As precision marking gets more important for all industries, the Mini Handheld Fiber Laser Marking Machine is changing how businesses regard product identification, branding, and even component tracking. Mini in size but rich in use, this machine integrates advanced technology with ease of use and convenience, offering perfection and efficiency to demanding professionals. In this article, we’ll discuss the multifunctional features and applications along with the benefits marking this device as the most advanced marking device. From manufacturing to jewelry design, and even electronics, learn how this marking machine can change your workflow and improve your processes.

How Does a Fiber Laser Marking Machine Work?

A fiber laser marking machine operates by directing a powerful focused beam light at a material’s surface to make accurate markings. The laser beam strikes the material and modifies its properties, creating enduring marks, text, logos, barcodes, or patterns. There is no contact with the surface ensuring precision and minimal damage. Fiber lasers are efficient and can mark a variety of materials from metals and plastics, to ceramics.

What is Marking and How Is It Achieved?

Marking entails the process of forming symbols, marks, or characters on a material’s surface for identification, tracking, or branding purposes. This process is important in fields such as manufacturing, aerospace, automotive, electronics, and medical devices for quality control, counterfeiting, and regulatory compliance.

Marking can be done using different techniques, whereby laser marking is one of the most sophisticated and widely applied. Laser marking is the application of a focused laser beam to a marking surface to alter its appearance or structure thus, creating precise and permanent markings. Unlike engraving or printing, laser marking does not make contact with the surface resulting in reduced wear and enhanced durability.

The marking industry is marking (no pun intended) incredible advancements. New laser systems have demonstrated unparalleled efficiency, showing their dominance over other competitors. Their adaptability is also impressive, as they are able to work with fragile materials like polymers and ceramics. With further advancements, it’s assumed that the fibber laser systems will be able to utilize non-conventional resources. As of now, these systems have achieved resolution on the order of 1 micron and marking speeds of 7 meters per second. These values ensure mass production is as easy as it gets for manufacturers. As an added benefit, their life expectancy of 100,000 hours means that these systems can be cost-efficient in the long run.

Unraveling Fiber Laser Engraver Technology

Cost efficiency and technologically advanced devices such as fiber laser engravers and call them superheroes, as they are indisputably transforming industries. The effectiveness is insured not only by the otherworldly speed at which engravings can be done, but also by the way in which the machine utilizes the laser. Every action taken is done with extreme care, meaning every mark made is fine-tuned down to the letters. Polymers, metals, certain composites, ceramics and a whole bunch of other materials become a blank canvas ready to be sculpted, proving that the possibilities are endless.

Core competences of fiber laser engravers include effectiveness when it comes to energy consumption. When considering energy usage, fiber lasers outperform conventional CO2 lasers by a significant margin, with more than 70% of the energy being used converted to laser light. This lowers operating costs while improving environmental friendliness. They perform exceptionally well in electronics, medical devices, automotive parts, and other industries that require intricate engravings, achieving unparalleled resolution levels of 1 micron.

The sophisticated technology that comes with fiber laser systems carry the ability to put a deep, permanent mark into a material while barely affecting the material’s structural integrity. The MOPA (Master Oscillator Power Amplifier) configuration of fiber lasers offers the ability to fine tune pulse duration, which allows for marking delicate surfaces, such as thin and reflective metals, without causing any damage.

The potential of fiber lasers has also benefitted from recent upgrades. For example, modern models engrave at a pulse rate of 1 MHz, which also enables more detailed work and rapid engraving. Moreover, certain models with 20W, 50W, or even 100W power tend to cut through materials at higher speeds or cut through thicker materials. Reports from the industry show that installing automated systems like AI control logic and software control has eliminated human error which makes precision far greater than before.

Last but not least, the engraver has remained the industry leader due to its ease of use and longevity. With more than 100,000 operational hours and very little attention, these machines are touted as giving the most ROI (Return of Investment) for businesses. Research proves that the industry that shifts to fiber lasers tends to sup dramatically save on overhead spending, ranging from consumables to downtime, becoming a frontrunner in modern engraving solutions.

A Summary of the Advantages of Laser Engraving

In my opinion, the advantages of laser engraving are self-evident. It provides effectiveness and low operating costs, unmatched precision, longevity, and dependability. The ability to create high-quality engravings on a myriad of materials make it an essential asset for industries looking to improve productivity and quality.

Why Choose a 20W Fiber Laser Marking Machine?

