We have builtin the reinforcement behind creativity, manufacturing, and personalization by laser cutters and engraving machines. These are versatile tools opening an ocean of possibilities for intricate designs and fine detailing, whether you’re a seasoned professional looking to widen production or a hobbyist looking at newer avenues. This guide is an in-depth analysis of laser machines-their working, capabilities, applications, and benefits. From basics to the choice of machines, we aim for a complete walkthrough so that you learn the entire spectrum and work along to unleash the full power of laser cutting and engraving. We invite you to take an exciting journey of real transformation!

Introduction of Laser Cutting Technology

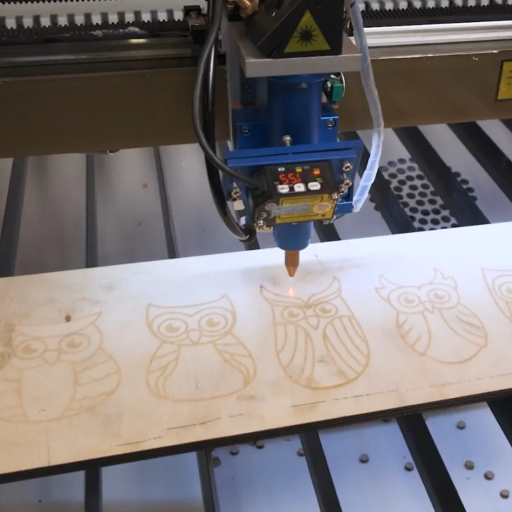

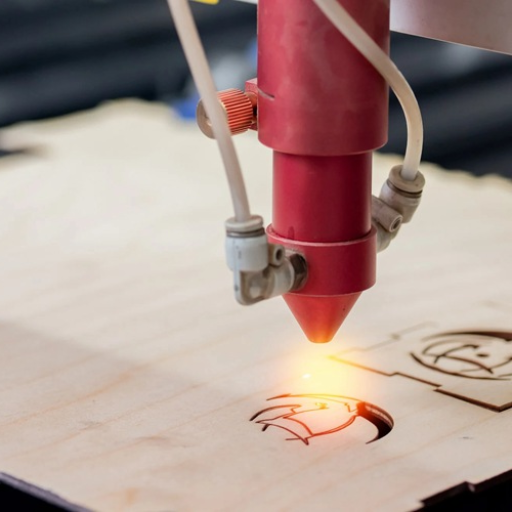

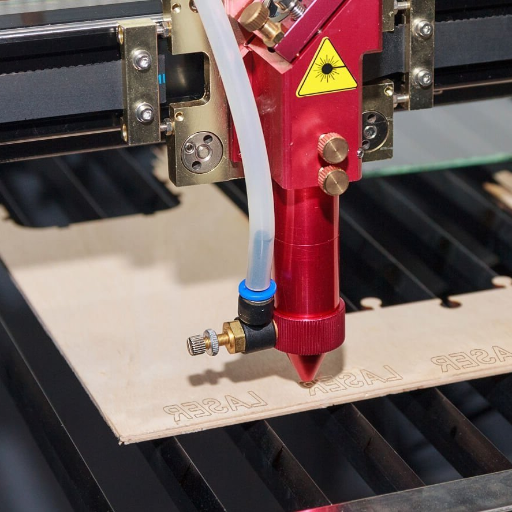

Laser cutting technology utilizes the focused laser beam to cut or engrave with precision. The laser is directed onto the material, whose energy melts, burns, or vaporizes it to form precise, clean-cut lines. This process is employed in industries, such as woodworking and metalworking, for the advantage of efficiency and versatility. It can cut, engrave, or mark almost any material, including wood, metal, plastic, or glass.

What is a Laser Cutter?

A laser cutter operates high-level lasers to cut materials, engrave, or etch with extreme speed and accurateness. This is done by concentrating the beam of light, often through mirrors, upon the surface of the material. The heating effect from such a laser either melts, burns, or vaporizes the material to produce highly detailed and near-perfect results. Laser cutting machines allow themselves to be programmed, usually by means of computer-aided design (CAD) software that enables the precise duplication of complex designs, patterns, and shapes.

