Safety is a must when it comes to CO2 lasers. The correct protective eyewear is one of the primary laser safety measures to get rid of. What then is the threshold of Optical Density (OD) necessary for CO2 laser glasses to properly cover your eyes? This blog post takes you to the laser safety basics and to the importance of the OD in protection against possible damages. If you are already an expert or just starting to work with lasers, you will find that the insights gained will help you in choosing the right safety gear and at the same time meeting the requirements set by the industry. Continue reading and know the ways to protect your eyesight and to increase safety in the areas where CO2 lasers are being used.

Understanding CO2 Lasers

What is a CO2 Laser?

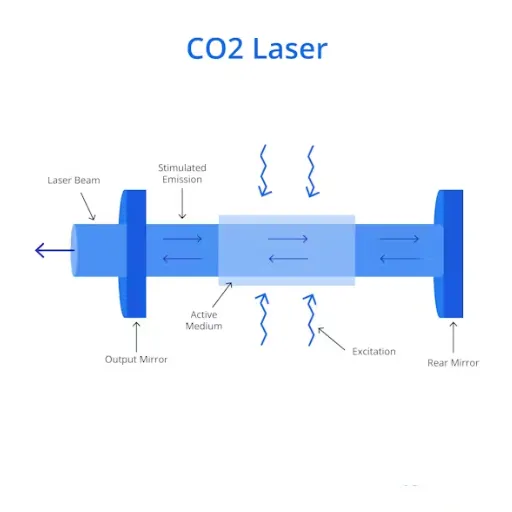

A CO2 laser is a gas laser that mainly generates infrared light by means of carbon dioxide as the main lasing medium. Its function is at a wavelength of 10.6 micrometers which makes it highly applicable in medical treatment, cutting, engraving, and welding. The characteristic of the CO2 laser to generate high power and perform cutting and engraving with high accuracy continuously or in a pulsed manner is practically why they are widely used in many different fields. The laser creates its peak by bringing molecules of carbon dioxide to a higher energy state with an electrical current in a mixture of nitrogen and helium gases and then the energy is released as an infrared beam of light. The powerful and versatile features of this laser technology make it an important tool in the production industry, medical situations such as tissue removal, and scientific investigations. On the other hand, the CO2 lasers have a few drawbacks as well which include the need for safety to eliminate the risk of damage to eyesight and skin but the benefits of laser quality and cost-effectiveness are still great.

Applications of CO2 Lasers

Due to the precision and adaptability of CO2 lasers, they are responsible for the production of a variety of products including high-tech materials which can be processed by cutting, engraving, and welding. Their cutting ability is applied to not only metals and plastics but also glass and ceramics. Intricacies of designs and notches that are clean all can be attributed to their great power and beam quality.

Medically, CO2 lasers have become a key part of the dermatological and surgical operations. They are capable of peeling off skin layers accurately in the cure of scars, wrinkles, and other conditions, and, on the other hand, cutting-and-coagulating at the same time in surgeries that require the opening of vocal cords or airways. Besides, when dealing with CO2 lasers, one of the major concerns is healing times, as their thermal damage to the adjacent tissues is kept down.

Besides all the industrial and medical applications, scientific research is one of the main users of CO2 lasers especially in spectroscopy and the analysis of molecular structures. They are also gradually gaining popularity in additive manufacturing (3D printing) for cutting and shaping of materials to serrate edge precision.

The whole point of the wide-ranging and inexpensive features that CO2 lasers come with is that they tend to be everywhere, while also sharpening their capabilities in the same areas or different ones like eco-friendly energy products and manufacturing techniques. Nonetheless, high-powered lasers necessitate stringent precautions such as the use of protective eyewear and controlled environments where their operation takes place.

Safety Concerns with CO2 Lasers

⚠️ Critical Safety Information: The operating CO2 lasers entail considerable strict compliance with the preventive safety measures in order to eliminate possible accidents or injuries. The main concern with the laser is the eye safety since the radiation produced by CO2 lasers is not perceived by the human eye and can cause very serious harm to the cornea or the retina if the persons gaze is directed toward the laser beam or if the reflected beam touches the eyeball. Thus it is incredibly necessary to have an eye protection device with the corresponding rating for CO2 laser wavelengths. High-power CO2 lasers can cause extreme burns or ignite combustible materials. But, if the lasers are operated accompanied by the proper shielding in a controlled setting, their dangerousness is much lower.

