An individual’s creativity blends seamlessly with his or her craftsmanship skills in woodworking- creating something can only be considered art. The process has changed more innovatively and accurately with today’s modern technology. The introduction of laser engraving and cutting machines has created a new standard, and these multipurpose tools are changing the way professionals, hobbyists, or even casual artisans approach wood. These machines come with advanced features that are easy to use, meaning intricate designs can now be crafted with unmatched finesse, and projects can be personalized and etched with remarkable precision. In this guide, I will walk you through everything related to laser engraving and cutting machines for wood, their skills, and advantages,, while also offering advice on how to pick the best machine suited for your needs. It does not matter if you are a curious beginner or a seasoned veteran; I will help you learn how to take your woodworking projects to the next level in this blog.

What is a Laser Engraving and Cutting Machine?

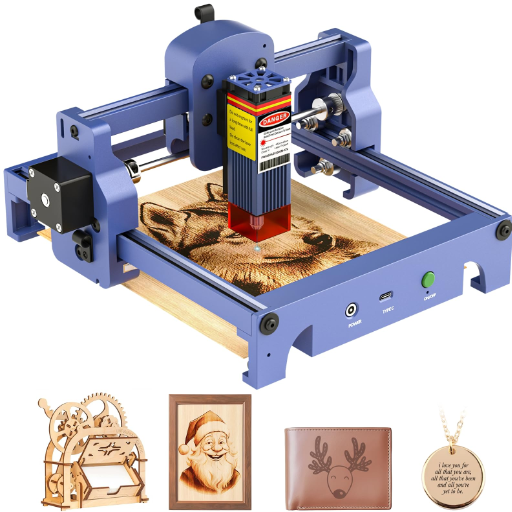

A laser engraving and cutting machine converts a laser into high-energy light, directing it at a material to engrave designs or even cut through it intricately. The machine is capable of engraving and cutting diverse materials such as wood, metal, and acrylic. Because of its accuracy and efficiency, it is primarily known for its use in the woodworking, manufacturing, and design industries.

How does a laser engraver work?

A laser engraver works by applying an intense light beam to the surface of a material to engrave designs. The following steps explain how precision and accuracy are achieved.

- Beam Generation. The light source powering the laser, be it a CO2, fiber, or diode laser, governs the beam generation step. Each type of laser has distinct wavelengths suited for different materials. For example, CO2 lasers are commonly used for non-metal materials like wood and acrylic, while fiber lasers are industrial grade and best suited for metals.

- Control System. Usually, the engraver is linked to a computer with control software that processes design files like svg or DXF and converts them into machine-readable code. The software also allows users to determine optimal values of parameters like speed, power, and resolution, which govern the engraving process.

- Focusing the beam. A powerful optical lens can focus the laser into a tiny point, enabling the concentration of energy, resulting in increased precision and accuracy.

- Material Interaction. Permanent markings are created when the laser vaporizes or burns a cross-section of the material’s surface layer, resulting in engraving. In cutting, the laser has enough energy to separate the material.

- Movement Mechanism: Laser engravers use a gangway motion system where the laser head moves along the X and Y axes or a galvanometer system for faster, more precise movements.

- Exhaust System: In modern engravers, an exhaust system is necessary to maintain safety, consistency, and to remove any debris, smoke, or fumes generated during the engraving process.

What materials can a laser cutter engrave?

Laser cutters can engrave many materials with unmatched precision and detail, making them highly versatile tools. Some of the materials that are most commonly engraved using laser cutting technology are:

- Wood

Includes plywood, MDF, hardwood, and softwood.

Used extensively for intricate designs, logos, and custom products.

- Acrylic

Acrylic has a smooth, glossy surface and is excellent for precision engraving.

Commonly used in the making of signage, awards, and decorative items.

- Leather

It can be genuine or synthetic leather.

Great for custom accessories such as wallets, belts, and tags.

- Glass

Using lasers, frosted designs can be intricately engraved onto glass surfaces such as bottles, windows, and ornaments.