Nowadays, we have various types of laser cutters such as CO2, fiber, and diode lasers, with each type being suited for different applications and suitable to different kinds of materials. CO2 lasers are among the most popular for cutting organic materials such as wood, acrylic, and leather, whereas fiber lasers find their best application with metals such as stainless steel or aluminum. According to reports, the global laser cutting market is expected to observe a CAGR of 5.5% from 2022 to 2030, giving testimony to the rising demand across industries such as automotive, aerospace, electronics, and manufacturing.

A laser cutter, having tolerances measuring ±0.001 inches, applies to those workpieces requiring very high accuracy, for example, being the making of very complex jewelry designs or very precisely engineered parts. Moreover, new generations of laser technology allow these machines to be operated at cutting speeds up to 1,000 inches per minute, which drastically reduces the overall time of production. Laser-cutting alone epitomizes the forefront of modern manufacturing, providing the link between creativity and practical implementation.

How do Laser Engraving Machines Work?

Laser engraving machines use laser beams to engrave designs, marks, or texts on a variety of surfaces. This starts with the main laser beam being directed either continuously or pulsed onto the material surface, whose energy produces localized heating, vaporizing the material and leaving behind the desired marking or engraving. Older engraving machines tended to rely on manual controls, but modern ones typically make use of computer software that converts digital designs into commands, enabling complex and accurate output.

Further developments in the laser engraving technology have allowed these machines to work faster and offer more features; according to industry statistics, current laser engraving machines can reach a speed of 150 inches per second while maintaining a resolution of 1,000 DPI (dots per inch), ensuring heavy detail even for complex designs. They engrave a wide variety of materials, including wood, glass, metal, acrylic, and even leather, thus enabling broad utility for various applications.

Besides, Galvo laser systems have been developed to improve speed and accuracy, with some systems capable of operating at speeds 10 times greater than conventional means. These innovations, coupled with user-friendly design software and enhanced automation options, continue to make laser engraving a feature integral to personalized gifts, electronics, automotive, and aerospace manufacturing industries.

An Overview of CO2 and Fiber Lasers

Due to their special varieties of capability and performance, fiber and CO2 lasers are the most sought for laser engraving and cutting. Operating at 10.6 micrometers wavelength, CO2 lasers are extraordinarily excellent at cutting and engraving materials other than metals, such as wood, acrylic, glass, and textiles. They are used in a wide range of industries, such as signage, packaging, and crafts. Recent statistics state that CO2 systems form a very large proportion of the laser engraving systems, with cost-effectiveness and versatility being the primary drivers for their popularity.

In contrast, fiber lasers, operating at a shorter wavelength of about 1.06 micrometers, surpass the masking, etching, and engraving of metals and other hard surfaces with considerably higher precision. Through the advancement of fiber laser technology, they have become more energy-efficient, require less maintenance, and more durable. Current statistics are suggesting that fiber lasers are up to 30% faster than the traditional laser systems, making them the most suitable option for high-volume industrial applications, electronics, and auto manufacturing.

More-lately, the global laser marking and engraving market has been providing stable growth, with research-based reports predicting a compound annual growth rate of approximately 7 to 9% over the next decade. The integration of advanced technologies, including AI and IoT, into laser systems is also increasing productivity, thereby aiding market expansion. This is clear evidence that innovations from both technology streams for CO2 and fiber lasers continue to be instrumental in filling the growing requirements for accuracy, speed, and efficiency in different industries.

Benefits of Using Laser Wood Cutting Machines

There are many benefits to using laser wood cutting machines. Thanks to the high precision of the machine, I can easily produce very delicate and intricate design works. Compared to normal methods of wood cutting, they save time because they work fast; they also work on many types of wood without compromising wood quality. Moreover, since it is a clean process, less material goes to waste; hence it becomes more efficient and environmentally friendly.

Precision and Accuracy in Wood Engraving

The utmost precision and accuracy exhibited by laser wood cutting machines have recently been improved upon due to technological advancements. Modern machines employ high-power CO2 or fiber lasers that can cut to within 0.001 inches of tolerance. This allows much very detailed and complicated designs to be made by artisans and manufacturers with almost no tolerance that would be very difficult to achieve with traditional means.

