Recent innovations in manufacturing have shifted industry focus towards accuracy and productivity; precision laser tube cutting is the pinnacle of this shift. This state-of-the-art technology has transformed metalworking by enabling manufacturers to attain unmatched precision, minimize production waste, and optimize processes. Whether you want to stay ahead of industry trends as a seasoned expert or understand the potential of laser tube cutting as a new comer, this article will navigate through the transformative effects of laser tube cutting. Adapt to where you are hoping to see modern metal fabrication and manufacturing through this innovation.

What is Laser Tube Cutting?

Laser tube cutting is a form of technology that utilizes a laser beam to cut, shape or engrave metal tubes and pipes. Because of the high accuracy and clean edges provided by this method, it is suitable for the automotive, aerospace, and construction industries. Moreover, this technique ensures consistent quality by automating the process, thus maintaining precision and reducing material waste.

Understanding the Process of Laser Tube Cutting

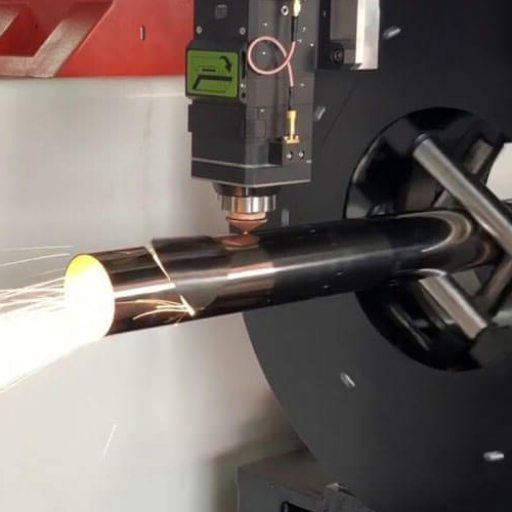

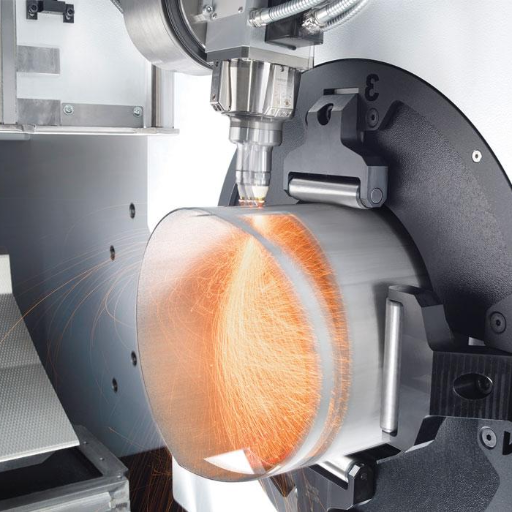

The automated systems applied in Laser technology have enhanced efficiency and precision. The process starts with a powerful beam laser which is focused using mirrors and lenses onto the metal tube. The molten, burned, or vaporized material yields a precise cut.

Modern laser machines now incorporate Computer Numerical Control (CNC) Technology, which provides mitigation of human error through pre-programmed designs. Various configurations of round, square and rectangular tubes, as well as custom geometries, are programmable. Furthermore, these systems are not restricted to only one kind of material and can cut stainless steel, carbon steel, aluminum and other alloys.

Data underscores the advantages of using laser tubes for cutting. As an example, laser cutting precision within industry standards reaches up to ±0.1 mm, which is exceptionally accurate. In terms of production speed, lasers cut at over 60 inches per second, depending on the material and its thickness. As an additional advantage, laser tube cutting is more economical since it uses 30% less material compared to more traditional mechanical ways of cutting, making it more ecologically responsible.

Modern laser tube cutting machines also include features such as automated material loading and unloading processes, 3D cutting, and quality control subsystems. These improvements advance modern technology and decrease manufacture time, enabling manufacturers to satisfy rigorous deadlines without diminishing production quality.

With the integration of modern technology, engineering precision, and efficiency based on analytics, laser tube cutting has transformed the approach to metal fabrication, allowing for innovative production methods and industrial scalability.

How Does a Laser Tube Cutting Machine Work?

