With the precision and efficiency it offers, laser cutting is a powerful tool that is changing the way people craft or manufacturers goods. Like any other high-tech process, not every Material can withstand laser cutting. Using the wrong substances for this process can pose dire safety risks, damage equipment, and have detrimental effects on the environment. This guide will help you understand which materials should never be laser cut and the reasoning behind it. By the end of this post, I hope to impart crucial insights that will safeguard you and your machinery as well as make results optimizing your results with laser cutting projects. From my experience, whether you’re an expert or a beginner, things you are supposed to avoid are equally important as the things you are supposed to know. So, stay informed, stay safe and keep reading.

What Are the Materials That Cannot Be Cut with a Laser?

Laser cutting is a precise and versatile process, but certain materials should never be cut due to safety risks or equipment damage. Here are key materials to avoid:

- PVC (Polyvinyl Chloride): Cutting PVC releases toxic chlorine gas, which is hazardous to breathe and can corrode your laser machine.

- ABS (Acrylonitrile Butadiene Styrene): ABS creates thick, acrid smoke, making it difficult to vent properly and potentially damaging your equipment.

- Polycarbonate: Laser cutting polycarbonate produces poor-quality results and emits toxic fumes.

- Fiberglass: Composed of a mix of glass and resin, fiberglass can emit harmful fumes and damage the laser system.

- Coated Carbon Fiber: The resin used in coated carbon fiber releases harmful and corrosive fumes, despite carbon fiber itself being laser-friendly.

Always prioritize health and equipment safety by consulting manufacturer guidelines for materials unsuitable for laser cutting.

Why PVC is Not Safe for Laser Cutting

Polyvinyl chloride (PVC) is widely used in applications like construction, packaging, and consumer goods, but it poses severe risks when subjected to laser cutting. When PVC is exposed to the high-intensity heat of a laser, it releases chlorine gas, a highly toxic and corrosive substance. Chlorine gas not only endangers the health of those nearby but also damages the laser cutting equipment by causing corrosion and build-up on essential components.

The harmful effects of burning PVC extend beyond immediate safety hazards. Chlorine gas can combine with water vapor in the air to form hydrochloric acid, which has long-term environmental and material implications. Additionally, the fumes can irritate the respiratory system and lead to serious health issues like chronic respiratory conditions, making PVC a particularly hazardous material in this context.

Studies have shown that the degradation temperature of PVC starts at approximately 212°F (100°C) and rapidly escalates during laser cutting, promoting significant toxic fume generation. For these reasons, many industry experts and safety organizations strongly advise against cutting PVC with lasers. Safer alternatives, such as acrylic or natural wood, should always be explored to ensure both health and equipment longevity.

Understanding the Risks of Polycarbonate in Laser Processing

Polycarbonate is another material that poses significant challenges when used in laser processing. Known for its toughness and versatility, polycarbonate is widely used in applications ranging from construction to automotive manufacturing. However, when subjected to laser cutting or engraving, polycarbonate presents several health, safety, and performance concerns.

One major issue is the release of potentially harmful gases during laser processing, including carbon monoxide and bisphenol-A (BPA). Studies indicate that when polycarbonate is burned or heavily heated, it breaks down into toxic compounds that can compromise respiratory health and pose environmental hazards. The thermal decomposition of polycarbonate typically begins at temperatures between 428°F (220°C) and 572°F (300°C), making it particularly dangerous during intense laser applications.

Beyond health considerations, polycarbonate’s physical properties can also create challenges in the cutting process. When exposed to high-energy lasers, the material tends to melt rather than vaporize, often leading to jagged edges, discoloration, and uneven results. These issues can undermine the precision and quality of the final product, especially when intricate designs or detailed cuts are required. Additionally, the melted residue can accumulate on laser components, causing mechanical wear and reducing the longevity of the equipment.

Given these risks, it is crucial for industries and users to consider safer alternatives or specialized processing methods when working with polycarbonate. Materials such as acrylic, which vaporize cleanly under laser cutting conditions, may provide better safety and performance outcomes.

