Stainless steel laser engraving has become a necessay procedure in a variety of industries because of its accuracy, permanence, and adaptability. This technology is extensively employed for marking serial numbers, logos, texts, and even complex designs which cuts across industries like manufacturing, art, and design. The purpose of this article is to highlight the major methods, equipment, and important factors of laser engraving stainless steel so that the readers possess the basic understanding needed in accomplishing high standard work. This guide should appeal to discerning professionals as well as those new to laser technology because it presents all the key information par an engraver’s mastery of the intricate work.

What is Laser Engraving on Stainless Steel?

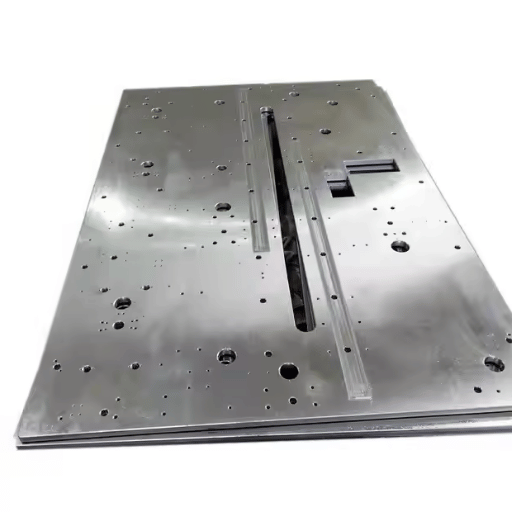

Engraving stainless steel with a laser involves a very particular process, wherein a concentrated laser beam is employed to mark the metal’s surface. The laser works on the material by melting, oxidizing, or even vaporizing some of its layers, thus creating very intricate designs, text, or patterns. The technique has a broad application range because it is effective on many materials and provides protective results which endure deterioration and corrosion while rendering high-grade detailing and elegance with strength and stainless steel’s durability.

Step by Step Explanation of the Laser Engraving Process

The engravings done using lasers on stainless steel are done with extreme levels of precision. Many factors set the outcome such as: engraving speed, laser power, and pulse frequency. For example: most stainless steel engraving jobs will require a laser power output of somewhere between 20 and 50 watts, and even then, it may vary based on how complicated the design is. Pulse Frequencies between 20kHz and 80kHz are better as shorter pulses means less heat being transferred to the surrounding areas thus protecting the material.

The engraving speed might be the second most important parameter, slower speeds are associated with deeper engraving, while higher speeds are associated with marking or etching surfaces. Generally, engraving speeds for stainless steel are between 200 mm/s and 700 mm/s. Striking a balance between quality and efficiency. Temperature control is also important because laser engraving increases the localized temperature well beyond the boiling point of the material which will result in melting or vaporization.

Today’s laser engraving machines can produce up to 1,000 DPI (dots per inch), producing sharp and detailed designs. As for the engraving depth, this can vary from 0.1 mm to 1 mm depending on the purpose and the tolerance level is ±0.01 mm. Thus, guaranteeing unrivaled consistency and precision. Captured under those parameters, precision laser engraving on stainless steel transforms it from a mere metallic surface to a powerful tool for heavy-duty industry, business, or art masterpieces where reliability and precision become essentials.

This is why stainless steel works for laser engraving

Stainless steel is an excellent choice of material for laser engraving as it is durable, non-corrosive, and preserves its shape when exposed to high temperatures. The woman’s photograph served as the perfect example for explaining laser engraving, as all the details on the photograph glass were perfectly indexed. Not only is stainless steel smooth, but it is also highly polished. The surface with which laser engraving is done on stainless steel is very smooth and reflective, thus stainless steel can be marked with laser engraving. Its application is not limited to construction only. The versatility of stainless steel is far reaching, for example, it finds application in aerospace industries, medical devices manufacturing and many more where both the marking to be done on the item and the marking’s endurance are important. There is an unlimited number of lasers that can be used for engraving where the size of engraving may be small or large, and the degree of burning will not be altered, thus ensuring that details will be viewed perfectly engraved with no smudging or blurring, and the wonders of nature will not change the marking laser engraved despite extreme exposure to void marking.

The Impact of Power Settings Laser on Marks

Laser power greatly maintains quality, depth and sharpness of engraving done on stainless steel. Changing laser power affects the beam’s width which obviously also affects height and surface of the material. Shallow or high detailed resolutions without any significant marking done on the material will require low power setting. Marking which is done on the material surface such as etching require lower power setting. Deeper engraving, where cuts are intended to be robust will require higher power for cutting them and is best suited for serial numbers or industrial level labeling.

