Engraving on metals using lasers offers many advanced advantages, such as efficiency, accuracy, and quality. The following guide to laser marking stainless steel aims to provide you with all the essential information, such as the reason behind choosing stainless steel, the process of laser marking, different types of machines, and their benefits. After reading the entire guide, we hope you achieve the intended results for whatever project you decide to undertake.

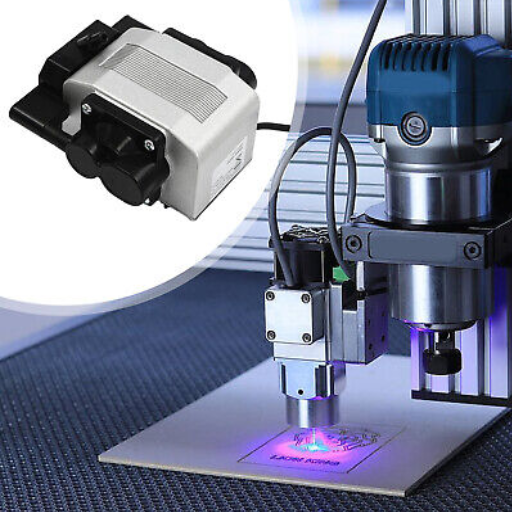

What is a Laser Marking Machine for Stainless Steel?

Stainless steel is one of the most popular materials used for engraving due to its incredible durability, precision, and aesthetic appeal. Product branding, intricate design creation, or industrial component marking can all be done using laser marking machines, which have changed the surface engraving technique done on this metal over time. Whether you are a beginner looking to accelerate your learning or a seasoned professional wishing to improve your techniques, this laser marking ultimate guide surely has something helpful for everyone.

How does a laser marking machine work?

A laser marking machine produces a highly intense laser beam that interacts with the material’s surface to be marked. It all starts with a fiber, CO2, or UV laser source, which forms a laser beam and concentrates it to create a light tube. This beam is sent through mirrors or a series of mellotron scanners, aiming the laser at the area where marking needs to be done.

The interaction of the laser beam with the surface of the stainless steel results in energy loss and heat, which etches, engraves, or discolors the material depending on the set parameters. Taking annealing as an example (often done with stainless steel), the laser works by heating the material to form oxidation, which results in markings that will endure and are distinctly non-removable. Other methods alter the portion of a material to be marked, such as manipulating the pigment on the outermost layer of the material instead of the surface, called discoloration.

Like any modern equipment, laser marking machines are integrated with cutting-edge technologies that permit the user to modify the laser’s depth, breadth, strength, and even exposure to fulfill particular requirements of the project they are working on. According to the latest research, fiber lasers are more efficient than CO2 lasers by about twenty to thirty percent in energy consumption, while boasting ten times the latter’s lifespan, making them the go-to option for industrial use. Laser marking offers unparalleled efficiency, achieving speeds of 7,000 mm/s while retaining remarkable accuracy of 0.001 inches.

This technology is of great value in fields like medical devices, automotive, aerospace, and electronics, where precision and longevity are highly critical. Maintenance is fairly simple, and the capability to be styled is overwhelming; thus, laser marking machines are changing the standards of producing high-quality, enduring marks.

What are the benefits of using a laser engraver for stainless steel?

- Exceptional Sharpness and Exactness

Laser engravers can create intricate designs and markings with an accuracy margin of up to 0.001 inches. This level of detail is crucial to the precision-reliant medical devices and electronics sectors.

- Long-lasting Lasered Etching

Laser engravers mark surfaces that are resistant to corrosion and wear from heat, moisture, and other environmental influences. Even under such extreme conditions, the markings will remain legible over time.

- Does Not Contact Workpiece

Since laser engraving does not entail any physical interaction with the surface of the stainless steel workpiece, it is done without inducing any force whatsoever. This greatly reduces the chances of material damage, deformation, or loss of workpiece integrity.

- Reduces Production Time

While maintaining quality outcomes, laser engravers operate at high speeds, which makes them ideal for use in high-volume production lines. Engravers significantly reduce production time while maintaining a consistent output.

- Lower Operational Costs

Since laser engraving does not require consumables such as inks or chemicals, it is a clean and environmentally friendly process. Little maintenance is needed, and the consumable-free process results in lower operational costs over time.

