Whether you’re a seasoned pro or a DIY hobbyist, cutting pipes with accuracy and efficiency can either make or break your entire project. Having the right tools and techniques will not only save time but also enhance the quality and functionality of your work. In this pipe cutting guide, we’ll walk you through selecting the most suitable tools for various materials and employing techniques that provide precise and clean cuts each time. You will work with metal, copper, or PVC; irrespective of the material, you will acquire the skills and wisdom to improve your craft. Prepare to make effortless professional results your new standard!

What Are the Essential Pipe Cutting Tools?

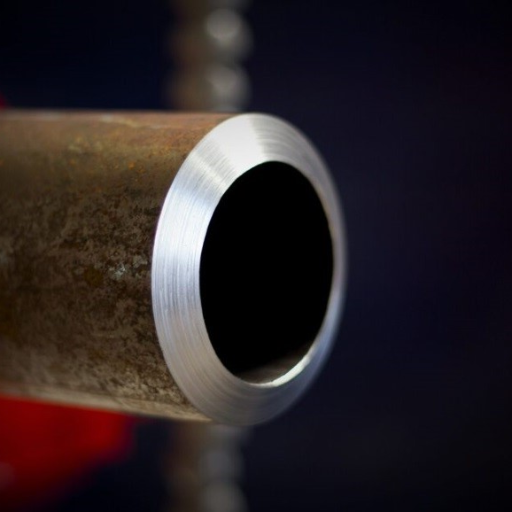

- Pipe Cutter: Used to cut a variety of pipes like PVC, Copper and Metal, Pipe cutter is a type of equipment that makes the cuts very straight and smooth.

- Hacksaw: Cuts both plastic and metal pipes very easily with a fine-toothed blade, Hacksaw is both multi-purpose and economical.

- Tubing Cutter: Works best with smaller pipes like copper tubing. Provides exact cuts and smooth edges.

- Miter Box and Saw: Make angled and straight cuts on pipes that are made from plastic.

What to Think About When Choosing Pipe Cutting Tools

When selecting the tools to cut the pipe, the efficiency and accuracy needs to be addressed first, which are determined by the material of the pipe. For example, PVC and plastic pipes are best handled with tools like a miter box and saw, or a ratcheting pipe cutter, as they create smooth cuts without cracking or deforming the material. For tougher materials such as steel or copper, more durable tools are needed. These include hacksaws and tubing cutters. Gold cutting is an example where tubing cutters are more efficient as they provide a smooth surface with minimal extra work needed for deburring.

New sharpening methods of cutting tools clear to the recent data sharpened the speed and preciseness of the processes done. Ergonomically designed ratcheting pipe cutters, for instance, enhance user fatigue management, improving workflow in plumbing contractors. Also, modern tubing cutters with hardened steel blades offer long-term reliability due to their ability to remain sharp for extended periods of use.

In relation to some large scale industrial pipe works, manual tools are set aside for electric saws and pipe beveling machines since they offer clean cuts at an unprecedented speed on thick materials. Having knowledge of these considerations as well as the type and size of the pipe aids in choosing the right tool and minimizes wastage or mistakes in maintenance and fitting.

Getting the Most from Your Pipe Cutters

For efficient use of pipe cutters, a proper approach, care in selecting the tool, and appreciation of the material being cut are required. First, choose a pipe cutter that matches the material of the pipe and its diameter. There is a good selection from simple manual ratcheting to much more sophisticated electric or hydraulic ones. Industry studies show adjustable pipe cutters provide a good fit when lengthwise cuts on copper and PVC pipes are made, saving approximately 25% of material when compared to traditional hacksaw methods.

In order to maximize efficiency, secure the pipe in the vise or clamp with enough force to eliminate any possibility of shifting or movement during the cut. Align the blade of the cutter to the pipe to be cut at an appropriate position to achieve consistent and smooth cuts. Maintain a constant grip on the manual cutters while rotating the tool around the pipe; for powered units, stick to the recommended settings for thickness and type of material. Research shows powered cutter automation greatly reduces time to cut by 40% and edge smoothness increases which is vital during complex installations.

Finally, always check the cut surface for burrs and rough edges that may affect fitting precision. Surface smoothing with a deburring tool or even sandpaper enhances finishing quality and ensures adequate connection integrity during assembly. Advanced tools in the hands of skilled tradesmen can simplify and elevate the standards of efficiency and accuracy achieved in pipe cutting operations.