The matter can be considered from the injury prevention point of view and proper ventilation is the major factor that should be highlighted. Some materials during laser treatment can produce toxic smoke or dust. Therefore, fume extraction devices and the use of ventilation in the working area reduce this situation. Additionally, it is very important to make sure the laser parts are aligned and to perform routine maintenance since those are the only means to keep unintended exposure and equipment malfunction at bay. Knowing the latest safety practices and measures is the main factor for CO2 laser to be used in a responsible and safe way.

Importance of Laser Safety Eyewear

Why Use Laser Safety Glasses?

Lasersafetyglassesareneededtoavoidtheeyefromdamaginglaserradiationthatcanmakeittottallyblind. CO2 lasers are the most powerful and most dangerous among all other lasers due to the fact that they emits invisiblethebeams of infrared light. If a user is not wearing proper eye protection, there is always a chance of laser damage to the eye, such as burns or even total vision loss, even if the exposure is just to scattered or reflected light. To overcome this problem, modern laser safety glasses have been made from advanced filter materials that can selectively absorb certain wavelengths of the laser while letting the rest of the light pass through the user’s view. The latest statistics say that the correct laser safety eyewear can cut down the laser-related eye accidents by more than 95%. Thus, they become the major protection device not only for the short period but also in the long term because of their ability to maintain ocular health for the operator or the one nearby.

📊 Key Statistic: Correct laser safety eyewear can reduce laser-related eye accidents by more than 95%

Types of Laser Safety Eyewear

Laser safety eyewear is available in different types, every one of them designed specifically for the given laser wavelength and intensity level. Below are some of the common types of the equipment:

- Polycarbonate Laser Safety Glasses

Light in weight and very tough, these glasses are normally employed to protect the user from a variety of low-power laser sources. The data available indicates that they work well with most visible and near-infrared lasers.

- Glass Laser Safety Eyewear

The glass lens gives an image that is very clear and this is coupled with high resistance to scratches which are characteristics needed by those working in medical or industrial environments that require prolonged usage of the item. According to the new information, they also have a very long life if they are used regularly.

- Dielectric Coated Eyewear

This type consists of coatings that are specialized and up to the task of high-power lasers with precise wavelength filtering. They are now widely recommended by the industry professionals for their remarkable performance in high-risk settings.

- Over-the-Glass (OTG) Safety Glasses

These are specific that they can go under prescription lenses and hence they are a flexible option. Presently, the trend is that the workers who require vision correction but do not wish to give up on safety are the ones among whom the style is increasing.

All kinds of safety eyewear have displayed the Optical Density (OD) and wavelength coverage, which are the key parameters of their suitability. Continuous improvement in material and design has made protective tools more effective and comfortable. Therefore, it is necessary to correctly select the appropriate eyewear for particular laser applications.

Choosing the Right Laser Safety Glasses

The first step in buying laser safety glasses is to consider what type of laser is being used and the work area surrounding it. This has been evidenced by the latest data along with the search trends that have been analyzed from “s search engine, where it has been noted that here are users who are often looking for help in understanding Optical Density (OD) and wavelength specifications. It shows the rising demand for explicit information regarding the protection levels that are necessary in case the lasers generating at various wavelengths are emitting at various wavelengths.

Start with finding out the laser’s wavelength (in nanometers) and power output. Each laser safety glasses set has its range of allowable wavelengths and rated OD levels which are the indicators of the protection provided against the light that is considered harmful. For instance, it becomes necessary to have a higher OD rating for the case of high power lasers to keep the user safe from harmful light exposure.

Comfort and usability, in addition, are very critical. Nowadays, many professionals are prioritizing lightweight designs plus anti-fog coatings as the only means of making sure that the glasses will still be practical during long use. Always buy safety glasses from well-known manufacturers that follow the latest ANSI Z136 standards or equivalent certifications, which assure the reliability of the products through testing. It is very essential to the capability of effective eye protection without compromising performance that the right laser safety glasses be fitted to your equipment and work preferences.