What types of laser technology are used for marking stainless steel?

When it comes to marking stainless steel, many types of laser technologies are available that can be used depending on the necessity. Some of the most efficient technologies include:

- Fiber Marking Lasers

As a result of its efficacy and accuracy, fiber lasers have become one of the favorites for marking stainless steel. This is due to its operations involving a laser beam being amplified through an optical fiber. For Fiber Marking Lasers, the engraving of serial numbers, barcodes, logos, and other pertinent marks that do require deep, permanent impressions is within its capabilities. It has proven and accepted for its long life span of about 100,000 hours of operation and low maintenance cost. Fiber marking can be achieved since its wavelength, on average 1064 nm, is perfect for metal marking, engraving, and etching.

- C02 Laser and Etching

C02 lasers are better used for non-metal materials; however, with the right coated materials, they can perform marking and etching of stainless steel. Employing a C02 mix gas, primarily C02, these gas lasers mark metal regions pre-treated for etching and marking surfaces. The C02 engraving does not have as broad use in steel etching, making it not the most common, C02 Mark lasers perform well with previously treated surfaces for etch and treat marking.

- MOPA Lasers

MOPA (Master Oscillator Power Amplifier) lasers are suitable for specialized applications like color and contrast marking on stainless steel, thanks to their ability to finely control pulse duration and frequency. MOPA lasers can create black annealing marks or even colored markings on stainless steel while preserving the material’s surface integrity. This level of precision is especially valuable in industries like jewelry, medical tools, and electronics.

What are the Best Laser Machines for Engraving Stainless Steel?

The most appropriate laser machines for engraving on stainless steel are fiber lasers and MOPA (Master Oscillator Power Amplifier) lasers. Fiber lasers are powerful, reliable, durable, and efficient due to their ease of use and accuracy. MOPA lasers are flexible with the pulse duration and frequency, which allows for high-contrast marking, coloring, and graceful marks without harming the material. Either type of laser is preferred due to its performance and accuracy in industrial and commercial settings.

What features should I look for in a laser engraving machine?

Performance is one of the most critical factors you can focus on when choosing a laser engraving machine. Different models can handle varying workloads, so thinking through your requirements is essential. In that regard, below are the top five features you must pay attention to:

- Laser Power

As with each laser device, the power affects the system’s optimal application. 20–30 watts will resonate engraving wood and leather. Higher power (50 watts) will surely do the trick for metals and acrylic. The power level affects efficiency and quality, so adapting it carefully is crucial.

- Assigned Area

The assigned area is the entire surface eligible for engraving or cutting. If the goal is to create small designs or perform small projects, a work area measuring 8×12 inches would suffice. Bigger projects would require working space measuring 20×30 inches or larger.

- Resolution And Precision

Higher DPI values lead to better results. However, there is a misconception that all machines with a higher DPI value lead to better engraving. A machine with 1000 DPI value would surely do better than small competitors, but higher-grade components are also necessary to sustain competitive, clean, and precise results.

- Material Compatibility

A good laser engraving machine should be able to work with wood, metal, glass, plastic, and even leather. Machines with multiple materials enable creativity and are suitable for different industries.

- Ease of Use and Software Integration

An ideal machine should offer user-friendly features such as simple control options and compatibility with CorelDRAW and Adobe Illustrator. Full automation will also help improve the engraving process, which is monitored in real time.

How do fiber laser machines compare to CO2 laser engravers?

- Introduction

CO2 laser engravers and Fiber laser machines have pros and cons, making them ideal for specific industries and materials. Below is their key comparison:

- Material Compatibility

Fiber lasers do better on the engraving and marking metals like stainless steel, aluminum, brass, etc. They are instrumental in producing high-precision engravings for industrial and jewelry applications. In contrast, CO2 laser engravers derive value from non-metallic materials like glass, leather, textiles, acrylic, and wood. CO2 lasers, for example, are extensively used in arts, crafts, and signage where softer organic materials dominate.