Commonly used in personalized gifts and promotional products.

- Metal (coated or anodized)

Coated metals, such as anodized aluminum, are suitable because of their high-contrast designs.

Perfect for industrial tags, nameplates, custom tools, etc.

Each of these materials has distinct properties that influence the outcome of engraving, which ensures countless possibilities for creative and industrial undertakings.

Differences between laser engraving and cutting machines.

|

Parameter |

Laser Engraving |

Laser Cutting |

|---|---|---|

|

Primary Function |

Surface marking or design |

Complete material separation |

|

Power Requirements |

Lower (<60W typically) |

Higher (60W and above) |

|

Speed |

Faster for same material thickness |

Slower for precise cuts |

|

Material Penetration |

Shallow engraving |

Full material penetration |

|

Setup Cost |

Moderate |

Higher, advanced hardware needed |

|

Operational Cost |

Lower than cutting |

Higher due to power use |

|

Post-Processing Need |

Minimal |

Sometimes required |

|

Application |

Custom designs, durability marking |

Cutting complex shapes and designs |

|

Best Materials |

Plastics, metals, ceramics, glass |

Metals, wood, acrylic |

|

Machine Versatility |

Often engraving-only |

Can engrave and cut materials |

Benefits of Using a Laser Cutter for Wood

These days, laser cutters are becoming increasingly common in crafts, design, and manufacturing due to their effectiveness when working with wood. Their usage includes, but is not limited to, crafting, design, engraving, cutting, and more. Below are some advantages of utilizing cutting laser technology.

- Woodworking Precision

Any woodworker will value precision, as it helps achieve meticulous and refined designs that are borderline impossible with handheld tools. This helps ensure complex shapes and small components are achieved. With laser systems able to cut at accuracies ranging from +/—0.1mm, one can guarantee that high-precision outcomes are achieved.

- Laser Cutter Efficiency

Not only do modern laser cutters offer precision, but they also do it with astounding speed. Any wood processing, be it engraving, cutting, or multiphase work, is done fast. With powerful lasers programmed within some machines, plywood up to 10mm thick can be cut and run in large-scale production within seconds.

- Dynamic Woods and Custom Designs

Plywood, MDF, softwood, and hardwood are examples of the multi-typed woods that laser cutters can work with. Moreover, tailored designs like patterns or logos can be done by amateurs, giving custom engravings tailored for other enthusiasts or professionals.

- Precise Cuts And Edges

There is no cutting method that compares to laser cutting, as the edges are smooth and sealed with little to no splinters. This is achieved through the concentrated heat working like a vaporizer on the material, cutting it at the designated marking, removing rough edges, and smoothing the material to lower the needed post-processing work.

- Material Save

The saving of many resources stems from the type of programming done through non-contact cutting techniques, which leads to the lasers being placed in a manner that optimizes and gives an accurate result in a material-efficient way. In turn, big savings on material resources like wood are achieved as cutting costs over time.

- Cost-Efficient for Businesses:

The benefits of laser cutters exceed those of traditional ones due to their efficiency. With reported resource savings, increased productivity, and gas and labor savings, all because of the increased work efficiency of the laser systems, it is proven repeatedly that productivity and overall benefits, as well as business profit, will soar.

- Savings Of Nature:

The nature-saving components of rudimentary methods are very scarce compared to those offered by the laser cutting wood techniques. The emissions during operation are also far fewer than those of industrialized cutting technologies. Many new technologies incorporated into laser systems come with features designed to filter harmful particles in the air, leading to fewer pollutants and improving the workspace’s cleanliness.

- Advanced Features with Modern Machines

The latest laser cutting systems come with design software and other modern features. For instance, woodworking is best done with CO2 laser cutters, and some machines enable AI-based depth of engraving and cutting power control.

Why choose laser engraving for wood projects?

The simplicity and customizability that laser engraving provides woodworks with astounding precision increase its appeal to consumers and wood design businesses. Personalized gifts, branded merchandise products, or decorative items can be efficiently designed and created using laser-engraving etching tools. Laser engraving works by burning light rays into the wood, making the process more advanced than traditional engraving techniques.