Proper selection of laser power setting, as further studies focessing on precision applications on lasers suggest, directly correlates to the need of the task at hand. For instance, a 20W laser has a lasseng depth of approximately 0.01 mm per pass on stainless steel whereas under the same conditions, 50W laser achieves 0.03 mm per pass. Considering the differing outcomes, it becomes apparent why power selection is critical to the desired results.

Moreover, laser power does affect the heat-affected zone (HAZ) of the material. Increased power can pose further risk of warping/ burning or unsightly changes in the elegant design which features. These intricate designs can have their detailing lost due to the increase in HAZ. Consequently, it is counterproductive for precision work. To aid in the problems discussed, achieving the right triad of power, acceleration, and beam focus is necessary. The result can keep consistent and clear engravings without damaging the structure.

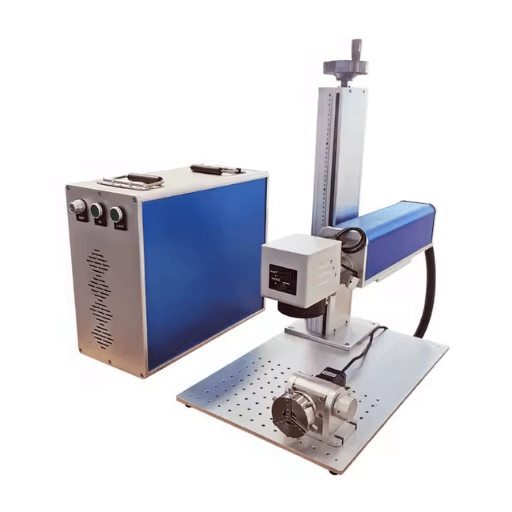

Which Laser Engraver is Best for Stainless Steel?

Comparison of Fiber Laser and CO2 Laser

A stainless steel engraver fiber laser is the best option for engraving stainless steel since it engraves the surface precisely without harming the material. It is far better to CO2 lasers, which are more suited for non-metallic materials because CO2 lasers are slower and less efficient than fiber lasers when dealing with metals.

Key Features of Laser Engraver for Stainless Steel

When choosing a laser engraver for stainless steel, pay attention to the most important features.

The ideal marking conditions for fiber lasers are 1064 nm wavelengths; therefore they are best for marking metals. The best fiber laser for engraving should have between 20W and 50W of power, given that stainless steel requires a lot of energy to engrave depp and permanent marks. Quicker the engraving desired, the higher the power setting required.

Ensures the possibility of achieving the high resolution engraving which is DPI per dot, detail requires number of dots and detail level 1000 is a good quality mark and reliable in precision.

The marking speed of fiber lasers will depend on the complexity of the design, reaching the maximum of 7000 mm/s which is a commendable rate and guarantees a lot of work without sacrificing quality.

The lifespan of laser modules made for engraving on stainless steel is quite remarkable, averaging 100,000 hours. This increase in lifespan reduces downtime and maintenance costs.

Most modern fiber laser engravers come with sophisticated software bundles that can read a variety of files from DXF to AI and SVG. These packages also allow for editing designs along with other settings modulation. As such, check whether the engraver matches all necessary software for your projects.

Cooling systems not only increase efficiency, but air or water cooled systems prevent overheating that may occur with extended usage. Regardless, they are critical for maintaining the equipment’s working condition.

With the factors analyzed beforehand, the laser engraver can be configured to the necessary parameters for stainless steel engraving without any compromise on execution, performance and reliability.

Benefits of Working with an Omtech Laser Machine

Omtech laser machines are unmatched in their precision and accuracy, cutting up to a flawless 1-2 percent of the intended area. Such precision is critical for engraving on stainless steel as it ensures professional standards.

Metal and non-metal materials are not the only things these machines process. They also work with wood, acrylic, glass and leather. Such features enhance the machines’ operability in other industries as well.

Business applications of Omtech products require devices to be serviced less often, reducing maintenance and operational expenses while still achieving the required standards of output.

The ease of the engraving and cutting Omtech machines processes is made possible through the integration of well-known design programs due to their user-friendly software compatibility.

By using quality components, Omtech ensures that their customers’ laser machines will be able to endure repetitive operations over lengthy periods of time without reliability or performance issues.

The operational efficiency and longevity of the machine is maintained by incorporating advanced air and water cooling systems which prevent overheating during extended operations.

For light marking and deep etching, the machines provide adjustable speed and power settings which allows users to customize the engraving procedure to their needs.

Omtech offers outstanding customer service, including online tutorials and training sessions to guarantee that users take full advantage of the machine’s functionalities.