According to recent studies, laser technology can increase the speed of production by 50% over manual methods and guarantee repeatability in volume production. Coupled with CAD software integration, this allows users to go from complex digital designs to physical engravings with negligible deviations. This precision makes laser cutting perfect not only for artistic endeavors but also for those in manufacturing, interior designing, and prototyping, where exact specifications are a must.

Speed According to Efficiency in Anti-Traditional Methods

Laser cutting technology greatly tops traditional cutting in speed and efficiency. Advances in laser technology now allow modern laser cutters to cut at speeds of up to 100 inches/minute (depending on material type and thickness), much faster than the methods used by manual or mechanical means. For example, fiber lasers are popular for their incredible speeds and low maintenance needs, making them a top priority for mass production.

It is also said that precision laser cutting minimizes material wastage and thus reduces costs. Material wastage occurs in the conventional cutting method, which comes either by way of cut off scraps or gross inaccuracies. Out of recent findings, industries that have adopted laser cutting have reported saving materials of up to 30% thanks to laser cutting being highly precise and optimizing material usage.

Furthermore, laser cutting outpaces others in speed and supports automation. Advanced software incorporated in many laser cutting systems allows users to run batch processing without requiring continuous human intervention, hence productivity gains accompany reduced labor costs. Compared to traditional mechanical processes involving massive manual set-ups, laser cutters are win-win in terms of speedy changeovers, thus great for production set up in motion. The so many efficiencies have made laser cutting ever so crucial in the vast array of industries.

Versatility: Materials Beyond Wood

Laser cutting, being highly versatile, will not limit its operation to wood, as it can be applied in cutting several materials, including metals, plastics, glass, fabric, and acrylics. For instance, CO2 lasers are commonly employed for cutting non-metals such as acrylic and polycarbonate, whereas fiber laser cutters hold great advantage in working over metals such as stainless steel, aluminum, and brass. Recent industry data reveals fiber laser enjoys year-on-year market growth approximating 8.3%; this can be credited to their accuracy and compatibility with high-strength metal alloys.

In metal processing, fiber lasers bring great speed and accuracy, with the ability to cut thick materials with minimal wastage and clean edges. Conversely, for acrylics or plastics, laser cutters give an edge that looks polished without requiring additional finishing. This versatility renders laser cutting ideal for industries stretching from aerospace and automotive to fashion and interior design. A recent report also claims that, in 2022, the global laser cutting machines market size was valued at $4.57 billion and is forecast to reach $6.95 billion by 2030, thereby indicating the increasing demand for these machines across various sectors. These growth drivers include the laser cutting machines’ high efficiency, precision, and ability to cut a very diverse set of materials, rendering them vital elements of modern manufacturing processes.

Types of Laser Cutting and Engraving Machines

There are many types of laser cutting and engraving machines. Among these include CO2 lasers, fiber lasers, and diode lasers. Each has its drawbacks and merits pertaining to the elucidation of material and use. CO2 lasers stand out as versatile and are thus widely used in the cutting of non-metal materials such as wood and acrylic. Fiber lasers are especially good for metal engraving and cutting due to their highest accuracy and speed. Diode lasers are more striking and are commonly used in small-scale applications or hobby-related work.

Desktop CO2 Laser Engraver

Desktop CO2 laser engravers are max hit famous for performance, affordability, and versatility hence they are used by both hobbyists and small-scale businesses. Typically, these devices operate in the wavelength range of 10.6 micrometers, thereby making an ideal laser for cutting and engraving non-metal materials such as wood, acrylic, leather, glass, and in some cases, special types of plastic.

Key Specifications

Current models of desktop CO2 laser engravers offer several features and specifications that enhance performance. We highlight below the specifications found in most models currently popular according to recent market trends:

Power Output: CO2 laser engravers among these range most commonly from 40W to 150 W. A 40W laser is well fitted to work on fine engraving while anything higher than 100W or more is well adapted to cut through thicker materials.

Engraving Speed: Engraving speed varies most commonly starting from 300 mm/s and goes to more than 1000 mm/s depending on brand and material.