Additionally, achieving higher levels of detail is one benefit that is not unheard of with laser engravers. They can engrave up to and below a 0.01 mm tolerance, which makes them unbelievably precise. Furthermore, as the best lasers used within wood engraving are CO2 lasers, it is well known that they work well with hardwoods, softwoods, MDFs, and even plywood. For these reasons, they deliver jaw dropping results. Other modern devices have also implemented automated controls and AI, allowing faster completion times while reducing the amount of materials needed, decreasing overall expenditure.

Among the many places to utilize eco-friendly devices, laser engraving is not the most obvious one. Surprisingly, when compared to CNC machining, laser engravers generate far less material waste and do not require as much power to operate. Studies have shown that using energy-conserving lasers saves up to 30% of the amount of power older models would use.

Moreover, laser engraving offers unmatched design flexibility. Users can create detailed custom graphics and engrave them directly onto wood surfaces since several software formats, including Adobe Illustrator, CorelDRAW, and CAD programs, are supported. This versatility allows both enthusiasts and experts to accomplish remarkable results with little effort, whether the work is for a hobby or professional mass production.

Advantages of laser cutting over traditional methods.

- Precision and Accuracy

Laser cutting provides unmatched accuracy compared to other cutting methods. For instance, a laser cutter can slice through a material within a tolerance level of 0.1 mm. Most other methods find it impossible to achieve such accuracy, particularly for small parts and detailed pieces.

- Versatility in Materials

Unlike other cutting tools, lasers can work on a wider variety of materials, such as wood, metal, acrylics, plastics, fabrics, and even paper. This makes laser cutters applicable to different industries, such as manufacturing, designing, and art.

- Non-Contact Process

The laser cutting method is non-contact, meaning the laser beam does not touch the cut object. There is zero chance of the material getting warped or damaged because traditional tools use contact, which often results in physical deformation. This is crucial, especially for fragile materials.

- Speed and Efficiency

Compared to traditional cutting techniques, laser cutting is significantly quicker. For example, thin materials can be cut in less than a minute, and automated systems can run continuously, which is optimal for mass production.

- Lowering Costs & Waste

The accuracy of laser cutting saves materials since it clears them as efficiently as possible. Unlike other procedures, it does not incur useless waste, which leads to further expenses. Furthermore, with fewer tools needed for replacement, maintenance costs in the long run become lower.

Applications of wood laser cutting in various industries.

- Furniture Crafting

The laser cutting technique is widely used in furniture making, elaborate designs, delicate cuts, and ornamental carvings on wood. Furniture makers can now create pieces with incredible quality and customization at an incredibly fast pace. For example, modern-day laser systems can save as much as 30% of the time needed to complete a job compared to older techniques.

- Architecture and Interior Design

Wood laser cutting can be used to etch custom flooring, decorative wall panels, or even custom-made art pieces like wall engravings. Because of its precision, laser cutting can be used to create more advanced designs that were never before possible in construction and architecture.

- Crafting and Art

Lasers can be employed in creating various beautiful wooden products, from jewelry pieces to intricate models. Because laser cutting deals with wonderful details, developing precise handmade artisanal products at larger scales is possible.

- Signs and Advertisements

Most people use laser cutting to make borders, logo signs, and wooden advertisement boards. This technology can be employed in the making of the most sophisticated signs, where the font and logo are cut with precision, ensuring a high-quality and durable sign that is ideal for advertising.

- Promotional Products and Puzzles

Almost every toy store has a robotic section. Wood laser cutting can obtain the raw materials for robot toys. In the same way, sculpted robot components can be fabricated with the help of laser engraving and cutting guides. Different types of movable parts robots can also be created with the help of wood laser cutting techniques.

Choosing the Right Laser Engraving Machine for Beginners

- User-Friendly

Look for a machine with easily operable software. An easy learning curve can get neophytes up and running quickly.