Best Ridgid Pipe Cutting Tools for Professionals

Ridgid has expertly crafted pipe cutting tools to satisfy the needs of skilled professionals. Their offerings include Ridgid 118 AutoCut, which has a compact design and Ridgid 151 Quick-Acting Tubing Cutter, famed for its resilience and rapid cut execution. For more demanding jobs, the Ridgid 466 Chain Pipe Cutter delivers precision cutting on larger pipes. These tools provide exceptional dependability, productivity, and accuracy required for professional pipe cutting operations.

How Do You Cut Different Types of Tubing?

- Copper Tubing: To achieve accurate and tidy cuts, take advantage of a tubing cutter like the Ridgid 151 Quick-Acting Tubing Cutter. Clamp the tubing within the cutter, turn the blade against the tubing, and spin it around the tubing until you get a clean break.

- Plastic Tubing: A utility knife as well as a plastic tubing cutter both work well. Maintain adequate pressure when cutting so the material does not become deformed.

- Steel or Heavy Metal Pipes: A chains pipe cutter like Ridgid 466 works best for thick pipes. Place the chain firmly around the pipe and adjust as necessary so a clean and even cut is achieved.

Best practices for plastic pipe cutting

Cutting plastic pipes should be done so with utmost care in precision and safety. Using tools designed specifically for the type of plastic being cut greatly minimizes the chances of generating micro-cuts, uneven edges that would lead to weaker structural integrity. For instance, PVC and CPVC pipes do best with ratchet-style cutters which control and minimize stress on the material while cutting. As stated in the latest reports, products made by Ridgid such as the PC-1375 outperform the rest by providing better cut quality and serving industry standards by reducing clean-up time by up to twenty-five percent.

Moreover, for large undertakings, productivity may increase by 40% with the addition of an electric pipe cutting tool. These types of tools have distinct advantages when working with HDPE pipes because they avoid deformation and provide consistent pressure control. On any given project, pay attention to the maintenance of the tool as it must be sharp and clean. Block and dull tools tend to create edges which do not fit seamlessly causing pipe leaks due to jagged edges.

Health and environmental matters also ventilate the workspace proactively, especially when working with ABS and PVC that can produce tiny particles that may be cut off and released. Protective eyewear as well as gloves are useful since sharp bindings tend to be injurious when plastic shavings are dealt with carelessly.

Best Techniques With Steel and Copper Tubing Cutters

As with every other type of cutting, knowing the right tools and how to use them for steel and copper tubing cutting will yield good results. A specialized tubing cutter is the most useful for these jobs as it gives straight and accurate cuts without mangling the tubing, ensuring it maintains its shape. Softer materials like copper tubing require different treatment, and one with a sharp cutting wheel and built-in reamer is perfect. This minimizes the chance of burrs forming in the pipe.

Recent research shows that quality tubing cutters can reduce material waste of the cutting process by as much as 15%. Manufacturers advise that consistent pressure is applied while the cutter is being turned around the pipe, whilst care must be taken to not apply too much pressure as this could crimp the tubing. A cutting fluid greatly reduces friction for the cutting tool’s lifespan when used on steel tubing, which is considerably harder than other materials. Studies show that cutting steel with proper lubrication can increase the performance of the tool by 30% in reduced wear of the tool over time.

Advancements in power-operated tubing cutters have aided in increasing productivity in industrial high-volume settings. Steel and copper can be cut with these machines using hydraulic or pneumatic systems with extreme accuracy, and the time for cutting is greatly reduced in comparison to manual methods. With the use of automatic cutters, productivity for a lot of companies has increased by over 40%, their operations are now more efficient and cost-effective.

Equally as important is the proper maintenance of tools. Shrpening and cleaning the cutting wheels guarantees reliable performance as well as preventing external damage. As for selecting a tubing cutter, its wall thickness and pipe size must be considered for long-term reliability and proper fit.

Leveraging Power Tools For Tubing Cutting

Power tools, when applied in the correct context such as in tubing cutting, require both technical finesse and strategy in my case. It’s imperative to note that power tools provide the user with a much easier time when it comes to bulk work and for handling thick materials, as opposed to manual tools which require a greater amount effort and time. Furthermore, I adapt work safety protocols by putting on goggles and safeguards as well as adapting to the manufacturer’s safety techniques. Furthermore, on a day to day basis, I ensure smooth operations with regular maintenance checks such as lubricating blades and replacing worn out rods.