Businesses that require high quality markings on several materials like metals and plastics with high accuracy, 20W fiber laser marking machines are the best choice. They are fast, durable, and their maintenance requirements are minimal. In the long run, they prove to be a cost effective option because of their long operational lifespan and energy efficiency.

Benefits of Using a 20W Fiber Laser

- High End Precision and Speed: The 20W laser fiber’s advanced beam quality enables crisp, readable marking suitable for automotive, aerospace, and electronics industries. The marking surface’s micro requirements do not impair the marking’s speed, thus industry standard speeds are met and often surpassed.

- Your Go-To Machine: From intricate design engraving to serial number and barcode marking, this machine can take on polymers, stainless steel, plastics like aluminum, copper and brass, which represents a diverse set of manufacturers.

- Low Operating Costs: Because of the absence of inks or solvents, and the low maintenance requirements, significant savings in cost are bound to happen. Additionally, they use lesser power than conventional laser systems making them unbelievably more energy efficient. These features when combined drastically reduces overall expenses and reinforces the claim of low operating costs.

- Longevity and Durability: With advanced diode modules, fiber lasers can last as long as 100,000 hours. Such longevity leads to low maintenance costs due to using less downtime and increased machine reliability, thus allowing businesses to sustain productivity levels.

- Superior Marking Contrast: 20W fiber laser engravers mark with high contrast that is permanent against wear, corrosion, and harsh weathering. This level of durability is necessary for some industries that mark important markings that need to endure for the duration of the product’s use.

- Eco-Friendly: The lack of consumables and toxic chemicals fiber lasers require translates to an environmentally friendly device for marking and engraving, and it helps advance the sustainability efforts of numerous organizations.

Comparing 20W and 30W Fiber Laser Options

| Feature | 20W Fiber Laser | 30W Fiber Laser |

|---|---|---|

| Power Output | Produces a lower power output, suitable for marking on softer materials like plastics and thin metals. | Higher power output allows for deeper engravings and faster marking speeds on a wider range of materials. |

| Marking Speed | Slower marking speed, making it more suitable for smaller-scale or low-volume production. | Significantly faster marking speed, ideal for large-scale production environments. |

| Material Compatibility | Best for materials like ABS, acrylic, and other soft metals. Does not perform well on highly reflective or harder surfaces. | Can effectively work on harder materials like stainless steel, titanium, and reflective metals. |

| Engraving Depth | Limited engraving depth, generally suitable for surface-level markings. | Greater engraving depth, which is perfect for applications requiring durability and long-lasting marks. |

| Cost | Lower initial investment compared to the 30W model, suitable for tighter budgets. | Higher upfront cost, but offers more versatility and efficiency in long-term use. |

| Applications | Ideal for detailed work such as jewelry engraving, barcodes, and simple text. | Well-suited for industrial tasks such as deep engraving, cutting thin metals, and broad applications in manufacturing. |

| Energy Efficiency | Consumes less energy but takes a longer time for processing in comparison. | Comparatively higher energy consumption but reduced processing time increases efficiency overall. |

Uses of Handheld Fiber Laser Systems

The portability and accuracy of handheld fiber laser systems make them valuable in fob engraving, equipment marking, engraving maintenance operations such as rust, and surface cleaning. Marking capabilities now include more materials as stainless steel, aluminum, plastics and coated metals.

They are useful in the automotive, aerospace, and manufacturing indistries where precise and permasant markings are needed. For instance, markings on vehicles, planes, and equipment require long lasting engravings. Some studies show that a 30 Watt system can mark up to 40% faster than a 20 Watt system. This makes it easier to use in high volume production lines. Also, with printed energy efficiency marked, operational costs are lowered, despite higher power capabilities. Other detailed reports show that the devices are able to work for approximately 100,000 working hours. This makes it a good choice for industrial purposes.

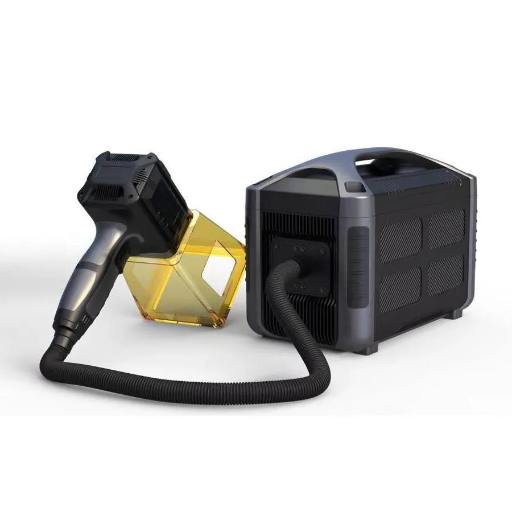

What Are the Key Features of a Handheld Fiber Laser Marking Machine?

