Choosing one particular engraver can be challenging with the multitude of options available on the market dealing with hobbies or small businesses. This is because they all use diode, CO2, or fiber lasers, which significantly impact the projects’ quality, speed, and versatility. Different types of renewers work best depending on the task at hand, meaning understanding the difference before making the purchase is crucial in deciding on the correct type of engraver. This guide is tailored to help you weave through the basics of all three types of lasers, which are some of the most popular. We will help you with everything from material compatibility to cost-effectiveness, ensuring you receive all the relevant information tailored to your requirements.

What are the Main Differences Between CO2 Laser, Fiber Laser, and Diode Lasers?

- CO2 Laser

Best For: , engraving and marking the non-metallic components which include wood, glass and acrylic.

Strengths: The laser’s exceptional accuracy and efficiency on non-metal and organic materials.

Limitations: Maintenance metals are more complex than other types of lasers.

- Fiber Laser

Best For: Engraving, marking, cutting metals, and plastics.

Strengths: Performance on metals, high power efficiency, and low maintenance.

Limitations: Tending to wood and organic components is not ideal.

- Diode Laser

Best For: It is designed for engravers who prefer small scales and also cut thin pieces of paper and fabric.

Strengths: Cost-effective, small size and ease of use make it perfect for beginners.

Limitations: Not suitable for metal works or heavy-duty tasks due to lower power output.

Understanding the Basics of Each Type of Laser

- CO2 Laser

CO2 lasers offer robust performance suited for industrial or artistic work. They work by energizing a carbon dioxide gas mixture, producing a high-energy beam. They are very versatile and can cut and engrave various materials, such as wood, glass, and leather.

Performance: CO2 lasers are highly efficient in nonmetallic materials such as wood, glass, and leather because their wavelength is approximately 10.6 micrometers. Moreover, they have a smaller spot size, which improves precision during intricate cuts and engravings.

Application: They are widely used in wood and glass signage, engraving, and manufacturing. Their uses extend into the medical field, where they are used for dermatological purposes like skin resurfacing or surgical procedures.

Power Range: They are commonly used in a variety of applications. CO2 lasers can produce 30W for detailed tasks, while industrial-grade projects can go beyond 400W.

Efficiency: They have a higher optical-to-electrical efficiency, which means that CO2 lasers waste less energy than other laser types.

- Fiber Laser

Fiber lasers are easily used to cut and mark metals due to their unmatched power and reliability. They possess optical fibers doped with rare elements such as erbium or ytterbium, amplifying light into a potent and concentrated output.

Performance: Capable of operating at around 1.064 micrometers, fiber lasers are pretty powerful when it comes to cutting and engraving metals such as stainless steel, aluminum, and even brass.

Applications: Fiber lasers are commonly used across various sectors, such as aerospace, automotive, electronics manufacturing, and even jewelry. They also provide precision for more delicate tasks like micro-marking and engraving.

Power and Speed: Fiber lasers generally operate between 20W and 30kW. They can rapidly cut or deeply engrave metal, and their processing speeds are also higher compared to other lasers.

Durability: Maintained at lower levels due to fewer movable parts and a closed-loop design, longevity is operationally increased while maintenance is reduced.

- Diode Laser

Diode lasers offer entry-level users and hobbyists a compact and cost-effective option. Their lightweight makes them ideal for small projects and projects on the go.

Performance: Diode lasers are best suited for softer materials like wood, paper, fabric, and plastic. They can emit wavelengths from 0.8 to 1.2 micrometers.

Applications: Ideal for educational purposes, personalized gifts, and even DIY projects.

Power Output: Because they are available in lower wattages, set in a range of 1W to 10W, they are unsuitable for heavy-duty tasks and thick materials.

They are cost-effective and straightforward to operate, making them ideal for novices entering the laser engraving and cutting world.

These types of lasers demonstrate unique advantages and disadvantages focused on particular uses. The right choice for each is based on the project’s needs, the material’s nature, and the needed accuracy.

How Do CO2 and Fiber Lasers Compare?

The comparison between CO2 lasers and fiber lasers shows considerable differences in areas such as performance, versatility, and practicality due to some key factors:

- Materials and Wavelength: CO2 lasers excel at non-metal materials like wood, acrylic, glass, leather, and fabrics due to their longer wavelength of around 10.6 µm. Fiber lasers operate at a much shorter wavelength (approximately 1.06 µm); thus, they specialize in marking, cutting, and engraving metals like stainless steel, aluminum, brass, and some plastics.

- Speed and Efficiency: CO2 lasers have slower processing speeds than fiber lasers due to the latter’s high energy density and focused beam, which ensures efficiency, especially when working with thin or highly reflective materials like polished metals.

