When it comes to precision, versatility, and efficiency, mini laser marking machines have revolutionized the way we approach engraving and marking tasks across various industries. Compact yet powerful, these machines offer a cutting-edge solution for creating detailed and permanent marks on a wide range of materials, from metals and plastics to wood and glass. But what makes them so indispensable? This guide dives deep into everything you need to know about mini laser marking machines—exploring their core features, benefits, and applications while helping you decide if one is the right fit for your business or personal projects. Whether you’re new to laser technology or looking to upgrade your marking process, this comprehensive article promises to equip you with valuable insights and actionable advice.

What is a Mini Laser Marking Machine?

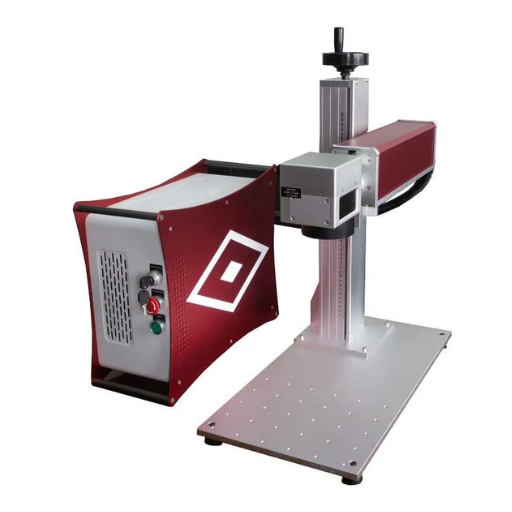

A mini laser marking machine is a compact and efficient device designed to engrave or mark a wide range of materials, such as metal, plastic, wood, and glass, with precision and clarity. These machines use laser technology to create permanent markings, including logos, serial numbers, barcodes, or custom designs. Lightweight and portable, they are ideal for businesses or individuals who require high-quality results in smaller spaces or for on-the-go projects.

Understanding the Basics of Laser Technology

Laser technology, an acronym for Light Amplification by Stimulated Emission of Radiation, operates by focusing a highly concentrated, coherent beam of light onto a material’s surface. This process involves exciting atoms or molecules of a lasing medium, such as gas, crystal, or fiber, to emit light at specific wavelengths. The emitted light is then amplified through reflection, producing a powerful, precise beam capable of interacting with various materials.

Modern laser marking machines utilize key advancements in laser types, including fiber lasers, CO2 lasers, and UV lasers. Fiber lasers, renowned for their high efficiency and low maintenance, are particularly effective for metals and high-contrast marking. CO2 lasers excel in marking non-metallic materials like wood or acrylic, while UV lasers are ideal for ultra-precise applications on delicate substrates such as glass or certain plastics.

Data highlights how rapid advancements in laser technology have transformed industrial standards. The beam quality of modern lasers allows for a focused spot size as small as a few micrometers, achieving exceptional precision with minimal heat-affected zones. For instance, recent optical systems enable speeds up to 7000 millimeters per second for high-throughput marking.

Additionally, these machines reduce operational costs by eliminating consumables like inks or dyes commonly used in traditional marking methods. They also play a pivotal role in traceability and anti-counterfeiting, which are becoming increasingly critical across industries such as aerospace, automotive, and healthcare.

This cutting-edge technology continues to evolve, emphasizing sustainability, efficiency, and versatility. It enables businesses to adapt to rapidly changing demands while maintaining the highest levels of quality and productivity.

Key Features and Benefits of Mini Laser Marking Machines

Mini laser marking machines have become a game-changer in modern manufacturing due to their compact size, precision, and adaptability. Below are the standout features and corresponding benefits:

- Compact and Portable Design

Mini laser marking machines are specifically designed with a small footprint, making them ideal for businesses with limited workspace. Despite their size, these machines deliver high performance, allowing for easy integration into various production environments.

- High Precision and Speed

Equipped with advanced laser technology, these machines can engrave microscopic details with a precision of up to 0.001 inches. This level of accuracy ensures consistent, high-quality markings, particularly crucial for industries like electronics and medical device manufacturing. Furthermore, their rapid marking speeds boost productivity, with some models capable of marking up to 300 characters per second.

