The invention of glass laser engraving machines has changed the ability to engrave and personalize glass surfaces intricately. For professionals, small business owners, or do-it-yourselfers, acquiring the best glass engraving laser machine greatly improves the overall quality of their work, making it simple. The following article reviews sandblasting engraving machines, showing the best features, performance, dependability, and market reviews. This objective specifically looks at how these devices are designed and how their operations can be simplified in advanced ways. These devices marked increased precision for the users with ease of operation, designed to improve productivity and performance by pre-programmed computer settings. Brace yourself for the guide on these devices and put your imagination to the test.

What is a Laser Marking Machine for Glass?

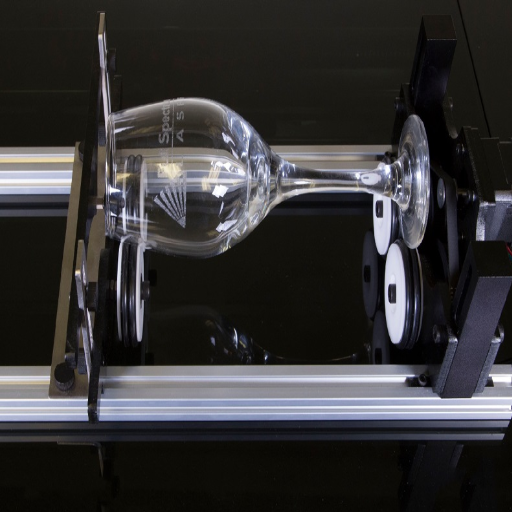

A laser marking machine for glass is a focused laser beam etching device that engraving or marking text, images, or designs on glass surfaces. The devices that focus laser beams on device glass employ high technology for the structural integrity of the glass, which allows easy and permanent etchings, engravings, or markings of excellent quality. Customization of glassware, decorative designs, logos, and serial numbers used for identification purposes is a carefully thought-out application of these devices. These devices are prolific thanks to their high accuracy, precise results, repeatability, and capability to work on fragile surfaces.

How Does a Laser Marking Machine Work?

Technologies such as laser marking machines deploy concentrated laser beams to generate specific patterns or marks on surfaces, including glass. The technology queues a laser beam from a laser source, which is finely focused using mirrors or lenses. The resulting beam is then used to interact with an object’s surface through various techniques, whereby its attributes are either engraved, discolored, or material removed, depending on lasers and other factors used.

Some approaches used could be engraving, implant annealing, carbon migration marking, and etching. While etching and engraving were traditionally employed for marking glass due to their clarity and durability, modern glass markers have fiber, CO2, and UV lasers integrated into them, allowing for broader application. UV laser technology stands out as the most reliable for glass etching due to its better detail precision, which results from shorter wavelengths, reduced heat exposure, and a lower level of cracks created for sensitive materials.

Recent research suggests that the effectiveness of laser marking technology has remarkably advanced in its speed and efficiency. Currently, laser marking machines can perform at a rate greater than 5,000 millimeters per second, and with a precision of up to 10 microns. Moreover, the devices’ laser lifespans have also improved. Many quality systems now provide up to 100,000 working hours.

Moreover, software has improved the functionalities of laser marking machines. Marking software allows operators to design complex patterns with logos and other changeable information, such as barcodes and QR codes. Specific systems even offer workflow optimization and AI features to reduce human error. The synergy of these factors makes laser marking indispensable in high-speed, precision, and adaptable modern technology manufacturing, medical devices, and consumer products industries.

Benefits of Using a Laser Marking Machine for Glass

- High Precision and Accuracy

Marking lasers create pinpoint accuracy and precision in engravings on glass because of detailed design features that do not harm the surface of the glass. Such accuracy is requisite when engraving logos, text, or intricate designs in luxury items or architecture.

- Permanent Markings

The durability and resistance to abrasions, fading, and chemicals of these markings make them suitable for harsh environments, such as industrial glass or medical devices, where marking longevity is critical.

- Non-Contact Process

Since the marking process is non-contact, the glass surface remains unscratched and uncracked during engraving. This attribute lessens the general upkeep that the machinery requires and increases production efficiency.