- Fiber lasers have a more robust construction, which makes them low-maintenance. Their lack of moving parts or mirrors in the laser source contributes to longer lifespans, reaching up to 100,000 hours. CO2 lasers, on the other hand, while effective, require more regular maintenance, such as mirrors and gas-filled tubes.

- Power and Cost Efficiency: Fiber lasers are more energy-efficient than CO2 lasers as they consume less power. This results in lower operating costs over time, even though the initial investment for a fiber laser is higher. CO2 lasers, however, tend to have a lower budgetary requirement upfront, making them easier for small-scale applications or primary-level use.

- Cutting Thickness: CO2 lasers excel at cutting thicker non-metal materials and some metals with gas (such as oxygen) moderation. Fiber lasers, on the other hand, cut and shear thinner metals at excellent quality and speed. Still, their performance on thicker materials is hindered by problems with heat dissipation.

Ultimately, the case scenario drives the selection of CO2 and fiber lasers. CO2 lasers are a dependable solution for engraving or cutting many non-metal materials. On the other hand, industries that deal with high precision, speed, and performance with metals are best suited with fiber lasers.

Pros and Cons of Diode Lasers

The widespread acceptance of diode lasers can be attributed to their small dimensions, high levels of efficiency, and reasonable costs. Please look at the main advantages and disadvantages of diode lasers mentioned below:

- Pros:

Affordability: Diode lasers are less expensive to manufacture and maintain. This saves a lot of money for small companies and hobbyists alike.

Wide Versatility: Diode lasers can serve several functions, including engraving, marking, and even cutting thin pieces of wood, fabric, and plastics.

Reliability and Longevity: Because these lasers operate with fewer mechanical parts, they are more durable. Their service life can often reach tens of thousands of operational hours.

Energy Efficiency: These lasers are very cost-effective because they have a high electrical-to-optical conversion efficiency rate, often exceeding fifty percent. This also means that they perform consistently while reducing operating costs.

Compact and Lightweight: Unlike CO2 and fiber lasers, diode lasers are much smaller and heavier. This makes integrating them into portable devices and compact machining systems easier.

- Cons:

Limited Power Output: Diode lasers have a much lower maximum poweroutput than CO2 and fiber lasers. This limitation makes them unsuitable for cutting or engraving thicker and more durable materials.

Diode lasers are less efficient for metals and reflective materials due to their particular absorption characteristics.

Unlike fiber lasers, diode lasers are less precise in efficiency-critical applications due to beam quality limitations.

Diode lasers can operate with the right scalar cooling systems; however, when these are needed to prevent system overheating during extended runtime, other configurations can become complex.

Despite the disadvantages of small-scale power output and material versatility, as well as the exposed limits of their use in heavy industrial tasks, diode lasers are a reasonable selection that optimizes cost and energy efficiency for light to medium-duty workloads.

Which Laser Engraver is Best for Engraving Metal?

Fiber laser engravers are considered the best available option for engraving metal. They have specialized capabilities for engraving different metals, such as stainless steel, aluminum, brass, and titanium. The fiber laser, with its highly powered and accurately focused beam, can perform deep and precise engravings that are sharp and clean, even for small, detailed engravings. In addition to excellent engraving quality, fiber lasers are efficient, durable, and, therefore, useful for industrial and small-scale work. A fiber laser engraver will offer the best trade-off between speed, quality, and reliability for engraving.

Can You Engrave Metal with a Diode Laser?

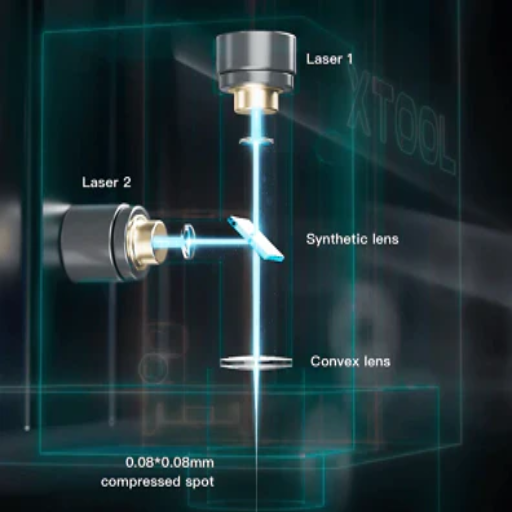

Although a more practical and inexpensive option, engraving metal directly with diode lasers is unusual. This is often the case because their power level is low, and the metallurgy offers insufficient absorption of metals. Most diode lasers use a 445-nanometer wavelength, which is bound to face challenges due to metal glare. With a unique technique or applied coating, certain metals can be engraved. Diode lasers, for example, can be pre-treated with marking spray, which significantly increases marking capability and is thus able to make certain metals engravable using the proper technique.