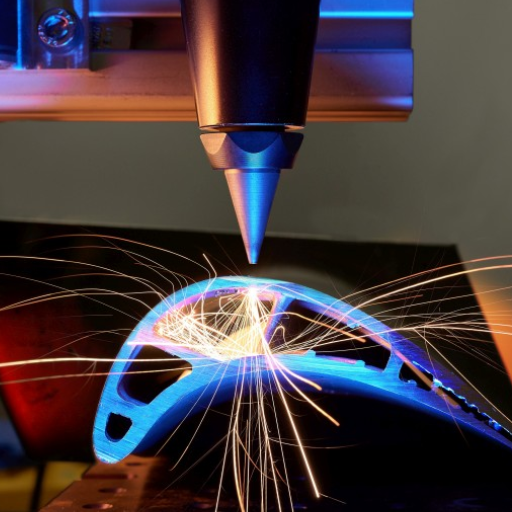

Why Metal Materials Cannot Be Cut with a Laser Cutter

Laser cutters are highly specialized machines, but their ability to process materials depends on the laser’s type, power output, and the thermal properties of the material being cut. When it comes to metals, standard laser cutters face substantial challenges due to several key factors.

Firstly, metals have high thermal conductivity, which means they rapidly disperse heat across their surface. This characteristic makes it difficult for standard laser beams to generate the localized heat required to efficiently melt, vaporize, or cut through the metal. Instead of concentrating heat on a specific point, the energy from the laser spreads out, reducing cutting precision and speed.

Secondly, metals tend to reflect a significant portion of the laser’s energy. For instance, materials like aluminum and copper are highly reflective to standard laser wavelengths, resulting in inefficiency and potential risks. Reflected laser beams can redirect energy back into the machine, leading to damage to laser components or even complete system failure in extreme cases.

Additionally, cutting metals requires exceptionally high-power lasers—typically fiber lasers or CO2 lasers with specialized adaptations. These systems can reach powers in the kilowatts (kW) range, but such machines are considerably more expensive compared to standard laser cutters designed for non-metal materials like wood or acrylic. For example, effective metal cutting with a fiber laser often requires power outputs upwards of 2 kW to cut thinner materials such as up to 6mm steel, while thicker metals demand even higher wattage.

Lastly, the safety requirements for cutting metals add to the complexity. Metal cutting generates excessive heat, sparks, and fumes that necessitate advanced ventilation systems and rigorous safety protocols, further increasing the operational cost and complexity. For many general-purpose laser cutter users, these additional requirements make cutting metals an impractical choice.

To summarize, the high thermal conductivity, reflective properties, and the need for advanced high-power laser systems make metal cutting beyond the capability of standard laser cutters. Specialized industrial-grade equipment is required for such tasks, ensuring safety and precision while addressing the unique physical characteristics of metals.

Why Some Materials Are Not Suitable for Laser Cutting?

Some materials are not suitable for laser cutting due to their physical and chemical properties. Highly reflective materials, such as certain metals, can reflect the laser beam, reducing effectiveness and potentially damaging the equipment. Additionally, materials that release toxic fumes, such as PVC or certain plastics, pose health and safety risks during the cutting process. Flammable materials, like some foams or fabrics, can ignite easily when exposed to the high heat of a laser. These limitations highlight the importance of selecting materials compatible with the specific capabilities and safety requirements of laser cutting systems.

The Role of Toxic Fumes in Restricting Laser Use

Toxic fumes generated during laser cutting present significant challenges, both in terms of safety and operational efficiency. When certain materials, such as PVC, polycarbonate, or specific plastics, are subjected to laser processing, they can release harmful substances like chlorine gas, benzene, and dioxins. These emissions can pose severe health risks to operators, including respiratory issues and long-term exposure hazards, as well as environmental concerns due to potential air contamination.

For example, studies have shown that laser cutting PVC can release smoke containing up to 60% hydrogen chloride, which is corrosive and highly toxic. Furthermore, prolonged exposure to fumes from certain plastics or composites has been linked to occupational health concerns. Mitigating these dangers requires strict implementation of safety measures, such as high-efficiency air filtration systems and specialized ventilation setups, which can significantly increase the overall cost and complexity of laser-cutting operations.

Addressing these challenges involves more than just adhering to safety protocols; it also requires careful material selection and compliance with regulatory standards for workplace safety, such as those outlined by organizations like OSHA and the EPA. By understanding the impact of toxic fumes and adopting preventative measures, users can ensure safer and more sustainable laser cutting practices.