- Cost of Operation

The data surrounding laser technology is limited, but available information suggests that fiber lasers are more energy-efficient than CO2 lasers. In high-volume production scenarios, fiber lasers save operational costs over time because they consume up to 50% less power. In addition, fiber lasers are generally more efficient because they require less maintenance and lack mirrors and lenses that rely on frequent replacement in CO2 systems.

- Speed and Precision

With metal engraving and marking, fiber laser machines are significantly faster—20% in some instances—than CO2 machines. The amount of precision achieved is excellent due to finer focus spot sizes, making them perfect for intricate detail work. Cuts through wider and softer materials for CO2 lasers, while slower, are of superb quality with smoother edges and lower charring.

- Lifespan and Durability

With an operational lifespan of roughly 100,000 hours, fiber lasers have a large expected lifespan compared to CO2 laser tubes’ 20,000 to 30,000 hours. This helps provide greater value for sustained use as it significantly reduces downtime. Additionally, due to solid-state design touches, fiber lasers are more durable in industrial settings, showing less susceptibility to alignment problems and wear and tear over time.

- Initial Costs

Engravers that utilize CO2 lasers tend to be more cost-effective for small businesses or hobbyists working with non-metal materials. Fiber laser machines’ specialized beam focus makes them perfect for intricate detail work, creating greater provided value despite the higher upfront cost compared to CO2 engravers.

- Safety Precautions and Environmental Impact

Due to their high energy efficiency and low upkeep, fiber lasers are more environmentally friendly than CO2 lasers. Moreover, they produce less excess heat and are more adaptable to clean, precision work. When cutting certain materials like acrylic and plastics, CO2 lasers may emit fumes that must be adequately ventilated.

Which brands are considered the best for stainless steel laser engraving?

Different brands capture attention with stainless steel laser engraving due to their quality, precision, and reliability. Here are some well-known brands that tend to like:

- Trotec Laser

With the impressive power of laser systems, Trotec is known all around the globe. Their machines such as Speedy and ProMarker series are optimized for enduring sharp cuts. Trotec devices are also equipped with advanced suites like JobControl that do stainless steel engraving with utter precision. Trotec captivates clients with exceptional customer support and training that aid professionals, which is crucial in engravings that require results above par.

- Epilog Laser

Epilog is a reputable name when dealing with laser equipment. They offer everything from the class Fusion Edge to the Fusion Pro series, which specializes in engraving stainless steel. Their machinery not only comes with advanced motion control systems but also innovative cooling systems for extended periods of usage. On top of these amazing features provided by Epilog, their easy-to-learn results bring peace of mind to the user to achieve repeatable results.

- Glowforge

Users at the hobbyist and small business levels will get the most out of Glowforge. They provide some of the most versatile laser engraving machines. Although commonly recognized for works of nonmetallic materials, Glowforge Pro can handle custom marking agents specific to stainless steel. It is best suited for first-timers who demand a cost-friendly brand without trading off on quality.

- OMTech Laser

OMTech, a leading laser cutting technology company, has specialized in building economical and dependable laser cutters. Their fiber laser series for marking metals, such as stainless steel, is popular among lower-end businesses. OMTech is often a go-to company for many small businesses because of its efficiency and cost-effective solutions.

- Raycus

Specializing in manufacturing outstanding fiber laser sources, Raycus is one of the most popular brands for engraving stainless steel. Their machines are well known for being fast, precise, and energy-efficient. Due to their high durability, Raycus products are mostly chosen by industries with heavy-duty engraving workloads.

- Orion Motor Tech

Orion Motor Tech’s goal is to maintain high-performance standards while focusing on low-cost features. Their fiber laser systems perform exceptionally well when engraving stainless steel, especially for small companies and DIYers alike. Their machines are user-friendly and well supported in terms of after-sales service.

How to Choose the Right Engraving Machine for Metal?

Think about the following factors when looking for a machine that engraves metals:

- Material Compatibility – Check whether the machine marks metals; if it does, check its fiber laser engravers for stainless steel, aluminum, and other metals.

- Precision and Speed—Ensure that the machine does not compromise on accuracy versus the project’s need for speed, since automated engraving is required for larger projects.

- Budget—Define the target range and scan for machines that are within that price range and offer the most value for money.

- Ease of Use—Pay attention to the interface, particularly if you’re a novice. Look for designs with straightforward instructions and setups.

