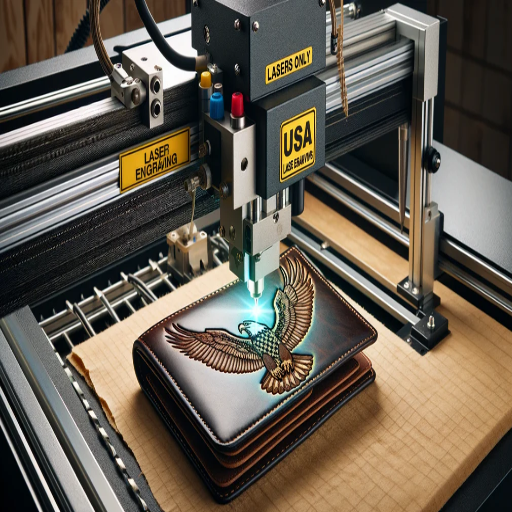

Combining technology and craftsmanship, laser-engraving leather has transformed the personalization and enhancement of leather goods. If you’re a DIY enthusiast looking to try something new, a small business owner hoping to add some distinct appeal to your products, or simply intrigued by this technique, worry not. This guide will cover everything you need to know, from the benefits of engraving leather and the appropriate materials to the engraving tools and professional tips you require. Get ready to learn the keys to turning prostate leathers into flamboyant art pieces.

What is a Leather Laser Engraving Machine?

A leather laser engraving machine is a specialized device for etching, engraving, or marking any drawing on leather surfaces with a very focused laser beam. It burns away a preset area of the leather material, revealing intricately carved patterns, text, or artwork beneath the surface. These machines are highly efficient due to speed, accuracy, consistency, and the ability to achieve professional results. They are commonly used in crafting, fashion, and personalized products because of the ease in handling intricate designs.

How does a laser engraver for leather work?

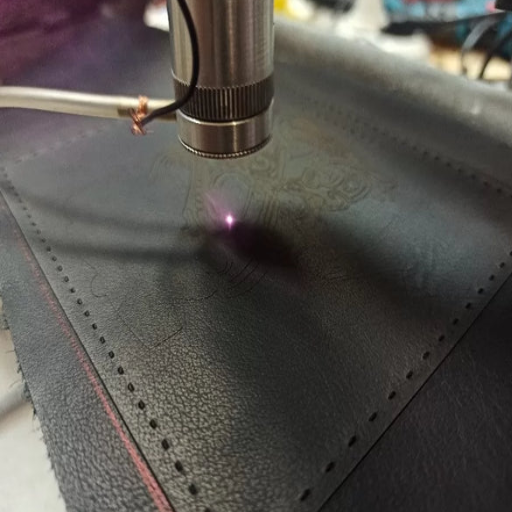

Laser engravers for leather work use a laser beam that generates heat to engrave or cut material with great precision. A design is first crafted with purpose-built graphic software, then sent to the laser engraving machine, which executes it. During the operation, the machine engraves the leather by burning away some parts of the upper laser-sensitive layer to reveal the pattern underneath. Other parameters such as laser power, speed, and resolution can be fine-tuned depending on the outcome.

Many engravers today use sophisticated CO2 lasers designed explicitly for leatherwork, which greatly enhance the machines’ functionality. Users input their parameters regarding the type and thickness of the leather to be worked on. For instance, soft leather is prone to burning, so lower power settings would be advantageous. On the other hand, thicker leather would require higher power settings to achieve deeper engravings.

Insights from recent market data indicate that laser engraving machines can achieve detailing as incredible as 1000 DPI (dots per inch), which is another way of saying ‘resolutions as fine as laser engraving is capable of achieving’. Additionally, the speed at which engraving is conducted can go as high as 1200mm/s. All this makes laser engravers accurate and highly efficient for mass production and individualized tasks. With increased automation and simplified controls, laser engravers remain a strong, flexible tool for detailing leather.

What types of laser engraving machines are available?