How Laser Beam Reflection Affects Safety

Laser beam reflection poses a significant safety concern in laser cutting and engraving operations, as reflected beams can lead to potential hazards both for equipment and personnel. When a laser strikes a reflective metal surface, such as aluminum or copper, portions of the beam can be scattered or redirected in unintended directions. This creates a dual risk of equipment damage and harm to workers. Even small fragments of reflected beams can reach intensities strong enough to cause eye injuries like corneal or retinal burns, emphasizing the importance of proper eye protection and safety measures.

To mitigate these risks, industries often invest in anti-reflective coatings and advanced beam delivery systems that minimize unwanted reflections. For instance, studies have shown that reflective metals can return up to 70% of the beam’s power back toward the source, significantly stressing sensitive components of the laser device. This highlights the need for machine components, like beam absorbers and high-durability optics, designed specifically to handle such reflective feedback. Additionally, workspaces must be configured with beam enclosures and refined optical alignment to further control and contain reflections.

Regulatory measures also play an important role in ensuring safety. Compliance with standards such as ANSI Z136.1 for Safe Use of Lasers outlines proper safety eyewear specifications, hazard classifications, and operating procedures that account for reflective risks. Combining these technical controls with rigorous operator training equips workers with the knowledge to operate safely in environments where reflective surfaces are common. By layering these protective strategies, organizations can efficiently minimize reflection-related hazards and ensure a safe working environment for all.

Impact of Laser Power on Different Materials

The interaction between laser power and various materials is highly dependent on the material’s physical and chemical properties, as well as the specific laser parameters used. Laser power plays a pivotal role in determining the depth of material penetration, the precision of cutting or engraving, and the overall quality of the resulting finish. Different materials respond uniquely to variations in laser power, necessitating tailored approaches for optimal performance.

For instance, metals such as stainless steel and aluminum generally require high laser power to achieve efficient cutting or engraving due to their reflective and high thermal conductivity properties. Research indicates that stainless steel cut with a 500W laser produces clean cuts with minimal thermal distortion, whereas lower power settings (e.g., 150-200W) may lead to incomplete cuts or rough edges. On the other hand, non-metals like acrylic and wood respond well to moderate laser power, ensuring smooth and precise engravings. Acrylic, when processed with 40-60W laser power, produces polished edges due to its predictable melting behavior, while higher powers may lead to excessive charring.

Furthermore, advanced materials like ceramics or composites require highly controlled laser power to prevent cracking or structural damage. Studies show that processing ceramics with lasers between 20W and 50W maintains structural integrity, while power exceeding these thresholds risks brittleness or unwanted fractures. Similarly, plastics, particularly those sensitive to heat (e.g., polypropylene), necessitate low-power settings to avoid warping or material degradation.

The thermal effects of laser power also play a critical role in applications like welding, marking, or surface treatment. For example, titanium, a popular material in aerospace and medical implants, demonstrates effective laser welding performance at around 200W, allowing for precise control of the heat-affected zone. Lower power may result in improper bonding, while excessively high power can compromise material properties.

Optimizing laser power based on material specifications and operational requirements ensures efficiency, accuracy, and durability while avoiding thermal stress or defects. By conducting thorough evaluations of laser-material interactions, industries can unlock the full potential of laser technology across diverse applications, including manufacturing, medical devices, and consumer goods.

How Does Laser Technology Affect Different Materials?

Laser technology affects different materials by altering their physical properties through processes like cutting, welding, engraving, or surface treatment. The impact depends on factors such as the material’s composition, reflectivity, and thermal conductivity. Metals, for instance, are efficiently cut or welded due to their ability to absorb and redistribute heat, while non-metals like plastics and ceramics require careful adjustments to avoid damage. Each material reacts differently to variations in laser intensity, wavelength, and pulse duration, highlighting the need for precise calibration to achieve the desired results without compromising structural integrity.