- Reasonable Price

Seek machines made for beginners that offer the best value for money. Lesser-known entry machines will almost always deliver the required functionality cheaply.

- Compatible Materials

Check design versatility. Different projects, such as wood, acrylic, and leather, require engravings, which means the machine should be versatile across various materials.

- Dimensions and Work Area

Like any other machine, the workspace and overall dimensions need to be considered. More compact designs help with tight spaces but limit the machine to smaller projects.

- Safety

Ensure the machine has an enclosed design, especially for beginners, to avoid injuries during operation. Other additional features, like emergency stop buttons, should also be checked.

- Research and Other Tools

Get the machine tutorials, responsive helpdesk, and active online forums. Choose brands that offer these resources, which are essential for troubleshooting and sharing tips with other users.

These principles will help beginners find a machine that seamlessly integrates into their laser engraving routines while fully capturing the craft’s simplistic complexity.

What should you consider when buying a laser engraver for wood?

It is best to attain a satisfying laser cutter by considering all relevant factors affecting its engraving capabilities and usability when choosing a laser engraver for wood. Here is the outline of basic points of the newest updates on:

- Power Output and Wattage

Wood engravings or cuts can be performed and effectively achieved using specific tools, and hence, tools for low-power and high-power outputs vary. For softwoods, a power of 20-40 watts is commonly used. However, for precision and depth on hardwoods, a power of at least 50 to 60 watts is advised.

- Engraving Speed

Turning out products after engraving in a given timeframe is crucial for larger projects; thus, speed becomes a considerable factor. Most modern graders increase their machines’ capabilities to allow rates of over 300 mm/s, and some slower models come with advanced settings for delicate or intricate pieces of woodwork.

- Engraving Area (Workbed Size)

The range of sizes that you can make depends on the range of sizes of the engraving area. Base level machines that automate grade are reported at having workbed areas at around 300 x 200 mm, while advanced engraving machines of professional grade boast areas of 600 x 400 mm or bigger for considerable amounts of woodwork. Software Compatibility

Make certain that the engraver is compatible with commercially available software like LightBurn and RDWorks. These applications have user-friendly design and editing features suitable for laser engraving, along with vector editing functionalities. Further, support for file types like SVG, DXF, and PNG adds versatility.

- Air Assist System

For wood engraving, an air assist system is a must. It improves cutting accuracy by blowing away smoke and debris that could obscure the view of the workpiece. Ensure the engraver has or supports an air assist feature for better engravings.

- Safety Features

Operating laser engravers can be dangerous, so look for protective features that minimize exposure to the laser beam, such as covers, shields, and emergency stop buttons. Machines without adequate laser beam safety features should be FDA certified or CE marked, designating safety compliance.

- Cost and Budgeting

Laser engravers for wood fall in this price range, starting at around $200 and going upwards of $5,000 for industrial-grade models. Whether you intend to purchase a hobbyist, a small business, or a professional production tool, set a budget to balance the machine’s performance and cost.

- Customer Reviews and Brand Reputation

Look for testimonials and reviews from customers to get an accurate understanding of the machine’s effectiveness and sturdiness before buying. More established brands, such as Glowforge, Ortur, and Thunder Laser, tend to offer better reliability and support.

Considering these details will allow amateurs and experts to select an engraver with modern technology suitable for their wood engraving requirements.

Top Features of a Wood Laser Cutter

- Precision and Accuracy

With wood laser cutters, users can cut intricate designs while ensuring astounding levels of precision. Even with complex patterns, clean and professional results are achievable.

- Customizable Power Settings

Different power settings allow users to work with varying types and thicknesses of wood, providing flexibility for engraving and cutting.

- Speed and Efficiency

Modern wood laser cutters offer fast speeds, which users can use to complete more projects in less time without compromising on quality.

- User interface

Many machines come with advanced software that allows access to more sophisticated features while maintaining the ease of use necessary for beginners.

- Support for Various Designs

The machines’ versatility in handling a wide array of designs, from engravings to detailed artwork, comes from their compatibility with multiple file formats.