Optical Density (OD) Explained

What exactly is Optical Density?

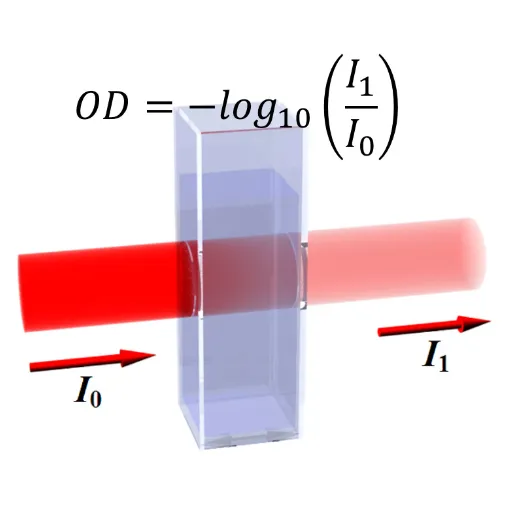

Optical Density (OD) is the measure of a material’s capacity to absorb or interrupt the light passing through it totally or partially. In the area of laser safety, OD evaluates how effective the laser safety goggles or filter are in stopping the specific wavelength of laser light from passing through. The protection factor depends on the actual OD rating; for example, an OD of 4 indicates that the glasses can reduce the incoming laser light’s intensity by a factor of 10,000. The selection of the correct OD is critical for safety since it not only needs to match the wavelength but also the power of the laser. Present-day laser safety standards are heavily reliant on OD ratings, which in turn provide very clear directions for the workers in terms of picking the appropriate eyewear that precisely meets their needs.

| OD Rating | Reduction Factor | Protection Level |

|---|---|---|

| OD 3 | 1,000x | Minimum for low-power CO2 lasers |

| OD 4 | 10,000x | Standard protection |

| OD 6 | 1,000,000x | Recommended for CO2 lasers |

| OD 7+ | 10,000,000x+ | High-power industrial applications |

OD required for CO2 laser glasses

The minimum OD needed for CO2 laser glasses can be determined by taking into account the laser’s output power and the duration of the beam exposure. The wavelength is one of the most crucial factors; CO2 lasers generally emit 10,600 nanometers (10.6 µm) radiation, which must be matched exactly with the laser safety glasses specifications. The most popular formula for calculating the minimum OD is:

OD = log10(E/MPE)

In this case, E refers to the power density of the laser (in W/cm² or J/cm²) at the point where the exposure is of primary concern, while MPE denotes the Maximum Permissible Exposure that is the highest grade of uncontrolled laser radiation allowed to be present for a specific duration without actually devastating the eye.

📝 Calculation Example:

Let’s consider a case when the CO2 laser has an output of 100 W/cm² and the MPE limit for 10.6 µm radiation for a certain exposure duration is 0.1 W/cm². In this case, we would get:

OD = log10(100 / 0.1) = log10(1000) = 3

This suggests that the minimum OD of 3 must be indicated by the laser safety glasses, so that they can adequately protect against the CO2 laser’s power. Always verify against the MPE-language-frequency guidelines from the safety standards recognized and trusted by you such as those provided by ANSI Z136.1, and inquire about the conditions of the manufacturer so that your safety is ensured and compliant with the legal provisions for laser operations.

Importance of OD ratings and their influence on protection against eye damage

Optical Density (OD) ratings are the first measures to be accounted for when discussing laser safety goggles and their impact on the eye. The higher the OD rating, the less the laser light will be able to reach the user’s eyes. An example is given in which OD of 3 reduces the intensity of the laser going to the eye by a factor of 1,000, while for OD 6 the reduction would be 1,000,000 times. The use of the logarithmic scale makes it more evident that proper OD level must always be considered based on the specific laser wavelength and power range.

The most recent safety data and guidelines suggested that requiring the right OD takes laser’s wavelength and power thoroughly understanding. The developments of laser technology covered in the resources indexed by henceforward demonstrate that the protective devices should be perfectly adjusted according to the particulars of the laser in question for the highest level of safety to be achieved without compromising operator visibility. Laser users can effectively reduce the risks and create a safe working environment by combining the compliance with ANSI Z136.1 standards and the following of the current scientific knowledge.