Surpassing competitors in precision engraving, Omtech laser machines effortlessly maintain even the most intricate details regardless of project size or variety, consistent over numerous projects and applications.

How to Laser Engrave Stainless Steel?

Setting Up Your Laser Engraving Machine

Pre-Operations Check: Start by cleaning the surface of the stainless steel thoroughly to remove dust, grease, or any contaminants. This is needed so there is no inconsistent markings caused by poor drawing quality.

Choose The Right Laser Settings: Adjust the power, speed, and frequency to match the type of work: for a stainless steel engraving, a high power level is mostly recommended and set to the hottest depending on the type of work done (annealing or etching)

Marking Solution (Optional): In cases where the laser cannot engrave stainless steel directly, an alternative is to coat the surface with a laser marking spray or paste. A brushed-on coating provides excellent contrast to the mark formed by the laser so long as the blade hits the covering.

Buckle The Piece: It is critical to fix the stainless-steel in position with clamps to prevent rotation for the duration machining is set so as to maintain precision.

Run A Test Engraving: Do a small test on a sample or inconspicuous area to ensure that the rest of the machine settings are correct.

Input The Engraving: With the design uploaded compete all portions, track, and suspend it against the material. During completion steps observe the process to check for precision. <

Post-Engraving Surface Cleaning: After the engraving is done, the stainless steel surface should be cleaned again in order to remove the residue or marking solution to ensure that it is neat and professional.

As you may have seen, engraved stainless steel can be industrial, artistic, or personal, but in any case these instructions provide enduring and accurate engravings.

Selecting Appropriate Settings for the Engraving Process

To achieve a quality engraving on stainless steel, setting the optimal engraving settings will matter a lot so, laser power, speed, focus and frequency are important parameters to take into consideration. Further down are the proposed ranges as well as the effects of each step during the engraving process:

Power of Laser: It would be best to put the power setting at 60-100% for almost all materials although it may need to be adjusted based on the material’s thickness and how deep the engraving is supposed to be. Delivers deeper and darker engravings but enlarges the heat affected zones.

Speed of engraving: Also frequently set within the 100 – 300 mm/s for both light and deep engravings. Slower speeds produce deeper engravings at more risk to overheating, faster results yield lighter engravings.

Engraving Fiber: The most clear and precise results from fiber lasers will be obtained at frequencies of 20-50kHz. High frequencies provide finer detailing and low contrast stark contrast.

Focus: Height must be exactly 1 or 2mm from the surface to ensure sharpness and accuracy of the engraving.

In the case of engravings on 1 mm thick stainless steel and moderate depth targets, an example setup could include 80% power, a movement speed of 200 mm/s, a frequency of 30 kHz, and a focus offset of 1.5 mm. In any case, changes should always be done with consultation of at least one test engraving. As an example, material finish and coating tend to have a great impact on the result.

A procedure for performing engraving is the following

Preparation of the Material: For the highest engraving quality, soaking the stainless steel with water and oil, dirt and other particles must be removed prior. An alcohol based cleaner might not be inappropriate here.

Set Up The Laser Parameters: Along with inserting primary parameters like laser power, set at an example 80%, speed at an example of 200 mm/s, and frequency with an example value set at 30 KHz, the software settings need adjusting. The focal distance also needs changing, for example setting it to 1.5 mm for the case when the engraving material’s thickness is 1 mm.

Performing Test Engravings: All proposed changes based on makeup and assumptions of material properties need to be applied in a test engraving on a spare piece of the substance.

Engrave the Design: If no deviations from expected parameters were observed, start the engaged engraving procedure while observing the laser path for uninterrupted processing throughout the sessions and adjusting if deviations from set conditions are found.

Inspect Final Output: Execute the output verification in lines with expectations regarding set parameters and the quality of the outcome.

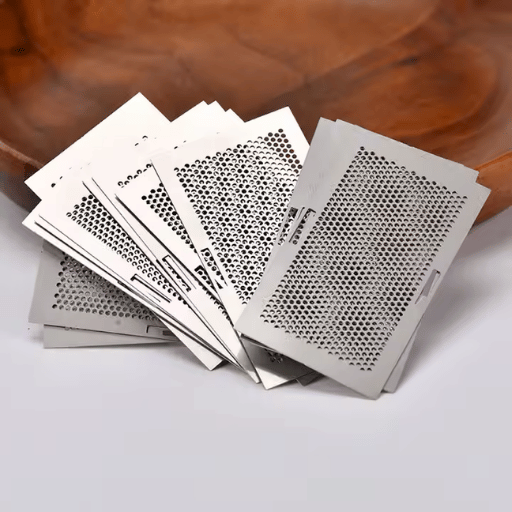

What are the Benefits of Etching Stainless Steel?