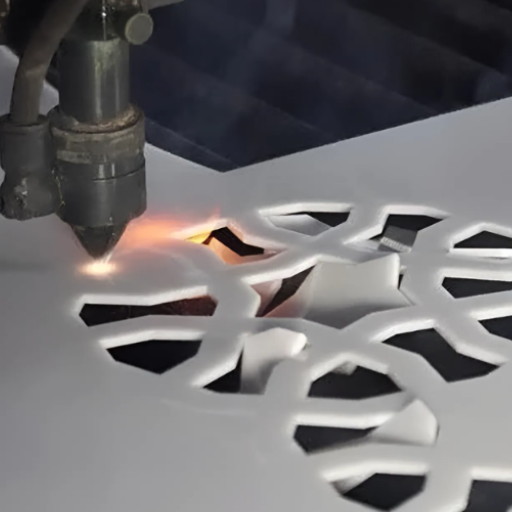

Comparison Between CO2 Laser and Fiber Laser for Cutting

When considering the choice between CO2 and Fiber lasers for cutting applications, it is essential to examine their performance, efficiency, and suitability for various materials.

- Wavelength and Material Compatibility

CO2 lasers operate at a wavelength of 10.6 microns, making them highly effective for cutting non-metallic materials such as wood, acrylics, plastics, and textiles. On the other hand, fiber lasers function at a significantly shorter wavelength of 1.06 microns, which enables them to excel at cutting metals, including reflective materials like aluminum, brass, and copper. Fiber lasers are less effective for non-metals due to their wavelength’s lower absorption in such materials.

- Cutting Speed and Precision

Fiber lasers are known for their faster cutting speeds, particularly on thin metal sheets. For instance, research has demonstrated that fiber lasers can be up to 3-4 times faster than CO2 lasers when cutting materials like stainless steel or mild steel under 6mm thickness, enhancing productivity in high-demand applications. CO2 lasers, however, may take longer due to higher power requirements and the different heat interaction with the material.

- Operating and Maintenance Costs

Fiber lasers generally offer significant cost advantages in operation and upkeep. Fiber laser systems have no moving parts or mirrors in the beam path, leading to lower maintenance demands. CO2 lasers require regular maintenance of mirrors, lenses, and gas refills, increasing their operating costs over time. On average, fiber lasers consume 50% less energy than CO2 lasers, translating to substantial savings in energy costs.

- Beam Delivery and Efficiency

The beam delivery system in fiber lasers utilizes flexible, fiber-optic cables, which ensure stable and efficient energy transfer, even in complex cutting setups. This contrasts with CO2 lasers, which rely on fixed mirrors and beam alignment systems, making them more prone to alignment issues and energy losses. Additionally, the wall-plug efficiency (the ratio of electrical energy converted into usable laser energy) of fiber lasers may reach up to 40%, whereas CO2 lasers typically achieve a much lower efficiency of about 10%.

- Initial Investment vs. Long-Term Value

CO2 laser systems are typically more affordable upfront, making them a popular choice for entry-level or specialized applications in non-metal cutting. However, fiber lasers offer a higher long-term value due to durability, reduced maintenance, and energy efficiency, particularly for businesses focused on metal processing.

By evaluating factors such as wavelength compatibility, cost-effectiveness, and performance on various materials, industries can select the laser technology best suited to their specific cutting requirements. While CO2 lasers remain a reliable choice for cutting non-metals, fiber lasers dominate in metal applications due to their superior speed, precision, and overall operational efficiency.

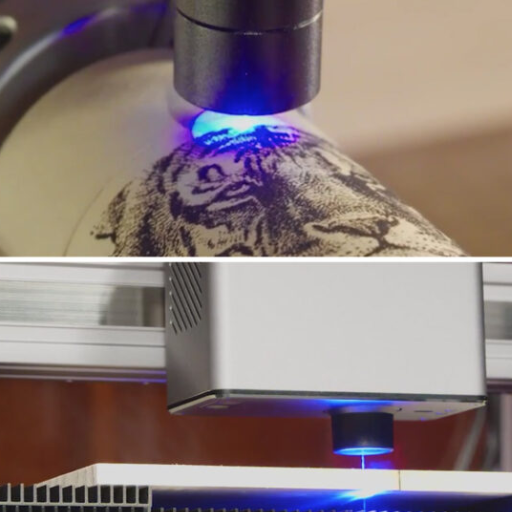

Understanding Diode Laser Capabilities and Limitations

Diode lasers are compact, highly efficient, and versatile devices that serve as key components in modern laser systems. Their primary capabilities include high electrical-to-optical efficiency, long operational lifespan, and cost-effectiveness compared to other laser types. These characteristics make diode lasers ideal for applications such as telecommunications, medical treatments, material processing, and consumer electronics.