- Environmentally Friendly

The marking process is clean, with no harmful substances used or waste produced. This quality addresses the demand for eco-friendly manufacturing methods.

- High-Speed Processing

These modern CNC machines have a high work speed, resulting in less time spent on marking and improving the workflow. Such speed is invaluable in mass production, where time and accuracy are equally important.

Typical Applications of Laser Marking on Glass

- Identification and Traceability

Laser technology is widely used to mark glass products, inscribe serial numbers, QR codes, and barcodes, and enable accurate identification and traceability. This is very important in the electronics and automotive industries to ensure authenticity and monitoring throughout the supply chain.

- Decorative Engravings

With drinkware, mirrors, and awards, laser marking allows intricate decorative designs engraved on glassware. The precision offered by laser technology guarantees etching of clean and elegant patterns, which makes it popular for branding and in the gift industry for personalization.

- Medical Equipment Labeling

Safety and regulations often mandate clear and permanent markings on medical tools and devices. Glass laser marking offers durable, high-contrast markings that can withstand stringent sterilization procedures, making it ideal for syringes, vials, and other glass medical containers.

- Architectural Glass Customization

The interior and architectural design industries apply laser marking for glass panel customization to inscribe logos, text, or patterns. This application beautifies the glass used for building, partitions, and decorative installations and improves overall aesthetics.

- Electronic Component Marking

Electronic glass parts, like displays and screens, are engraved using laser technology. The marks made are accurate and can endure environmental, heat, and harsh conditions over long periods, ensuring the components’ operability, durability, and longevity.

What to Consider When Choosing a Glass Laser Engraving Machine?

To cope with laser engraving glass, it is essential to include the following tips:

Select a machine that does clean and precise engravings without damaging the glass surface. The glass laser engraving machine chosen should have the power to avoid overheating, yet engrave glass efficiently while maintaining control. It helps to have a user-friendly machine, as engraving software that meets all design requirements and file formats can be uploaded easily.

Finding a machine with solid construction that provides minimal maintenance and is reliable for long-term performance should be prioritized. Ensure the dimensions of intended projects are met by the size of the engraving area and the machine itself.

Make sure your set budget preserves warranty options and customer support for troubleshooting. Ensuring those two ends do not seal the budget helps tailor the machine to all set engraved needs.

A supporting warranty ensures your budget, as estimating troubleshooting in advance enables selecting an engraving machine tailored to your decision bed. Focusing on the client’s engraved project will undoubtedly meet all set laser needs.

Key Features of the Best Glass Laser Engraving Machines

- High Precision and Accuracy

The best glass laser engraving machines provide astonishing precision, allowing for very intricate details and etchings. They usually come fitted with high-powered macros with spot sizes as tiny as 0.025cm(0.01 inches) in diameter for fine engraving work.

- Adjustable Power Settings

Machines with adjustable power settings are essential for controlling the intensity of the laser beam to work with different glass thicknesses and levels of engraving depth. This is easier with machines with a power range of 20W to 150W, which helps etching and deep engraving.

- Durability Build Quality

The best laser engraving machines are made from top-quality aluminum or steel frames because these guarantee engravers everlasting, dependable, precision, whisper-quiet machines. Minimizing vibrations while ensuring consistency in the glass engraving increases the quality of the work done.

- Efficient Cooling Systems

A good precision laser engraving machine has advanced precision cooling capabilities. The CAD cam machine must be equipped with water or air cooling systems that prevent overheating during extended periods of usage. High-quality machines always ensure out-of-this-world efficiency.

CO2 Laser vs. Fiber Laser for Glass Engraving

| Parameter | CO2 Laser | Fiber Laser |

|---|---|---|

|

Wavelength |

10,600 nm (long wavelength) |

1,060 nm (short wavelength) |

|

Precision |

Moderate, suitable for intricate designs |

Low, prone to uneven results |

|

Engraving Speed |

Fast on non-metal materials |

Higher speed, risk of glass damage |

|

Cost |

Lower operational and purchase costs |

Higher initial investment |

|

Suitability for Glass |

Ideal for delicate and thin glass |

Unsuitable, risks cracking or burning |

Budget Considerations for Laser Engravers

When choosing a laser engraver, a budget always comes to mind, as it determines the initial payment and the cost of engraving in the future. From as low as $200 for entry-level machines to over $ 20,000 for industrial systems, laser engravers come with various price ranges. CO2 laser engravers could be a reasonable consideration for beginners and small business owners as they are one of the most affordable mid-range devices, priced at $1,500. These machines can efficiently and accurately work on wood, glass, and acrylic, but not on metals. Conversely, those who engrave metals often have exceptional precision, known as Fiber Laser Engravers. However, with better quality comes better prices starting at $10,000 and going higher depending on customization.

