Aluminum is a favored material of various industries from aerospace, automotive, etc. It offers a peculiar combination of strength, light weight, and corrosion resistance. Welding aluminum is a totally different realm, where numerous challenges warrant newer solutions. Here comes the laser welding, which with its unmatched accuracy, speed, and efficiency has revolutionized aluminum joining.

In this guide, we will discuss everything you need to know about laser welding aluminum. The process’s scientific details, the advantages of using it, and the applications will be fully covered here. If you are an advanced professional seeking to further enhance your skills or a novice wondering what this laser technology is all about, this is the place.

Table of Contents

Introduction to Laser Welding Aluminum

What is Laser Welding?

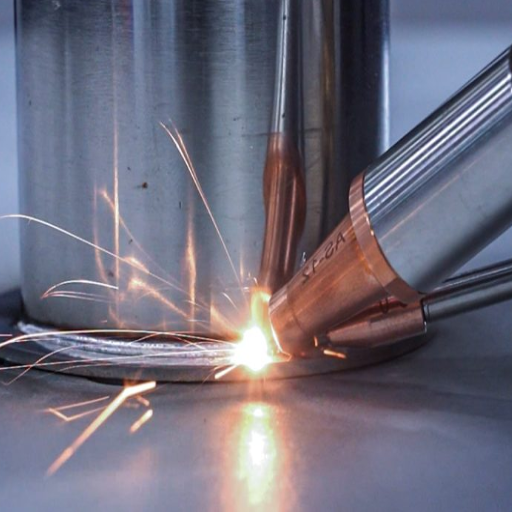

Laser welding is a joining process that requires utmost precision, where a focused laser beam is used to melt and join metals, typically aluminum. The process utilizes the intense heat of the laser to precisely target and weld select spots. Aluminum is a material with the best strength-to-weight ratio and corrosion resistance, wherein laser welding greatly benefits due to aluminum’s high thermal conductivity and reflective nature.

Industries like aerospace, automotive, and manufacturing use it because it allows clean welds that are very strong, with comparatively narrow weld seams and little distortion. Modern laser technologies, fiber lasers, and diode lasers have taken the advantages further to energy efficiency and cost savings, making the applications ample.

The Importance of Laser Welding in Modern Manufacturing

As a modern technologies that manufacture, this newer method with a laser affords a calcium-precise, fast, and flexible way of welding. The infusions of laser welding technology into production lines from automotive to aerospace are another bunch of set solutions.

Market Growth: Recently, sources have quoted an increase in the laser welding CAGR at 7.3% during the period of 2023-2028, nourished mainly by demand for lightweight materials, electric vehicles, and advanced medical devices.

With prime benefits:

- Low-heat generation: Most of the processes generate heat through melting that can easily distort the part or machine goose

- Automation friendliness: Fast and scalable automatic laser welding systems

- Production efficiency: Up to 40% increase in operating capacity maintenance of quality standards

- Environment-friendly: Generates very low emissions and solid waste among other conventional methods

Overview of Aluminum and Its Alloys

This metal stands out among the group because of its low density and lightweight characteristics and and a range of unique attributes making it suitable for endless industrial applications. Some of its properties are:

- Low density and lightweight nature

- Corrosion resistant

- Good thermal conductivity and electrical properties

- High ability to be recycled-One-fourth of aluminium ever produced is still in use today.

Market Data: The global aluminum market size has valued more than 167 billion USD in 2022 and is expected to grow on a CAGR of 5.8% during 2023-2030.

Common Aluminum Alloy Series:

- 2000 Series: Contains copper, very strong, used in aerospace applications

- 6000 Series: Contains magnesium and silicon, excellent corrosion resistance and medium strength

- 5000 & 3000 Series: Better weldability with lesser chance of cracking

Benefits of Laser Welding Aluminum

Precision and Accuracy in Welding

Laser welding aluminum is one of the most precise processes in welding, making it an ideal method for those welds for which integrity must be qualified. The laser welding machine acts as a heat source with almost pinpoint accuracy, so there is great control over the weld pool, which results in less thermal distortion than would occur in traditional welding methods.