Every laser engraving machine is tailored towards specific applications and materials. The main categorizations include:

- CO2 Laser Engraving Machines

Engraving non-metal materials, including wood, acrylic, leather, and glass, commonly uses CO2 lasers. CO2 lasers operate at 10.6 microns, making them optimal for engraving highly detailed designs. These machines are standard among both professionals and hobbyists since they range from 30W to 100W, with some even exceeding 100W.

- Fiber Laser Engraving Machines

Fiber lasers are best suited for engraving metals and certain plastic materials. They operate at a wavelength of 1.064 microns and can engrave or mark serial numbers, barcodes, and intricate designs on metal surfaces quickly and accurately. Fibers are also available in high-power options, up to 100 watts. Most models range between 20 and 50 volts, making them optimal for precise engravings.

- Diode Laser Engraving Machines

These machines are some of the cheapest available, generating much interest from hobbyists. However, they are restrictive, as they only engrave into softer materials such as wood, paper, and certain plastics. For light-duty and exploration engraving, these machines act as a perfect first step, as they range from 1W to 15W.

- UV Laser Engraving Machines

With a wavelength of 355 nanometers, UV lasers are very effective when working with fragile materials like glass, ceramics, and certain types of electronics. They generate very little heat, making them a ‘cold’ engraving technology. As a result, they suffer very little risk of damaging delicate components. Engraving is used in very precise industries, such as pharma and electronics, so UV lasers are predominant in those sectors.

- Hybrid Laser Engraving Machines

As the name suggests, these types of laser machines incorporate features of several laser types. These enable users to engrave a greater variety of materials, all within a single device. As such, small businesses and industrials commonly use these highly versatile machines. They may feature CO2 and fiber laser modes for increased functionality and range of materials that can be used.

- Galvo Laser Engraving Machines

For these systems, dynamic mirrors aim the laser beam. As a result, engraving speeds are extraordinarily fast, for some models, up to 7000mm/s. They are perfect for engraving promotional items or marking products in a mass production environment where efficiency is of the utmost importance.

What is the difference between a laser cutting and engraving machine?

Laser cutting severs parts of a material, while laser engraving does not cut through a material but rather carves designs by removing a layer of the surface.

| Parameter | Cutting | Engraving |

|---|---|---|

|

Process |

Full penetration |

Surface removal |

|

Depth |

Through material |

Partial depth |

|

Power |

>60W |

<60W |

|

Speed |

Slower |

Faster |

|

Materials |

Metals, plastics |

Wood, leather |

|

Applications |

Shapes, parts |

Logos, designs |

|

Focal Length |

Long |

Short |

How to Choose the Best Laser Engraver for Leather

When choosing a laser engraver, especially for leather, focus on the following key details:

- Power Level—Select a machine with enough laser power, usually 30W to 60W, for clean cuts and intricate detailing that will not damage the leather while engraving.

- Bed Size—Take note of the dimensions of the bed or work area. A larger bed is more convenient if the projects are bigger or if several items will be worked on at the same time.

- Material Compatibility – Check that the engraver is meant to work with leather and different thicknesses.

- Speed and Precision—Pick a machine that is reasonably fast but has high precision and a high level of detail in the work performed to create intricate arrangements in the engravings.

- Software Features – Favour simple software that allows versatile designs with many options for customization.

- Ventilation System – Ensure the machine has good fume exhaust or ventilation to maintain air quality and safety, since engraving with leather produces a lot of smoke.

Focusing on these details helps ensure that the laser engraver you select meets your specifications and produces the best work.

What features should I look for in a machine for leather?

As with any type of machinery for leatherwork, ensure that this one offers power, safety, and effectiveness all at once:

- Power and Wattage

A laser engraver with a power range between 40W and 100W works perfectly when working with leather. Machines of lesser power might face difficulties cutting thicker leather pieces, but those with higher power will cut and engrave much more quickly.

- Adjustable Speed and Power Settings

If the project requires special burns or alterations, make sure to adjust your parts to increase speed and power. This is quite helpful when working with different types or thicknesses of leather.