- Versatility in Material Compatibility

Mini laser markers can handle a broad range of materials, including metal, plastic, glass, ceramics, and wood. This versatility makes them suitable for multiple applications, such as engraving serial numbers, logos, barcodes, and decorative designs.

- Cost-Effective and Energy-Efficient

Designed with efficiency in mind, these machines consume less power compared to traditional marking systems, offering substantial cost savings over time. Additionally, their low maintenance requirements and long-lasting laser sources contribute to reduced operational costs.

- Enhanced Traceability and Anti-Counterfeiting

Mini laser marking systems provide permanent and tamper-proof markings, crucial for industries such as aerospace, automotive, and healthcare. By ensuring traceability and combating counterfeiting, these machines help maintain supply chain integrity and regulatory compliance.

- Eco-Friendly Technology

Unlike older marking techniques, mini laser markers use no inks, solvents, or chemicals, making them an environmentally friendly option. Their non-contact process minimizes waste and pollution, aligning with sustainability goals.

- User-Friendly Operation and Software Integration

Advanced mini laser marking machines come equipped with intuitive software interfaces for easier operation. Integration with existing systems, such as ERP or quality management systems, allows for seamless data transfer and streamlined workflows, enhancing efficiency across production lines.

- Durability and Longevity

Built with high-quality components, these machines are designed to endure tough industrial conditions. With a typical laser source lifespan of up to 100,000 hours, they offer excellent reliability and long-term investment value.

How Mini Laser Marking Machines Differ from Traditional Options

| Aspect | Mini Laser Marking Machines | Traditional Marking Methods |

|---|---|---|

|

Precision |

High precision, intricate details |

Lower precision, less detailed |

|

Speed |

Fast marking process |

Slower marking process |

|

Material Compatibility |

Works on diverse materials |

Limited material compatibility |

|

Setup Time |

Minimal setup required |

Longer setup time |

|

Maintenance |

Low maintenance needs |

High maintenance needs |

|

Durability of Marks |

Permanent and wear-resistant |

May fade or wear over time |

|

Environmental Impact |

No consumables, eco-friendly |

Uses inks/chemicals, less eco-friendly |

|

Cost |

High initial investment |

Lower initial cost |

|

Customization |

Easy digital customization |

Manual adjustments needed |

|

Safety |

Requires safety precautions |

Generally safer to operate |

How Does a Laser Engraving Machine Work?

Laser engraving machines work by directing a focused laser beam onto a material’s surface to remove layers and create precise, permanent designs. The process begins with software that translates the desired design into a format the machine can understand. The laser then emits a high-energy beam, which generates heat to vaporize or alter the material at specific points. This controlled removal of material allows for detailed engravings on a wide range of surfaces, including metals, plastics, and wood. The precision and efficiency of laser engraving make it ideal for various industrial, commercial, and artistic applications.

The Role of the Laser Beam in Engraving

The laser beam serves as the central tool in the engraving process, utilizing concentrated light energy to achieve unparalleled precision. Modern laser systems operate within specific wavelengths, commonly in the infrared spectrum, allowing for controlled interaction with various materials. For instance, CO2 lasers are highly effective on non-metal materials like wood, acrylic, and glass, while fiber lasers excel at engraving metals such as stainless steel, aluminum, and titanium.

The precision of laser engraving is often measured in terms of DPI (dots per inch), with state-of-the-art machines achieving resolutions of up to 1,000 DPI. This high level of detail enables intricate designs, such as custom logos, serial numbers, and complex patterns. Additionally, advanced laser systems offer dynamic power settings, ranging from milliwatts for delicate materials to significant wattage for deeper engravings or cutting applications. For example, a 60-watt CO2 laser is capable of engraving wood at a depth of 0.5 mm with exceptional clarity.

The efficiency of laser engraving extends to its speed, with some industrial systems capable of processing up to 3,000 mm per second. This not only enhances productivity but also ensures consistency across multiple units. Furthermore, the non-contact nature of laser engraving minimizes material waste and tool wear, making the process both cost-effective and environmentally friendly. Whether for detailed artwork, industrial labeling, or customizable items, the laser beam remains at the forefront of innovation in engraving technology.