Of equal importance is the diode laser’s power. High-power diode lasers- those over 10 watts- are likely to be capable of better marking (albeit slowly and less accurately when compared to fiber lasers) on softer metals like aluminum. In other words, these softer materials will indeed outperform more rigid materials. This difference often renders the subtle performance decline in dual laser configuration less preferable for professional or industrial-grade engraving. Despite their disadvantages, diode lasers are still the most dominant type for nonmetallic materials like engraving wood, acrylic, and plastic due to the ease of operation they grant users.

Best Practices for CO2 Laser Engraving

CO2 laser engraving can be used extensively across different industries on non-metal materials such as wood, glass, leather, acrylic, and even fabrics. Ensure that these guidelines are closely followed to achieve the best results:

- Choosing the Right Material

Ensure the material you want to engrave suits a CO2 laser system. Appropriate materials include untreated wood, natural leather, and specially designed laser-safe plastics. Avoid materials such as PVC, which releases toxic fumes when engraved.

- Adjusting Power and Speed Settings

Proper power and speed settings are necessary for clean and precise engravings. Felt, for instance, requires lower power and higher speed to prevent burning, but hardwood would need higher power and slower speed to achieve depth. Always test a small section of scrap material before starting the final engraving.

- Using High-Resolution Artwork

Your engraving can only be as good as your design file. Vector files containing intricate details are better for engraving, so SVG or AI formats are recommended. If you seek sharp results, use high-contrast images with at least 300 dpi for photo-engravings.

- Focus the Laser Properly

In the engraving process, the precision of the laser beam needs to be focused correctly, as it impacts the overall results. Most CO2 laser systems are designed with focusing accessories or have automatic focusing capabilities. Verify the focus distance for your specific laser lens type since improper focus will always lag, blurring the finish and causing unequally defined engravings.

- Ensure proper ventilation

The engraving process generally creates smoke and noxious fume byproducts that are visually obscuring and pose safety concerns in a work environment. With these in mind, ensure the workspace has appropriate circulation and an external ventilation system or air purifier to capture and destroy harmful particulate and chemical matter.

- Optimize raster and vector settings.

Configure setting combinations for each contour cut, such as pieces of raster engraving, vector engraving, or both. Artistic engravings and text are raster, while contours and other cut-through editing are done through vector cutting. By doing so, efficiency is bolstered, as wasted material is minimized.

- Routine Maintenance for your Laser Machine

For optimal results, the mirrors, lens, and exhaust system of a CO2 laser should be periodically cleaned. Their neglect would lead to a build-up of dust and debris, which would negatively affect the power of the laser, as well as the precision of the engraving. It is recommended to follow the guidelines of the manufacturer’s maintenance schedule to achieve constancy.

Following these best practices will improve the quality, accuracy, and efficiency of your CO2 laser engraving projects.

Why Choose a Fiber Laser Engraver for Metal?

A fiber laser engraver is a top choice for metal engraving because of its technology and efficiency. Fiber lasers have a different wavelength than CO2 lasers, typically 1064 nm, which enables them to effectively mark and engrave metals like stainless steel, aluminum, brass, and titanium. These machines achieve and transmit markings of the utmost detail, be it for serial numbers, intricate designs, or even barcodes.

Fiber lasers’ outstanding advantages are their speed and cost-effectiveness. They engrave faster than traditional methods, reducing production cycles and increasing total output. According to industry data, they outperform CO2 lasers by up to 10 times in specific metal applications. Due to their robust and compact design, fiber lasers also require minimal maintenance. The laser source often exceeds 100,000 operational hours and adds to the device’s long-term value.

Fiber laser systems are compelling because of their eco-friendly attributes. With up to 50 percent higher energy efficiency, they help reduce operating costs and lower power consumption. The non-contact engraving process further adds to the reduced material waste, maintaining the durability of the engraved design since it is embedded into the metal surface.

In sectors like aerospace, automotive, and consumer goods manufacturing, fiber lasers provide multifunctional applications that yield exact, repeatable, and quality-compliant results. From deep engraving to marking in high contrast, fiber laser engravers serve as dependable and highly effective devices for accomplishing tasks.

How to Choose the Right Laser for Your Needs?