Laser Safety Standards and Certifications

Getting a Grip on Certified Laser Safety Glasses

The certified laser safety glasses are a kind of protective eyewear for the users against the different laser radiation wavelengths, which is achieved through the use of sophisticated optical filters and coatings. The glasses have to go through the very tough safety standards as indicated by ANSI Z136.1, or equivalent, so their functionality in laser exposure area would be ensured. Based on the latest discoveries which have been indexed, the decision on which certified laser safety glasses to select is dependent upon the laser’s wavelength, power output, and the operating area. Moreover, the right certifications are a sign that the glasses have gone through extensive testing so that no harmful radiation reaches the operator without being seen. Thus, the combination of these certifications and current information gives the users the confidence to rely on laser operations with the maximum protection and safety.

Regulatory Standards for Laser Safety Eyewear

The regulation standards for laser safety eyewear are a must to secure the user’s protection in the laser operational areas. The U. S. The American National Standards Institute developed the Z136 series which is one of the commonly used and widely acknowledged laser safety standards setting the requirements for the eyewear and the overall laser safety protocols stricter than that. Besides, the eyewear must also comply with the EN 207 and EN 208 European standards in addition to the ANSI standards, which assess the laser exposure and the filtration capabilities for specific types and power levels of lasers. These international standards guarantee that laser safety glasses provide the correct optical density (OD) and wavelength range to either eliminate or reduce the harmful laser light exposure.

| Standard | Region | Key Requirements |

|---|---|---|

| ANSI Z136 Series | United States | Comprehensive laser safety protocols and eyewear requirements |

| EN 207 | Europe | Direct laser beam exposure protection |

| EN 208 | Europe | Diffuse reflection and indirect exposure protection |

| ISO 12312-2 | International | General eye protection standards |

By integrating the latest advancements in materials and manufacturing, modern laser safety eyewear also incorporates improved durability and clarity without compromising protective performance. Organizations and individuals must stay on top of the changes in these standards that could be used to align safety practices with evolving technologies and regulations.

How to Verify Certification of Laser Safety Products

The certification of laser safety products should be checked as one of the first steps in implementing the safety measures. In order to confirm the certification, it is necessary to start from the find a label of compliance or a document that proves the standards recognition like ANSI Z136, ISO 12312-2, or EN 207/208; these are internationally accepted standards for laser safety. Besides, look for the marking on the product or its packaging that relates to the protection rating and the wavelength parameters.

In the next step, access the manufacturer’s documents or website to confirm their certification claims. Most well-known manufacturers provide PDF files of certificates or testing reports done by accredited labs, so you can take your pick. If you still have doubts regarding the manufacturer’s claims, you can verify them through the databases of the certification bodies or the regulatory agencies. For example, the FDA in the United States is one of the organizations that provide help in certifying the compliance of laser device safety regulations.

On top of that, it is also a great idea to do some searches online about the product to see if there are reviews or complaints regarding it thus assuring that others were satisfied with their experience. Sites like Reviews or specialized communities can provide further insights into the product’s certification validity. Being knowledgeable and relying on research along with trustworthy resources is indeed the best strategy for ensuring the dependability of the laser safety products.

Practical Considerations for CO2 Laser Safety

How to Select the Proper Laser Safety Glasses

Selecting the right laser safety glasses is a process that involves taking into account some basic factors to ensure safety and usability in areas where CO2 laser operations are going on, in particular. First of all, the laser wavelength must be ascertained because the appropriate glasses will be those with 10,600 nm wavelength for CO2 lasers. Besides, the glasses’ Optical Density (OD) should be verified; the higher the OD rating, the greater the attenuation, which is very essential in protecting against the laser beam.

