settings where on-site marking is required.

Q: What types of industries benefit from using handheld laser engraving systems?

A: Industries such as automotive, aerospace, electronics, and jewelry benefit from using handheld laser engraving systems. These systems provide flexibility and precision, making them ideal for marking and engraving intricate designs on both metal and non-metal components.

- The Ultimate Guide: Mopa Fiber Laser Marking Machine

- The Ultimate Guide to Choosing the Best Laser Tube Cutting Machine

- CNC Cutting vs Fiber Laser Cutting: Which is the Better Option?

- Understanding the Difference Between CNC and VMC Milling Machines: Complete Comparison Guide

- Exploring the 5 Different Types of CNC Machines: A Comprehensive Guide

- Laser to Cut Tree Branches: Transforming Sci-Fi Concepts into Reality

- The Ultimate Laser Tube Cutting Machine: Revolutionizing Metal Fabrication

- Laser Dental Cleaning vs Traditional Methods: Revolutionizing Dentistry with Laser Teeth Cleaning