Problems are not only solved by purchasing a new machine, but also require maintenance and ongoing investments. CO2 lasers have additional expenses that need to be considered for operation. These devices tend to have a laser tube that requires periodic replacement, ranging between $200 and $1000 per tube. Despite being expensive, fiber lasers require less long-term investment with lasting diodes and minimal need for part replacements. Other factors like the total system cost of cooling, electricity consumption, and software renewals also require fine attention for better long-term outcomes.

Picking the right machine for engraving comes down to evaluating your requirements. If engraving is a side project or involves non-metal materials, a moderately priced CO2 engraver is more than adequate. On the other hand, businesses that deal with metal engraving or require fast, precise work should consider the long-term cost-effectiveness of a fiber laser. Brand comparisons, warranties, and customer reviews might lean one way or the other, but they help assess costs for the machine’s lifespan.

How to Use a Laser Engraver on Glass?

Using a laser engraver for glass crafting requires a systematic approach and tactical precautions regarding the tools involved to yield the finest outcome.

Select the Suitable Adjustments: Change the wrench settings on the engraver’s motor to produce sufficient power. Use a low power output slightly above idle and a moderate shaft rotation speed to enhance the outcome without cracking or uneven engraving.

Prepare the Surface: Guarantee thorough cleaning of the glass to remove dust and fingerprints, as both can significantly affect the engraver’s outcome.

(Optional) Use Masking Materials: Applying tape or a thin layer of liquid soap reduces the possibility of chipping, thus enhancing the engraving marks produced.

Securing the Glass: While using the engraver, it is essential to ensure that the glass is in a fixed position, guaranteeing that it does not move during the cutting process.

Put on the test: Make a demonstration marking on the glass using a mock piece to enhance the fine-tuning of the settings that come with it.

Engraving: Gage watchfully controls dust and debris to ensure clean results.

Scrubbing off residues: Gripping a damp cloth will allow you to wipe excess markings, enhancing a polished gleam after engraving marks have been put on the glass.

Ensure you follow every manufacturer’s guidelines regarding the laser engraver in focus, guiding safety directions with glass materials.

Preparing Glass Products for Engraving

Etched glass products require detailed professional preparation to ensure optimal clarity and are finely engraved. They require specific procedures to be both properly prepared and precisely engraved. Below is adjusted information about the steps taken before one begins the engraving process:

- Choosing Glass

Not all varieties are equally suited for engraving. Unlike tempered glass, annealed glass is less affected by thermal stress, making it ideal for laser engraving. Research suggests that annealed glass also endures 38% more thermal stress than the alternatives.

- Cleaning Glass Surfaces

Before engraving, the glass should be scrubbed meticulously to ensure no remnants of dust, oil, or fingerprints remain. Residues strongly affect engraving precision and are best removed with isopropyl alcohol mixed with water in a 70/30 ratio. Studies indicate a laser’s accuracy can be severely undermined by microscopic debris, reducing the overall quality of the engraving by approximately 25%.

- Surface Masking

Applying special laser masking materials not only shields the unwanted parts of the glass surface from harsh laser engraving but also minimizes chipping. Professional engravers recommend using high-temperature masking tape, as it is more resistant to heat. This quality guarantees a much tidier outcome.

- Finding The Right Settings: An Overview

It is a good idea to first test the speed, power, and frequency settings on a piece of scrap glass similar to your final product. For instance, the power settings for glass engraving are usually below 20%, and the speed settings are generally above 300 mm/s to avoid cracking the glass and ensure finer detail. Check your laser engraver’s user manual for the suggested settings provided by the manufacturer.