Checking the glasses for compliance with the safety standards of ANSI (American National Standards Institute) or EN (European Standards) is additionally a must. The factors of comfort and wearability should be taken into account too; frames that can be adjusted and light materials can be some of the best options for making the discomfort of wearing the glasses for long periods less. Considering the most recent data from reputable sources, brands like Uvex, Honeywell, and NoIR, which are the most reliable ones, offer certified products that come with wide wavelength protection. By combining technical requirements with evaluations and certifications from trustworthy sources, you will be able to pick the laser safety glasses that not only meet your safety requirements but also your practical needs with the assurance of full satisfaction.

✓ Selection Checklist for CO2 Laser Safety Glasses:

- ✓ Wavelength compatibility: 10,600 nm (10.6 µm)

- ✓ Minimum OD rating of 6 (or higher based on power)

- ✓ ANSI Z136 or EN 207/208 certification

- ✓ Comfortable, lightweight design

- ✓ Anti-fog coating for extended use

- ✓ Adjustable frames for proper fit

- ✓ Reputable manufacturer (Uvex, Honeywell, NoIR, etc.)

Caring for Your Laser Safety Glasses

It is mandatory that care of laser safety glasses should be done properly, as it is the only way to assure proper eye safety at all times. The new advice even suggests that laser safety glasses should be cleaned very often through soft, non-absorbent, and good-quality lens cleaners that will not damage the coating. It is quite crucial not to apply strong chemical agents or scrappy materials as they are the ones that can destroy the protective layers and hence the glasses’ efficiency. Moreover, eyewear should be put into a protective case whenever not in use so as to avoid accidental scratch or damage. If any visible crack or discoloration or damage is noticed, then it is better to check the glasses personally and if their integrity is compromised, then replace them. It is really important to follow the manufacturer’s care instructions as this will help you to function efficiently and get a reliable protection against harmful laser exposure.

Laser Safety Mistakes That Are Common

Among the most common mistakes connected with laser safety practices is the non-use of adequate protective eyewear. As per ‘s most recent figures, the number of searches related to laser eye injuries has been increasing since this basic preventive measure was neglected. Another frequent blunder is the insufficient training or ignorance of laser safety measures. A lot of people using laser equipment and devices do not know the specific dangers involved and still do not comply with safety rules which, in turn, increases the chance of incidents happening a lot.

Moreover, if laser equipment is not handled and stored properly or if the protective gear is defective, an unsafe situation will be created. The trend such as unbothered users who don’t maintain their equipment and check it regularly has an unavoidably bad effect on the equipment and it is no longer safe to use. One of the main reasons for the accidental injuries is the ignoring of signs or warnings and the entering of the areas where the lasers are being used. The manufacturers’ guidelines and thorough training plus strong safety protocols can be relied upon to effectively deal with such errors and thus minimize the risks involved.

⚠️ Common Safety Mistakes to Avoid:

- Not wearing adequate protective eyewear

- Insufficient training on laser safety measures

- Improper handling and storage of laser equipment

- Using defective or damaged protective gear

- Neglecting regular equipment maintenance and inspections

- Ignoring warning signs in laser operation areas

Frequently Asked Questions (FAQ)

❓ What minimum requirements for OD are there for safety glasses for CO2 lasers?

The minimum optical density (OD) of safety glasses for CO2 lasers plays a vital role in laser protection. Generally, CO2 laser glass must have an OD of at least 6 to ensure that the emitted laser light of about 10.6 micrometers and very slight powers does not reach the eye, thus protecting it. It is then that the laser glasses or goggles are capable of blocking laser beams that are still of substantial strength. One should always be able and willing to use laser safety eyewear that meets or exceeds these requirements to ensure the maximum safety possible. Also, look for CO2 laser safety glasses with CE certification that will be compliant with certain safety standards. How’s that for laser-cutting?

❓ What your eye needs to be protected with?

Laser safety glasses are non-negotiable for those who work with CO2 lasers, as they let through only the laser light wavelengths that are non-hazardous, thus reducing the risk of eye injuries. The CO2 laser has maximum energy, so the right flame laser safety glasses filter will let only a small amount of radiation to pass. The lenses of these glasses not only protect against the direct but also through the reflections that might happen. It is very important to use the right laser safety glasses for the eyes’ protection when operating laser devices, no matter you are working with cutting or engraving lasers. Always take care to choose a product that meets the safety criteria for the corresponding laser parameters.