Understanding Laser Source and Its Importance

The laser source is the core component of any laser system, playing a fundamental role in determining its power, precision, and application scope. A laser source functions by generating a concentrated beam of light through the amplification of electromagnetic radiation. Laser sources are categorized into several types, including CO2 lasers, fiber lasers, and diode lasers, each tailored to specific applications.

Fiber lasers, for instance, are known for their high efficiency and precision, making them ideal for marking, cutting, and engraving on metals and non-metals. Statistics show that they account for a significant share of industrial laser applications due to their durability and energy efficiency, with power outputs ranging from 20W to over 100kW in advanced systems. CO2 lasers, on the other hand, excel in cutting and engraving non-metal materials such as wood, acrylic, and paper, offering exceptional quality and speed at competitive costs.

The selection of an appropriate laser source is critical as it directly impacts key performance parameters like beam quality, wavelength, and energy consumption. Modern laser technology prioritizes energy efficiency, with many systems reporting up to 70-80% electrical efficiency in industrial applications. Additionally, innovations in laser sources have contributed to reducing operational costs and expanding application versatility, cementing their importance in fields ranging from manufacturing to medicine. Understanding the characteristics and advantages of different laser sources allows businesses to make informed decisions tailored to their specific needs.

Exploring the Marking System and Its Components

A modern marking system is a sophisticated assembly of technologies working cohesively to deliver precise, efficient, and durable markings across a variety of materials. Below are the key components and their roles:

- Laser Source

The laser source is the core of the marking system, responsible for generating the concentrated beam of light used for marking. Contemporary systems often utilize fiber lasers, CO2 lasers, or ultraviolet lasers, with fiber lasers being particularly popular due to their longevity, high power efficiency, and minimal maintenance requirements. Fiber lasers can deliver lifespans of up to 100,000 hours, making them ideal for industrial environments.

- Marking Head and Scanner

The marking head contains galvanometer scanners, which rapidly move mirrors to direct the laser beam with exceptional precision. High-speed scanning allows detailed patterns, text, and codes to be marked in milliseconds. Modern advancements in mirror polishing and motor technology have enhanced scanning speeds up to 10,000 millimeters per second in some systems.

- Control Software

Sophisticated software provides the user interface for creating designs and controlling marking parameters. This software allows users to adjust laser power, pulse frequency, marking speed, and focal length to achieve optimal results. Some advanced software solutions integrate with enterprise resource planning (ERP) systems, enabling seamless production workflows.

- Cooling System

Thermal management is critical in laser marking systems to ensure consistent performance and prolonged component life. Air-cooled systems are commonly used in compact setups, while water-cooled systems are preferred for high-power industrial applications due to their superior efficiency in heat dissipation.

- Material Handling Mechanism

Automation plays a crucial role in modern marking systems, with many devices incorporating conveyor belts, robotic arms, or rotary devices to handle workpieces efficiently. This ensures faster throughput while maintaining accuracy in mass production scenarios.

What Are the Applications of Mini Laser Engravers?

Mini laser engravers are widely used across various fields due to their precision and versatility. They are commonly utilized for engraving personalized designs on materials like wood, acrylic, and metals, making them popular in the production of customized gifts and promotional items. Additionally, these devices are frequently employed in small-scale manufacturing for creating intricate patterns, serial numbers, or logos on products. Artists and hobbyists also use mini laser engravers to craft detailed artwork and prototypes. Their accessibility and compact design make them ideal for education and DIY projects as well.

Engraving on Metal Parts and Other Materials

Engraving on metal parts has grown increasingly precise with advancements in laser technology, enabling exceptional detail and efficiency. Fiber laser engravers are particularly effective for metals like stainless steel, aluminum, brass, and titanium due to their ability to create deep, permanent marks with high precision and contrast. This makes them indispensable in industries such as aerospace, automotive, and medical device manufacturing, where durability and accuracy are critical.

Laser engraving also allows for versatility when combined with other materials like wood, leather, and glass. For instance, businesses frequently use laser engravers to customize multi-material products such as metal and leather keychains or glass containers with metal lids, offering a polished and professional aesthetic.

