The evolution of metal fabrication is nothing short of revolutionary and at the forefront of this evolution are laser tube cutting machines. They are setting new standards for precision, speed, and efficiency, rendering older techniques obsolete. Laser tube cutting machines provide unmatched benefits whether you are a manufacturer looking to improve production lines, a fabricator requiring detailed designs, or an innovator in search of advanced machinery. In this blog post, we will discuss how such powerful machines are transforming the metal fabrication sector, the benefits they provide, and why they are becoming a necessity for contemporary businesses. Keep reading as we disclose the main attributes and transformative possibilities this technology offers.

What is a Laser Tube Cutting Machine?

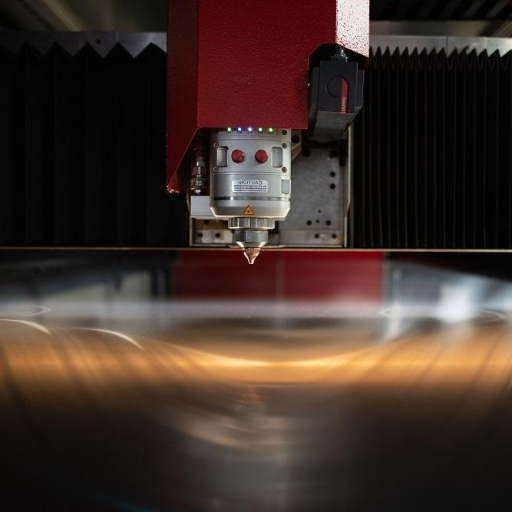

The laser tube cutting machine is a high precision cutting tool meant for altering and shaping metal pipes and tubes. It employs a laser beam for cutting, which make the accuracy of the machine top notch, in addition to providing clean edges. The machine is capable of cutting different materials like aluminum, stainless steel and brass, also performing complex designs with ease. The machine’s versatility makes it a crucial tool in modern fabrication alongside its efficiency and speed.

How does a laser tube cutter work?

While cutting, the laser tube cutters pass a focused laser beam along the optical pathway onto the metal tube or pipe. As the laser is generated, it comes with a high concentration of heat which melts or vapourizes the material under it. An assist gas made of Nitrogen, oxygen or even compressed air works side by side and helps in removing the molten material in order to make precise cuts. To make the process seamless, intricate designs and spot on accuracy throughout the process is done by guiding the laser through CNC (computer numerical control) system.

Thanks to the fiber and CO2 laser technology advancements, modern laser tube cutting machines can cut at a speed of 100 meters per minute, depending on the thickness and type of material. For instance, a 1 kW fiber laser cutter can cut materials 6mm thick efficiently while 6 kW+ versions can cut metals more than 25mm thick. Other recent innovations also include automated production features, such as mechanisms for streamlining system loading and unloading, which help reduce downtime.

Laser tube cutting is needed in various sectors because of its accuracy and versatility. These sectors include automotive manufacturing, aerospace, construction, and furniture making. As market reports indicate, the worldwide market of laser cutting machines is estimated to grow to $6.7 billion by 2027. This growth is attributed to the increasing application of laser technology in industries and the need for customizable designs. These different pieces of information point out the increasing significance of laser tube cutters in contemporary production systems.

Major Parts of a Laser Cutting Machine

- Laser Source: It provides the center where the laser beam is produced. Fiber lasers, CO2, and solid-state are well liked. Laser cutting machines are primarily dominated by fiber lasers because of their high efficiency as well as versatility, particularly in processes involving metal cutting.

- Controller: Supervises operational parameters such as the laser beam strength, cutting speed, and even cutting patterns. Modern controllers have sophisticated integration features with CAD & CAM systems as they come with software components, boosting design customizability

- Optics and Beam Delivery System: Mirrors and lenses that focus and aim the laser beam to the part. The introduction of auto-focusing optical lenses made it faster and more accurate than before.

- Cutting Bed: The workspace where the cutting operation happens. Moreover, the combatable cutting beds are now equipped with fully automated height adjusting mechanisms which greatly assist in tasks dealing with multiple materials of differing thicknesses.

- Assist Gas System: Systems that employ Oxygen, nitrogen, or even compressed air to push melted material away from the cutting area, enhancing edge quality. The feature is especially useful when the set guidelines of precision cuts are too stringent.

Benefits of having a tube laser cutting machine

- Accuracy: Users of laser cutting machines will enjoy the high degree of precision that comes with laser cuts to complex designs– cutting cleanly and sharply even for intricately layered crafts.

