During the rust removal process, machinery, tools and surfaces are usually worn over time which is quite expensive and a nuisance. Hand-operated rust removal processes are often abrasive, labor-intensive, and time-consuming further requiring intricate steps to be taken, which tend to dissolve the material beneath. Laser technology is arguably the most advanced form of removing rust with undisputed accuracy and eco-friendliness. In this guide, we look at the emerging process of laser rust removal, its working mechanism, pros when compared to older techniques, and the reasons it is rapidly gaining favor across numerous sectors. In case you are an innovative laser solution thinker, equipment prone to rust conservator, or just a general professional, this article will explain the functionality and potential of lasers and help you make informed decisions.

How Does a Laser Cleaning Machine Work?

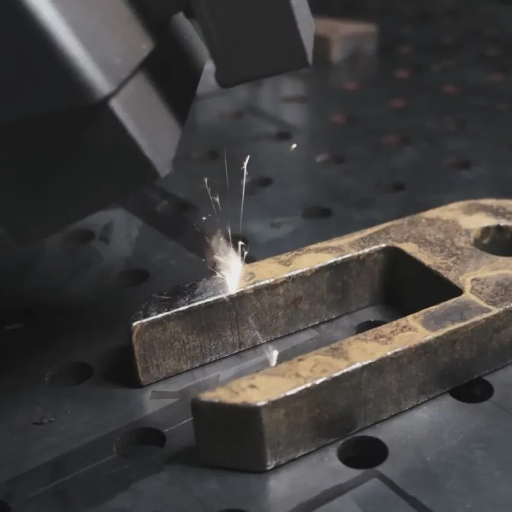

Laser cleaning utilizes a laser cleaning machine, which emits powered laser beams capable of accurately removing any rust or contaminants from a surface. The surface beneath an unwanted material is not destroyed; instead, the high-energy laser pulses heat and vaporize it. These processes are executed in a manner that guarantees effective cleaning while preserving the base material.

What is the Science Behind Laser Cleaning?

The fundamentals of physics explain how laser cleaning works: through laser ablation. The removal of contaminants from a surface via high laser intensity is called laser ablation. Contaminants, such as rust, dirt, or paint, are swiftly removed through processes such as rapid heating, vaporization, or sublimation. The energy from a high intensity laser is directed towards these unwanted materials, and the precision with which a beam maintains ensures that the underlying, desired, material is not affected.

Studies show that laser cleaning can achieve energy density of up to 1 GW/m², which allows for the effective removal of even the most tenacious contaminants. Other studies also argue that the type of laser used for cleaning, such as fiber lasers that operate at 1064 nm, defines how efficient the cleaning will be and its effectiveness on various surfaces. For example, nanosecond pulsed lasers are popular due to their effectiveness in providing a balance between material removal and interaction control.

The Focused beam of lasers and it’s application on metal surfaces

The straightforward techniques for metal surface manipulation encompasses laser beam application. Optimal processes for separating (ablation) contaminants from the metallic surface is thoroughly dictated by the wavelength, pulse duration, energy density, and substrate metal. Interactions with metallic surfaces involves concentrating laser energy. Rapid heating occurs as a result which is as a result, the contaminant is vaporized (ablative cleaning) or removed without inflicting damage to the surface underneath. For instance, research proves that nanosecond or picosecond lasers are a greats in taking out oxidation layers, coatings or residual material without thermal damage.