- Add Masking Material (Optional)

Coating the glass surface with a thin layer of dish soap or special engraving gel can effectively dissipate heat generated during the process, reducing the risk of overheating and surface damage. Industry experts believe this augments the surface roughness while ensuring the contours created on the surface of the material are more harmonious.

- Avoid the Buildup Of Heating

The single most important factor when working on glass is preventing overheating, which is one of the leading reasons for glass breakage. For this reason, proper cooling techniques, such as short burst engraving or the use of a cooling apparatus, are recommended. Other engravers place a moist sponge next to the engraving area, which absorbs most of the heat.

Following the steps outlined allows the glass to be adequately prepared for engraving, guaranteeing intricate, high-quality designs with minimal damage. As with any industry, keeping track of the latest tools and techniques is vital to improving the engraving process.

Step-by-Step Guide to Engraving Glass

- Step 1: Choose the Right Tools

Etching glass can be done with some basic tools. Depending on the engraving is complexity, a rotary tool or a laser engraver can be used. For engraving, rotary tools such as Dremel can be used with diamond burrs which are great for detailed work. Laser engravers would be perfect if engravings are complicated, because they do intricate designs. Check to see if the tools are in working condition to ensure they will work with the glass you are using.

- Step 2: Prepare the Glass Surface

To prepare the glass surface, you must clean it thoroughly with soap, water, and a glass cleaner to ensure no dirt, oil, or fingerprints are left behind that can interfere with the engraving. After drying, consider applying masking tape or a stencil to the area to be engraved. This way, accuracy will be ensured while also preventing unintentional etching.

- Step 3: Follow Guidelines for Accuracy

Implement techniques appropriate for your project to put the design on the glass. To aid in engraving, paper stencils, transfer films, or even pencil outlines can serve as instructions. Digital designs meant for laser engraving can be uploaded directly into the software’s drive.

- Step 4: Controlled Pressure

When using a rotary tool for manual engraving, gentle and even pressure is key to avoid cracking the glass. For example, thin engraving layers are better than trying to accomplish deep cuts in one motion. The tool can be angled slightly for better control when steady movement is required for an even finish.

- Step 5: Patented Refining With Cooling Methods

Power tools heat glass during engraving, which puts pressure on the material. To alleviate this, employing short bursts of work with cooldowns between allows the material to cool and reduces stress on the glass. Other pioneering techniques involve applying a specialized cooling spray or a wet sponge to lower the temperature and salt the glass, weakening the stress applied.

- Step 6: What to Remember for Safety

Remember to observe safety precautions for glass engraving, as they are critical. Always put on protective glasses to guard your eyes from pieces of glass and dust. Moreover, wearing a dust mask is crucial to avoid breathing in fine glass dust, as it can pose a serious health threat. Make sure that you work in a place with good ventilation or have a vacuum system designed to clean the air to reduce floating materials.

- Step 7: Precise Steps Polishan

Once the engraving is completed, check over the work done to see if any changes must be made or details added. Ensure the glass is correctly cleaned by getting rid of the remaining dirt particles. Make sure you polish the etched part with a soft cloth for a better final touch, as it leaves a shiny, professional look.

- Pro-Tip: Latest Technologies

Striking advancements have been made to laser engraving technologies regarding detail precision and resolution. An example is CO2 laser engravers, which can engrave at over 600 inches per minute, depending on the device, while achieving depths of up to 0.5 mm. The precision, combined with updated design software, enhances project flexibility, especially for custom designs.

Using the strategies above, you can reduce the chances of damaging the surface while achieving precise and deep engravings on glass. Remember to stay sharp with new tools and innovations to perfect your skills.

Tips for Achieving High-Quality Glass Engraving

- Pick the Right Tool for the Job

The glasswork industry requires a particular laser engraving machine or rotary tool specifically developed for glass. Always ensure a device has the correct settings to work with delicate materials like glass. A good example would be CO2 laser engravers, which contain power settings.

- Use Low Power and High Speed Settings

Setting the laser engraver to low power but maintaining a high speed will reduce the chances of overheating and cracking the glass. A CO2 laser set to 10-15% power and 80-100% speed will ensure precise and clean detail without damaging the work.

- Maintain Adequate Ventilation While Engraving

Ensure your working space is cleared of any possible clutter hindering airflow. It’s essential to mitigate any dust and small glass shard particles that could arise from your work. To clear any debris from the area where you work, an exhaust setup or air assist system on your engraving machine will work well to improve engraving quality.