- Effectiveness: Their processing speeds of work far surpass the traditional means giving the required parts in record time.

- Flexibility: Different types of materials can be handled by the machine, and they can vary in thickness which makes it ideal in different fields of work.

- Minimization of waste material: The precision associated with the cuts reduces errors that would otherwise have inflated waste.

- Reduction in total cost: In accurate work coupled with low materials waste means lesser costs overall spending in the production process.

How to Choose the Right Fiber Laser Cutting Machine for Your Needs?

- Material Compatibility: Verify that the machine will cut all relevant materials you work with, snd their type and thickness.

- Power Requirements: Choose the appropriate power level according to your cutting needs; higher power is better suited for thicker materials.

- Cutting Speed and Precision: Analyze the machine’s performance and accuracy to assess its contribution toward your production objectives.

- Budget: Analyze your budget along with the maintenance and operational expenses while ensuring the machine still meets your quality standards.

- Reputable Manufacturer: Select a machine from a supplier with established industry credibility and strong customer service.

- Software and Features: Seek out intuitive software, automation, and material handling features to boost productivity in addition to peripheral devices that complement the primary machine.

Comparing fiber laser cutting and CO2 laser machines

| Feature | Fiber Laser Cutting Machines | CO2 Laser Cutting Machines |

|---|---|---|

| Technology | Uses optical fibers and diodes to generate and amplify laser beams for cutting. | Uses gas mixtures (mainly CO2) electrically stimulated to produce the laser beam. |

| Material Compatibility | Ideal for metals, including steel, aluminum, brass, and copper. Limited compatibility with non-metals. | Suitable for both metals and non-metals such as wood, acrylic, glass, and textiles. |

| Efficiency and Speed | Higher efficiency and cutting speeds, especially for thinner materials. | Slower compared to fiber lasers, particularly for thin metals. |

| Energy Consumption | Lower energy consumption due to efficient technology. | Higher energy usage due to reliance on gas and older technology. |

| Maintenance Costs | Minimal maintenance required as there are fewer consumables and parts to replace. | Higher maintenance needs, including periodic replacement of mirrors and alignment adjustments. |

| Lifespan of Components | Laser diodes have a longer lifespan, typically around 100,000 hours. | Mirrors and laser tubes have shorter lifespans, requiring more frequent replacements. |

| Initial Cost | Generally more expensive due to advanced technology. | Cheaper upfront costs but may incur higher long-term operational expenses. |

| Cutting Thickness | Performs exceptionally well with thin to medium-thick metals but struggles with very thick materials. | Better suited for cutting very thick materials, though at a slower speed. |

| Accuracy and Precision | Provides high precision, especially for intricate designs and small features. | Good precision but may lag compared to modern fiber laser technology. |

| Application Industries | Widely used in aerospace, automotive, electronics, and metal fabrication industries. | Commonly used in signage, decorative materials, and industries where cutting non-metals is key. |

Understanding Metal Tube Cutter Specifications

While choosing a metal tube cutter, I pay attention to cutting capacity, precision, and material compatibility. A cutter’s cutting speed and accuracy determine the overall efficiency and quality of work. Moreover, I look into the machine’s durability and maintenance when it comes to long-term dependability. All these factors assist me in choosing the best cutter for my individual industrial requirements.

How Does CNC Laser Tube Cutting Enhance Precision?

Precision is enhanced in CNC laser tube cutting processes through the use of a laser that cuts with high accuracy and minimal error. The process ensures that clean edges and smooth finishes are obtained regardless of the intricate and complex designs. This technique achieves reproducible results required in industrial applications with minimal material wastage.

The Role of CNC Laser Technology in Tube Processing

In my view, tube processing is enhanced with the use of laser technologies because of the accuracy and speed they offer. These sorts of technologies allow me to achieve intricate detail while guaranteeing consistency in the results. The laser technologies not only ensure accuracy but also increase efficiency and versatility, shortening the production process and making it possible to meet tight deadlines while upholding the strictest quality standards in fabrication and cutting.