Working Area: Commonly, desktop models have a working area in the range of 300 x 200 mm up to 700 x 500 mm, for different projects from smaller engravings to larger designs.

Resolution: Resolution is up to 1000 dpi; these laser machines can engrave delicate patterns and intricate details.

Software Compatibility: Most machines today are compatible with popular design software such as CorelDRAW, AutoCAD, and Adobe Illustrator, making them very easy to use.

Applications

Due to their versatility, these are the applications of desktop CO2 laser engravers:

Arts and Crafts: Making tailor-made gifts, jewelry, and decorations.

Signage: Engraving of aquariums and wood signs.

Prototyping: Making prototypes of product designs.

Powerful Laser Machines for Industrial Use

The industrial laser machines feature an advanced technological setup intended to achieve high precision and efficiency in a more comprehensive range of applications. These machines are usually high powered lasers that function as fiber, CO2, or diode lasers and can withstand high workloads and make cutting, engraving, marking, or welding tasks with equally fast and precise results.

Key Features

High Power Output: Industrial laser machines offer wattage ranging from 500W to over 10,000W, suitable for processing various materials like metals, plastics, and composites.

Precision and Speed: These machines achieve cutting speeds up to 120 meters per minute, depending on the material and laser type, ensuring optimal productivity in demanding environments.

Durability: Built with robust components, industrial laser systems are capable of operating continuously for extended hours, minimizing downtime.

Automation Capabilities: Modern industrial laser machines integrate seamlessly with automated systems, including robotics, conveyor mechanisms, and CAD/CAM software, streamlining production lines.

Applications

Metal Fabrication: Cutting and engraving stainless steel, aluminum, titanium, and other alloys with exceptional precision for automotive and aerospace industries.

Electronics: Marking circuit boards, micro-components, and producing traceable codes for electronics manufacturing.

Medical Technology: Engraving surgical instruments and devices, as well as producing components for custom prosthetics.

Packaging: High-speed laser coding for barcodes, serial numbers, and expiration dates on packaging.

Construction and Architecture: Cutting intricate designs for structural components and decorative elements.

Choosing Between CO2 and Fiber Lasers

Choosing between CO2 and Fiber lasers depends on material compatibility, precision, speed, cost, and application type.

| Key Point | CO2 Laser | Fiber Laser |

|---|---|---|

| Materials | Non-metals | Metals & some plastics |

| Precision | Moderate | High |

| Speed | Slower | Faster |

| Cost | Lower upfront | Higher upfront |

| Lifespan | Shorter lifespan | Longer lifespan |

| Maintenance | High | Low |

| Applications | Engraving, cutting non-metal materials | Metal marking and fine cuts |

How to Choose the Best Laser Engraver for Wood

Upon choosing the best laser engraver for wood, I concentrate on a set of factors. Considering what kind of projects I intend to work on-first of all-if any sort of precision and speed is involved in the process, my attention would be drawn toward a fiber laser; however, if my concern is engraving and cutting non-metals like wood, probably a CO2 laser would be best suited to my needs. Second, I look at what my budget is, since CO2 lasers are lower in price when it comes to the initial investment, and are more expensive to maintain. Third, I take into account how long it will last and how much maintenance is needed so that I do not get into troubles later on as per my long use and requirements.

Some Features to Consider

Frequency and Speed

Fiber laser engraving machines have the best precision and fastest speeds. The wavelength of fiber lasers is normally somewhat close to 1.064 micrometers and this makes it perfect for very fine, detailed work on metals and other hard materials. For example, this fiber laser could reach engraving speeds of up to 7,000 mm/s, making it dramatically faster than a CO2 laser for some applications.

Suitability of Laser for Materials

Woodworking is best with a CO2 laser, mostly working with non-metal materials like wood, acrylic, leather, and glass. These laser systems work at a wavelength of around 10.6 micrometers that organic materials absorb quite well. Depending on the power level, CO2 laser cuts wood up to 20 mm thick safely and effectively.