- Cover the Masking Material

Masking tape helps protect areas that should not be engraved. When applying thin layers of protective coatings, apply them to the glass being worked with to avoid scratches. Such techniques are beneficial for intricate patterns and sharp-edged designs.

- Test On Scrap Glass First

Before finalizing your design, perform precision engraving tests on surplus glass. If there is any discrepancy, calibrate the power, speed, or design elements accordingly. This practice enhances accuracy, sustains consistency, and significantly diminishes material waste.

What are the Best Glass Laser Engraving Machines Available?

- Glowforge Plus

Best-suited for hobbyists and professionals alike, the versatile and user-friendly Glowforge Plus engraving machine works on a multitude of materials, including glass. It is a preferred Glowforge model due to its quality and precision engravings.

- OMTech 50W CO2 Laser Engraver

Because of its power and reliability, the OMTech 50W CO2 Laser Engraver is perfectly suited for detailed glass engraving. It guarantees exceptional results by providing precise control over every engraving parameter.

- Flux Beamo

The best option for smaller-scale engraving projects comes from a compact device named Flux Beamo. With its step by step process and simplified software dashboard, this device is great not just for experts, but even beginners working with glass.

- Epilog Zing 24

Favoured for its precision and durable features, this high-performance machine is best suited for professionals who want unrivaled quality and speed in glass engraving, making Zing 24 their solid choice.

- Ten-High 40W Laser Cutting and Engraving Machine

Perfect for entry-level users and small-scale businesses, the affordable and effective Ten High 40W machine provides engravings on glass and other materials, ensuring consistent results.

When choosing a machine, consider these options as they fulfill the requirements of different specifications, projects, and budgets.

Top Recommendations for CO2 Laser Engravers

- OMTech 55W CO2 Laser Engraving Machine

The OMTech 55W is a mid-level laser engraver that is precise and versatile when it comes to use. It’s 20″x12″ work region makes it useful in many applications. It has a Ruida digital control system, which makes it easy to operate, and it can process glass, wood, acrylic, and leather. The machine can produce vector and raster engraving, yielding exceptional detail and accuracy. Priced between $1700 and $ 2000 as of October 2023, this laser engraver is ideal for small businesses and DIY lovers straddling the intersection of serious performance and affordability.

- Glowforge Plus

The Glowforge Plus a flexible tool for both advanced and beginner users thanks to its cutting edge design and ease of use. It has a 40W laser tube, a 20″x18″ bed for rapid and precise cuts, and accurate engraving. Data for the Glowforge Plus is stored in the cloud, enabling users to set up and execute projects wirelessly from their computers or smartphones. It stands out in engraving intricate patterns on glass, metals, and acrylics. For those looking to simplify their operations and use the latest technologies, the device is available at an unmatched $4000.

- Boss Laser LS-1416

The Boss Laser LS-1416 is a fully equipped CO2 laser engraver with a compact design. It is integrated with advanced CorelDRAW and Adobe Illustrator Plug-ins, allowing seamless software operation. Its construction guarantees inline laser glass and industrial-grade application endurance. At $3,000, it is an excellent purchase for professionals aiming for laser precision in cutting and engraving dense materials.

- TRIUMPH 80W CO2 Laser Engraver

Starting from a competitively low price of $2,500, the TRIUMPH 80W laser engraver stands out for its industrial-grade performance. Higher-grade materials like wood and rubber are also easily incorporated, greatly expanding the range of applications. Their 800mm x 500mm cutting area also ensures space for bulk glass engraving. Detailed designs are no challenge for users due to the high-speed stepper motors and advanced engineering software optimised for precision.

Each machine balances functionality, price, and ease of use, catering to various applications. Knowing your projected outcome, available funds, and the materials you plan to work with will enable you to shop within the appropriate range of CO2 laser engravers. For a more in-depth analysis, it is highly advisable to check trustworthy retailer sites.