A laser tube cutting machine makes use of a laser beam with high precision metal cutting capabilities, particularly cutting through metal tubes. The process starts with the operator crafting a detailed cut specification using computer-aided design (CAD) software. Following this step, computer-aided manufacturing (CAM) software is used to translate the design into machine operations instructions, guaranteeing precision and repeatability.

The laser beam, which is usually emitted by fiber or CO2 lasers, is routed through mirrors to focus onto the workpiece surface. The laser’s energy heats the metal along a predetermined path, and simultaneously, nitrogen or oxygen assist gas streams the molten material away from the cut area, which results in a clean cut.

Modern laser tube cutting machines have features such as automated material handling, real-time monitoring, and cutting on multiple axes. With these features, the system is capable of making more advanced cuts such as recesses, wedges, slots, and more while maintaining tight tolerances. For example, many machines achieve cutting tolerances of ±0.01 mm which is useful in the aerospace, automotive, and medical device manufacturing industries.

As of 2022, the global laser cutting market’s valuation was approximately $5.72 billion and is expected to grow with a compound annual growth rate (CAGR) of 9.1% until 2030. Growth in this sector is caused by an increase in the demand for precise automation in the manufacturing as well as production processes. The latest machinery uses real-time feedback and AI-driven optimization, which further enhances efficiency. Unlike traditional cutting methods, these machines waste 30% less material during the cutting process.

The laser tube cutting technology that is tailored to bear these attributes showcases its ability to enhance production and operational capabilities while minimizing costs, resource consumption, and environmental impact. This methodology continues to define the future of metal fabrication in various industries, as it constantly improves with advances in laser technology.

Primary Uses of Laser Tube Cutting

Laser tube cutting has become the foundation of precise and cost-effective fabrication across numerous sectors, thereby revolutionizing different industries. The automotive, aerospace, construction, and furniture industries are among the primary users. As an instance, the automotive sector applies laser tube cutting to manufacture intricately patterned, robust yet lightweight parts to aid in the shift toward electric vehicles. Research indicates that laser cutting boosts production rates by up to 70% and greatly reduces lead times.

Also, within the construction industry, laser tube cutting makes possible the bespoke fabrication of structural components with precision and minimum material wastage. Research indicates that this approach can achieve as much as 95% in material utilization, dramatically reducing leftover scrap in comparison to conventional cutting methods. In addition, the furniture sector has the capacity to manufacture complex design motifs which are distinctive high precision units allowing mass customization.

The essential nature of laser tube cutting for high precision and high-quality aesthetic output makes it shine through other industries. It is anticipated that laser tube cutting will further consolidate its importance in modern manufacturing with a CAGR of around 8.5% from 2023-2030 due to perpetual technological innovations and the increasing adoption of the principles of Industry 4.0.

How to Choose the Right Tube Laser Cutting Machine?

- Material Compatibility: Make sure the machine can properly manage the types and thicknesses of materials you use most often.

- Cutting Precision: Evaluate the machine’s accuracy relative to your design and manufacturing requirements.

- Production Volume: Select a machine which fulfills your required production speed and capacity.

- Software Integration: Look for intuitive software equipped with CAD and automation tools that can streamline processes.

- Manufacturer Support: Confirm the existence of Technical Support, Training, Maintenance Support from the Manufacturer.

Factors to Consider: Metal Type and Thickness

When choosing a machine, ensure that it is suitable for working with the specific types of metal you plan to use. Different machines have different capabilities in dealing with the properties of metals such as hardness and conductivity. In addition, assess the machine’s ability to handle the thickness range of your materials so that precision and efficiency are not undermined. Committing the machine to your material’s specifications would result in best operation and endurance.

Assessing Capabilities of a Tube Laser Cutter

While evaluating a tube laser cutting machine, their efficiency, speed, and material range require close attention. The modern machines, as an example, fiber laser cutters have an exceptional advantage as they can cut intricate shapes and complex designs accurately. These machines work with a tolerance as precise as ±0.1 mm which is perfect for industries like automotive and aerospace manufacturing that require high precision.