The Strength, Endurance, and Beauty of the Engraving

The etched form of stainless steel is resistant to environmental attacks like corrosion, heat, and moisture. This form has durability because of the protective oxide layer present on the surface of the steel, which is formed in the etching process. As some industry studies state, some grades of stainless steel 304 and 316 possess certain degrees of corrosion resistance for salt spray test durations between 500 to 1,000 hours, which makes them superb for indoor and outdoor usage.

Modern methods or new technologies in etching such as chemical and laser etching can create highly accurate and replicable designs. Take, for instance, laser engraving systems which are capable of enabling positional accuracy of about ±0.01 mm during operation. This precision ensures that even the most detailed patterns or text yields identical results every time. Such capability is crucial for sectors like aerospace, medical, and electronics manufacturing, which demand stringent adherence to specifications.

Among other metals wrought, etched stainless steel material is one of those costs effective, especially in mass production. For example, chemical etching can process hundreds of pieces at only hundreds of tooling without significantly wearing out the tools. Added to that is the fact that there is no mechanical stress involved in the process, making the pieces free from warping or distortion, thus making them, leading to less rejected parts.

Taking advantage of these benefits, etched stainless steel components are used extensively and with great precision in signage, industrial panels, and instruments, offering dependability with an aesthetic appeal in multiple sectors.

Cost-Effectiveness of Laser Etching

Due to its low material wastage and precision cuts, laser etching is noted for its cost-efficiency. For example, mechanical engraving, which is a form of engraving done with a machine, comes with a material waste scale of 10-15%. In comparison, laser etching’s wastage is lower than 2%. Operational costs also differ, laser systems coming with little maintenance and a longer longevity than, most industrial-grade lasers lasting over 20,000 hours, continuously running before a replacement is necessary. Lowered operational costs accumulate with increased production rates, modern laser etching machines depending on the intricacy of the design, processing up to 300 parts an hour. This ease translates to heightened throughput and improved scalability for industries with high demands. Affordability alongside other expenditures, quality laser etching provides a sensible selection for manufacturers.

Can a 10w Laser Engrave Stainless Steel?

Overview of the Capabilities of a 10w Laser

Although a 10w laser is considered weak on the industrial scale, it has the capability of engraving stainless steel, albeit with precise conditions. The amount of effective engraving that can be done is dependent on several engraving parameters which include the settings on the laser, the material itself, and even the prep work done before the engraving is initiated. Here is an analysis of multiple parameters and their implications:

Power Settings:

Engraving stainless steel with a 10w laser demands optimal power settings. Slowing down the speed coupled with raising the power output will ensure better material penetration.

Focus:

Focal adjustment is significant during engraving and also for depth precision. Results from lasers lacking focus might yield accuracy issues overall.

Material Preparation:

Surface cleansing helps the engraving process and ensures smoothing since the lava tend to evaporate.

Use of Marking Paste:

Engravings become more visible with the use of a laser paste but it interacts with the engraving on a chemical level, hence it is able to withstand erosion more efficiently.

Cooling Mechanisms:

Wasting stainless steel’s efficiency as an excellent conductor of heat has to be managed due to cooldown build-up using heating techniques without risking the materials warping or other forms of damage.

Design Complexity:

With a 10w laser, simple designs are more achievable as soldered or extremely tiny engravings require power to maintain randomness consistency.

A 10w laser can take moderate usage on engraving stainless steel projects after optimizing all the above parameters.

Some more demanding applications may need higher powered systems.

Considerations and Limitations of Using a 10w Laser for Engraving

Every drawing is of a different type and has its own specs. In the case of 10w laser, there are specifics to follow. Processing of metals demand commensurate energy inflow and apportionable litheness of the material.

With a wide array of calculating perfect efficiencies, one can get 25-35 minutes worth of work for average one inch tube. For more detailed engraving with tiny details, hydraulic restrictors can be a good addition too within the centered cutting tools.

A high-quality engraving with smooth metall over the surface is very straight forward. Best Primary Energy Resolution (PER) settings are 12.5<

lastpass:500:500.

Though stainless steel works with the 10w lasers, some additional preprocessing may be needed. An example would be applying a laser bonding agent. While it improves both contrast and strength, it does also increase prep work and cost.

Users can operate the 10w laser for precision engraving within its performance limitations by considering these factors in conjunction with the project requirements.