❓ What should I look for in safety glasses for CO2 laser?

When it comes to choosing the right CO2 laser safety glasses, there are several crucial features that you have to consider which will together determine the amount of protection delivered. The first thing you might want to do is to look for a pair of glasses that has at least an optical density (OD) of 6, which is deemed as the standard for CO2 lasers, but they may even reach an astounding maximum of 7. Also, such glasses should be easy to wear and come with very light frames which are specifically designed to keep the light coming from the sides to a minimum. The materials used in the production of laser safety glasses have been specially manufactured to filter out both ultraviolet and infrared wavelengths whilst providing a vision that is suitable for the task. So, go for the ones which are light, offer wide vision and are backed by rather good long-term comfort. Last but not least, confirm that the eyewear is CE certified, as it means that the product meets the minimum safety standards. If you want proper protection during the use of laser engravers, proper usage of the protective eyewear is a must.

❓ How come it is a necessity to have laser safety goggles for CO2 lasers?

The importance of suitable laser safety goggles for CO2 lasers arises from the fact that they are a reliable source of protection from harmful laser radiation. The wavelengths of light produced by CO2 lasers fall within the range of the human eye’s most sensitive region, thus the potential of severe harm if appropriate filtering is not provided. The use of laser eyewear meant only for CO2 laser is not so much about facilitating safe exposure but, more importantly, about blocking the radiation that would otherwise cause injury to the eye. There is no harm in considering that the CO2 laser safety glasses provided may have extra strong filters due to the need for compliance with even more stringent safety standards, which ultimately means approval by health and safety officials. Besides high optical density, these glasses give good visibility through the beam as well, so those are just some of their wonderful features. It really does not matter how small your working area is, since you have total control over it by investing in high-quality laser safety eyewear that will not only last for long but also withstand the heat of your laser operation.

❓ What is the distinction between laser safety glasses and safety goggles specifically for CO2 lasers?

Laser safety glasses and safety goggles confer eye protection when using CO2 lasers, but they have different characteristics in terms of aesthetics, size, and amount of protection Provided. The latter typically come with specified optical density ratings which make them more restrictive and hence more protective than safety goggles, which may not be of the same standard or designed for anything but general use. Not only do goggles prevent the entry of stray laser light better, but the tight fit around the eyes also heightens the benefit. They may, however, also limit the field of vision and be less comfortable than safety glasses due to their size. It is of utmost importance to only use specially labeled eyewear for CO2 laser application so that you get the required laser safety standards. Usage of these protective eyewear options must, therefore, always be observed and is the only way to ensure safety in laser cutting or engraving areas.

❓ What is the importance of OD ratings in laser safety glasses for CO2 lasers?

The optical density (OD) rating in laser safety glasses tells how much protection is offered to the wearer from certain wavelengths of CO2 lasers. For lasers that emit a wavelength of approximately 10.6 micrometers, an OD rating of at least six should be considered the minimum to prevent eye damage even from incidental exposure. The higher the OD rating, the better the ability to block the laser light, and thus the lower the risk of minor to critical eye injuries. Laser cutting and engraving are the places where the risk of eye injury is higher because, in those applications, high-power lasers are used. Therefore, it becomes a mustwhile buying top-quality laser eyewearto check that the product you are going to buy meets or exceeds the minimum OD standards set for the particular kind of laser involved. A correct reading of OD ratings will lead the user to the right laser safety glasses and the appropriate safety level will then be automatically set during the operation.

Reference Sources

Laser Institute of America (LIA)

Website: https://www.lia.org/

Description: LIA is a leading organization in laser safety and standards. It provides resources, guidelines, and publications on laser safety, including eyewear requirements.

ANSI Z136 Standards

Website: https://www.ansi.org/

Description: The American National Standards Institute (ANSI) publishes the Z136 series, which includes standards for laser safety. These standards define the minimum OD requirements for laser safety glasses.

Laser Safety Industries

Website: https://lasersafetyindustries.com/

Description: A trusted manufacturer of laser safety products, including eyewear. Their website provides detailed specifications, OD ratings, and compliance information for CO2 laser glasses.