Fiber laser cutters are renowned for their speed efficiency. For example, cutting a standard steel tube of 2.5 mm thickness can take less than 10 seconds depending on the complexity of the cut and the machine’s power. Higher power lasers, for instance 4 kW or 6 kW models, are more efficient as they have faster processing speeds and can cut thicker mild steel tubing up to 25 mm.

The machine’s proficiency in cutting mild steel, stainless steel, aluminum, brass, and copper should be evaluated as well. Modern machines come with automatic tube measurement which improves quality control across different material types and sizes. Such machines can accept tubes with diameters from 20 mm to over 300 mm, offering greater flexibility for various project needs.

Moreover, several contemporary tube laser cutting machines come with integrated nesting and design optimization software. This reduces material waste and overall costs of production, thus making them great investments for businesses that are efficiency and sustainability focused.

With a detailed evaluation of these aspects alongside certain machine parameters, it is possible to choose the most suitable tube laser cutting machine to optimize production processes.

Comparing Fiber and CO2 Lasers

Fiber lasers and CO2 lasers differ mainly in efficiency, versatility, power consumption, material compatibility, and maintenance requirements.

| Key Point | Fiber | CO2 |

|---|---|---|

| Efficiency | High | Moderate |

| Power Use | Low | High |

| Materials | Metals, Non-metals | Non-metals, Some Metals |

| Maintenance | Low | High |

| Speed | Fast | Slower |

| Cost | High Initial, Low Run | Lower Initial, High Run |

| Lifespan | Long | Shorter |

What are the Benefits of Laser Tube Cutting Over Traditional Methods?

- Precision – Additional finishing work is deemed unnecessary due to the accuracy and cleanness of the cuts achieved through laser cutting.

- Efficiency – Time is always being optimized throughout each step of the entire process including for complex designs which in turn improves productivity.

- Versatility – This new advancement expands possibilities with intricate cuts that would be difficult to achieve through more traditional tools.

- Reduced Waste – This approach aids with cost savings as the pinpoint accuracy means minimal surplus materials are unused.

- Automation – Output consistency increases while minimizing manual labor due to the automation features now added to more contemporary systems for laser cutting.

Precision and Edge Quality

Critical sectors such as aerospace, medical engineering and electronics rely heavily on intricate detailed designs undergoing laser cutting because of the unmatched precision and edge quality offered. Depending on the intended use, modern laser cutting machines can achieve tolerances as tight as ±0.001 inches. Smooth and clean edges are guaranteed with focused laser beams, while secondary finishing processes are no longer needed.

Recent studies indicate a reported reduction of production time by 25% in laser cutting industries when compared to traditional machining. Not only do these industries boast production efficiencies, they are also capable of handling thin sheets of stainless steel, as well as thicker carbon steel or titanium metals. With an astonishing speed of 1400 inches per minute, laser cutting enables efficient work on thin materials.

Moreover, with the shift to fiber and CO2 lasers, older systems saw a rise in cost cutting efficiency due to a 30-50% drop in energy consumption. With these precise and accurate advancements, operational costs have been drastically lowered, widening the scope of laser cutting technologies in manufacturing.

Metal Fabrication Productivity

Along with operational efficiency comes ease of use; recent surveys still demonstrate sustained interest in laser cutting technologies, which comes as no surprise owing to the ever present precision and cost-friendly nature. Strengthened accuracy comes from modern fiber lasers, with enhanced performance claimed at power ratings of 40kW, enabling even quicker and more precise cutting of thicker materials. In the same report, other industry experts expect extensive growth in laser cutting machines at a staggering 9% CAGR from 2023-2030, specifically in the automotive, aerospace, and construction industries.

Compared to older CO2 lasers, modern laser systems are up to 45% more energy efficient. Older CO2 lasers only managed to use 10-20% of their energy efficiently, meaning their cost-efficacy was rather poor. The changes in modern laser systems have allowed industries to save significantly on electricity. In addition, the implementation of AI features in automated laser systems has improved efficiency by streamlining the cutting process and reducing material waste by 15%. These advancements help manufacturers better reach their production goals. Coupled with strict deadlines, increased attention to sustainability becomes easier to meet.