One of the standout advantages of diode lasers is their ability to emit light at specific wavelengths, allowing for fine-tuned applications. For instance, diode lasers in the 800-980 nm wavelength range are commonly used in medical procedures like laser hair removal and photodynamic therapy. Additionally, advancements in diode technology have improved their power output, with industrial-grade diode lasers now capable of delivering several kilowatts of energy, making them suitable for high-speed cutting and welding of thin metals.

However, diode lasers are not without limitations. Beam quality can be lower than that of fiber or CO2 lasers, particularly at higher power levels, which can restrict their use for applications requiring extreme precision. They also show reduced performance when working with thicker or highly reflective materials, as energy penetration becomes a challenge. Cooling requirements, though less demanding than in many other laser systems, remain a critical consideration to prevent thermal buildup and ensure consistent operation.

Recent innovations in diode laser technology have aimed to address these limitations. For example, new beam-combining techniques and wavelength stabilization methods have significantly enhanced their precision and usability. These developments continue to expand the range of applications for diode lasers, solidifying their role as a flexible and efficient tool across industries.

What Happens When You Use a Laser Cutter on Prohibited Materials?

Using a laser cutter on prohibited materials can result in serious safety hazards and damage to the equipment. Certain materials, such as PVC or vinyl, release toxic fumes when cut, which can harm both the operator and the environment. Additionally, materials like highly reflective metals can damage the laser system by reflecting the beam back into the machinery. Some prohibited materials may also create excessive smoke or debris, clogging ventilation systems and increasing the risk of fire. Always consult the manufacturer’s guidelines to ensure safe and proper operation when using a laser cutter.

Consequences of Cutting Materials That Cannot Be Cut

Laser cutters should never be used on banned materials because it has unlawful consequences and poses operational hazards. One of the dangers is called the disruption of oxygen, which suffocates operators and endangers the surrounding area’s environment. For example, when PVC is cut, it liberates poisonous chlorine gas that head attacks respiratory functions and damages vital parts of the apparatus. In addition, burning carbon fiber composites or epoxy materials also poses risks as they emit thick smoke and soot that can filter ventilation systems, causing an increased fire hazard.

The reflective nature of specific metals poses further concern, such as copper or aluminum. Metals like these will bounce the laser beam back to the equipment and damage the optics or other delicate parts of the cutter, causing expensive repair or maintenance. Plus, laser cutters should never be used for overgrown untreated wood and paper because it can be dangerous for workplace health during the uncontrolled causes of fire explosions.

Also, it is important to understand that attempting to use excessive materials or thicknesses will result in not only inefficient cutting, but also cause poor cutting performance, raised production costs, and inconsistent or incomplete cuts. These errors increase waste which is particularly detrimental for production quality. As a laser cutting machine operates within manufacturer’s safety guidelines, maintenance costs are reportedly reduced significantly by 25%, alongside a noted longer lifetime of the machine. Such estimates make the adherence and compliance with the material restrictions impactful for the operation’s ecological footprint.

How Laser System Damage Occurs

Laser system damage occurs primarily due to improper material usage, inadequate maintenance, or exceeding operational limits. From my perspective, such damage often happens when unsuitable materials are used, as they can generate excessive heat, toxic fumes, or debris that clogs critical components. Additionally, neglecting routine upkeep, like cleaning lenses or replacing worn parts, can lead to system inefficiencies and eventual breakdown. Consistently pushing the system beyond its recommended parameters also strains components, increasing the risk of damage. By prioritizing correct usage and regular maintenance, I believe most damage can be effectively prevented.

Environmental Risks and Toxic Fumes Release

From my perspective, environmental risks and toxic fumes release are significant concerns when systems are improperly managed. By ensuring proper ventilation and adhering to safety guidelines, we can minimize the release of hazardous substances into the atmosphere. I also believe regular monitoring and implementing eco-friendly practices can substantially reduce the environmental impact, making operations safer for both people and the planet.

What Are the Cutting Methods for Safe Laser Processing?

For safe laser processing, several cutting methods are commonly employed to ensure precision and minimize risks. These include:

- Fusion Cutting – This method uses laser energy to melt the material, with an assist gas like nitrogen or argon to blow the molten material away. It is ideal for materials like metals and ensures a clean, smooth finish.

- Flame Cutting – A laser heats the material until it burns, and the cutting process is assisted by oxygen, which enhances combustion. This is commonly used for thick steel and creates a fast, efficient cut.