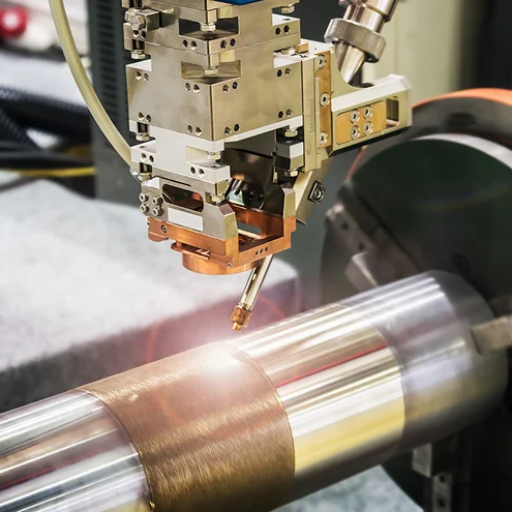

From the absorption perspective, most metals like as well as steel, aluminum and copper are appropriably suited for infrared lasers at 1064 nm because of their greater than one absorption at that wavelength. For instance, studies show that copper surfaces respond efficiently to laser cleaning when coupled with adequate energy density levels because they have an absorption rate of around forty percent at this wavelength. In addition, the use of ultrafast lasers with high repetition rates increases the rate of cleaning whilst retaining accuracy, making them preferable for high precision applications like aerospace or automotive components.

Data from recent industrial applications show that laser cleaning can accomplish surface cleaning rates up to 15 m²/h for expansive areas which varies with the laser power and system design. This capability makes it a competitive choice compared to conventional abrasive cleaning methods. Moreover, new developments in beam delivery systems such as scanner heads and automated controllers provide greater freedom for removing complex geometries and other difficult to access areas.

The increasing field uptake of laser technology in different industries shows its versatility and environment friendly nature as there are no abrasive materials or toxic chemicals employed. These features together with the precision and flexibility of the laser makes such cleaning revolutionizing in terms of surface maintenance and restoration of metals.

Advantages Of Laser Technology In Rust Removal

Laser technology as a means of rust removal is extremely effective, and it is also green which makes it appealing in all industries. Especially in aerospace engineering, one of the biggest advantages of lasers is that their application is detrimental to the object being worked on, in terms of precision. Lasers can easily get rid of rust without affecting the metal underneath, which is critical in sensitive or detailed parts. According to new information, laser cleaning systems, when removing rust and other surface cleaning, can achieve almost 90% efficiency, and when compared to traditional methods, it takes laser systems considerably less time to clean.

Cutting of waste is another big benefit of using lasers. And by cutting waste, I mean harmful waste. There is often a solution using abrasives like sand paper or stronger chemical based cleaners to remove rust. Such alternatives pose a risk to the user as well as the environment. While using lasers, no abrasive particles are formed and the whole procedure is free of chemicals, which is exactly what the modern anti-sustainability movements are advocating for. Research indicates that companies that adopt laser cleaning technology waste 20–30% less, and with such compliant measurements further enhance environment policies.

Besides, the development of laser technology has increased its versatility. Contemporary systems include flexible laser settings and automated controllers, which enable users to adjust the cleaning intensity for different types of surfaces and varying levels of rust. It has been reported that automated processes in laser cleaning have increased productivity by 40% in the automotive, aerospace, and manufacturing industries.

In any case, the application of laser technology for corrosion cleaning offers unparalleled accuracy, ecological responsibility, and effectiveness compared to other techniques, and provides a revolutionary service for industry across the globe.

What Are the Types of Laser Cleaning Machines?

Laser cleaning machines are mostly differentiated as handheld and automatic systems. Automated machines offer ease of use regarding scaling. They are appropriate for bigger operations as they are programmed to deliver precision results in industrial settings. Handheld units, however, are more flexible and ideal for smaller detailed tasks or hard to access regions. Both types differ in power levels and features to fit distinct cleaning tasks.

Analyzing Fiber Laser and Pulsed Laser Technologies

Pulsed lasers and fiber lasers are both popular technologies with extensive use in laser cleaning, with each having its unique advantages. Notably, fiber lasers have high energy efficiency, small size, long operational life up to 100,000 hours, and are powerful. They use optical fibers doped with rare earth elements such as erbium or ytterbium which serve to deliver precise high powered laser beams. These lasers are useful in heavy duty tasks like rust removal and surface conditioning as they enable prolonged use with consistent output.