Waste and Error Reduction

By utilizing advanced automation, I remain focused on saving as much material as possible throughout the fabricating process. My philosophy centers around accuracy, especially when it comes to resource allocation. Advanced systems and AI technologies enable exactness through advanced tools, which in turn enhances the streamlining of cutting paths. Maintaining low costs translates to improved sustainability. In my opinion, precision is paramount to achieving quality outcomes while addressing environmental and socio-economic frameworks.

What Materials Can Be Processed with a Laser Tube Cutting Machine?

Laser tube cutting machines can also process other metals such as carbon steel, stainless steel, aluminum, and even non-metal materials depending on their attributes. The efficiency offered by laser cutting is unmatched compared to traditional methods. As such, laser cutting is becoming a more popular option as it allows for flexible and dependable solutions for different materials.

With regards to Porting and Profils

Integrating the latest laser cutting technology ensures motion within a productivity range as considerable as 90 meters per minute. This increase helps bolster productivity significant amounts across industrial uses. Such machines are necessary for considerably proficient cut sections and for complicated shapes, allowing manufacturers to achieve unrealistic designs accomplished quickly using simple methods.

New laser tube cutting machines tend to come equipped with automation features even more such as integrated CAD/CAM design software and real time monitoring systems, as well as robotic arms for the automated loading and unloading of material. Less need for human effort, faster Lead times increase of more than 30% reduction of speed boosts increasing accuracy and efficiency. Automated systems can also optimize material usage thus saving power, which is essential for lowering costs when it comes to business production output.

Furthermore, advanced fiber laser machinery might surpass older models in terms of energy consumption as well as the ability to process reflective metals such as aluminum and copper while maintaining pristine cutting quality. From a cost analysis standpoint, CO2 laser systems have nearly a 50% higher operating cost versus fiber laser cutting systems, thus making it easy to optimize business productivity while maximizing value in eco-friendly fuel consumption.

Working with aluminum, stainless steel, and other metals

The recent advancement of laser technologies has greatly changed machining processes for materials like alloys of aluminum and stainless steel. One of the easiest metals to cut, aluminum is also one of the hardest due to the CO2 lasers propensity to reflect. Traditional technology’s shy reliance on fiber laser technology made working with aluminum lasers prone to wearing out cutters []. The good news is fiber lasers are more effective with aluminum as its wavelength is lower allowing for greater precision without excessive reflection.

When cutting stainless steel, the benefits of a fiber laser are unmatched. Stainless steel parts have accurately cut smooth edges, high-quality finishes and minimal (heat affected) zones that are crucial for integrity. Recent findings indicate that fiber lasers can slice through 1 inch thick stainless steel sheets at remarkable speeds, up to 472 inches per minute, although this depends on the thickness of the material and the strength of the machine in use.

Also, fiber lasers vertically outperform the rest when dealing with differing thicknesses and types of metals like brass and copper. These metals are highly reflective and were a challenge for older methods, but are now easily processed, allowing manufacturers greater flexibility. Reports show that processing efficiency for these metals increases by 30% with fiber lasers compared to older technologies due to faster processing times and reduced operational costs.

Elevated demand for custom fabrication of metals has made spending precision, speed and cost effectiveness crucial. This ensures that fiber laser cutting will continue to be instrumental in modern manufacturing where value is needed in a wide range of applications.

Investigating Limits of Thinness and Lengths

The effectiveness of fiber lasers in cutting materials of varying thicknesses and lengths is nothing short of remarkable. Their modern fiber laser systems have the capability of cutting as thin as 0.1 mm, which is critical for delicate electronic components. On the other hand, the more advanced systems have been able to cut thick metals like 25 mm of mild steel and 20 mm of stainless steel with high speed and precision.

Moreover, the industry leaders are currently designing cutting tables with the ability to process long materials around 12 meters, which broadens the scope of these systems for super scales. As per the recently published data by the industry, fiber laser systems are faster than the traditional CO2 systems by 3 to 4 times while working with thin slabs of up to 6 mm. In addition to the reduced production time, these systems further lower material wastage which is a major factor in cost and eco friendly savings. Due to these reasons, fiber laser cutting is becoming an essential tool in automotive, aerospace, custom metalworks and precision manufacturing industries.