Customizable woodworking is strikingly made more accessible thanks to these features, making wood laser cutters a must-have.

What makes a good engraving cutting machine?

A good engraving cutting machine stands out by offering a balance of precision, versatility, and ease of use, while also incorporating advanced technology to meet user demands. Here are the key factors to consider:

- High Precision and Accuracy

The best engraving cutting machines have robust laser systems and advanced optical mechanisms to ensure precise and detailed cuts and engravings. For optimal results, look for models with a resolution of at least 1000 DPI (dots per inch) and high repeatability (typically ±0.01mm). This level of precision is crucial for intricate designs and professional-quality work.

- Speed and Efficiency

Cutting speed directly affects productivity, particularly for commercial use. Machines offering cutting speeds between 500mm/s and 2000 2000mm/s and engraving speeds up to 4000mm/s are ideal for high-output environments.

- Material Compatibility

A good machine supports a wide variety of materials, including wood, acrylic, leather, glass, metal, and fabric. Machines with adjustable laser power (e.g., 40W to 150W) allow users to work with different densities and thicknesses, expanding the scope of possible projects.

- User-Friendly Software

Intuitive software is a must-have feature, enabling seamless design imports and control adjustments. Machines compatible with industry-standard design software such as Adobe Illustrator, CorelDRAW, or AutoCAD make it easier for users to create designs. Support for multiple file formats like SVG, DXF, BMP, or JPG ensures greater flexibility.

- Size and Work Area

The cutting bed size dictates the machine’s usability for specific projects. Models with larger work areas, such as 20”x12” (500mm x 300mm) or even 36”x24” (900mm x 600mm), are suitable for handling larger pieces, while compact models offer convenience for small-scale tasks.

- Durability and Maintenance

High-quality engraving cutting machines have durable components, such as all-metal frames or reinforced gantries, to withstand extended use. Maintenance requirements should also be minimal, with features like auto-cleaning lenses or guided maintenance alerts included in premium models.

- Safety Features

Lasers can be hazardous if not properly handled. Top-tier machines include safety features, such as enclosed designs, emergency stop buttons, air assist systems to reduce flammable debris, and certifications like CE or FDA compliance.

- Price and Warranty

Consider the balance between cost and features. Entry-level machines may start around $300 to $500, while mid-range options with more advanced capabilities are typically priced between $2,000 and $5,000. Premium industrial-grade models can exceed $10,000. Always check for extended warranties, often around one to three years, and customer support availability.

These attributes collectively define a quality engraving cutting machine, capable of delivering precise, efficient, and safe results for personal and professional applications.

CO2 vs. diode laser: Which is better for wood?

|

Parameter |

CO2 Laser |

Diode Laser |

|---|---|---|

|

Power |

Higher (40- 150W) |

Lower (5- 10W) |

|

Cutting Speed |

Faster |

Slower |

|

Material Penetration |

Deeper cuts, thicker wood |

Limited penetration |

|

Setup Cost |

Medium to high |

Low to medium |

|

Operational Cost |

Moderate |

Low |

|

Versatility |

Broad material range |

Limited to certain materials |

|

Portability |

Requires fixed setup |

Lightweight, portable |

|

Cutting Quality |

Cleaner, smoother edges |

Good but less precise |

|

Best Use |

Business, high-volume tasks |

Hobbyist, small projects |

|

Durability |

Long-lasting tube life |

May require frequent upgrades |

How do you clean and care for your engraving machine?

I take a preventative approach to maintaining my engraving machine. *Before doing anything,* I turn off the machine and unplug it. I then take a soft cloth to wipe any visible marks on the exterior while scraping off any loose dust floating around. As for the internal components, I meticulously clean the lens and mirrors with a microfiber cloth, avoiding scratches at all costs. Additionally, I make sure ventilation pathways are free of any blockage and routinely check for software updates to keep the machine running smoothly. Sprinkle in the vacuuming, and I care greatly for internal components. Besides that, I make sure there is no visible damage to the moving parts, lubricating them as necessary.