Unlike other lasers, a pulsed laser operates by emitting laser energy in short bursts. This allows for cleaning within very thin margins, as precision is of utmost importance, for cleaning fine electronic components or restoring historical artifacts. When contaminants need to be removed without damaging the underlying substance, there needs to be a peak of power for a few microseconds; pulsed lasers achieve this seamlessly. A good example is nanosecond pulsed lasers, which are capable of producing pulses between 1 to 200 nanoseconds and average power levels of 30W to 500W depending on the system utilized.

Recent market reports emphasize the increasing use of both technologies across different industries. Fibers lasers continue to be favored by automotive and aerospace industries due to their durability, while more delicate environments utilize pulsed lasers. Other reports indicate growth of the global market for laser cleaning is forecasted to increase at a CAGR of 4.8% from 2023-2030, highlighting an industry wide shift towards less wasteful and more cost efficient methods compared to traditional cleaning systems.

Comparing CW Laser Cleaning Machines with Pulsed Laser Cleaners

CW laser cleaning machines are ideal for continuous heavy-duty tasks, while pulsed lasers excel in precision and delicate applications.

| Key Point | CW Laser | Pulsed Laser |

|---|---|---|

| Energy Type | Continuous | Pulsed |

| Power Output | Higher | Lower |

| Precision | Moderate | High |

| Best Use | Heavy-duty | Intricate |

| Heat Impact | Higher | Lower |

| Material Adapt | General | Specific |

| Cost-Efficiency | Varies | High for fine |

| Maintenance | Robust | Delicate parts |

Comparison of Handheld and Stationary Systems

It is essential to consider the features and applications of both handheld and stationary laser systems before making a decision. Handheld lasers offer great maneuverability because of their light weight which allows the operators to move them in awkward or compact spaces easily. They are perfect for on-site maintenance, engraving jobs on large objects that cannot be moved easily, and other on-the-go processing tasks. Lower initial costs, compact designs, and intuitive operation often provided in handheld systems are particularly beneficial to businesses that are mobile or require flexibility.

A greater level of power stability combined with advanced automation options makes stationary laser systems ideal for tasks that are precision heavy and high in volume. As precision and uniformity are two core characteristics in extreme industrial settings, these systems excel there. The Laser Machines Market Analysis Study indicates that stationary systems contribute to over 60% of global laser machining production. This showcases their popularity in factory settings. Moreover, these systems can be easily integrated to CNC platforms which improves the accuracy of working on designs that are complex.

Is Laser Rust Removal Effective for All Metal Surfaces?

Although laser rust removal works for most metal surfaces, its effectiveness differs with the type of metal and the level of corrosion present. Steel and aluminum surfaces perform well, whereas highly corroded or ultra-thin metals require extra attention to avoid damage. It is a precise, eco-friendly approach employed in many industries.

Factors that Impact the Effectiveness of Laser Cleaning

Several factors affect the efficiency of removing rust and other contaminants from a metal surface. The power and wavelength of the laser are of utmost importance. Research indicates that while high power lasers clean rust faster, they require careful use to avoid damage to the underlying material. Industrial lasers used for rust removal range from 100 to 2000 watts, with higher power facilitating increased cleaning speed.

An equally important consideration is the kind of material to be cleaned. Various metals absorb laser energy differently, as they each possess unique thermal and optical attributes. Steel and aluminum surfaces, for instance, undergo disparate changes owing to reflectivity and conductivity differences when subjected to laser cleaning. Some researchers argue that due to its high reflectivity, aluminum necessitates the use of optimized parameter lasers for effective cleaning.

The process is also influenced by the level of corrosion or the degree of contamination of the surface. Less severe rust deposits can often be cleared in a matter of seconds, while more severe cases may require several iterations or changes to the laser settings. Moreover, the elimination of oil, debris, or any other foreign matter tends to augment the effectiveness of surface cleaning.

Recent studies in the industry demonstrate that laser cleaning systems operate with an efficiency rate of approximately 95 percent for the removal of light rust and scale from industrial machinery, establishing their popularity in automotive and aerospace manufacturing. With improvements in laser technology, including automated and real-time surveillance systems, the field of laser cleaning is rapidly advancing toward becoming the preferred, reliable, and environmentally safe method for surface treatment.