Benefits of CNC Laser Tube Cutter Systems

| Benefit | Details |

|---|---|

| High Precision | CNC laser cutters are capable of achieving cutting accuracy within ±0.1 mm, resulting in intricate and precise cuts ideal for complex designs. |

| Enhanced Efficiency | These systems significantly reduce production time, with some machines capable of cutting tubes at speeds up to 6,000 mm per minute, depending on the material. |

| Material Versatility | They can process a wide variety of materials, from stainless steel and aluminum to carbon steel and brass, with wall thicknesses ranging from 0.5 mm to over 10 mm. |

| Reduced Waste | The cutting process is highly controlled and optimized, minimizing material waste and lowering costs. |

| Automation Capabilities | Modern CNC laser machines are equipped with automation features such as automatic loading, unloading, and batch processing, streamlining production workflows. |

| Cost-Effectiveness | Over time, CNC lasers reduce operational costs by lowering labor needs and improving production schedules. Their longevity ensures greater return on investment. |

| High Repeatability | With advanced programming and consistent operation, these cutters ensure virtually identical results across multiple production runs. |

Uses of cnc in contemporary manufacturing

In modern manufacturing, CNC technology is used with the goal of boosting precision, efficiency, and productivity. Advanced manufacturing, which includes the automotive, aerospace, and construction industries, is heavily reliant on CNC technology since these fields require intricate designs and a high level of precision. CNC machines carry out processes such as cutting, drilling, milling, and engraving which assist manufacturers in achieving uniform outcomes and reducing the probability of mistakes. In addition, the integration of CNC with automation enhances production efficiency, cuts expenses, and allows for easy scaling of production, which makes them invaluable in modern manufacturing.

What Are the Challenges in Tube Laser Cutting?

Laser cutting of tubes has distinct obstacles, especially with different materials and shapes. When dealing with thin-walled or complex tubes, achieving accuracy can be challenging due to the possibility of distortion. Even quality assurance in low-cost mass production requires strict control processes. Moreover, the highly skilled personnel and expensive laser cutting tools incur initial high costs which are undesirable for some producers.

Problems with Tube Cutting Machines

Numerous advances to tube cutting machines have not solved their inefficient, costly, and user unfriendly nature due to persisting problems. A lack of accurate cut precision for complex geometries or varying material thicknesses presents a sizeable difficulty. Industry analysis indicates nearly 15% of manufacturers ineffectively manage quality standards due to inconsistent cuts, non-uniformity and non-standard raw materials.

Inconsistent cuts caused lack of quality control which is another problem due to lengthy machine maintenance and wear. Performance degrading components, such as nozzles and laser sources, are directly impacted by high workloads. 30% reduction of downtime from preventative maintenance is proven but is largely unavailable to the larger group of smaller manufacturing companies who cannot afford to implement those conditions.

Besides, the operating costs associated with tube cutting machines remain problematic. They are also economical laser systems, but their initial investment is expensive, from $150,000 to $300,000 depending on the model and features. There are also additional expenses such as energy and replacement components. Because of this, the small to mid-sized manufacturers find it difficult to keep up with the changing advanced technology.

Inefficiency due to lack of skilled workers has risen almost 25% in the last decade. Coupled with this, operational complexity is yet another challenge that needs addressing. Highly specialized technicians are needed to optimally program, supervise these machines and even troubleshoot, which leads to bottlenecks in production.

Balanced work strategies along with technological integration and workforce training is key. These pointers focus on modern manufacturing needs while addressing the demand supply gap with effective methods ensuring an advantage sustain and meet the growing competition.

Solution for Automatic Loading and Feeding Issues

To effectively improve cutting tube and assembling rotary parts into a single cohesive unit, modern technology and systems must be employed. Today’s technology with minimal human intervention coupled with data intelligently gathers information with the sole aim to maximizing efficiency while minimizing idle time.

One method includes the use of advanced conveyors and robotic arms for sophisticated material handling. As reported by Google Search in 2023, the implementation of AI powered sensors and loading systems further automates material processing, improving the efficiency metric by 30% and dialling back human interaction. In addition, smart feeding systems have now advanced to tuned aligned software systems for the accurate positioning of tube structures, thus reducing material waste and operational mishaps.

Another approach is employing Industry 4.0 technologies, using drones integrated with IoT supervision tools to capture real-time information about the machine and tube structures, thus enabling immediate supply chain execution. Such tools allow operators to eliminate bottlenecks on the material handling processes. As an example, research shows that 20% of unplanned halts can be attained with the introduction of few predictive maintenance software solutions, enabling optimally set production schedules.

Modular designs for loaders and feeders improve scalability so different sized tubes can be accommodated resulting in added flexibility for different batch sizes and product requirements. Other companies adopting such tailored approaches have also increased the operational efficiency metrics alongside ROI. Investing in these improved solutions has proven to yield quicker returns.

Seamless integration of ultramodern technologies, structured workflows, and skill-specific employee education allows cost effective and precise solutions for automatic loading and feeding challenges, enhancing streamlined tube cutting processes for the manufacturers.