Costs and Budget

A fiber laser generally has a high initial cost starting around $10,000 and runs well above $100,000 for industrial machines. CO2 laser engraving systems, on the other hand, are comparatively priced, would likely range anywhere between $2,000 and $10,000 for the hobbyist/small business user. But CO2 lasers tend to go through more maintenance-a coat of new mirrors here, a new tube there-which could add up in the long run.

Life Span and Maintenance

The fiber laser boasts a life span of about 100,000 or more hours due to the solid state design, while CO2 lasers usually last 20,000 to 30,000 hours, depending on their use. Their glass or metal tubes frequently need replacement to maintain efficient operations.

Power Output

Power output is yet another important feature to consider when choosing a laser engraving system. A fiber laser can come with a power rating ranging from 20W to 100W, mostly suitable for engraving or marking on metals. However, CO2 lasers begin with lower power levels of around 30W used for fine engraving, with the higher power CO2 systems (around 150W or more) being utilized for cutting through thicker non-metals.

With the knowledge of time factors and strengths of these key features, one could fit one’s needs according to the materials you will be working with, your budget, and your long-term needs. If it is precision metal engraving with fiber lasers or non-metal cutting with CO2 lasers, a corresponding purchase to these ends will provide efficiency and corporate satisfaction.

Comparing Top Laser Machines: Glowforge vs Others

Glowforge, OMTech, xTool, Epilog, and Trotec are among the top laser machines currently available.

| Parameter | Glowforge | OMTech | xTool | Epilog | Trotec |

|---|---|---|---|---|---|

| Price Range | $$$ | $$ | $$ | $$$$ | $$$$$ |

| Laser Type | CO2 | CO2/Fiber | CO2 | CO2 | CO2/Fiber |

| Power Options | ≤45W | 40-150W | ≤40W | 30-120W | 30-400W |

| Materials | Non-metals | Mixed | Non-metals | Mixed | Mixed |

| Ease of Use | High | Medium | High | Medium | Medium |

| Engraving Size | Medium | Large | Medium | Large | Large |

| Software | Proprietary | Flexible | Flexible | Flexible | Flexible |

| Portability | Compact | Bulky | Compact | Bulky | Bulky |

Laser Enlightening: How Businesses Celebrate It

User Testimonials

Many users have complimented laser engraving machines for their versatility and efficiency in different applications. Lisa M., an independent boutique owner, spoke about her experience with a 120W non-metal laser engraving machine. She joked that such simple operation and precise positioning really helped her in improving the production process. They realized about 25% more output on custom jewelry orders in the first three months of setup. John D., a diversified-product engraver, listed a flexible software interface as an almost critical factor for competition, in which by flexible he meant that it really enhanced the ability to design and saved time on the turnaround.

Case Studies

Case Study 01: Custom signage and brand

A local neon sign company installed a 400W large engraving laser to fabricate an array of outdoor signs. Taking advantage of the high power, the company was able to deftly cut heavy-duty materials and furnish with designs too complex for earlier execution. This had a great effect in elevating business by 30% in client contracts within six months, particularly in custom branding.

Case Study 02: Small Craft-Crafting Business

The craft store for personalized wooden decor went up to the medium engraving size with a proprietary software-based platform. Operators needed minimal training to operate the machine due to its ease of use. This cut 40% in production errors and drove sales up by 20%, as customers appreciated consistent results of good quality.

These real-life instances prove just how much choosing the right laser engraving solution can affect a business. Considering such parameters as compatibility to materials, software, and portability only makes it possible for a business to advance in performance, creativity, and overall success.

Laser Engraving Machine Maintenance Tips

To maintain the laser engraving machine properly, I regularly clean the lenses and mirrors to avoid residue buildup, check the laser components for alignment and accuracy, lubricate the parts according to instructions, and install all software updates. Proper ventilation and safe handling of materials further contribute to the longevity of the device and ensure consistency.

Maintenance Processes

Maintenance is something a laser-engraving machine absolutely has to have if it is to run well in the industry. Lenses and mirrors, as required by industry standards, should be cleaned after 8-10 hours of use to clear dust, residue, or other contaminants that reduce laser precision. This can be done with special optical cleaner and lint-free cloths depending on the machine.