Preventing Damage to Metal

In order to avoid damage during laser cleaning, it is important to fit the laser parameters to the material’s surface features to avoid damaging the metal. Cleaning parameters of laser power, pulse frequency, and scanning speed need to be set in a way so they facilitate cleaning without damaging the metal. A new study claims that delicate surfaces like aluminum or thin metal sheets respond better to low power settings and higher pulse frequencies. Besides, a lot has been achieved in abuse prevention owing to real time monitoring systems that provide effective control on feedback regarding the laser and material interaction. For instance, contemporary systems for cleaning lasers have been able to maintain surface roughness control within a variance of 5 microns which is wonderful precision for aero space and even medical manufacturing industries.

Moreover, multi-pass cleaning (where the number of passes of low intensity lasers is increased) has shown marked reduction in risk of damage while maintaining very high cleaning efficiency, generally greater than 90 percent. Other studies recommend techniques that highlight the need for complete area testing on small non-critical regions before cleaning the entire section. Ultra modern technology used along with these aims stand to achieve the most reliable means of cleaning lenses while ensuring adaptability on a variety of metals and industrial purposes.

Comparing Laser Rust Removal with Traditional Methods

Unlike sandblasting, chemical treatments, or abrasive grinding, laser rust removal utilizes more sophisticated techniques and advanced eco-friendly technologies. The aforementioned methods use outdated techniques that depend on dangerous chemicals or abrasives that can harm the substrate and create hazardous waste that is difficult to clean. Laser technology, on the contrary, offers contact-free cleaning with laser instruments that helps minimize waste and the need to use sand or chemicals.

As an example, modern lasers, including fiber lasers, boast energy efficiencies of up to 95%, meaning they are sustainable. Experts believe that with sufficient power, lasers have the ability to surpass manual cleaning methods with surface rust removal speeds of 5 to 10 square meters per hour. Also, as result of the targeted nature of laser application, components are preserved for longer periods because the wear and tear on the materials by abrasive techniques is eliminated.

Research in Surface Engineering showed that using lasers for cleaning increased environmental safety compared to sandblasting, as it reduced waste by approximately 80%. Moreover, current developments permit the use of automated systems for laser cleaning, which enhances uniformity and safeguards the cleaning operators through lowered access to the area. The combination of these factors shifts the perception of laser rust removal towards a more effective and environmentally conscious option, making it more widespread in numerous fields such as aerospace, automotive, and construction.

Can Laser Cleaners Be Used for Other Cleaning Applications?

Indeed, beyond rust removal applications, laser cleaners can be used for other cleaning functions. These include the removal of paint, grease, oil, and other contaminants from surfaces without harming the surface layer. This flexibility allows them to be used across various industries such as manufacturing, automotive, and heritage restoration.

Usage in Removal of Paint and Coatings

Laser cleaners have shown great capabilities in removing paint and coatings from different surfaces. Through laser ablation processes, these devices release short and powerful bursts of light which vapor and heat the paint or coating layers into fumes without affecting the material beneath. For example, in industrial settings, laser cleaners are able to strip off coatings from metal surfaces so that they can be used afterwards in welding or repainting processes.

As per the available data on the market, laser cleaning technologies are being used in more industries because of their accuracy and effectiveness. A report in 2023 mentioned that the laser cleaning market is set to expand by more than 8.4% each year between 2022 and 2030 because of the need for environmentally friendly and non-abrasive cleaning methods. Furthermore, laser cleaning in the automotive industry minimizes the time to prepare for paint removal by up to 50% compared to conventional methods, which results in substantial savings in costs and time.

This method is also quite popular in restoration of cultural heritage, where lasers can safely remove layers of paint or dirt from vulnerable historical structures and artifacts without inflicting any damage. The increasing versatility of laser cleaning devices demonstrates their importance across numerous fields.