- Cutting Bed Size

The machine must also have a cutting bed that is relative to the size of the leather leaves being etched. However, a larger cutting bed of 20″ X 12″ or more is definitely beneficial for large-scale projects.

- High-Precision Laser

For delicate engraving and detailing, ensure that the machine you choose has a high-precision laser. Precision is recommended when working with small leather products such as wallets or keychains, as the engravings need to be precise.

- Durable Build and Materials

Look for a machine made of high-quality material so it can work over an extended period of time without breaking or needing replacements. Consider other options, such as a steady framework to limit shaking during use.

After paying attention to these features, you should be able to pick out a leather-working machine that is appropriate for your project and efficient.

What is the importance of laser power in engraving?

The effectiveness, speed, and depth of engraving are highly reliant on laser power. It also affects the efficiency of cutting or engraving various materials, which may range from softer surfaces like leather to harder metals, acrylic, and wood. With higher laser power, deeper engravings are obtained, and cutting becomes more efficient, especially for thick or dense materials. For instance, CO₂ lasers with 40W of power can engrave leather, wood, and acrylic, whereas engraving metal would require 100W or more.

Some industry insight states that using insufficient laser power results in inconsistent engraving, slower processing time, and, in some cases, damage to the object’s surface. On the other hand, delicate materials receive scorching and burning when too much power is applied. Having the right amount of laser power enables the achievement of great results. While engraving leather with intricate designs, the power shouldn’t exceed mid-range. In this case, 20 to 30W would be optimal, ensuring precision without compromising the material’s look.

In addition, the latest innovations in laser technology have made it possible to have adjustable power settings, which can now be tailored based on the needs of the project, providing more versatility. According to recent research, today’s laser engravers with adjustable power settings boost production efficiency by 25%, which makes them important for industrial experts and enthusiasts alike.

What Types of Leather Can Be Engraved?

Engravable materials include leather, genuine leather, synthetic leather, and even faux leather. The most durable type, genuine leather, is made from animal hides and engraves beautifully due to its texture. Synthetic leather, like polyurethane or PVC, will offer a smoother surface, which works best for engraving, making the material ideal for intricate designs. The cheaper alternative, faux leather, can be engraved but requires more delicate settings to avoid damaging the product. Choosing untreated leather or leather with a light finish is recommended for a more precise result. Always test on a smaller scale before masking the final piece.

What is the difference between genuine leather and synthetic leather?

Genuine leather comes from animal hides, so it has a natural feel and is durable, unlike synthetic leather, which is cheaper, less durable, and man-made.

| Parameter | Genuine Leather | Synthetic Leather |

|---|---|---|

|

Material |

Animal hides |

PU, PVC, textiles |

|

Durability |

High |

Moderate |

|

Feel |

Natural, grainy |

Smooth, uniform |

|

Smell |

Natural leather |

Plastic-like |

|

Eco-Friendliness |

Biodegradable |

Non-biodegradable |

|

Cost |

Expensive |

Affordable |

|

Maintenance |

Requires care |

Easy to clean |

Can I use a laser engraver on faux leather?

Sure, a laser engraver can be employed on faux leather, but there are some essential safety steps to remember. Faux leather is often made of faux materials like polyurethane (PU) or polyvinyl chloride (PVC), which produce hazardous fumes during engraving. For safety purposes, always keep the workspace well-ventilated and equipped with an exhaust or air filtration system to eliminate toxic fumes. During the engraving process, lower power and speed settings should be applied to minimize burning or warping of the material. Testing on a small faux leather piece before engraving will help set the best parameters for clean and precise outcomes. Lastly, the specific kind of faux leather should be checked and adjusted accordingly because how it is made can influence the results.

How does laser engraving vary between different types of leather?

Laser engraving processes differ considerably based on the type of leather used since they have different chemical composition, texture, and surface treatments. Animal hides are classified as genuine leather and respond well to laser engraving due to their structure. This means the engraving process is consistent and accurate, as deep detailing is achieved effortlessly. Nevertheless, the type of tanning used, plant-based and chrome tannery, might affect how deep the incision is, along with differences in color at the engraving.