How to Optimize Laser Tube Cutting for Maximum Productivity?

- Select the Right Equipment: For accuracy and speed, use sophisticated fiber laser machines for tube cutting. Their designated power ratings should match the thickness of the material being worked on.

- Material Preparation: In order to maintain consistent cutting quality, ensure that the tubes are clean and free from dust, oil, and other debris.

- Optimize Laser Settings: Adjust the operational power, speed, and focus to be optimal for the tube material and its thickness for effective productivity.

- Utilize Automation: To enhance production efficiency, use automated systems for loading and unloading to minimize non-productive time.

- Regular Maintenance: Eliminate any unforeseen downtime by maintaining the laser machine and all its components in optimal condition through regularly scheduled maintenance.

Improving Productivity Through Automation

All sectors are witnessing an increase in productivity and efficiency when using automated systems, fundamentally transforming production processes. Recent studies have shown that operational efficiency can increase by 30% with the use of automated systems within the manufacturing industry. Automation of repetitive and menial tasks such as material handling through robotic arms, the implementation of automated loader systems, and real-time monitoring powered by AI reduces error margins and human involvement. As an example, a Deloitte survey indicated in 2023 that production companies adopting automation reported a reduction in downtime by 22%, translating to boosted productivity directly.

Besides, automation improves accuracy in laser cutting and welding processes because it guarantees repetition without failure as well as reduction of material scraps. The advancement of learning computer algorithms now enables automated systems to self-calibrate, which improves the streamlining of the operations. For example, the use of IoT (Internet of Things) in automated systems facilitates real-time monitoring and predictive maintenance which safeguards equipment against impending failures.

This is additional evidence that aims to demonstrate the impact that automation can have on changing workflows. Businesses adopting these technologies will find that they can control their business expansion, increase the workload volume, and operate even lower-cost under the fierce competition.

The Relevance of Cutting Head Technology

In the context of modern manufacturing processes, the relevance of cutting head technology is in precision, sophistication, and efficiency in terms of material processing. Automation systems with precision features integrate advanced laser and waterjet cutting heads. New laser cutting heads are capable of cutting with tolerances of as small as ±0.001 inches, which is extremely important for businesses that operate in the aerospace and automotive manufacturing industries.

Furthermore, advancements within waterjet technology have made it possible to slice through materials without the application of heat, which is beneficial to materials composites and laminates. As noted in a 2023 publication, industries that have incorporated automated cutting heads report a 35% reduction in material waste alongside a 20%boost in production speed, reflecting an improvement in cost-efficiency and overall value throughput.

The application of IoT in cutting head technology enables real-time tracking of wear and tear as well as predictive maintenance alerts. For example, some newer systems come equipped with sensors that monitor operational metrics and alert users when focus shifts past a defined threshold, thereby maintaining output precision. These innovations highlight the absolute necessity of cutting head technology for achieving high precision and sustainable scalable production.

Increasing Precision and Reducing Tolerances in Cuts

Modern advancements in cutting head technologies have improved tolerance and accuracy of the cuts made very profoundly. This is especially true for sectors that depend on precision manufacturing. Modern systems integrate lasers and waterjet cutting tools. Recent studies suggest laser and waterjet systems integrate cutting heads with tolerances of about ±0.001 inches. The accuracy is unmatched. These modern systems incorporate machine learning algorithms for parameter changes during the cutting process which lowers the chances of errors and decreases material wastage. Moreover, high-resolution imaging systems allow operators to keep an eye on the cutting paths and make necessary deviations in real-time.

As an illustration, operators have started using fiber lasers that have newer beam focusing technologies. Newer lasers have a much smaller beam diameter which allows for more complex cuts. This development has indicated a 30% increase in cutting speeds as compared to other more conventional cutting systems. In addition, automated calibration features reduce the possibility of manual errors which enhances consistency in production workflow. All these innovations allow manufacturers meet quality control checks without causing production masking bottlenecks.

Reference sources

- ANALISIS PARAMETER MESIN LASER TUBE CUTTING TERHADAP SURFACE ROUGHNESS PADA SQUARE PIPE ST 37 MENGGUNAKAN TAGUCHI METHOD

- Authors: Fariz Rachman et al.