Why is Beveling Important in Pipe Cutting?

Pipe cutting requires beveling because the edges of the pipe must be prepared for welding while making sure that the pipe is aligned appropriately for the welding joint. This as well enables the weld defect chances through having a clean edge as well as a surface that enhances penetration. Moreover, beveling as well assists in not causing material stress while enhancing the safety and quality of the piping system.

Overview of the Beveling Process

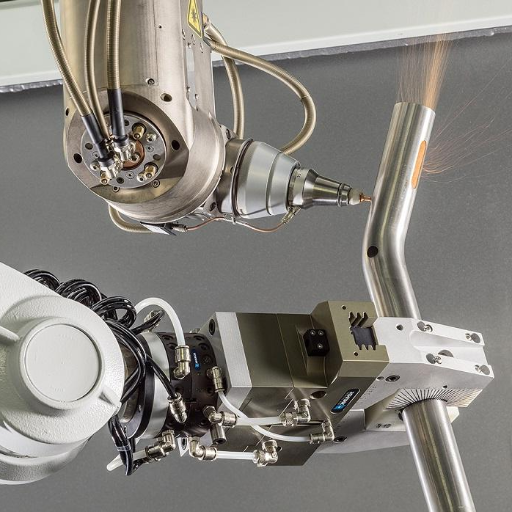

The beveling process starts with grinding and cutting a certain degree of the edge of a pipe. This is specifically done when preparing a pipe for welding. Most tools can be used for this process, and they include portable beveling machines, manual bevelers, and more industrial machines for bigger projects. The type and angle of a bevel depends on the welding specific needs, and common ones including V, J, and U. The bevel needs to be accurate because the subsequent weld is dependent on it which needs to marry and secure the two pipes.

The beveling of items is made easier using specific Tools and Machines

Relatively new to the market is a category of tools known as beveling tools which are designed to enable more efficient and accurate pipe preparation for welding. The portable pipe beveling machines have been enhanced to offer some degree of automation, greatly alleviating the workload of the employees. Some models have also been fitted with controls that enable the user to set the bevel angle anywhere from 0 to 45 degrees. This level of control guarantees accuracy of the bevel and consistency for a smooth finish.

With the capability of processing materials such as stainless steel, carbon steel and other alloys at remarkable speeds, industrial-grade beveling equipment is gaining popularity in big projects. These machines are also capable of performing both internal and external beveling which makes them very flexible. For example, new machines used for beveling can now attain feed rates of 3 meters per minute. This is particularly useful where there is a high demand for work.

In an attempt to reduce the amount of heat-damaged material surrounding the cut, new techniques in cutting such as thermally-assisted mechanical beveling have come up. These techniques also allow for better operational control and safeness, reinforcing the fact that precision instruments have great impact on welding standard.

Safety and Precision in Beveling Operations

In any beveling work, ensuring safety and quality precision is crucial to operator safety and the integrity of the workpiece. Correct training and compliance with safety guidelines are especially important in high-speed beveling machine operation. Operators must don appropriate PPE, which at a minimum includes safety goggles, gloves and hearing protection to safeguard against flying debris or excessive noise. Furthermore, arms of the beveling appliances require regular maintenance and inspection in order to eliminate malfunctions that would result in loss of precision or safety. Incorporation of modern technologies like automated control systems with mechanical safeties and stringent safety guidelines boost productivity and maintain the greatest care and accuracy in beveling operations.

How to Ensure Safety When Using Pipe Cutting Tools?

While using pipe cutting tools, safeguard your safety by always wearing the right personal protective equipment like safety goggles, gloves, and hearing protection. Check tools for any pre-use damages and make sure they are in good working condition. Be sure to fasten the pipe, so it doesn’t move during the cutting procedure. Use the manufacturer’s guidelines and adhere to the intended purpose of the tool. Keep the place of work organized and free from clutter that could contribute to tripping hazards. Lastly, staying alert and focused while avoiding distractions will minimize risks.