Industry Data Snapshot: Modern fiber laser systems can achieve engraving speeds of up to 7,000 mm/s while maintaining a resolution as fine as 0.001 inches. This efficiency has reduced production times and operational costs, allowing businesses to scale up mass customization capabilities. Furthermore, CO2 lasers typically excel at engraving softer non-metal materials and can handle intricate designs on materials like acrylic or hardwood, delivering exceptional versatility for various applications.

Ultimately, the evolution of laser technology continues to redefine engraving capabilities across diverse materials, boosting both creative and industrial applications to new heights. These tools are invaluable for creating durable and visually appealing designs that meet today’s high industry standards.

Using Mini Lasers for Plastic and Non-Metal Materials

Mini lasers are highly effective tools for engraving and cutting a range of plastic and non-metal materials, thanks to their precision and versatility. Plastic materials such as acrylic, polycarbonate, and ABS are commonly used with mini lasers, as their relatively low melting points make them ideal for clean engraving and cutting without excessive warping. Acrylic, for example, is widely favored due to its ability to produce smooth, polished edges when processed with a laser.

The power settings and speed of mini lasers can often be adjusted to suit different material thicknesses and compositions. For example, an entry-level laser with 5-10 watts of power is sufficient for delicate engraving, whereas higher wattage lasers, up to 40 watts or more, are needed for deeper cuts. Additionally, safety is a crucial factor when working with plastics, as some like PVC release harmful fumes during laser processing, necessitating proper ventilation or fume extraction systems.

Non-metal materials such as wood, leather, and fabric can also be effectively engraved with mini lasers, allowing infinite customization possibilities for crafts and industrial products alike. The precision and efficiency of mini lasers significantly reduce material waste, making them not only a creative asset but also an eco-friendly option for various industries. Recent advancements in this technology further enable finer detailing and faster processing speeds, ensuring superior results even on intricate patterns.

Ultimately, the adaptability of mini lasers opens up endless possibilities for creating aesthetically powerful and functional designs.

Integrating Laser Engravers for Wood Projects

Laser engravers have revolutionized woodworking by offering unparalleled precision, efficiency, and creative potential. From detailed etchings to precise cuts, these devices are ideal for crafting everything from custom furniture to intricate art pieces. Advanced engraving machines use CO2 or diode lasers, which ensure accuracy even for delicate designs, minimizing waste and promoting sustainable practices.

According to recent insights, modern laser engravers are capable of achieving engraving depths ranging from 0.1mm to 5mm depending on the wood type and machine specifications. Woods like birch, maple, and cherry are widely favored due to their fine grain and consistent density, which result in stunning, high-quality finishes. Experts highlight that laser speeds often exceed 500 mm/s for engraving and can reach up to 1000 mm/s for cutting lighter woods, streamlining production workflows.

Additionally, the integration of software like LightBurn offers extensive design customization, allowing users to edit and control patterns with ease. Whether for hobbyists creating personalized decor or manufacturers scaling up product lines, laser engravers enhance efficiency and showcase craftsmanship, meeting the demands of both artistic expression and industrial precision.

How to Choose the Right Mini Laser Engraver for Your Needs?

Selecting the right mini laser engraver depends on understanding your specific requirements and priorities. Start by considering the types of materials you’ll be working with. Some engravers are better suited for softer materials like wood or leather, while others can handle metals and glass. Next, evaluate the engraving area size—ensure it aligns with the scale of your typical projects.

Focus on power and precision; higher wattage provides stronger cutting ability, while good resolution ensures finely detailed engravings. Portability and ease of use are also crucial if you’re a beginner or short on space. Lastly, look for engravers with reliable safety features, user-friendly software compatibility, and positive reviews from trusted sources to ensure durability and performance. By aligning these factors with your goals, you can confidently choose the best engraver for your needs.

Evaluating Portable Design and User-Friendliness

When evaluating portable design and user-friendliness, I prioritize compact and lightweight engravers that are easy to handle and store, especially since I often need to move or reposition them. I also look for intuitive controls, straightforward setup processes, and software that integrates seamlessly with my workflow. These features ensure a smooth and efficient engraving experience, even for someone with limited space or technical expertise.