Cleaning Welds Using Laser Technology

The advancement of laser technology brought about breakthroughs in weld cleaning because it is non-destructive, accurate, and environmentally friendly. Cleaning welds with a laser is less complicated than abrasive or chemical cleaning techniques which are labor intensive, hazardous, and time committing. Focused laser beams remove the rust, oxides, and contaminants from the surfaces.

Research conducted recently shows that the efficiency of operations increases with laser weld cleaning. For instance, modern systems can achieve an astounding 15 square meters per hour depending on the strength of the laser, outperforming traditional methods. Additionally, lower maintenance needs and material wear improve the cost-benefit ratio. In terms of market analysis, the laser cleaning market is expected to expand by 4.6 percent from 2023 until 2028 because of the growing industrial applications and environmental policies.

While previously mentioned gains are helpful in cuts in costs by speed up the machinery, laser weld cleaning also contributes toward advanced sustainable practices. The reason being, it’s not using any chemicals or abrasives, it does not generate any harmful byproducts which means it accompanies global attempts in cleaning industrial waste and carbon footprints. This advanced technology is steadily transforming automotive, aerospace and energy industries, thus proving its worth as a great tool for the future of welding and surface treatment.

Dealing with contaminants from metal surfaces

Precision cleaning surfaces of welded components is a process marked with an extraordinary level of attention to detail however traditional methods. Sandblasting and chemical cleaning do get the job done. However, they bring with themselves a range of disadvantages including, environmental impact, increased operational cost and even risking the integrity of the surface itself. That is precisely the time when innovative methods such as laser welding cleaning come into play.

Recent research suggests that laser weld cleaning has significantly bettered when compared to other methods in terms of efficiency, accuracy, and even cost. For instance, some studies claim cleaning with a laser allows operational time to drop by as much as 40 percent and still attain a acceptable standard of cleanliness. In industries such as aerospace and automotive where exactness is a requirement, achieving dremeled surface finish free from oils, rust, oxides, and other contaminants without harming the delicate underlying metal surface material is critical.

Moreover, the modern systems of laser cleaning are exceptionally energy efficient, as many of them consume 50-70% less energy than traditional equipment, which contributes greatly to the reduction of electricity use. These systems are also designed to comply with the rigorous levels of legal requirements, as there is almost no secondary waste produced, unlike chemical methods that need expensive disposal processes. Along with new technology developments, laser cleaning devices are becoming more sophisticated and economical, with compact and portable units available for wider use.

In summary, laser weld cleaning improves operational efficiency, but also shifts the industry towards more environmentally friendly and cost-efficient strategies. Its adoption is on the rise as industries transition to modern manufacturing that incorporates more sustainable resources.

What Are the Potential Challenges and Solutions in Laser Cleaning?

A smaller business may be deterred from obtaining the equipment due to the high initial investment cost of the laser cleaner. This can be solved with the introduction of leasing options or government subsidies for adopting environmentally-friendly technologies.

Governed safety procedures are another obstacle as operators require extensive training to safely and efficiently operate the equipment. This concern is resolvable with comprehensive training programs, increasing the confidence of the users and providing manufacturers with the assurance that their equipment is being utilized safely.

As with any other form of cleaning, laser cleaning cannot be performed on every material or surface. Conducting material compatibility tests prior to implementation helps in determining its feasibility for specific use cases.

Surpassing the Plasma Formation and Ablation Threshold

For effective removal of contaminants without damaging the underlying substrate, laser cleaning technology relies on reaching the ablation threshold of a material. The ablation threshold is the minimum energy density of material that can be removed through laser irradiation, and it my change significantly based on the materials optical properties like reflectivity, absorption and thermal conductivity. Some metals, like aluminum for example, tend to have much lower ablation thresholds compared to harder materials such as titanium due to their differing thermal properties.