High-Speed Tools Safety Tips

Accidents can happen when operating high-speed tools, which is why following all safety practices is important. Each tool comes with a manual and reading it is always a good place to start. Flying objects, loud noise, and injuries to the hand happen frequently when using high-speed tools, so safety goggles, gloves, and hearing protection must be worn. Always check the tool for damages as to avoid malfunctions, and safeguard your grip to make sure the tool has not been rigged with improper safety guards that could lead to faulty handling. Clear the workspace to keep it organized and free from obstacles and clutter to maintain better focus. Moreover, refrain from loose-fitting clothing as to avoid snags. Last, never bypass tool safety features while keeping alert and taking breaks periodically to avoid fatigue.

How to Safely Maintain Pipe Cutters

Taking good care of a pipe cutter will ensure its longevity and safety during usage. Inspection of the cutting blade is also a step that should not be skipped. Be sure that the cutting blade is not damaged and has no wear issues. If a blade is damaged and rendered useless, it can lead to uneven cuts which are not only dangerous, but will require distractions increasing the chances of accidents. Proper lubrication on the moveable parts of the cutter will prevent rust as well as smooth operation. Well maintained tools can increase efficiency and precision improving workflow by 30% according to new data.

Even so, do not forget about cleaning the cutter after every use to maintain its functionality and remove all debris and residue. Storing in moist environments can lead to corrosion so store in dry places as well. Having a maintenance schedule provides good results on tool failure prevention according to modern engineering techniques. Following these best practices will increase the safety and performance when operating pipe cutters.

Understanding Tool Replacement and Maintenance

Proper tool replacement and maintenance are essential for operational efficiency and safety. Like all tools, a pipe cutter performs best when its components are in good condition. Tools should be maintained by inspecting them periodically for wear and tear, especially for cutting edges, handles and moving parts. Tools with parts that significantly degraded or no longer works as intended should be attended to as well. Following manufacturers recommendations on replacement periods and maintenance check ups will ensure the accuracy and effectiveness of the tool for a long time. Having a proactive policy in caring for and replacing tools ensures improved operational safety for all persons involved.

What Are the Latest Innovations in Pipe Cutting Machines?

The most recent developments in pipe cutting machines aim at maximizing productivity, accuracy, and operator safety. Enhanced accuracy is achieved by incorporating laser systems for cutting in most modern machines. In addition, automated systems allow cuts to be programmed where minimal effort is required, thus reducing average time spent and mistakes made. Some machines are also designed to be lightweight and portable which allows them to be used conveniently on site. Enhanced operational safety includes advanced mechanisms such as guards, protective shields, and emergency shutoff controls. The combined efforts of these innovations lead to streamlined workflow in improving productivity when performing pipe cutting activities.

Examining Adjustable and Portable Tools

The introduction of portable and adjustable tools has had a positive impact on many fields by offering convenience to workers on the move. These tools serve a particular purpose and are designed to be lightweight, thus making it easier for users to execute tasks with high efficiency while travelling. Adjustable aspects of the tools, like set dimensions or different functions enhance versatility to suit an array of project needs. Examples of such tools include portable power drills which have adjustable drill speeds and compact pipe cutters with adjustable blades. With the features of versatility and mobility combined in the tools, they allow for precise and efficient work at very little time.

Improvements in Cold Cutting Procedures

The most recent cuts cold procedures enhancements are for precision and safety optimization of various industries. These innovations comprise development of automated systems which minimize manual intervention and improve precision.

Enhanced blade materials such as carbide and diamond tips provide improved durability while increasing ease in cutting tougher materials. There is also an increasing development in jet water and abrasive cold cuts technologies widening their range of application to heat sensitive materials processing. These technologies are still in the cutting phase. These techniques not only offer clean results but offer more environmentally friendly practices having less annihilation and energy expenditure.

Advanced blade technology for clean, fast cuts

In my point of view, new blueprints of blades have changed the entire cutting process by adding effectiveness and precision. Optimized cut shapes, improved layer and new materials add to the strength of the blade and accordingly protection of wear and slashing. These add-ons will not only enhance how the blade works, but also meet the varied demand of industries which require tougherilder tasks.

Reference sources

- Heat Pipe Embedded End Mills:

- Key Findings: This study explored the use of heat pipe technology in end mills to manage heat during milling operations. The heat pipe significantly reduced tool temperatures (by up to 29%) and thermal stress, enhancing tool life and performance. It also demonstrated potential for dry milling, reducing reliance on cutting fluids.