Reference Sources

- Title: Fabrication of superhydrophilic surfaces for long time preservation on 316L stainless steel by ultraviolet laser etching

- Authors: Chunyang Pan, Changfeng Xu, Jun Zhou

- Publication Date: January 13, 2022

- Summary: This study explores the creation of superhydrophilic surfaces on 316L stainless steel using ultraviolet laser etching. The research investigates the relationship between laser process parameters (such as repeat frequency, pulse width, scanning speed, and number of scans) and the resulting surface microstructure and wetting ability. The findings indicate that the superhydrophilic properties can be maintained for up to 30 days under various environmental conditions.

- Methodology: The authors conducted experiments to optimize laser parameters and analyzed the surface characteristics using contact angle measurements and microscopy techniques(Pan et al., 2022).

- Title: Surface texturing of stainless steel engraved by laser etching

- Authors: Yoshiyuki Horiguchi, Ryoji Shinhori, Motoaki Osawa

- Publication Date: March 31, 2021

- Summary: This research examines the effects of laser etching on the surface texture of stainless steel in a sulfuric acid solution. The study demonstrates that laser irradiation can accelerate local corrosion, forming groove patterns that enhance surface texture. The depth and width of the grooves are influenced by laser power and scanning speed.

- Methodology: The authors used laser etching techniques in conjunction with electrochemical methods to analyze the corrosion patterns and surface morphology through scanning electron microscopy (SEM)(Horiguchi et al., 2021).

- Title: Analyzing the effect of the parameters of laser etching process influencing the corrosion resistance and surface roughness of marine grade 316 stainless steel

- Authors: Aditya Korakana, Sparsha Korakana, Nitin Ulmek, A. Pagare

- Publication Date: March 5, 2020

- Summary: This study investigates how different laser etching parameters affect the corrosion resistance and surface roughness of marine-grade 316 stainless steel. The findings highlight the importance of optimizing laser settings to enhance the material’s performance in corrosive environments.

- Methodology: The authors performed a series of experiments varying laser parameters and assessed the resulting surface characteristics using corrosion tests and surface roughness measurements(Korakana et al., 2020, pp. 452–462).

Frequently Asked Questions (FAQs)

Q: For engraving stainless steel, which laser is the most suitable?

A: Fiber laser systems are usually the best lasers for engraving metal, including stainless steel, owing to their precise and efficient engraving capabilities. Steel can be marked for direct identification with stainless steel, and it can be done so with high-contrast, making fiber lasers ideal for stainless steel.

Q: Is it possible for a diode laser to engrave stainless steel?

A: While a power diode laser can engrave metal, description wise it is not as effective as a fiber laser when engraving stainless steel. Softer materials are best suited for use with a diode laser. The optimal outcome when cutting metal is achieved using a fiber laser, which is specialized for that purpose.

Q: What is the difference between laser marking and laser engraving on stainless steel?

A: Keeping the material intact while laser marking stainless steel involves engraving stainless steel high-contrast marks with surface engraving. Laser engraving, on the other hand, cuts through the material and creates a permanent mark. Both processes employ lasers, but the desired outcome determines which one to use.

Q: What settings would help achieve a marked color while engraving on stainless steel?

A: Cowing color on stainless steel is marking with a laser with the right power and speed settings alongside the laser’s frequency. More options for color marking can be done with a MOPA fiber laser. Usually, a test piece is available to make the necessary adjustments.

Q: What steps are in place to eliminate rust on laser engraved stainless steel part?

A: It is imperative to maintain stainless steel in ship shape if rust is to be avoided on its engraved sections and high grade steel alloy must be used. Also teasing the region directly under the engraving mark with a coating like Cermark increases life time and corrosion resist.

Q: Can a CO2 laser engraver be used for engraving on stainless steel?

A: Engraving metals such as stainless steel with a CO2 laser is not recommended; marking compounds are necessary. Metal engraving is best completed with a fiber laser system as it is capable of direct metal surface penetration.

Q: What applications can benefit from laser engraving on stainless steel?

A: Laser engraving on stainless steel is best for items that require marking with strong identification such as, to personalize markings or for industrial parts traceability and to mark tumblers and keychains, as they are marked with the brand name. Marks do not fade easily and are permanently etched onto the metal.

Q: How does using a focal lens affect the laser engraving process on stainless steel?

A: The focal lens has great impact on marking because it concentrates the laser beam to a specific point and increases the level of detail that can be engraved. Changing the focal length will get the required depth when marking stainless steel.

Q: Can stainless steel be marked directly without any extra coatings applied?

A: The marking of stainless steel without additional coatings is possible and works best when using a fiber laser system. This technique guarantees a strong and permanent mark which is appropriate where no additional coatings or additives are needed.