Reference Sources

1.Experimentally Shown Air Pollution Produced by a Moving Tabletop Laser Cutter And Engraver 1:

- Key Findings: This study examined the relevant laser cutters and engravers used in the industry, focusing on the airborne pollutants generated as a byproduct of comminution. Special attention was given to the impact of inadequate removal devices.

- Methodology: The investigation focused on engraving processes involving materials such as wood and glass. This work quantifies the amount of particulate matter in the air and proposes some ways to reduce emissions.

2. Lasers in Material Processing Technology, Vol. 2: Development of a Laser Engraving and Cutting Machine from a 3D Printer 2:

- Summarized Results: The complete study dealt with the incorporation of a laser engraving module into a 3D printer. Also referred to as multi-purpose CNC machines, the modified printers performed engraving and cutting of materials such as wood, veneer, and acrylic glass. Additionally, they were capable of stencil creation, box manufacturing, and printed circuit board manufacturing.

- Approach: The study primarily focused on adding a laser module to an existing 3D printer. Optimization of the laser’s power, cooling systems, control firmware, and other aspects was a key area of the study. Other cornerstone elements measured were the system’s x-y-z noise floor levels and operational noise-capable design changes complete with user-friendly interfaces.

3. Top Laser Engraving and Cutting Machine Manufacturer and Supplier in China

Frequently Asked Questions (FAQs)

Q: What is a laser engraving machine used for?

A: A laser engraving machine is commonly used for precise cutting and engraving on various materials, including wood and metal. It utilizes laser cutting and engraving technology to achieve detailed designs, making it ideal for crafts, industrial applications, and personalized gifts.

Q: How does a laser cutter and engraver work?

A laser cutter and engraver uses a focused beam of light generated by a laser tube to cut and engrave materials. CNC laser technology allows for accurate, repeatable cuts and engravings, controlled by a computer program to create intricate designs.

Q: What types of materials can a CNC laser cutter work with?

A: A CNC laser cutter can work with various materials, including different types of wood, acrylic, plastic, and some metals. Depending on the power of the laser, it can effectively cut and engrave materials like wood and metal.

Q: What is the difference between CO2 and fiber lasers?

A: CO2 lasers are typically used for cutting and engraving non-metal materials, such as wood and plastics, while fiber lasers are more efficient for cutting metals. The choice between the two depends on the primary use of the laser cutting and engraving machine.

Q: Can I use a desktop laser for both cutting and engraving?

A: Many desktop laser engravers and cutters are designed to perform both tasks. These machines, like the Ortur Laser Master 2, can efficiently cut and engrave materials, making them versatile tools for small businesses and hobbyists.

Q: What is the best laser engraver for wood projects?

A: The best laser engraver for wood projects often depends on your specific needs, such as size, power, and budget. The 10W laser models are popular for their efficiency in cutting and engraving wood, while larger machines may provide more versatility for various materials.

Q: How do I maintain my laser cutter engraving machine?

A: Regular laser cutter engraving machine maintenance includes cleaning the lens and mirrors, checking alignment, and ensuring the laser tube functions correctly. Keeping the machine clean from dust and residue will prolong its lifespan and performance.

Q: What safety precautions should I take when using a laser cutter machine?

A: Always wear appropriate safety gear, including protective eyewear, when using a laser cutter machine. Ensure proper ventilation to avoid inhaling fumes, and never leave the machine unattended while operating to prevent accidents.

Q: Can I engrave images onto wood with a laser engraver?

A: You can engrave images onto wood with a laser engraver. Most modern laser engraving cutting machines support various file formats, allowing you to upload photos and designs that can be accurately engraved onto the wood surface.

- Harnessing the full potential of technology Fiber Laser: A Step by Step Guide

- Unlocking the Power: How Does Laser Cleaning Technology Function?

- Laser Cutter vs CNC Machine: Understanding the Difference Between CNC Cutting and Laser Cutting

- Is a Laser Engraving Machine the Best Investment for Your Business?