- Methodology: Numerical simulations were conducted using finite element analysis to compare dry milling, fluid cooling, and heat-pipe cooling scenarios.

- Cutting Techniques in Decommissioning Projects:

- Key Findings: The research reviewed various cutting tools and techniques for dismantling nuclear facilities. It highlighted the importance of selecting tools based on material type, contamination levels, and operational constraints. Tools like mechanical nibblers, shears, and abrasive cutters were emphasized for their efficiency and adaptability.

- Methodology: The study was based on practical experiences from decommissioning projects, focusing on tool performance, waste minimization, and safety measures.

- Low-Cost Automatic Sheet Cutter:

- Key Findings: This study introduced a portable, low-cost automatic sheet cutter for SMEs. The system, controlled by Arduino, improved cutting precision and efficiency for materials like rubber and PVC. It was designed to be user-friendly and adaptable for small-scale operations.

- Methodology: The cutter was developed using stepper motors and an Arduino-based control system. Performance was evaluated through precision tests, showing acceptable accuracy for SME applications.

Frequently Asked Questions (FAQs)

Q: What guides have been published about types of tools used to cut pipes into sections?

A: Available types of pipeline cutting tools include, but are not limited to, hand operated and mechanical tube cutters, automated saws, and high speed rotary tools. These tools are specialized for specific tasks depending on the materials as well as the tube dimensions.

Q: What with regards material selection will ensure the safest tool for use in cutting pipes?

A: In the case of cutting tubes and pipes, the safest tool is determined to be based on both material and thickness. In such instances, safety features such as guards, protective shields, and handles are accessible. Additionally, care and instructions provided by tool manufacturers should be strictly adhered to.

Q: Since there are many types of tubes, which tools are considered the best when working with aluminum tubes?

A: Aluminum tubes can easily be cut using a metal saw as well as rotary tools fitted with the right accessories. The majority of these tools deliver simple operations on aluminum as well as clean cuts.

Q: Does a tube cutting apparatus have the ability to work with both tubing and piping materials?

A: A good number of tube cutting appliances that are commercially available do have the ability to accept both pipe and tube materials. Be certain, however, that the specifications for your tool matches the size you have in mind as well as the material.

Q: How is a high-speed rotary tool helpful in cutting tubes?

A: Precision and control, especially for small-diameter tubes, are a few benefits that high-speed rotary tool offers while cutting tubes. Its high-speed capabilities enable precision cuts, while the proper accessory makes it versatile enough to tackle an expansive range of materials.

Q: What criteria should I keep in mind while selecting a tube cutting accessory?

A: While selecting a tube-cutting accessory, think about the material and diameter of the tube as well as the type of cut required. Other accessories such as blades and reamers should also be considering, as they need to be customizable with your rotary tool for the job at hand.

Q: Are powered saws good in ease of use when it comes to cutting tubes?

A: A powered saw is indeed easy to operate when it comes to cutting tubes; this, of course, is assuming a few conditions are met. For example, the saw features a power-to-weight ratio designed towards effortless use as well as ergonomic handles for easy manoeuvring. Remember to follow all safety procedures for best outcomes.

Q: What are the benefits offered by using a reamer after cutting tubes?

A: Apart from ensuring all burrs and sharp edges have been removed, the use of a reamer helps to smoothen the edge of a cut tube. More importantly, damage to the tube and components that are meant to be connected won’t occur, allowing smoother assembly of auxiliary parts.

Q: Are tube cutting tools capable of cutting high strength materials?

A: Certainly, most tube cutting tools are equipped to cut through tough materials. As always, using the proper tool as well as the correct accessory matched to the material at hand will provide effective cutting as well as prolong the life of the tool.

- Unlocking the Power of Laser Cutting: Everything You Need to Know

- Optimizing Production with Fly Cutting in Fiber Laser Machines

- 3D CNC Router Machine: Your Guide to Rotary CNC Routers

- Unlocking the Potential of a 3-Axis CNC Machine: What Can It Do?

- Understanding How Laser Marking Machines Work: A Complete Guide to Laser Marking Technology

- Understanding Speed in Laser Marking: How to Optimize Your Laser Marking Machine

- UV Laser vs Fiber Laser Marking Machine: Choose Your UV Marking

- Buying a Cheap Laser Cutter: Pros and Cons of Budget Laser Machines