- Support and Warranty – Go for trustworthy brands regarding customer assistance, maintenance, and the warranty offered, as that will guarantee dependability.

Considering the foregoing elements helps one make an informed choice of a machine that caters to their needs best.

What factors affect the performance of a metal engraving machine?

| Factor | Impact on Performance |

|---|---|

|

Laser Power |

Affects the depth and speed of engraving |

|

Material Type |

Harder materials require higher power |

|

Engraving Speed |

High speed may reduce engraving quality |

|

Precision |

Determines the detail and clarity of output |

|

Maintenance |

Regular upkeep ensures consistent results |

What is the ideal laser power for engraving stainless steel?

The laser power needed for engraving or even marking stainless steel varies with material thickness and engraving depth. Sharper and clearer markings on stainless steel typically require 20 – 50 watts of laser power, while more intricate cutting needs 50 – 100 watts of fiber laser power.

Metals like stainless steel are best marked with fiber lasers due to their enhanced beam quality and efficiency. According to various professionals, a 30W fiber laser is still suitable for detailed marking, but deeper engraving or thicker material requires at least a 60W fiber laser.

For balanced engraving quality, laser speed settings must be altered with power settings—for example, light etching requires faster speed and lower power, and deeper markings require slower speed paired with higher power. It is important to check all possible combinations of these settings since coatings, finishes, and even the thickness of the stainless steel greatly influence the end result.

Consistent high-quality results require the proper setting of the laser system, its regular maintenance, and routine calibration.

How do you determine the marking speed required for your projects?

To achieve the optimal marking speed for my projects, I first examine the material’s type, coating, and thickness, as they will impact the final result. Then, I mark a sample piece using different combinations of speed and power until I find the most effective balance between clarity, engraving depth, and overall efficiency. Constantly assessing my results enables me to fine-tune processes to be optimal for every specific project.

What Applications Can Benefit from Laser Engraving on Stainless Steel?

The accuracy and lasting mark of laser engraving make it very handy across industries when working with stainless steel. Daily use cases include creating industrial components such as serial number barcodes, logos, and industrial markers essential for traceability and regulation compliance. The medical industry also widely uses it for marking surgical instruments and devices, as these markings can survive harsh sterilization. This also allows for custom engraving around the pieces, enhancing their aesthetic and professional value, making the personalized goods even more appealing.

How is stainless steel marking used in industrial applications?

Marking stainless steel plays an important role in offenses like medical instruments and the automotive industry, which require high adaptiveness and optimal resource use. Other sectors that also depend on stainless steel marking, such as aerospace, medical, automotive, and general manufacturing, need carefully crafted designs for logos or markings that they use specially for marking.

- Identification and Traceability

Steel marking is very helpful in determining a product’s life expectancy and monitoring its components. In automotive, markings such as barcodes, serial numbers, and QR codes are used on parts like engines or brake systems to track manufacturing and supply details such as date and location. According to research, using lasers for marking can help reduce the loss of fake parts by 30%, which is extremely beneficial.

- Regulatory Compliance

Surgical implants and instruments are stamped with UDI (Unique Device Identification) codes and made with industrial-grade stainless steel. They can withstand multiple rounds of sterilization while still being accurate. Reports show that using UDIs in the health care system increases patient safety noticeably while reducing inventory mistakes by an estimated 40%.

- Branding and Personalization

Several businesses use stainless steel marking to improve branding by etching logos and designing certain product cutouts. For instance, marketing tools like reusable water bottles and stainless steel tumblers are often personalized through laser marking, which helps companies to improve brand visibility and enhance customer retention rates.

- Strength and Resistance

One of the most important benefits of stainless steel marking is the ability to withstand extreme conditions. Industrial machines laser marked with safety instructions or warning labels undergo extreme temperatures, chemicals, and gritty surroundings, maintaining clarity. Prolonged durability diminishes the frequency of re-marking data, suggesting data marked from laser engraving, thus reducing time and resource costs for companies.

Significant marking and engraving technologies, such as fiber lasers, achieve rapid, precise, and affordable marks suited for industrial use. With industrial applications becoming increasingly sophisticated, stainless steel marking will remain at the forefront of meeting diverse demands for safety, efficiency, and quality across industries.