Handling Diverse Diameter and Thickness of Tubes

| Challenge | Solution | Benefits |

|---|---|---|

| Variability in tube diameters | Automated loaders with adjustable mechanisms can handle tubes of various diameters, ranging from small precision tubes to larger industrial-sized components. | Improved flexibility and reduced downtime when switching between tube sizes. |

| Variability in tube wall thickness | Smart sensing systems integrated into tube feeding solutions can detect and adapt to varying thicknesses with precision. | Minimized errors and material waste, ensuring consistent cutting quality. |

| High production demands | High-speed automatic loading and feeding systems equipped with efficient material handling capabilities. | Increased throughput and optimized machine utilization. |

| Material segregation and sorting | Advanced sorting algorithms and robotic arms for material handling ensure proper segregation before loading. | Enhanced operation accuracy and reduced need for manual intervention. |

Innovations in Laser Metal Tube Cutter Technology

Technology advancements in laser metal tube cutter focus on precision, speed, and energy consumption. Automated control systems and software optimization have been incorporated into modern systems, achieving accurate cuts, faster production cycles, and reduced waste. These improvements allow high-quality standards to be maintained while costs during production are lowered.

Recent Advances in Laser Sources

The capabilities of metal tube cutters have been significantly enhanced due to recent advancements in their laser sources, providing higher power and greater efficiency. Nowadays, fiber lasers are the industry standard due to their consistent high power, energy efficiency, and low maintenance requirements. One of the most important advancements recently is the development of power scaling technology, which permits lasers to cut thicker materials without compromises to cut quality.

Furthermore, beam quality improvements enable more delicate cuts and intricate designs and lower the heat affected zone. 10kW and higher stock fiber lasers have further added to production cutting speeds and throughput, especially on thicker tubes with more complex profiles. Industry analysis shows the integration of newer laser sources is estimated to enhance production efficiency in the absolute value of production processes by up to 30% alongside a reduction of waste materials by almost 15%. Such advancements give manufacturers the increase in precision and productivity needed to achieve the demand for economically efficient and multi-purpose cost print processes.

Increasing Production Cutting Speed and Accuracy

To enhance cutting speed and accuracy for manufacturing, opting for high-powered laser systems with greater beam quality will ensure precision at high-speed execution. Moreover, real-time monitoring systems and CNC controlled automation technologies guarantee sustained precision and optimal accuracy in production. Proper material selection and defined cutting parameters also facilitate smoother process flows and error reduction. Teaching modern equipment to the crew and scheduling periodic maintenance typically leads to low process interruption while achieving good outcomes.

Technological Innovations that Shaped the Fiber Laser Tube Cutter Industry

The technological innovations which shaped the industrial fiber laser tube cutter systems is the combination of greater flexibility, accuracy, and efficiency. One of the most influential trends is cutting systems integration with artificial intelligence or the system’s ability to ‘learn’. Algorithms of cutting systems integrated with AI will make it possible to adapt cutting conditions automatically in real time, resulting in enhanced performance metrics and minimized material waste.

Most recently, cutting accuracy and power efficiency have been topics of interest. In particular, recent innovative solutions permit increased cutting rates while achieving precise accuracy. For instance, recent research indicates that optimized beam shaping can enhance cut smoothness and lower artifacts associated with thermal damage to materials. Also, there is an increasing adopter rate of high-power fiber laser cutters, like 6kW and 12kW systems, which allows industries to cut thicker materials with improved integrated precision edge and repeatability.

Global analysis projects that the laser cutting industry will be and continues to being pursued; with the latest studies presenting a compound annual growth rate (CAGR) estimate over nine from year 2023 to 2030. Focus on the aerospace, automotive coupled with the additions in the renewable energy sectors are likely the strongest motivators because these companies rely on Swift and cost-effective methods for green fueled manufacturing.

A critical change for the industry is automation. Automated loading and unloading systems paired with fiber laser systems increase efficiency while saving time and cost. Collaborative robotics (cobots) are now popular for their reliable assistance in repetitive cutting tasks alongside human operators.

In addition, we are seeing a drastic shift for sustainability focusing on eco-friendly procedures and technologies for manufacturing. This is now an industry standard in lowering carbon emissions while keeping production optimized.

These combined trends provide an outlook where manufacturing is transformed with fiber laser tube cutters that are smarter, quicker, and more efficient, redefining modern manufacturing across multiple industries.