Considering Marking Speed and Precision

When selecting an engraver, marking speed and precision are critical factors to ensure high productivity and exceptional quality. Marking speed refers to how quickly the machine can complete the engraving process, which is essential for meeting tight deadlines or handling large volumes. Many modern engravers boast speeds of up to 1,000 millimeters per second, significantly enhancing workflow efficiency. Precision, on the other hand, determines the sharpness and accuracy of the engravings. Laser engravers, for instance, often achieve resolutions of 1,000 dots per inch (DPI) or more, allowing for intricate detailing in text, logos, and complex patterns.

Innovations such as fiber laser technology have further improved both speed and precision by delivering concentrated energy to the material with remarkable accuracy. This makes them suitable for a variety of materials, from metals and plastics to delicate surfaces like glass and wood. For professionals and businesses, balancing these attributes can lead to a substantial reduction in turnaround times without sacrificing the clarity and finesse of the finished product. Ultimately, the ideal engraver should align with your specific engraving needs while offering consistent performance in both speed and detail.

Selecting Between Handheld Fiber Laser Marking Machine Options

When selecting a handheld fiber laser marking machine, it’s crucial to focus on the key specifications and features to ensure it aligns with your specific applications. These machines are typically evaluated based on laser power, marking speed, precision, compatibility with materials, and overall durability.

- Laser Power

Laser power, often measured in watts, directly affects the machine’s ability to mark different materials effectively. Machines with 20W to 30W power are ideal for lighter materials like plastics or thin metals, whereas higher power models, such as those offering 50W or above, excel in engraving deeper marks on harder surfaces like steel or alloys.

- Marking Speed

For enhanced productivity, marking speed is a critical factor. Modern fiber laser machines can achieve speeds of up to 7000mm/s, which helps streamline operations in industries requiring high-volume output. However, it’s essential to balance speed with precision, especially for intricate designs or data matrix codes.

- Precision and Spot Quality

The beam quality of a fiber laser marking machine determines the sharpness and detail of the engraving. Machines using MOPA (Master Oscillator Power Amplifier) technology enable greater control over pulse duration, improving precision and contrast when engraving colored metals or plastics. Spot sizes as small as 0.01mm enhance clarity for detailed text and images.

- Material Compatibility

The adaptability of a handheld fiber laser machine to work with various materials is pivotal for versatility. Top-tier machines are optimized for both metal and non-metal surfaces, handling everything from aluminum and stainless steel to plastics, PVCs, and even reflective materials.

- Durability and Operating Life

Fiber laser technology is renowned for its longevity, often offering over 100,000 hours of operation with minimal maintenance. Additionally, robust designs with dustproof and temperature-resistant features ensure machines perform consistently across diverse environments.

- Ease of Use and Portability

Handheld options are specifically designed for flexibility, allowing operators to engrave large, fixed objects or areas not accessible by traditional machines. Lightweight designs, coupled with user-friendly software interfaces, further simplify operation and improve efficiency.

- Cost Efficiency and Budget

Pricing for handheld fiber laser marking machines varies significantly depending on the power, features, and brand. Entry-level models may start at $3,000, while high-end units can range up to $15,000 or more. Consider the machine’s ROI by factoring in long-term maintenance costs, energy efficiency, and productivity gains.

What Makes the ACMER S1 a Popular Choice?

The ACMER S1 is a popular choice due to its exceptional precision, reliability, and ease of use. Its compact design allows for portability without compromising performance, making it ideal for a variety of applications. The machine is energy-efficient, reducing operational costs, and offers low maintenance requirements, ensuring long-term value. Additionally, the ACMER S1 is equipped with intuitive controls, allowing users of all experience levels to operate it effectively. These features make it a highly dependable and cost-effective solution for professionals.