Comparative Analysis of Popular Laser Machines

| Parameter | CO2 Laser | Fiber Laser | UV Laser |

|---|---|---|---|

|

Wavelength |

10,600 nm (long wavelength) |

1,060 nm (short wavelength) |

355 nm (short, high-energy wavelength) |

|

Precision |

Moderate, crisp on non-metals |

High for metals, poor on glass |

Extreme precision, minimal heat damage |

|

Engraving Speed |

Moderate, best on organic materials |

Fast, excels at metals |

High, ideal for intricate designs |

|

Cost |

Lower cost, affordable operation |

High initial, lower maintenance |

High cost, specialized equipment |

|

Material Compatibility |

Non-metals, glass, wood, acrylic |

Metals, some plastics, coated glass |

Plastics, silicon, sensitive materials |

|

Typical Applications |

Packaging, signage, and glass engraving |

Metal marking, serial codes |

Fine-detail medical devices, electronics |

Reference Sources

- “Laser-induced micro-scale polychrome marking of glass materials” (“Laser-Induced Micro-Scale Polychrome Marking of Glass Materials,” 2023)

- Publication Date: 2023

- Key Findings: This paper uses laser technology to investigate the creation of multi-colored micro-scale markings on glass. The abstract does not detail specific findings regarding the achieved colors, resolutions, and the relationship between laser parameters and marking quality.

- Methodology: The abstract does not detail the specific laser parameters or methods for achieving polychrome marking. The full text would provide further information.

- “Improving Etched Flatness by Micro Airflow Array Pressurization in ITO Glass Laser Machining” (Chen et al., 2023)

- Publication Date: 2023

- Key Findings: This study focuses on improving the flatness of etched ITO glass during laser machining by using a micro-airflow array pressurization system. The goal is to prevent warpage and ensure high-precision etching of micron-scale circuits. The study finds that controlled airflow pressure can compensate for initial workpiece flatness variations within a critical pressurization parameter range.

- Methodology: The methodology involves modeling micro-airflow and pressurized micro-deformation, investigating surface flatness concerning airflow parameters, and calculating critical pressurization parameters using a data-twin approach. These parameters were then applied to industrial ITO glass etching.

- Top Laser Marking Machine Manufacturer And Supplier In China

Frequently Asked Questions (FAQs)

Q: What is a laser marking machine for glass?

A: A laser marking machine for glass is a specialized device that uses laser technology to etch or engrave designs, text, or images onto glass surfaces. This process is known as laser etching glass.

Q: How does a laser cutter work for glass?

A: A laser cutter works by focusing a high-intensity laser beam onto the glass surface. Depending on the power and settings of the laser, the beam either cuts through or engraves the material. This precision allows for intricate designs and clean edges.

Q: What is the best laser engraver for glass?

A: The best laser engraver for glass typically combines high power, precision, and speed. Models such as the desktop CO2 laser engraver are popular for glass etching due to their ability to handle detailed designs and various glass types.

Q: Can I use a diode laser for glass engraving?

A: While diode lasers can be used for engraving glass, they are generally less effective than CO2 lasers. CO2 lasers are preferred for glass etching as they provide better results and can engrave deeper into the material.

Q: What are the advantages of using a laser engraving machine for wood and metal?

A: Laser engraving machines for wood and metal offer high precision, speed, and versatility. They can create intricate designs and patterns on various materials, including wood, metal, and glass, making them ideal for customization projects.

Q: What types of glass can be etched using a laser engraver machine?

A: A laser engraver machine can etch various glass types, including wine glasses, bottles, and decorative glassware. The ideal choice will depend on the machine’s power and the thickness of the glass.

Q: What settings should I use for laser etching glass?

A: The settings for laser etching glass will depend on the type of laser engraver used and the thickness of the glass. Generally, lower speeds and higher power settings are recommended for deep etching, while faster speeds with lower power can achieve lighter designs.

Q: How does a cutting and engraving machine differ from a standard laser engraver?

A: A cutting and engraving machine combines both functions, allowing users to cut through materials and engrave designs in one device. This versatility makes it suitable for various projects, including those involving glass, wood, and metal.

Q: Is using a laser engraving machine for glass at home safe?

A: Yes, using a laser engraving machine for glass at home is safe, provided you follow safety guidelines. Ensure proper ventilation, use safety goggles, and keep a fire extinguisher nearby to mitigate any risks involved in the engraving process.