What are the creative uses for laser-etched stainless steel?

Almost every versatile material, from functional to artistic, can effectively use laser-etched stainless steel. Due to the intricacy and detail possible with laser etching, it is popular for both practical and decorative purposes.

- Custom Logos and Signage

Precision laser etching is best suited for engraving logos and pictures on businesses’ stainless-steel signage because of its excellent durability and ability to withstand harsh weather conditions. Stainless-steel signs capture the distinct charm and professionalism a company needs to make a positive and long-lasting impression. As per a recent survey, the market demand for custom-made stainless-steel signage has been rising by over 20% annually, showcasing the value of stainless steel signage for one’s brand identity.

- Memorabilia and Gifts

Stainless steel laser etching is popularly used for making personalized gifts like engraved jewelry, plaques, and water bottles. Due to the precision laser technology used in etching names, dates, and soul-touching art, these items become unique and preserved for ages.

- Stainless Steel for Architecture and Steelcraft.

In modern architecture, making stainless steel into amazing shapes is considered the ultimate awe-inspiring work. Laser etching panels can be used as decoration for walls, staircases, and elevators, and also serve as modern design features. This approach is a positive development observed in construction.

- Industries such as medicine and mechanics.

In medicine and industry, laser-etched stainless steel is a major requirement for making sharp and clear labels. Surgical and mechanical tools can be labeled with an identifier, barcode, or security information. Standards and requirements are met using high-power laser systems. The advanced system is useful for etching intricate curves used in these demanding industries.

- Modern stonemasonry and sculpting.

Modern artists favor advanced laser technologies, which enable the creation of elaborate, long-lasting designs ranging from abstract artworks to personal name pendants. These tools require precision crafting and can withstand wear and tear.

The combination of durability and versatility ensures that stainless steel is a highly valued element for creative projects. This is why innovation across various fields is still pushing stainless steel, which is used for laser etching.

What Maintenance is Required for Laser Marking Machines?

Maintenance measures should be performed routinely to ensure optimal performance of the laser marking equipment. Some of the tasks to perform regularly include:

- Soaking the Laser Lens—A soft cloth adhered to a cleaning solution was advised to be used on the lens to remove all dust buildup that could reduce the machine’s veracity.

- Wiping the Cooling Devices—Ensure that the machines have adequate coolants so they do not overheat. Check them periodically.

- Checking the Moving Parts – Make sure that all screws and rotating parts are adequately secured. Ensure they work as they ought to.

- Renewing the Software—From time to time, check the machine’s functions and see if there are any bugs that would reduce its efficiency. Addressing them enhances the machine’s capability.

Simple intervention routines like the ones listed above will save you downtime with the laser marking machine. Always consult the user manual for tailored maintenance guidance prerequisites.

How can a laser engraver be kept in optimal condition?

Preventative maintenance, including proper usage of engraver settings, staying updated with the latest advancements, and care of the laser engraver, are all critical factors for achieving the optimal condition of the laser engraver. The key steps below will help renew and maintain the performance and longevity of your machine

- Cleaning of the optical components must be performed.

As time elapses, laser engravers frequently accumulate dust residue or smoke particles, negatively affecting the quality of the laser output due to the lenses and mirrors not being cleaned. It is considered industry standard to, at a minimum, clean the optics with lens cleaning solutions for laser equipment after every 8 to 10 hours of machine use. Reduced efficiency from dust accumulation has been shown to exceed 30%, leading to irregular consistency in engraving results.

- Supervise the cooling mechanism.

Cool water or air supports the notion of a spindle laser engraver or laser-cut working rotor, while their principles do expand beyond this application field. Hi-tech water coolers and precision cooling fans are generally autoregulated in today’s market, ensuring more proper cooling, which is shown to be one of the leading causes of failure in the laser tube.

To maintain the performance and quality of the water, free from deposits, precipitation, and corrosion, and to ensure smooth function.

Ensure the coolant water is replaced every six months and achieves maximum cooling performance.

- Update Software and Firmware

When the laser engraver’s firmware and software are updated, its functionality, security, and compatibility with new design tools improve. Recently, manufacturers have released patches that often add capabilities for new file types and improve cutting speeds. It is a good practice to check for software updates on the manufacturer’s website every three months.