Technical Achievement: Present-day laser welding machines maintain a positional accuracy of 0.01 mm with heat-affected zones kept so small as to almost not affect the mechanical properties of the base material.

Speed and Efficiency Advantages

| Aspect | Laser Welding | Traditional Methods | Improvement |

|---|---|---|---|

| Welding Speed | 50-100 inches/min | 15-30 inches/min | Up to 6x faster |

| Production Rate Increase | 30%+ improvement | Baseline | Significant boost |

| Material Distortion | 60% reduction | Standard levels | Major improvement |

| Post-Processing | Minimal required | Extensive finishing | Time & cost savings |

Minimal Distortion in Materials

Top among the benefits of automated laser welding systems is distortion reduction in materials. Laser welding provides heat application at very concentrated spots for precise and localized welding. As a result, the heat-affected zone (HAZ) gets reduced to a minimum.

Common Challenges in Laser Welding Aluminum

The Reflectivity Challenge

One of the main obstacles in laser welding aluminum is its high reflectivity. Aluminum reflects the majority of laser energy:

Critical Issue: Studies report 90-95% of the incident infrared laser light may be reflected, especially at common wavelengths like those from CO2 or fiber lasers.

Solutions to Combat Reflectivity:

- Use shorter wavelengths: Blue laser light increases aluminum’s absorption by 3x compared to infrared systems

- Tangibles: Real-time feedback systems optimize beam delivery

- Resources: Chemical or mechanical cleaning decreases reflectivity

- Advanced laser control: 15-20% gain in process stability with modern systems

Thermal Conductivity Challenges

Aluminum’s high thermal conductivity presents significant welding challenges:

| Material | Thermal Conductivity (W/m·K) | Welding Challenge Level |

|---|---|---|

| Aluminum | 235 | High |

| Steel | 50 | Moderate |

Mitigation Strategies:

- Pre-heating: Aluminum at 150°C gives 30% better penetration during welding.

- Increasing laser power density: This increases energy concentration in the welding zone.

- Modified beam profile: Optimal heat distribution.

- Real-time monitoring: Compensates for rapid heat dissipation.

Risk of Cracking and Prevention Methods

Cracking is among the biggest concerns in aluminum welding, especially hot cracking and stress corrosion cracking.

Industry Data: The American Welding Society (AWS) shows that preheating can reduce cracking incidences by 50% for high-strength aluminum alloys.

Comprehensive Prevention Strategies:

- Optimization of Alloy Selection

- 5xxx and 3xxx series alloys have better weldability

- Lesser chance of cracking compared to 2xxx or 6xxx series

- Preheat Conditions

- Temperature range: 250°F to 400°F

- Reduces thermal gradients and residual stresses

- Improves material ductility

- Proper Filler Materials

- Use ER4045 or ER5356 with higher silicon content

- 30% reduction in hot cracking frequencies

- Weld Parameter Adjustment

- Control travel speed, current, and voltage

- Minimize heat input and ease cooling speed

- Post-Weld Heat Treatment (PWHT)

- Relieves residual stress

- Improves corrosion resistance

- Reduces stress corrosion cracking risks

Techniques for Laser Welding Aluminum

Best Practices for Successful Laser Welds

High-quality laser welds in aluminum depend on appropriate equipment, exact process control, and knowledge of material behavior.

Key Statistics: Proper surface preparation reduces defects by 50%, while fiber lasers reduce welding defects by 35% compared to CO2 lasers.