- Sublimation Cutting – In this approach, the laser vaporizes the material directly without passing through a liquid phase. It is especially useful for non-metals like wood or plastic, delivering high accuracy.

- Controlled Fracture Cutting – Used for brittle materials such as glass, this method applies the laser to create localized heating, causing controlled cracking along a specific path.

By selecting the appropriate cutting method based on material type and design needs, laser processing can remain safe, effective, and environmentally conscious. Taking additional measures like proper ventilation and maintaining equipment ensures enhanced safety in operations.

Identifying Materials Suitable for Laser Cutting

Laser cutting is a versatile technology capable of working with a wide range of materials, each offering unique properties and applications. Below is a detailed analysis of common material categories suitable for laser cutting:

1. Metals

Laser cutting is particularly effective for cutting metals, both ferrous and non-ferrous. Materials such as stainless steel, carbon steel, and aluminum are widely used due to their durability and structural qualities. For example, stainless steel is commonly used in kitchen equipment and automotive parts, while aluminum is favored in aerospace and signage applications. Metals with reflective surfaces, like copper or brass, can be cut effectively using specialized lasers such as fiber lasers.

2. Plastics and Polymers

Acrylic (PMMA) and polycarbonate are popular materials for laser cutting. Acrylic is frequently used in signage, decorative panels, and display stands because of its precise edge finish after cutting. On the other hand, polycarbonate is ideal for creating durable components due to its resistance to impact and high temperatures. Care should be taken to ensure the plastics used do not release harmful fumes upon cutting.

3. Wood and Derivatives

Natural wood, plywood, and MDF (medium-density fiberboard) are excellent candidates for laser cutting. These materials are widely used in furniture making, personalized engravings, and architectural models. Hardwoods like oak and walnut produce sharp, clean edges, while MDF is valued for its uniformity and affordability.

4. Textiles and Leather

Synthetic and natural textiles, as well as leather, are suited for laser cutting and engraving techniques. Materials like polyester, felt, and cotton are frequently used in fashion, upholstery, and custom design projects. Laser technology enables intricate patterns and reduced material wastage, enhancing production efficiency.

5. Glass and Ceramics

For applications requiring precision, glass and ceramic can be successfully processed using laser engraving or controlled cracking techniques. These materials find use in industries like kitchenware, electronics, and medical devices. Advanced laser systems ensure clean edges without compromising the structural integrity of these brittle materials.

6. Composites

Carbon fiber-reinforced plastics (CFRP) and other composites are increasingly utilized across high-tech industries such as aerospace and robotics. Laser cutting ensures precision for these complex materials, essential for producing lightweight yet robust components.

By recognizing each material’s unique characteristics and adapting cutting parameters accordingly, laser cutting technology can maximize efficiency, quality, and versatility across industries. The evolution of modern equipment now even allows for the processing of traditionally challenging materials like reflective metals and composites, paving the way for greater possibilities in design and manufacturing.

Best Practices for Safe Laser Cutting and Engraving

- Understand Material Properties

Before starting any laser cutting or engraving project, ensure you understand the properties of the material you’re working with. Certain materials, such as PVC, ABS, and some foams, can release toxic fumes or catch fire when exposed to laser heat. Opt for laser-friendly materials such as wood, acrylic, leather, or specific types of metals, and always consult material safety data sheets for detailed guidelines.

- Maintain Proper Ventilation

Adequate ventilation is crucial to minimize exposure to harmful fumes and particles. Install an efficient exhaust system or fume extractor near the laser cutter to remove pollutants like smoke, vaporized particulates, or chemical byproducts. Regularly check and clean filters to keep air quality optimal during operation.

- Use the Correct Power Settings

The laser settings should be appropriate for the material and thickness. Excessive power can lead to charring or burning, while insufficient power might result in incomplete cutting or weak engravings. Manufacturers provide recommended settings for common materials—always refer to these guidelines and perform test cuts before starting the final project.

- Wear Safety Equipment

Protect yourself with safety goggles rated for the specific wavelength of your laser cutter. Some cutting processes also release fine dust or chemical vapors, making a dust mask or respirator indispensable for extended tasks. Never operate a laser cutter without proper safety gear.