- Lubricate Moving Parts

Proper lubrication of guide rails and bearings is essential for belt and laser head movement. Manufacturers’ updated maintenance records indicate that machines with regular lubrication tend to last 20% longer than unsustained counterparts. To prevent damage to machine components, always use the suggested lubricating agents.

- Align and Inspect the Laser Beam

Depending on the angle at which the laser is directed, cuts and engravings may either taper or be uneven. It is critical that lasers, especially those subjected to vibration and movement, are set at the correct angles in a process known as alignment. Data suggests that thorough precision alignment should be done every 50 hours.

Replacing cut-off pieces like belts, laser filters, and tubes is a standard requirement. Under optimal conditions, some CO2 laser tubes are expected to work for 2000 to 5000 hours. Monitoring these components helps ensure timely replacement and prevent excessive downtime.

- Operate within Recommended Parameters

If you have an engraver, be careful not to exceed power and speed settings. These parameters are very delicate, and going beyond them may result in engraving damage, reduced laser tube life, and even poor-quality engravings. To avoid this, always test with materials stated by the manufacturer.

These steps, along with others aimed at improving engraving quality, will definitely give you excellent results and keep your engraver in pristine condition. Performing periodic maintenance greatly enhances the engraver’s longevity while guaranteeing exceptional project results. Do not forget to check your engraver’s manual for other specific instructions that suit your device.

What common issues can arise with metal marking machines?

The operation and maintenance of metal marking machines can cause a wide range of problems, which can prove quite detrimental. The following explains five issues with metal marking machines.

- The Problems with the Machine’s Software

Inconsistent marking quality or precision are two widely associated issues with marking lasers not being calibrated frequently. Along with Inconsistent marking quality, two other reasons leading to poor marking quality are vibration, overuse, and mishandling. Regularly verifying that calibration has been conducted greatly helps resolve productivity decreases stemming from reduced misalignment issues.

- The Machine Overheating

Without access to sufficient cooling or ventilation while the system is continuously active, a machine overheating issue may arise. Malfunctioning components due to insufficient cooling while overheating pose additional tuning problems, creating undue strain, leading to being marked poorly. Marked patterns turning faint and distorted marks of varying qualities are detrimental for multiple purposes, and streamlining efforts is crucial.

- Surface Contamination

A person can effortlessly hinder the marking process with the help of dust and debris. Decaying from periodic activities alongside metallic alleviating particles can get access during the marking procedure which may destabilize high quality outcomes and overall internal productivity, This can prove to be extremely beneficial. While in Mark, cleaning all workspaces, including settings such as lenses, is essential in achieving peak productivity.

- Software or firmware malfunctions

Marking metal machines are mostly operated through software installations that might be damaged or require updates, causing lags, glitches, or unresponsive malfunctions. Scheduling backups helps prevent downtime by ensuring all software runs with the most recent version.

Failing to tackle these issues and implementing waiting, strategically crafted solutions risks severely diminishing the lifespan and efficiency of a metal marking machine.

How often should maintenance be performed on a laser engraving machine?

Like almost all machines, a laser engraving machine requires maintenance and upkeep to ensure it stays in good working order. The maintenance your machine will need depends on its usage and where it is used. I recommend performing basic cleaning and routine checks after every use to keep peripherals working optimally and minimize preventative maintenance. In tandem with these actions, more thorough maintenance such as component inspection and laser system alignment should only be performed monthly, if the manufacturer hasn’t specified more vigorous upkeep. Frequent upkeep guarantees sustained performance and protects the owner from incurring costs due to ceasing operation repairs.

Reference Sources

- “Experimental investigation into fibre laser marking on stainless steel 304”

- Authors: M. Pandey, B. Doloi

- Publication Date: June 2, 2022

- Journal: Advances in Materials and Processing Technologies

- Key Findings:

- The study focuses on the operation of laser marking on stainless steel 304, emphasizing the importance of oxidation at high temperatures for permanent marking.

- It identifies key process parameters such as transverse feed, average laser power, and scanning speed that significantly affect the marking quality.

- The results indicate that decreased transverse feed leads to increased mark intensity, achieving a maximum intensity of 0.95 at a feed of 2 μm/laser stroke.