Essential Best Practices:

- Pre-Weld Surface Preparation

- Remove oxides and contaminants (oils, dirt)

- Use chemical or mechanical cleaning methods

- Critical for preventing porosity and weakness

- Selecting Appropriate Laser Source

- Use high-power laser with optimum wavelength

- Fiber lasers offer highest absorption rate for aluminum

- Better control of energy distribution

- Aluminum Preheating

- Temperature range: 100-150°C

- Reduces thermal gradients during welding

- 25% reduction in hot cracking

- Welding Parameter Control

- Laser power, beam focusing, travel speed

- Shielding gas mixture optimization

- 20% increase in weld quality through real-time monitoring

- Shielding Gas Selection

- Argon or helium for oxide protection

- Helium increases penetration depth by 10-15%

- High thermal conductivity benefits

- Post-Weld Inspection

- X-ray imaging and ultrasonic testing

- Early detection of subsurface defects

- Prevention of catastrophic failures

Advanced Laser Welding Methods

The process of laser welding has seen major technological developments, linking high precision with speed and enormous process efficiency.

Innovation Spotlight: Hybrid laser welding combines laser welding with arc welding methods, improving tensile strength by 15-20% while decreasing defects like cracks and pores.

Cutting-Edge Technologies:

- Hybrid Laser Welding

- Combines laser with arc welding methods

- Deep penetration and speed advantages

- 15-20% improvement in tensile strength

- Adaptive Control Systems

- Sensors and machine learning algorithms

- Real-time parameter adjustment

- 30% improvement in operational efficiency

- Femtosecond Lasers

- Ultrafast lasers for micro-welding

- Almost absent thermal impact (HAZ)

- 40% improvement in accuracy over conventional pulsed lasers

- Advanced Delivery Systems

- Fiber-optics and beam oscillations

- Solves joint fit-up and alignment issues

- 25% reduction in cycle times for automotive manufacturing

Laser Welding vs. TIG Welding Comparison

| Factor | Laser Welding | TIG Welding |

|---|---|---|

| Speed | Up to 6x faster production | Slower, manual control |

| Precision | Extremely high, minimal distortion | High manual control, more distortion |

| Heat Input | Low thermal energy, clean welds | Higher heat input, wider HAZ |

| Automation | Highly automated, consistent results | Manual operation, skilled operators required |

| Initial Cost | Higher equipment investment | Lower initial cost |

| Production Cost | Lower for high volume | Higher labor costs |

| Applications | Mass production, precision work | Complex repairs, small-scale projects |

Equipment Required for Laser Welding Aluminum

Types of Laser Welding Machines

Market Dominance: Approximately 70% of the global laser welding market is accounted for by fiber lasers, mainly due to their scalability, minimum maintenance, and ability to work with reflective materials.

Comprehensive Equipment Overview:

- Fiber Laser Welding Machines

- Power range: 500W to 12kW

- Uses fiber optics for beam direction

- Excellent for reflective materials like aluminum and copper

- Leading manufacturers: IPG Photonics, TRUMPF

- Minimal maintenance requirements

- CO2 Laser Welding Machines

- Power range: 1kW to 20kW

- Uses carbon dioxide gas as gain medium

- Effective for non-metallic and soft metal materials

- Lower efficiency, high maintenance

- Declining preference due to fiber technology improvements

- Diode Laser Welding Machines

- Power capability: Beyond 6kW

- Compact and lightweight design

- Highly energy-efficient using semiconductor diodes

- Perfect for plastic welding and some metal applications

- Nd:YAG Laser Welding Machines

- Versatile for many materials

- Excellent for thin materials like aluminum and magnesium

- High intensity and control capabilities

- Being replaced due to poor energy efficiency compared to fiber lasers

- Hybrid Laser Welding Machines

- Combines laser with MIG or TIG methods

- Enhanced weld quality, speed, and penetration depth

- Ideal for shipbuilding, automotive, and pipeline construction

- Greater flexibility and cost-effectiveness

Essential Protective Gear for Laser Welders

Safety is paramount in laser welding operations. Proper protective equipment is crucial for preventing injuries.

Safety Statistics: Industry data shows a 60% reduction in heat injuries when wearing appropriate protective clothing, and a 75% reduction in inhalation illnesses with proper respiratory protection.