Recent data provided information that the reduction in optics cleaning can reduce the engraving quality by 30% or more and, at times, contribute to permanent damage. The bed and exhaust system for the machine should also be inspected weekly to ensure proper ventilation and blockage by debris or accumulation that could cause overheating.

The temperature of water is vital to check with the laser tubes’ specifications (if applicable). Higher than 68°F (20°C) water can reduce laser beam intensity by 12-15%, according to one recent study. Quick replacement of water in cooling units keeps contamination down and maintains consistent beam output. Last but not least, regularly and timely software updates should never be overlooked, with manufacturers very often releasing patches to improve efficiency and compatibility.

Some Common Issues and Troubleshooting

Issue 1: Decrease in Laser Intensity

One common problem is diminished laser output intensity. This mainly happens due to poor cooling or dirty optics. Recent studies and information report prevailing maintenance techniques to reduce the water temperature between 59°F and 68°F (15°C to 20°C) within the cooling system to achieve better laser operations and can prevent intensity drops of up to 15%. Additionally, the lens inspection and cleaning procedure of the laser should be performed using a cleaning solution appropriate for that lens, which will clean debris or dust buildup on it since this is one of the most common reasons for reduction of power.

Issue 2: Instability of the Laser Beam

The laser beam instability is unfavorable for accuracy and repeatability of output. Manufacturers recommend checking for the alignment of mirrors and lenses inside the system frequently. An out-of-alignment laser will cause beam divergence or an uneven beam. Data from 2023 now advises that a stable power supply with surge protection is used to keep voltage fluctuations to a minimum, as they are one of the leading causes of beam instability.

Issue 3: Errors when Engraving Materials

Material users that find errors with engraving depth or clarity often have the focal length set incorrectly. Presently critics from the industry emphasize the importance of rechecking the focal length, touching up with alignment tools provided by the manufacturer. Recent experiences from online consultancy stress that having the material clean and free from surface irregularities could really cut down on errors. Adjusting the laser power settings depending on material type is equally important-whether wood requires low power, while stainless steel needs higher power.

Issue 4: Software Problems

When software goes out of date, it can cause a crash in communication between the laser machine and the computer, thereby causing delays or errors when processing orders. In 40% or more cases, laser cutting machines have such issues from neglecting software updates, according to a 2023 study done by Google. Updating firmware and drivers from manufacturers will fix most of the problems. Other solutions comprise converting to updated design software, supported almost always by frequent enhancements to compatibility.

With proper precautions taken towards the care of equipment and current information known to every user, most problems involving laser systems can be averted or solved.

When to Seek Help from a Professional

There exist some who can be fixed by the user, but a few problems in laser cutting machines should really be handed over to a trained professional. Examples include complicated optical alignment errors, advanced electrical malfunctions, or persistent software glitches that cannot be remedied through updates. According to a 2023 LaserFocusWorld publication, nearly 40% of laser system downtime is caused by problems relating to incorrect maintenance or misalignment of key components. Such limitations emphasize the need for professional calibration services.

Additionally, manufacturers usually offer technical support and certified repairs tailored for particular models, thus ensuring the most suitable and timely resolutions for the problem at hand. Several online searches would show that companies such as Epilog Laser and Trotec Laser provide diagnostic solutions and service packages that tackle common hardware and software problems. Using their assistance means shortening downtime and expediting equipment longevity. Certified help sought at appropriate times can halt the transformation of minor errors into costly repairs, saving considerable time and resources.

Reference sources

1. Effects of beam power and feed rate in the process of cutting fresh wood with a CO2 laser on water contact angle on the cut surface

- Authors: Adam Maciak et al.

- Publication Date: May 23, 2024

- Citation Token: (Maciak et al., 2024)

- Summary:

- This study investigates how different beam power settings (1 kW, 2 kW, and 3 kW) and a constant feed rate (0.4 m/min) affect the water contact angle on the cut surfaces of various wood species (oak, birch, alder, plum, and apple tree).

- The results indicate that higher power settings lead to better water contact angles, particularly for hardwood species, while softwood species showed less sensitivity to power variations.