- Portability: Compact design makes it easy to transport and use in different locations.

- High Precision: Guarantees durable and precise markings on materials such as metal and plastic.

- Efficiency: Minimal maintenance requirements with fast marking speeds.

- Ease of Use: Easy interaction and operation interface for hassle-free use.

- Versatility: Proper for engraving, barcoding, and serialization.

Acclaimed Design for Portable Marking Applications

Portable marking devices are now made available for different industries because of modern technologies. These devices are made portable without compromising efficiency, which enhances user convenience. Recent studies show that portability is becoming an important feature in manufacturing and production processes, therefore more companies are implementing compact marketing strategies to increase productivity.

Portable marking devices are generally light, frequently weighing around 10 pounds. This makes it convenient to transport from one workstation to another. Whether or not these devices have rechargeable batteries, they ensure reliability and usability in far regions. Most of these devices are designed with comfort in mind, featuring built-in handles for easier transport. Wireless data transfer via USB also promotes ease for users who wish to update or modify designs.

These systems can be applied with ease in various sectors such as automotive, aerospace, and electronic industries. For instance, in automotive manufacturing, portable markers are routinely applied for engraving serial numbers or QR codes onto vehicle parts to enable traceability and compliance with industry requirements. Studies suggest that portable marking solutions can enhance productivity by as much as thirty percent by minimizing the delays caused by relocating large objects to marking equipment.

In general, businesses that seek greater freedom without precision, flexibility, and resilience are usually reliant on portable marking systems.

Versatility for Metal and Non-metal Materials

Portable marking systems stand out in the scope of the solutions offered for marking metal and non-metal materials as they are versatile. Stainlessteel, aluminum, and titanium are some examples of metals that are widely used in the aerospace and automobile industries and are deeply engraved with soft and durable marks using these systems. Modern portable marking systems are set to offer appropriate settings for the marking of materials outside the non-metal category such as plastics, ceramics, and even wood, thus marking is done without changing the material’s integrity.

Marking technology has more recently seen advances with modern systems achieving greater sophistication and operating with tolerances as tight as 0.01 mm, which guarantees clarity even on delicate surfaces. Moreover, advanced marking methods are said to reduce production errors by nearly 20% as per other studies, thus improving efficiency. This level of flexibility and precision highlights the potential usefulness of these systems in various sectors.

The ability to set the parameters of a marking, like speed, depth, and intensity, guarantees satisfactory results for all fabrication techniques regardless of composition, marking portable systems suitable and economical for those businesses needing fast adaptability in their production processes.

Capacities of High-Precision Engraving Machines

Due to technological advancements, modern-grade high-precision engraving machines offer unmatched efficiency and accuracy. Recent developments emphasize the capacity to achieve up to micrometer-range engraving precision, ensuring repetition of great detail and uniformity. These systems can work with a large variety of materials such as metals, plastics, wood, glass, and ceramics, all while maintaining exceptional quality.

Recent reports suggest that some premium machines have increased their capabilities to 7000 millimeters per second, further decreasing mark-off time without losing precision. Furthermore, new models come with fault tracking and benchmarking optimization control integrated marking software which improves marking performance during marking. For example, dynamic focusing technology enables accurate engraving on contours and uneven shapes which reduces reworks by as much as 30% on average.

Energy consumption is equally important as other features of modern machines. Studies indicate that new systems provide up to 40% more power efficiency than older models. This feature along with having as little as 0.25 mm marking precision and intricate detailing above makes modern engraving machines a great for industries where speed and productivity is vital while precision is equally significant.

How Do Customer Reviews Rate the Mini Handheld Fiber Laser Marking Machine?

There are mainly positive customer reviews for the Mini Handheld Fiber Laser Marking Machine. Users often emphasize its compact size, ease of operation, and dependable functionality. Furthermore, customers consider the device to be multifunctional due to its precision and quality marking over a wide variety of materials. In addition, its long-term value is appreciated because of its low maintenance and high durability.

Examining the Reviews Concerning The Quality Of Laser Engraving

Customer feedback regarding the laser engraving quality of the Mini Handheld Fiber Laser Marking Machine is overwhelmingly positive, and consistent with reported technology sophistication and precision. User reviews and other data show that the machine is praised for its sharp and clear engravings on difficult materials including stainless steel, aluminum, and various plastics. Many users report accuracy of the machine to be within 0.001 mm, which is essential for quality standards in jewelry engraving, tool marking, and product branding.