Features of the S1 Portable Laser Engraver

| Feature | Details |

|---|---|

|

Laser Power |

2500mW / 3500mW |

|

Engraving Size |

130x130mm (5.1×5.1 inches) |

|

Product Dimensions |

250x250x162mm |

|

Spot Size |

0.04×0.04mm |

|

Engraving Speed |

Up to 10,000mm/min |

|

Laser Wavelength |

445±5nm |

|

Product Weight |

1.5kg |

|

Packing Weight |

2kg |

|

Engraving Materials |

Wood, plastic, paper, leather, etc. |

|

Laser Type |

Diode laser |

|

Machine Power |

24W / 36W |

|

Power Supply |

DC12V/2A or DC12V/3A |

|

Focal Length |

2mm |

|

Engraving Accuracy |

0.01mm |

|

Laser Module Life |

10,000 hours |

|

Control Software |

LightBurn, LaserGRBL |

|

File Formats Supported |

JPG, PNG, BMP, SVG, AI, etc. |

|

Pre-assembled |

Yes, ready to use out of the box |

|

Safety Features |

Limit switches for X and Y axes |

|

Portability |

Compact and lightweight design |

Advantages of Using ACMER S1 for Small Businesses

- Cost-Effective Solution: The ACMER S1 is designed with energy efficiency and low maintenance requirements, helping small businesses reduce operational costs while ensuring long-term reliability.

- Compact and Portable Design: Its lightweight and compact structure allow small businesses to save valuable space in work areas and easily transport it for on-the-go operations.

- Enhanced Productivity: The S1 boasts high-speed engraving capabilities that significantly improve turnaround times, enabling businesses to complete projects faster and meet customer demands more effectively.

- User-Friendly Interface: With intuitive controls and minimal setup requirements, even those with little technical expertise can operate the device with ease, eliminating the need for expensive training sessions.

- Versatile Application Range: The ACMER S1 supports engraving on multiple materials such as wood, acrylic, leather, and metal, opening up diverse revenue streams for businesses by catering to varied customer needs.

- High Precision and Quality Output: Equipped with advanced laser technology, the S1 ensures fine detailing and consistent results, which are crucial for creating high-quality products that stand out in competitive markets.

- Durability and Longevity: Built with robust materials, the ACMER S1 delivers dependable performance and withstands extended usage, making it a reliable investment for small enterprises.

- Customization Opportunities: The machine allows small businesses to provide personalized products, such as custom logos or designs, which enhance customer satisfaction and foster brand loyalty.

- Supports Eco-Friendly Practices: The energy-efficient system of the ACMER S1 reduces power consumption, aligning with sustainable business practices and minimizing environmental impact.

- Affordable Entry Point: With a competitive price point, the ACMER S1 makes advanced laser engraving technology accessible to small businesses, supporting their growth without significant upfront investment.

These advantages position the ACMER S1 as an indispensable tool for small businesses striving to enhance efficiency, reduce costs, and boost profitability with versatile and high-quality solutions.

Comparing ACMER S1 with Other Mini Machines

When evaluating the ACMER S1 against other popular mini laser engraving machines on the market, distinct differences arise in terms of performance, features, and value.

- Precision and Engraving Speed

The ACMER S1 surpasses competitors with its precision, offering up to 0.01 mm repeatability, ensuring sharp and refined engraving results. Many comparable machines in the same price range only provide 0.02 – 0.05 mm precision, leading to less detailed outcomes. Additionally, the ACMER S1’s engraving speed reaches up to 10,000 mm/min, a feature that allows users to complete projects faster than models like the LaserPecker 2 or Ortur Laser Master 3, which generally offer speeds within the range of 6,000 to 8,000 mm/min.

- Compatibility with Materials

While some mini laser engravers are limited to soft materials like wood and leather, the ACMER S1 supports a broader range of materials, including metals, ceramics, glass, and acrylics. Comparatively, competitors often struggle with harder materials, requiring expensive upgrades or more powerful equipment to achieve similar results.

- Usability and Software Integration

Equipped with user-friendly software and full compatibility with formats like SVG, PNG, JPG, and DXF, the ACMER S1 simplifies setup and operation. While other machines, such as the Atomstack A5 Pro, require additional plugins or manual configuration, the ACMER S1 offers seamless integration with most design platforms for maximum efficiency.

- Safety Features

The ACMER S1 includes cutting-edge safety protocols, such as an automatic laser shutoff during unexpected movements or overheating. Comparable devices often lack such robust safety systems, putting both the machine and its operator at greater risk during prolonged usage.