Comprehensive Safety Equipment List:

- Laser Safety Glasses

- Wavelength-specific protection

- Must comply with ANSI Z136.1 or EN 207 standards

- Appropriate Optical Density (OD) rating required

- Fire-Resistant Protective Clothing

- Materials: Treated cotton or leather

- Protection against sparks, heat, and molten metal splashes

- 60% reduction in heat injuries when properly used

- Heat-Resistant Gloves

- Materials: Leather or aluminized fabric

- Protection from burns and radiant heat

- Essential for handling hot materials

- Respiratory Protection

- HEPA masks or built-in respiration systems

- Filters toxic fumes and fine particulates

- 75% reduction in inhalation illness risk

- OSHA recommended for all welding operations

- Auto-Darkening Welding Helmet

- Face and eye protection from bright flashes

- Adjustable shade levels

- Lightweight construction for comfort

- Steel-Toe Safety Footwear

- Steel toes and heat-resistant soles

- Protection from impact, sparks, and molten metal

- 50% reduction in foot injury rates

Automation Tools in Laser Welding Applications

Automation tools have revolutionized laser welding applications, bringing unprecedented precision and efficiency to industrial operations.

Advanced Automation Technologies:

- Robotic Systems

- Streamline repetitive operations

- Consistent, high-quality outputs

- Ideal for complex or highly repetitive work

- Vision Systems & AI

- Real-time monitoring and seam alignment

- AI optimization of welding parameters

- Predictive maintenance capabilities

- 40% reduction in defect occurrence

- Industrial Internet of Things (IIoT)

- Seamless communication with manufacturing systems

- Enhanced data collection and analysis

- Quality control and predictive maintenance

- 20% reduction in operational costs

Industries Utilizing Laser Welding Aluminum

Automotive Industry Applications

Laser welding aluminum has become one of the main fabrication processes within the automotive industry due to its ability to deliver precise and lightweight solutions.

BMW Success Story: Integration of laser welding in BMW’s production line resulted in 30% reduction in welding time and 20% improvement in material efficiency.

Key Applications in Automotive:

- Car body panel joining

- Roof joint assembly

- Critical safety component fabrication

- Electric vehicle (EV) battery enclosures

- Lightweight aluminum frame assembly

Benefits for Automotive Manufacturing:

- Weight reduction for improved fuel efficiency

- Meets strict emission regulations

- Reduces thermal distortion

- Better quality and durability

- Advanced automation integration

Aerospace Sector Requirements

In aerospace, where safety and functionality are paramount, the highest levels of precision, reliability, and material performance are demanded. Aerospace components undergo extreme conditions such as high temperature, pressure fluctuations, and corrosive elements.

Critical Industry Fact: A 1% reduction in aircraft weight leads to 0.75% fuel savings, besides operational cost reduction and reduced carbon emissions.

Key Aerospace Requirements:

- Lightweight Construction

- Materials: Titanium, aluminum alloys, carbon fiber-reinforced polymers

- Maintains structural integrity while reducing weight

- Critical for fuel efficiency and performance

- Precision Manufacturing

- Dimensions toleranced in microns

- CNC machining and 3D printing integration

- Laser welding provides strong welds without heat distortion

- Compliance and Quality Control

- AS9100 and NADCAP standards compliance

- Rigorous testing and inspection requirements

- Full reliability in flight-critical applications

- Advanced Technology Integration

- Automation and advanced analytics

- Improved efficiency and defect reduction

- Enhanced safety and functionality

Electronics and Consumer Goods Manufacturing

The electronics and consumer goods manufacturing sector is undergoing rapid evolution fostered by innovations in technology and consequent changes in consumer demands.

Manufacturing Innovations:

- Automation and Robotics

- Smart factories with IoT systems and AI analytics

- Real-time monitoring and predictive maintenance

- Supply chain management optimization

- Up to 20% operational cost savings (McKinsey report)

- Sustainability Focus

- Recycled materials utilization

- Electronic waste minimization

- Circular economy programs

- E-waste recycling market: $49.3B in 2022 → $139B by 2032

- Product Customization

- Flexible production systems

- Advanced 3D printing technologies

- Faster product iteration

- Better satisfaction of diverse customer needs

- Popular Applications

- Wearable fitness trackers

- Smart home devices

- IoT-connected electronics

- Medical device components

Frequently Asked Questions

How is the laser welding conducted for the joining of aluminum?