On the contrary, faux leather is created from synthetics such as Polyurethane or Polyvinyl chloride (PVC) and can easily melt during engraving due to the engraving and fume processes. The laser’s power and speed must be adjusted cautiously to avoid overheating these materials. With such natural leather types as suede having a brushed surface, the laser engraving variations don’t stop there. Its soft touch makes it susceptible to higher laser settings, which will mar its gentle and fuzzy allure and will no doubt produce quality designs. Ultimately, the type of leather derived will determine the efficiency of the engraving and the laser parameters set.

What is the Engraving Process for Leather?

Leather engraving is the process of marking leather skins or hides with intricate designs using a laser. The leather has to be cleaned and flattened before commencing. The leather engraving machine must be set for power and speed to ensure proper engraving without burning or excessive cutting. A prepared design will be uploaded to the machine while the leather is fixed at the engraving machine. The laser will then over-mark the supplied engraving design, which will be followed precisely and accurately. A clean-up step can now be performed to remove lingering substances that make the skin lose its shine. The end product will be appealing if the material is well-treated with the correct settings.

What are the steps in using a laser engraving machine for leather?

- Design Preparation

To begin, either create or choose a design using a graphic design tool compatible with your engraving laser machine. Make sure the size of the design is proportional to the leather piece that you want to engrave.

- Set Up the Laser Engraving Machine

Power on the laser engraving machine, then connect and pair it with your computer. Transfer the design into the machine software, and set the resolution and speed of engraving for the leather to ensure quality results.

- Preparing the Leather

Using a clean, soft cloth, wipe the leather piece to remove any traces of dust residue. Depending on your preference, you can keep the leather steady on top of the engraving surface using clamps or adhesive tape during the engraving process.

- Adjust Machine Settings

Adjust the machine’s power and speed using different types and thicknesses of leather. Check the manufacturer’s instructions or take a guess and run a test on a scrap piece.

- How To Clean and Maintain Leather After An Engraving Task

Now that you have beautifully engraved leather, clean it with a leather cleaner. You can also use a soft cloth dipped in water, which will gently wipe away any leftover soot or residue that is delicate from the engraving process. Such cleaning is best suited for maintaining looks and having a polished appeal.

- Checking And Reviewing Final Touches

Maintaining standards is crucial in these forms of business. Thus, a thorough check of the engraved leather design is essential to see that the marking is done accurately and is of high quality. If some parts look like they need more depth, use a conditioner for leather or polish to bring life to the engraved piece.

All of the mentioned steps help to get clean, perfect, and precise engravings that are consistent every time and meet leather standards.

How do I set the laser settings for optimal results?

Correct laser settings are essential to maintain high-quality engravings on the leather surface. First, assess the type and thickness of leather used, as these factors determine the best power and speed settings. Softer and thinner leather must have lower power settings with moderate speeds to reduce the risk of burning or discoloring. While tougher or thicker leather needs higher power settings, so deeper penetration is achieved, allowing for a more defined design.

To calibrate the parameters, perform a test run on a scrap piece of the same leather. For engraving leather, start with the recommended settings provided in the laser machine’s user manual or issued by the manufacturer. Gradually replace lower power, speed, and DPI (dots per inch) settings during the test until the outputs are satisfactory. Since finer detail is achieved with finer DPI, balance must be maintained to avoid overburning.

Moreover, confirming the laser beam focus by adjusting the focal distance under the alignment of the machine and specifications is critical. To prevent soot and residue accumulation, cover the leather surface with masking tape or any similar material. Correctly circulating air in the workspace will also help to reduce the presence of smoke, which can impact the engraving quality. With these settings and adjustments, your laser engraver will provide accuracy and repeatability.”

Reference Sources

- “Roll‐to‐Roll Patterning of Indium‐Tin‐Oxide Electrodes Using a Low‐Cost Laser‐Marking Machine” (Sajal Chakraborty, S. Ahn, 2023)(Chakraborty & Ahn, 2023): While focused on indium-tin-oxide electrodes on PET film, the methodology of optimizing laser parameters (power, focal length) for precise patterning without substrate damage is directly applicable to leather marking. Using a low-cost laser marking machine suggests that similar machines could be adapted for leather.