- Regular Maintenance and Inspection

Conduct routine inspections of your laser cutting equipment to ensure optimal operation. Clean lenses, mirrors, and work surfaces regularly to prevent debris buildup that could compromise performance. Follow the manufacturer’s maintenance schedule for laser tube replacements and other critical components.

- Never Leave the Machine Unattended

For safety reasons, never leave the laser cutter operating without supervision. Fires can start unexpectedly, especially when working with flammable materials. Always keep a fire extinguisher nearby and train all operators in its proper use.

- Keep a Clean Workspace

A clutter-free workspace not only improves efficiency but also reduces fire hazards. Remove any excess material scraps, residues, or flammable objects around the laser cutter before starting your project.

- Follow Local Regulations and Standards

Adhere to local safety regulations and compliance standards for laser machine operation. For example, ensure your machine falls within permissible wattage and class standards as defined by governing bodies such as the FDA (for the United States) or CE certification in Europe. These standards help protect users from excessive radiation or other risks.

By combining these best practices with constant vigilance, you can achieve both high-quality results and a safer working environment while laser cutting or engraving.

Reference Sources

-

Laser Processing and Analysis of Materials:

- Focus: This book discusses the limitations of laser processing for certain materials, emphasizing the risks of runaway reactions and unsuitability for high-power applications.

- Key Findings: Materials with high reflectivity or those that release toxic gases during laser interaction are not ideal for laser processing. Examples include certain metals and halogenated compounds.

- Methodology: Theoretical analysis of material properties and their interaction with laser wavelengths.

-

Materials for Laser Cutter Machines3:

- Focus: This instructional module identifies materials that are unsafe or unsuitable for laser cutting, providing detailed safety guidelines.

- Key Findings:

- Unsafe Materials: PVC, polycarbonate, styrene, and materials containing halogens or nitrogen-carbon bonds (e.g., nylon, ABS) due to toxic gas emissions like hydrogen cyanide or chlorine.

- Other Risks: Porous ceramics and stones can cause steam explosions if not dried properly. Plastics like polypropylene foam are significant fire hazards.

- Methodology: Practical experiments with various materials, combined with safety data sheet analysis and community consensus.

- Top CNC Fiber Laser Cutting Machine Manufacturer And Supplier In China

Frequently Asked Questions (FAQs)

Q: What laser cutting materials should not be cut using a laser?

A: Certain materials are not suitable for laser cutting, such as PVC, which releases toxic gases, and reflective materials like certain metals, which can cause damage to the laser. It’s crucial to avoid these to maintain laser safety and equipment integrity.

Q: Why are reflective materials dangerous for laser cutting?

A: Reflective materials can reflect the laser light back into the laser source, potentially causing damage to the laser and reducing cut quality. This can lead to costly repairs and equipment downtime.

Q: Can a CO2 laser cutter be used for cutting leather?

A: Yes, a CO2 laser cutter is ideal for cutting leather, providing clean cut edges and intricate designs. However, it’s important to ensure the leather does not contain any harmful chemicals that could be released when heated by the laser.

Q: What types of laser materials are suitable for laser cutting?

A: Materials such as wood, acrylic, and certain plastics are suitable for laser cutting. These materials can be processed with a laser to achieve precise cuts and engravings.

Q: What happens if you cut materials that should not be cut with a laser?

A: Cutting materials that should not be cut can release toxic fumes, damage the laser, and compromise cut quality. It’s essential to verify the material’s compatibility with laser processing before use.

Q: Is it possible to cut thicker materials using a laser?

A: While lasers are capable of cutting thicker materials, there is a limit to their effectiveness. The best laser for such tasks is usually a high-powered CO2 laser cutter, which can cut carbon and other thicker materials efficiently.

Q: How does a laser engraver differ from mechanical cutting?

A: A laser engraver uses laser light to vaporize material, allowing for intricate and precise designs without physical contact. Mechanical cutting, in contrast, uses physical tools to remove material, which can be less precise and more wear-intensive.

Q: What are the ideal materials for laser cutting?

A: Ideal materials for laser cutting include wood, acrylic, paper, and some textiles. These materials can be cut well and provide clean, crisp results when processed with a laser.

Q: How does laser safety impact laser cutting material selection?

A: Laser safety is a crucial consideration when selecting materials for laser cutting. Materials that release toxic fumes or pose a risk of fire when heated by the laser should be avoided to ensure a safe working environment.