The joining of aluminum is done by laser welding in that the laser radiation is focused into a beam to melt the pieces of aluminum being joined. This operation, with the ability to precisely control weld parameters, produces a very clean weld with minimal porosity. Laser energy density is a very crucial parameter as it affects heat input along with penetration depth. Generally, continuous-wave lasers are utilized, but pulsed lasers can weld aluminum to some degree of thickness. Surface conditions of aluminum must be attended to before welding, otherwise good-quality welds cannot be realized.

How does high heat conduction in aluminum interfere in laser welding?

Aluminum being a good conductor of heat, the heat generated during laser welding is quickly conducted away from the zone in the welding area. If not controlled, this might lead to no melting. Thus, best would be to increase the laser power to higher energy density in order for proper welding. Should also be accompanied by shielding gas to avoid oxidation, which is of utmost importance in aluminum welding. Proper knowledge of the melting point of aluminum and its behavior under heat will result in successful, full penetration welds.

What are some advantages that laser welding of aluminum offers?

Laser welding of aluminum confers several advantages such as laser welding of thin materials with great precision. As the laser-related processes are focused energy processes, clean and narrow welds can be produced. This sort of weld can be beneficial in complex welding-required designs. Furthermore, laser welding reduced the chance of warping compared to heat-intensive conventional welding such as MIG and TIG welding, making it a very productive form of welding aluminum in contrasting environments.

What to look for in an aluminum laser welder?

Specifications to consider when purchasing a laser welder for aluminum relate to the laser type, say fiber versus a laser used for more general welding applications. Among the other few considerations are:

- Laser power-the higher the power, the more the energy output

- Type of laser optics used to focus the beam

- Thickness of aluminum parts that determine which welding techniques apply

- Requirement for keyhole welding or will autogenous welding suffice

- Use of the correct shielding gas to prevent oxidation

Reference Sources

This comprehensive guide is based on extensive research from leading industry publications and academic sources, including:

- Research and Progress in Laser Welding of Wrought Aluminum Alloys

- Laser Welding of Aluminium Alloys and Dissimilar Metals

- Trend and Innovations in Laser Beam Welding of Wrought Aluminum Alloys

- Recent Developments in Laser Welding of Aluminum Alloys to Steel

- Laser Welding of Aluminium Alloys 5083 and 6082 Under Conduction Regime

Conclusion

Laser welding aluminum represents a transformative technology that combines precision, speed, and efficiency in modern manufacturing. From aerospace to automotive industries, this advanced welding method continues to push the boundaries of what’s possible in metal joining applications. As technology evolves and automation becomes more sophisticated, laser welding will undoubtedly play an increasingly vital role in shaping the future of manufacturing worldwide.

Whether you’re considering implementing laser welding in your operations or looking to optimize existing processes, understanding the principles, benefits, and challenges outlined in this guide will help you make informed decisions and achieve superior welding results.

- Laser Machine for Marking: Understanding Fiber Laser Marking and Engraving Technologies

- Understanding CNC Routers: The Ultimate Guide to CNC Routing vs Mill Technology

- ATC CNC Router Machine: CNC Router with Automatic Tool Changer

- Laser Dental Cleaning vs Traditional Methods: Revolutionizing Dentistry with Laser Teeth Cleaning

- Mastering EDM Cutting: Unleashing the Power of Wire EDM Machines and Electrical Discharge Machining

- The Melting Point of Nylon: Understanding the Thermal Properties of Plastic Materials

- Expert Guide: How to Choose the Perfect CNC Router for Hobbyists with Maximum Rigidity

- Understanding the Difference Between CNC and VMC Milling Machines: Complete Comparison Guide