- “Laser Marking of a Small-Sized QR Code on a Plastic Surface” (Pāvels Narica, Jānis Fedotovs, 2019)(Narica & Fedotovs, 2019): This study’s focus on optimizing laser parameters for marking small QR codes on plastic is relevant. Leather, like plastic, is a non-metallic material, and similar parameter optimization would be crucial for achieving high-quality markings on leather without burning or damaging it.

- “Laser marking system for plastic products” (S. Gulak et al., 2019)(Gulak et al., 2019, pp. 361–364): This paper describes a UV laser marking system for high-resolution marking of plastics. UV lasers are often preferred for non-metallic materials due to their ability to create high-contrast markings without requiring additives. This technology could be adapted for leather marking.

Frequently Asked Questions (FAQs)

Q: What types of leather can I use with a laser engraver machine?

A: Various leather types can be used for laser engraving, including vegetable-tanned leather, suede leather, and napped leather. To achieve the best engraving results, it’s essential to ensure the leather is suitable for engraving.

Q: How can I personalize leather using a laser engraving machine?

A: You can personalize leather using a laser engraver to etch names, logos, or designs onto leather products such as leather patches, wallets, or belts. The laser engraving process allows for detailed and precise designs.

Q: What is the difference between cutting and engraving leather with a laser system?

A: Engraving leather involves etching designs or patterns into the surface, while cutting leather means using the laser to cut through the material entirely. A laser engraving and cutting machine can perform both functions, allowing you to engrave and cut leather items as needed.

Q: What should I consider when selecting the best leather for laser engraving?

A: When choosing the best leather for laser engraving, consider the leather’s thickness, texture, and finish. High-quality leather that is smooth and has a consistent surface will yield better engraving results. Avoid overly processed or synthetic leathers that may not engrave well.

Q: What are the advantages of using a CO2 laser engraver for leather projects?

A: A CO2 laser engraver is well-suited for laser engraving leather because it can cut through various leather types with precision. It offers high-quality engraving results and is versatile for different leather projects, whether engraving or cutting leather items.

Q: How do I adjust the laser power and speed for different leather types?

A: Adjusting the laser power and speed is crucial for achieving optimal engraving depth and cutting results. Generally, thicker leather may require higher power and slower speeds to cut through effectively, while thinner leather can be engraved at faster speeds with lower power settings.

Q: Can I use a diode laser for engraving leather?

A: Yes, a diode laser can be used for engraving leather; however, it may not be as effective as a CO2 laser for cutting through thicker leather. Diode lasers are typically more suitable for detailed engraving on thinner leather items.

Q: What maintenance is required for a laser engraver machine used on leather?

A: Regular maintenance for a laser engraver includes cleaning the lens and mirrors, checking for debris or residue on the machine, and ensuring that the laser system is functioning correctly. Proper maintenance will help prolong the machine’s lifespan and maintain high-quality engraving performance.

Q: How can I achieve the best engraving results on leather?

A: To achieve the best engraving results on leather, ensure you use the correct settings for engraving depth, power, and speed specific to the type of leather you are working with. Additionally, testing on a scrap piece of leather before starting your project can help you fine-tune these settings.

Q: What leather products can I create with a laser cutting machine?

A: With a laser cutting machine, you can create a wide range of leather products, including wallets, belts, bags, keychains, and custom leather patches. The machine’s versatility allows for intricate designs and precise cuts that enhance the final product.

- Ultimate Guide to Handheld Fiber Laser Welding Machines: Revolutionizing Industrial Welding

- Mastering the Art of Hand Welding: Tips and Tools for Beginners

- Mastering EDM Cutting: Unleashing the Power of Wire EDM Machines and Electrical Discharge Machining

- Understanding the Gold Melting: Unveiling the Melting Point of Gold