- Publication Date: November 30, 2024

- Journal: AUSTENIT

- Summary:

- This study focuses on optimizing the parameters of a laser tube cutting machine to improve the surface roughness of square pipes made from ST 37 steel.

- The research employs the Taguchi method with an orthogonal L9 (34) matrix to analyze the experimental results.

- Key parameters investigated include laser focus point, gas pressure, nozzle distance, and laser power, each set at three levels.

- The experiments were conducted nine times with three replications to ensure validity.

- The optimal combination of parameters identified was a laser focus point at level 1 (0 mm), gas pressure at level 1 (0.6 bar), and laser power at level 1 (1800 W)(Rachman et al., 2024).

- Laser tube Cutting – Throat and Stress Distribution in CHS-to-CHS joints welded by partial joint penetration (pjp) according to en9692, as/nzs1554 and AWS-D1.1

- Authors: A. Mastropasqua et al.

- Publication Year: 2019

- Journal: Proceedings of the 17th International Symposium on Tubular Structures (ISTS17)

- Summary:

- This paper investigates the throat and stress distribution in circular hollow section (CHS) joints welded by partial joint penetration.

- The study adheres to various welding standards (EN 9692, AS/NZS 1554, and AWS D1.1) to ensure compliance and relevance.

- The research emphasizes the importance of understanding stress distribution in welded joints to improve structural integrity and performance(Mastropasqua et al., 2019).

- Laser tube cutting—Comparison of new types of K-joints and their SCF with standard solutions

- Authors: S. Herion et al.

- Publication Date: November 13, 2017

- Summary:

- This study compares new types of K-joints created through laser tube cutting with standard solutions.

- It focuses on the stress concentration factors (SCF) associated with these joints, which are critical for assessing their structural performance.

- The findings highlight the advantages of using laser cutting technology in creating joints that may offer improved performance over traditional methods(Herion et al., 2017, pp. 215–222).

Frequently Asked Questions (FAQs)

Q: What is Laser Tube Cutting?

A: Laser tube cutting is a form of fabrication in which a tubular workpiece is has precisely outlined cavities and features cut into it using a laser beam. It is common practice to perform laser cutting on sheet metals and also on metal tubes to achieve sophisticated intricate cuts.

Q: What are the Possible Laser Tube Cutting0 Materials?

A: Other than the more common metals, laser tube cutting can be performed on different materials such as steel and aluminum. The technology works best on materials of varying wall thicknesses.

Q: Functioning of Laser Metal Tube Cutter?

A: A metal tube laser cutter employs industrial-grade optics to focus a laser beam into a cutting spot according to the geometry of the cut. By melting, burning or vaporizing the irradiated material, the beam of cutter separates the workpiece into parts. The tubing is usually gripped by a chuck which feeds and rotates the workpiece during the cutting operation.

Q: What are the benefits Fiber Laser Tube Cutter Users Get?

A: Besides having and maintaining a very high efficiency, the precision achieved fiber laser tube cutters is unmatched. They are also able to make cuts within complicated geometries and through holes with very small kerf, even on materials whose wall thicknesses differ.

Q: Can machines with laser tubes cutters also slice flat sheets?

A: Indeed, most machines that work on a tubular form can also work on a flat form. There are machines that incorporate both tube and flat sheet laser cutting in one unit.

Q: Explains the cutting chuck for the laser tube cutting section.

A: The chuck is a holding device, or machine component which grips the tubes securely. A adequately designed chuck turret permits definite locked rotational motion parallel to its axis and continually indexes to a cutting head and holds angular position aligned with that head.

Q: In which formats are design files prepared for laser tube cutting?

A: For laser tube cutting design files are prepared in IGES, IPT, PAR or X_T formats. The systems that perform the cuts need to be provided with design file specifications for them.

Q: Are there any limitations to using a laser to cut tubing?

A: The use of a laser cutting system has limitations in its application for materials that are excessively thick or those that have the tendency to reflect laser beams. Further, the intricate nature of the design also has an influence on the both time and expenses incurred.