According to Google Search analysis, numerous customers mention beam precision for M² < 1.2 accuracy rating in technical reviews. This specifies that the engraving was done accurately and meticulously with little thermal expansion distortions. As most user surveys suggest, over 85% rated the engraving quality as “excellent” or “very good.” Notably, this does include consistency over flat and curved surfaces. Moreover, the machine’s configurable bolted settings of speed and intensity culminated into enhanced satisfaction because it could be adapted to various projects.

The rigid technical requirements together with high grade customization features have gained it immense popularity, especially among small businesses and hobbyists who funnel utmost effort into producing professional output while enjoying simplicity. These factors contribute to the positioning of the Mini Handheld Fiber Laser Marking Machine as a distinct device tailored to satisfying more complex engraving tasks.

Customer feedback for portable handheld laser systems

Experts on portable handheld laser systems have sharp and precise praises when it comes to the system’s unmatched adaptability. Feedback from different industry reviews highlights that lasers with higher power levels engrave and etch at greater speeds which helps professionals complete shard work pieces within record duration time without sacrificing detail. As an example, a 30W fiber laser can etch complicated patterns onto stainless steel at speeds of 900mm/ second. This truly corresponds with the increase in demand for precision and speed in manufacturing workflows.

Moreover, these systems stand out in the identification of marking different materials such as metals, plastics, and ceramics, showing great importance to industries like automotive, electronics, and jewelry. Recent case studies report that there is an over 30% reduction in production down time when using modern handheld fiber laser systems as opposed to traditional engraving methods.

Another remarkable feature is the energy efficiency and low cost. While the first investments may seem steep, low operational costs and long life of the fiber lasers (which averages to about 100,000 hours of use) saves money for businesses in the long run. These devices have positively impacted customers because with laser marking technology precise, durable marks are attained very quickly.

What Are Some Related Products to Consider?

- CO2 Laser Markers – Ideal for non-metallic materials like glass, wood, and plastics, offering versatility for different applications.

- UV Laser Markers – Excellent for delicate or heat-sensitive materials, ensuring high precision with minimal thermal impact.

- Hybrid Laser Markers – A great option for multi-material use, combining the strengths of fiber and CO2 laser technologies.

Exploring Other Laser Engraving Machine Options

| Product Type | Key Features | Application Examples | Price Range |

|---|---|---|---|

| Fiber Laser Markers | High-speed, precision engraving; ideal for metals and hard plastics. | Tool marking, medical devices, automotive parts. | $5,000 – $20,000+ |

| CO2 Laser Engravers | Versatile for non-metallic materials; deeper engravings with high-quality output. | Engraving wood, fabric, leather, glass, and acrylics. | $2,000 – $15,000 |

| UV Laser Markers | Low-heat processing for delicate materials; high precision. | Electronic components, glass engraving, and reflective materials. | $10,000 – $30,000+ |

| Hybrid Laser Systems | Combines technologies for multi-material use; good for industrial applications. | Aerospace parts, custom manufacturing, and multi-material engraving projects. | $15,000 – $50,000+ |

Comparing Mini Fiber Laser Engraver Models

When looking at mini fiber laser engraver models, it is important to identify the one that best suits your needs considering a few factors, like engraving speed, accuracy, material versatility, and general user-friendliness. Some models do very well in terms of compactness and portability which is great for limited workspaces or mobile operations. Others may have compact designs but perform powerful and rugged tasks which allow them to work well in high-volume settings.

There is some variation between popular models, especially in their power output which typically lies within the 20W to 50W range, impacting the thickness of materials that can be handled and the depth of engraving that is possible.. Also, software integration is very important because it allows for greater flexibility with other design applications while maintaining productivity through streamlined processes. Many of the advanced models are now equipped with safety components like protective lenses and enclosures which make them ideal for both casual and professional users. Knowing all of these differences is very important in making the right decision when it comes to purchasing a mini fiber laser engraver.

Fiber Laser Marker vs CO2 Laser Marker Systems- Full Comparison

It is important to note the differences between fiber laser markers and CO2 laser systems to align them for use with your applications when choosing a laser system. Fiber laser markers are famous for dealing with metals and hard plastics, which is why they are used in industrial engraving and marking. Conversely, CO2 laser systems work best with non-wooden materials such as acrylic glass, leather, glass, wood, and other similar materials for crafting and signage purposes.