- Methodology:

- The research utilized a diode-pumped pulsed fiber laser for marking in a single pass.

- Experimental studies were conducted to analyze the effects of varying parameters on marking quality, with measurements taken to assess the intensity of the marks produced(Pandey & Doloi, 2022, pp. 1–14).

- “Parametric analysis on fiber laser marking characteristics for generation of square-shaped marked surface on stainless steel 304”

- Authors: M. Pandey, B. Bhattacharyya, B. Doloi

- Publication Date: November 1, 2021

- Journal: Materials Today: Proceedings

- Key Findings:

- This study investigates the effects of various laser marking parameters on the quality of square-shaped markings on stainless steel 304.

- It highlights the relationship between laser power, speed, and marking quality and provides insights into optimizing these parameters for better results.

- Methodology:

- The authors conducted a series of experiments to evaluate the impact of different laser settings on the marking process.

- The study involved measuring the quality of the markings produced under various conditions to determine optimal settings(Pandey & Doloi, 2021).

- “Influence of Laser Marking on Microstructure and Corrosion Performance of Martensitic Stainless Steel Surfaces for Biomedical Applications”

- Authors: N. G. Henriksen et al.

- Publication Date: June 1, 2022

- Journal: HTM Journal of Heat Treatment and Materials

- Key Findings:

- The research examines how laser marking affects the microstructure and corrosion resistance of martensitic stainless steels, which are commonly used in biomedical applications.

- It was found that the laser energy input significantly influences the corrosion behavior of the marked surfaces, with variations in chemical composition affecting the outcomes.

- Methodology:

- The study employed nanosecond pulsed laser irradiation to create markings and analyzed the resulting microstructures using various techniques, including X-ray diffraction and corrosion testing(Henriksen et al., 2022, pp. 177–196).

- Top Laser Marking Machine Manufacturer And Supplier In China

Frequently Asked Questions (FAQs)

Q: What is a laser marking machine for stainless steel?

A: A laser marking machine for stainless steel is a device that uses laser technology to engrave or mark stainless steel surfaces. It employs a focused beam of light to create permanent designs or text on the metal surface.

Q: How does the laser marking process work for stainless steel?

A: The laser marking process directs a concentrated laser beam onto the stainless steel, which heats the surface to create a contrast. Depending on the settings used and the type of laser employed, this can either etch or engrave the material.

Q: What are the applications of stainless steel engraving?

A: Applications of stainless steel engraving include product labeling, barcodes, logos, serial numbers, and decorative designs. It is commonly used in manufacturing, automotive, and jewelry.

Q: What lasers are used in stainless steel laser engraving machines?

A: Common lasers used in stainless steel laser engraving machines include fiber lasers, CO2 lasers, and diode lasers. Fiber lasers are particularly effective for marking and engraving on metal surfaces.

Q: Can I use a metal laser to cut stainless steel and engrave it?

A: Many metal laser machines are versatile enough to cut and engrave on stainless steel. However, the specific capabilities will depend on the power and type of the laser machine.

Q: What is the difference between deep engraving and surface marking?

A: Deep engraving involves removing a significant amount of material to create a noticeable recess, while surface marking only alters the top layer of the stainless steel without significant material removal, creating a design that is usually less deep.

Q: What is the best laser engraver for metal surfaces?

A: The best laser engraver for metal surfaces typically features a high-powered fiber laser marker, which provides precision and efficiency for marking and engraving stainless steel parts and other metal types.

Q: How do I choose the right laser for stainless steel engraving?

A: To choose the right laser for stainless steel engraving, consider factors such as the type of stainless steel, the desired depth of engraving, speed requirements, and whether you need additional features like cutting capabilities.

Q: What are some standard marking methods for stainless steel?

A: Common marking methods for stainless steel include laser marking, dot peen marking, and using marking sprays. Laser marking is preferred for its precision and durability, while dot peen is often used for industrial applications.

Q: Are there any limitations when using a stainless steel laser engraving machine?

A: Limitations can include the thickness of the material, the type of stainless steel being used, and the laser machine’s power. Some types of stainless steel may require more powerful lasers for effective engraving or cutting.