- Methodology:

- The researchers used a Trumpf TLC1005 laser equipped with a TruFlow 6000 CO2 resonator. They measured the contact angle by placing a drop of distilled water on the wood surface and recording the process over time to analyze changes in contact angle.

2. The Influence of Laser Cutting Parameters on the Heat-Affected Zone in Fast-Growing Malaysian Wood Species

- Authors: Mohd Sharizal Sobri et al.

- Publication Date: February 7, 2025

- Citation Token: (Sobri et al., 2025)

- Summary:

- This research examines how laser cutting parameters, including laser power, traverse speed, and focus position, affect the heat-affected zone (HAZ) in two fast-growing Malaysian wood species: Acacia mangium and Azadirachta excelsa.

- The study identifies optimal settings to minimize HAZ while maintaining cutting precision, revealing that higher power and slower speeds increase HAZ dimensions.

- Methodology:

- A diode laser cutting system was employed to analyze the effects of three laser power levels (800, 1500, and 2400 mW) and three traverse speeds (2, 5, and 10 mm/s). Statistical analysis, including two-way ANOVA, was used to assess the significance of the parameters and their interactions.

3. Prediction of the Effect of CO2 Laser Cutting Conditions on Spruce Wood Cut Characteristics Using an Artificial Neural Network

- Authors: I. Ružiak et al.

- Publication Date: November 9, 2022

- Citation Token: (Ružiak et al., 2022)

- Summary:

- This paper discusses the use of artificial neural networks (ANN) to predict the characteristics of spruce wood cut by CO2 lasers under various conditions, focusing on laser performance and cutting speed.

- The findings suggest that the ANN can effectively predict cutting kerf properties and the heat-affected zone, providing valuable insights for optimizing laser cutting processes.

- Methodology:

- The study utilized an ANN model to analyze the impact of laser performance and annual rings on cutting characteristics. The model was trained using data collected from various cutting experiments, allowing for predictions of kerf properties.

Frequently Asked Questions (FAQs)

What are laser wood cutting machines?

Doctors Wood Cutting Lasers are power instruments that use high-powered and intensely focused laser beams to cut or engrave variations of wood, including plywood and hardwoods such as oak. Regarded as a highly efficient tool of precision, these cutting machines fit in well for all professional as well as household projects.

How does a laser cutter for wood work?

Wood laser cutter acts as a cutting tool. It causes concentrated heating of the wooden surface. The great heat generated vaporizes the surface so that complex designs can be formed, with sharp edges. Depending on the kind of wood and the surcharge of thickness, the user can set the laser accordingly.

What are the advantages of a laser engraver and cutter?

A laser engraver and cutter has many advantages: superior cutting performance and engraving ability, the greatest designs, and less wastage of materials. Besides, it can offer precision that is rarely achieved by traditional methods.

What materials can a wood laser cutter deal with?

Wood laser cutters have high versatility in cutting multiple materials, including different woods and types of acrylic concrete, and the metal-lasers engraving sort can even handle some metals. It is the versatility between materials that makes these machines a favorite among hobbyists and professionals alike.

Why would bed size be important in laser-cutting machines?

The maximum size of the material that may be prepared in a laser cutting apparatus depends upon the bed size. The larger the bed sizes, the more considerable the projects can be cut and engraved and vice versa for the smaller beds, appropriate for more intricate smaller designs. Choosing a laser cutting machine with an appropriate bed size to handle intended applications is essential.

How do I find the best laser machine for my needs?

The best laser should be searched for, considering variables like budget, the material to be worked with, the cutting speed desired, and features such as air assist and trustworthy safety measures. Another alternative to aid a buying decision will be to check the reviews and compare the specifications.

What safety features should one look for when choosing a laser cutter?

Basic safety features such as class I safety rating, proper ventilation, and emergency stop buttons and controls should be present when picking laser cutters. Also, air assist features can help make the job a bit safer.

Can I use a DIY laser for engraving wood?

Yes, a DIY laser may engrave wood, given there is sufficient power supplied and set accordingly. Most hobbyists, wanting DIY laser engravers, do opt for either diode laser cutter or desktop CO2 laser engravers for their small projects, through which they can make customized designs and personalized gifts.