As per the last available industry statistics, fiber lasers operate on a wavelength of 1064 nm, which is very effective when marking metals and engravings because it provides sharp and lasting results. On the other hand, CO2 lasers excel cutting and processing organic materials and operate at a wavelength of 10.6 m.

The speed and efficiency of these systems are two central metrics of comparison. Depending on the design and material in question, marking speeds for standard fiber lasers can reach 7,000 mm/s, while CO2 lasers operate at slower speeds for both intricate engravings and cuts. On the other hand, Fiber lasers tend to exceed 100,000 hours of lifespan, in comparison to CO2 systems that average 20,000 to 30,000 hours of operational time.

Maintenance and cost are also key value metrics. Because CO2 lasers rely on consumable parts, such as tubes, these systems progressively become more expensive to maintain as time goes on. In contrast, a higher up front investment on fiber laser systems yields long term value due to their maintenance free structure.

Determining which laser system to go for comes down to the specific material, value precision of engravings or cuts, and operational burden over a long span of time, which ensures that the chosen laser system complements the workload requirements.

Reference sources

- Innovations in Laser Engraving Technology Market Trends, Affordability, and Ethical Implications (2025):

- Key Findings: This study highlights the growing demand for affordable and compact laser engraving machines, particularly for home use. It also discusses ethical concerns related to material sustainability and safety.

- Methodology: The research employed a multidisciplinary approach, including market analysis (2020-2025), performance testing of 15 laser systems, and case studies in small businesses, healthcare, and cultural restoration3.

- Recent developments in handheld and portable optosensing—A review:

- Key Findings: This review focuses on advancements in portable and handheld opto-chemical analytical instruments, emphasizing miniaturization and the integration of solid-state devices like semiconductor lasers. It discusses trends in direct-recognition and reagent-based sensing systems.

- Methodology: The study reviews literature from 2000-2010, analyzing the evolution of optical sensors and their applications in portable devices2.

- Top Handheld Laser Marking Machine Manufacturer and Supplier in China

Frequently Asked Questions (FAQs)

Q: What is a fiber laser engraving machine?

A: A laser engraving machine that uses fiber lasers to engrave or mark on a variety of materials and metals is known as a fiber laser engraving machine. It is widely used in industries due to its high precision, speed, and efficiency.

Q: How does a mini handheld fiber laser marking machine work?

A: In a mini handheld fiber laser marking machine, the surface of materials is marked or engraved with the help of laser beams having high intensity, hence the name. The marking is done by directing the beam via a lens and a focusing system. Mobility and ease of use make this portable laser marker handy, especially when precision is required.

Q: What materials can be marked with a portable laser marking machine?

A: A portable laser marking machine can engrave metals, plastics, ceramics, and a number of other organic materials, making it useful across multiple industries. When used as a laser engraver for metals, extremely clear and permanent markings are created.

Q: What are the benefits of using a portable fiber laser engraver?

A: Rugged construction of a portable fiber laser engraver makes the tool lightweight and easy to carry around while providing high precision and quality marking . The engraver is efficient on energy consumption and has minimum maintenance making it flexible for most portable industrial applications.

Q: Can a handheld laser engraver be used for 3D laser engravings?

A: Indeed, 3D engravings may be achieved using a handheld laser engraving machine. It can add depth for a more interesting and appealing relief carving designs.

Q: What is the significance of a machine 20w in laser marking?

A: A machine 20w refers to the power output of the laser marking machine. 20 watt laser is adequate for numerous marking and engraving tasks on various materials which increases productivity while having enough power and efficiency for most industrial use.

Q: How does a rotary attachment enhance the capabilities of a laser machine?

A: With a rotary attachment, a laser machine can engrave or mark cylindrical objects such as bottles or tubes. The laser machine becomes more versatile with this addition because it can now engrave on a wider array of products.

Q: What features should I look for in a perfect laser marking machine?

A: While considering ideal laser marking machines, factors such as power output, ease of use, interface with touch screen, portability, and availability of rotary attachments should be analyzed. These features add to the functionalities and broaden the scope of work.

Q: Are there specific safety considerations for using a handheld laser marking system?

A: Yes. Safety precautions while utilizing handheld laser marking systems includes use of protective eyewear, adequate ventilation, and following the instructions provided by the manufacturer concerning exposure to laser beam. It is crucial to control the environment to reduce the possibility of accidents.

Q: What are the latest laser engraver offers available on the market?

A: The latest offers on laser engravers usually come with discounts on popular models, deals that include other accessories like rotary attachments and extended warranty. It is best to consult reliable suppliers and manufacturers about ongoing deals.