Moreover, the formation of plasma is an important event in laser cleaning. If the laser energy surpasses the ablative threshold, the material that is to be removed can be ionized, and a plasma plume can be produced. This plasma further aids in the breakdown of materials, thereby assisting in the cleaning process. On the contrary, these effects must be managed as excess plasma leads to negative surface results and diminishes energy use efficiency. Latest developments published in scholarly works describe the application of femtosecond lasers that generate low heat and plasma and require precise cleaning of sensitive surfaces. For instance, femtosecond pulsed lasers are actively being studied for cleaning frontier microelectronics and heritage artifacts while achieving contaminant removal rates surpassing 95% with minimal damage to the surfaces.

As per the market figures from 2023, the global market for laser cleaning is estimated to expand at a compound annual growth rate (CAGR) of 9 %, suggesting wider acceptance in areas such as automotive, aerospace, and cultural heritage conservation. Its adoption stems from the demand side because of the environmental advantages it provides due to the absence of chemical solvents and overall waste reduction. The installation of some real-time monitoring feedback systems, such as spectroscopy, guarantees better outcomes while ensuring safety and efficiency during the laser cleaning process.

Managing Rough Layer of Rust Variability Within a Substrate

In removing the rust from the specific material using a laser, my focus is on the precise parameter modification of the laser. As it relates to the level of corrosion and the material type, adjustments in pulse scanning, power level and frequency need to be done to achieve cleaning level suitable for the construction material. For removing the a rust layer without changing the shape and form of the substrate it needs cutting with very carefully controlled methods. Tools such as thermal cameras and spectroscopy which help capture change pertaining to rust thickness need to be employed. Since they provide dynamic options, the system can be tailored to set precise results. Maintaining construction material shapes is my skill. This is achieved from careful targeted cutting measures as their structures are protected and the surface shape is preserved.

Responsible Environmentally Friendly Procedures

When cleaning the rust, practice implementing friendliness certainly needs to be observed. This is quite critical especially when engaging in large scale industrial cleaning. If the material is a solid block, free of chemicals in a non-contact way when dealing with laser cleaning, then it may well be one of the safest approaches to supporting the environment. Abrasive solutions affects cleaning and other harmful chemical solvents are done free with laser technology as cited in the former paragraph so the use of traditional rust removing ways highly affects the environment. In other parts of this work it has been noted that there is an expected value of 4.5% from 2023 to 2030 when cleaning the laser market globally increases with the use of environment friendly tools.

Research shows that compared with other methods such as sandblasting or chemical treatment, laser cleaning systems use less water and generate less waste. For example, while sandblasting creates a lot of dust and refuse, laser cleaning leaves no secondary waste because contaminants are vaporized. Actual practices in areas like aerospace and automotive industries have proven that the use of laser cleaning not only reduces the environmental burden, but also improves concern for safety in the workplace due to decreased exposure to toxic substances. Such innovations demonstrate the contributions of new technologies to more environmentally friendly industrial operation.

Reference sources

- Successes and challenges in laser cleaning metal artefacts: A review

- Authors: M. Bertasa, C. Korenberg

- Journal: Journal of Cultural Heritage

- Publication Date: January 1, 2022

- Citation: (Bertasa & Korenberg, 2022)

- Summary: This review discusses the advancements and challenges in laser cleaning techniques for metal artefacts. It highlights the effectiveness of laser cleaning in preserving cultural heritage while addressing issues such as the potential for damage to the artefacts and the need for careful selection of laser parameters.

- Methodology: The authors conducted a comprehensive literature review, analyzing various studies and case reports on laser cleaning applications, focusing on the types of lasers used, their effectiveness, and the challenges faced in practical applications.

- Method to improve the classification accuracy by in situ laser cleaning of painted metal scraps during laser-induced breakdown spectroscopy based sorting

- Authors: Jaepil Lee et al.

- Journal: Plasma Science and Technology

- Publication Date: December 9, 2024

- Citation: (Lee et al., 2024)

- Summary: This study investigates the impact of laser cleaning on the classification accuracy of metal scraps during laser-induced breakdown spectroscopy (LIBS). The findings indicate that pre-cleaning painted metal surfaces significantly enhances the accuracy of LIBS classification.