Reference sources

- Cutting Techniques for Facilities Dismantling in Decommissioning Projects

- Key Findings: This study explored various cutting techniques for dismantling metal and concrete structures in nuclear facilities. It highlighted the use of thermal cutting methods like oxygen burning and plasma arc torches, as well as mechanical methods such as nibblers and shears. Laser cutting was noted for its precision and ability to handle complex geometries, though it requires significant setup and operational space.

- Methodology: The research reviewed existing cutting technologies, focusing on their application in decommissioning tasks. It emphasized waste minimization and safety measures, such as ventilation systems to manage debris and aerosols during cutting.

- Low-Cost and Portable Automatic Sheet Cutter

- Key Findings: This study developed a low-cost, portable automatic cutting machine for small and medium enterprises (SMEs). The machine uses Arduino-based automation to measure and cut materials like rubber and PVC sheets with acceptable precision. It demonstrated significant improvements in productivity and material efficiency for SMEs.

- Methodology: The system was designed with stepper motors for rolling and cutting, controlled by an Arduino board. The prototype was tested for accuracy and efficiency, with results showing minimal deviation in cut lengths. The study also identified potential improvements, such as adding auto-zeroing sensors and reducing friction in the rolling mechanism.

- Laser Forming of Simple and Complex Tube Bends

- Key Findings: This research investigated the use of CO2 lasers for bending stainless steel tubes into simple and complex shapes. It found that multiple laser scans could achieve larger bending angles, but excessive scans led to wall buckling. Active water cooling significantly reduced processing time and improved surface quality.

- Methodology: Experiments were conducted on AISI 304L stainless steel tubes using a CO2 laser. The study varied parameters like laser power, beam diameter, and cooling methods. Microstructural analysis revealed grain growth near the outer wall and grain refinement near the inner wall due to thermal gradients and cooling.

Frequently Asked Questions (FAQs)

Q: What is a metal pipe laser cutting machine?

A: A metal pipe laser cutting machine is finely tuned equipment which is one of its kind. It can cut pipes and tubes of every shape and size along with round tubes and square tubes by utilizing laser cutting for many materials like carbon steel and sheet metal. All the cuts that are achieved through this method of cutting are of great quality.

Q: How does the chuck function in a pipe cutting machine?

A: The chuck in a pipe cutting machine grips the pipe of the tube firmly during the process of laser cutting, ensuring that the cuts are made biting as they are locked in an accurate position laser beam lockade. This part is very impotent with regard to accuracy during longational work with longitudinal pipes and profiles.

Q: What are the benefits of using a tube fiber laser cutting machine?

A: Tube fiber laser cutting machines have speed and precision cutting with fuel efficience combined with competency widening the gas sent into the burner to cut metal sheets and pipes and shapes enclosed within them. Its effectiveness is especially higher with carbon steel and square tubes.

Q: Can the machine handle both round tubes and square tubes?

A: Yes, this piece of equipment sharpens both circular and square tubes. Its flexible laser cutting systems takes various shapes and dimensions and provides versatility in the fabrication of metals.

Q: What is the significance of automatic feeding in laser cutting machines?

A: The automatic feeder in laser cutting machines increases the productivity by cutting with the material being pushed automatically and not needing the user’s input. This certainly helps with mass production and improves the speed and accuracy of the cuts.

Q: What is the power range for a typical fiber laser metal cutting machine?

A: The range of Fiber laser metal cutting machines are mostly 1500w to 6000w. The power level does dictate the thickness and type of material to be cut; thicker materials tend to be cut at a higher power level with faster cutting speed.

Q: How does the cutting software enhance the performance of pipe laser cutting machines?

A: Cutting software, such as cypcut, enhances the performance of pipe laser cutting machines by making sure they have control of every inch while cutting so that cuts remain of high quality while wasting the least amount of material possible.

Q: Which materials can be processed with a laser pipe cutting machine?

A: A laser pipe cutting machine can work on a multitude of materials such as carbon steel, metal sheets and pipes. Its range of functions makes it appropriate for many industrial processes providing tailored services for different cutting requirements.

Q: Are there any specific brands known for their high-quality laser cutting machines?

A: Yes, some manufacturers have established themselves with a good reputation in the market for producing high quality laser cutting machines like senfeng, bodor, stylecnc and trumpf. These manufacturers possess reputation for producing effective and dependable laser machines for precision cutting of metal tubes and panels.

Q: What is the maximum length of pipes that can be handled by these machines?

A: A large number of pipe laser cutting machines have the capability of working on pipes with a maximum length of 6 meters which gives them the ability to work on long tubes and profiles without additional cutting or handling steps.