- Cost-to-Performance Ratio

Priced competitively at under $400, the ACMER S1 provides outstanding value. Its advanced capabilities, typically found only in higher-end models priced above $600, make it a standout choice for individuals or small businesses. Machines such as the xTool D1 Pro, while powerful, often come with a significantly higher price tag without significantly outperforming the ACMER S1 in practical use cases.

The ACMER S1 consistently stands out with its impressive combination of advanced features, user-friendly design, and exceptional value. For those in search of a versatile, high-performance engraving solution, this mini machine remains a top contender.

Reference Sources

-

Laser marking as environment technology

Published on De Gruyter, this article discusses the use of laser marking machines, including their environmental benefits and applications. Link to source -

Semi Finished Products Traceability Improvement with Laser Marking

Published by Springer, this chapter examines the role of laser marking in improving traceability and durability for semi-finished products. Link to source - Top CNC Laser Marking Machine Manufacturer and Supplier in China

Frequently Asked Questions (FAQs)

Q: What is a mini fiber laser marker?

A: A mini fiber laser marker is a compact and efficient marking tool used for engraving and marking on various materials, including metals and plastics. It combines portability with precision, making it ideal for small-scale industrial laser marking tasks.

Q: How does a portable laser engraving machine work?

A: A portable laser engraving machine utilizes a focused laser beam to engrave or mark surfaces. The laser output is controlled to create precise designs on materials such as wood, metal, and plastic, offering a versatile marking solution for various applications.

Q: What are the benefits of using a handheld laser for marking and engraving?

A: Handheld lasers provide flexibility and ease of use, allowing for on-site marking and engraving. They are particularly useful for small and intricate designs, offering a precision mini solution that is both portable and efficient.

Q: Can a laser engraver mini machine be used on wood?

A: Yes, a laser engraver mini machine can be effectively used for engraving on wood. It offers precise control over the marking and engraving process, making it a suitable machine for wood projects.

Q: What makes a desktop laser marking machine suitable for small businesses?

A: A desktop laser marking machine is an ideal choice for small businesses due to its compact size, ease of use, and versatility. It provides a reliable marking and engraving tool that can handle a variety of tasks without requiring a large workspace.

Q: What is the typical engraving area of a mini portable laser engraver?

A: The engraving area of a mini portable laser engraver varies by model but typically ranges from 100×100 mm to 200×200 mm, providing enough space for small to medium-sized projects.

Q: Are portable fiber laser marking machines safe to use?

A: Yes, portable fiber laser marking machines are safe when used according to the manufacturer’s safety guidelines. They often include safety features such as protective enclosures and laser safety glasses to ensure user protection during operation.

Q: What types of materials can a 20w small laser marking machine handle?

A: A 20w small laser marking machine can handle a wide range of materials including metals, plastics, ceramics, and more. Its versatility makes it suitable for various industrial laser marking and engraving applications.

Q: How does a diode laser engraver differ from other laser engravers?

A: A diode laser engraver uses a semiconductor diode as its laser source, which is typically less powerful than other types of lasers like CO2 or fiber lasers. It is ideal for precision mini tasks and small-scale projects, especially on non-metal materials.

Q: What should be considered when choosing a marking laser for industrial use?

A: When choosing a marking laser for industrial use, consider factors such as laser power, material compatibility, marking speed, precision, and overall durability. A compact laser with a high laser output and reliable performance is crucial for efficient industrial operations.

- Understanding Fibre Laser Cutting Machines: A Comprehensive Guide

- Master the Art of Laser Cutting & Engraving Plastic

- Common Types of Laser Marking: A Guide

- The Best Laser Engraver for Leather: Unlocking the Potential of Laser Engraving Machines

- Laser Rust Removal: Pulse Laser Cleaner for Rust, Oxidation & More

- Unlocking the Power of Laser Cleaning for Glass Surfaces: Revolutionary Mould Cleaning Technology

- Do Laser Cutting Machines Use a Lot of Electricity Understanding Power Consumption

- Fiber Laser Marking Machine: Split Fiber Laser Engraving