- Methodology: The researchers employed a nanosecond pulsed laser to ablate paint from metal surfaces and analyzed the resulting LIBS spectra. They proposed a method to determine the optimal number of cleaning shots required for high classification accuracy based on changes in LIBS signal intensity.

- Investigation of airborne nanoparticles emitted during the laser cleaning process of corroded metal surface

- Authors: Hyoungwon Park, Changkyoo Park

- Journal: Environmental Research

- Publication Date: January 1, 2024

- Citation: (Park & Park, 2024, p. 118353)

- Summary: This paper examines the emission of airborne nanoparticles during the laser cleaning of corroded metal surfaces. The study highlights the potential health and environmental risks associated with these emissions.

- Methodology: The authors conducted experiments to measure the concentration and size distribution of nanoparticles generated during the laser cleaning process, using various laser parameters to assess their impact on emission levels.

Frequently Asked Questions (FAQs)

Q: What components make up a laser rust remover, and how does its removal process function?

A: Components in a laser rust cleaner include a control console unit, an LCD monitor, a power supply unit, and a laser generator. It works by reducing the beam of a selected wavelength laser pointer into a cone-shaped beam using lenses positioned at specific angles. This removes rust without inferring damage.

Q: Is it feasible to clear paint off surfaces using a laser paint stripping tool?

A: Yes, a laser paint removal tool or equipment effectively strips paint using focused laser radiation emiting low-level infrared lasers. The underlying material is protected from any form of damage ensuring faster performance without scratches.

Q: What are the benefits of fiber laser cleaning and how does it differ from traditional techniques?

A: Effectiveness is enhances with lasers due to further power concentration. Lasers registered at mutligigawatt power output could remove allorether like and unite completely different lasers. The process does not inflict mechanical damage allowing precise removal of rust.

Q: Would using a laser cleaning machine for rust removal affect the metal negatively?

A: No, as long as it is operated correctly, a laser cleaning machine does not affect the metal negatively. The laser can effectively remove rust and additional contaminants while preserving the underlying metal.

Q: What power levels are available for laser rust removers?

A: Different forms of laser rust removers exist at different power levels including, 200w and 1500w geared towards different cleaning requirements and surfaces. More powerful settings are usually reserved for more extensive removal of rust and paint.

Q: Are laser rust removal machines suitable for carbon steel surfaces?

A: Yes, laser rust removal machines can be used to clean carbon steel and other metallic surfaces. They have a high efficacy rate when it comes to rust and oxide layer removal while preserving the material beneath it.

Q: What is the advantage of using laser cleaning over plasma cutters for rust removal?

A: Laser cleaning has many advantages over plasma cutters like, cleaner cuts, possibility of cleaning a specific area, and the possibility of cleaning without any contact, ideal for detailed and sensitive work.

Q: How effective is laser cleaning for surface preparation in industrial applications?

A: Laser cleaning is extremely effective for surface preparation in industrial applications. It provides a clean surface devoid of any contamination which is critical for processes like welding, painting, or coating.

Q: Is it possible to use laser cleaning machines on small items?

A: Absolutely, laser cleaning machines are usable on small items. The precision with which they can be controlled makes them suitable for intricate work such as detailed components.

Q: What types of contaminants can be removed from the surface using a laser?

A: A wide range of contaminants can be removed from the surface using a laser. These include rust, paint, dirt, rolled oxide layers, and prepared metal surface, ensuring it is ready for further processing or utilization.

- Bismuth: Unveiling the Melting Point Mystery of This Unique Metal

- The Ultimate Guide to the Portable Handheld Laser Marking Machine

- UV Laser Marking Machine: Precision Laser Marking

- What is the Cost of a Laser Welding Machine Price Details of Small Laser Welders

- Unlocking the Power: How Does Laser Cleaning Technology Function?

- Fiber Laser vs CNC Machine: Understanding the Cutting Edge of Technology

- Understanding Speed in Laser Marking: How to Optimize Your Laser Marking Machine

- Top 10 Countries for Best CNC Machining Services: Global CNC Machine Industry Guide