Determining the correct laser for your requirements is predicated on understanding your specific application and the various types of lasers available. Here are the essential factors to assess:

- Compatibility with Materials

Evaluate the range of materials you will incorporate, including metals, plastics, woods, or ceramics. It isn’t easy to surpass fiber lasers’ efficiency for metal marking or engraving due to their high energy density. On the other hand, CO₂ lasers are usually preferred when working with non-metal materials such as wood, paper, and some grades of plastics.

- Power Output

Laser power must be taken into account as it influences the ease of engraving and cutting different materials. For instance, 20W to 50W fiber lasers are perfect for light engraving and marking, but deeper engraving and cutting thicker materials require higher power, such as above 100W. The same observation applies to non-metal CO₂ lasers that range from 30W to 150W.

- Speed and Precision

The level of detail and speed required in a process also significantly influence it. Fiber lasers are known for their precision and speed, which is helpful in small designs or mass production. Other systems that utilize advanced galvanometer scanning technology also claim to achieve higher speed and accuracy.

- Application Requirements

Determine the type of laser you need, be it for engraving serial numbers on metal parts, cutting intricate wooden designs, or high-contrast marking of surgical instruments. Each laser excels in certain areas, so it is vital that all intended applications are matched with the correct type of laser.

- Operating Costs and Maintenance

Fiber lasers, for example, operate at a lower cost and only need minimal upkeep thanks to their solid-state design and long life, which is often over 100,000 hours. On the other hand, some CO₂ lasers come with recurring expenses such as required tube replacements and higher maintenance, which, under frequent upkeep, add expenses to long-term value.

- Workspace and Size Constraints

Consider the dimensions of this laser machine against the space available at your workstation. While bigger machines offer higher versatility in project sizes, more compact models are available without sacrificing functionality.

- Budget

Lasers are priced differently and may start from a few thousand to high-end industrial systems exceeding $100,000. Ensure that your budget makes sense while having the selected laser provide the required performance, durability, and value expectations.

- Safety Features

Look for isolated working zones without exposure to the laser, automatic shutdowns, and proper ventilation so toxic fumes do not harm the user. Raising the enclosed user area greatly shields the operator from damage, making safety an overriding issue.

As the reports indicate, the global laser engraving market is expected to grow at a compound annual growth rate (CAGR) of 7.6% from 2023-2030. This growth is propelled by the surge in custom marking demand in the aerospace and medical industries and the use of lasers to add eco-friendly manufacturing practices. A good share of this growth is from fiber lasers due to their energy-efficient nature and versatility.

All these factors, taken into consideration along with the prevailing market trends, would optimally help you decide on the right laser for your needs in terms of quality, efficiency, and investment returns.

Factors to Consider When Selecting a Laser Engraving Machine

To ensure efficient performance, a well-rounded laser engraving machine must meet specific requirements for power, technology, and work area. The following are some crucial factors that should be considered before selecting.

- Power and Wattage

Determining the speed at which a laser can cut through or engrave materials depends on the wattage power level. Light engraving tasks that deal with soft materials like wood do best with 20 to 50-watt lasers, while denser materials like stone require higher-watt laser engravers that cut at 150 watts or more.

- Type of Laser Technology

CO2, fiber, or diode lasers all serve a different purpose. If you work with wood, leather, and plastic, CO2 laser engravers would be best. On the other hand, fiber lasers are better for engraving metal and advanced markings on harder surfaces.

- Work Area Size

The work area should be appropriately scaled based on the projects that must be completed. For extensive commercial projects, bigger bed sizes like 24” x 36” are ideal, while limited compact spaces require smaller models.

- Precision and Speed

The sophisticated laser engraving machines available today provide precision that surpasses 0.001 inches and speed measured in mm/s, aligning the machine with intricate patterns and designs. Productivity maximization, particularly with filler orders, relies heavily on speed defined in mm/s

- Material Compatibility

No machinery is suitable for every material. Evaluate the primary materials that form the basis of your project, whether it is wood, acrylic, paper, or even metal, and check if the machine handles that material. Some high-end models have different settings that allow them to switch between materials.

- Software and Usability

Software applications help modern engraving machines streamline their operations. Buy a machine that accepts popular design software file formats such as DXF, AI, and SVG. Material-specific design software eases the process and eliminates the need for multistep materials learning.

- Costs and Maintenance

The costs associated with buying and maintaining should be considered carefully. The starting cost for beginner machines is in the hundreds, while commercial machines might be over $10,000. Don’t forget to evaluate ongoing expenses such as paying for replacement components, routine servicing, and periods of inactivity.

- Safety Features

Features such as enclosed designs, emergency stop buttons, and appropriate ventilation systems that control hazardous light, fumes, and heat, as well as laser light exposure, are crucial.

- Trends in the Market and New Advances

The laser engraving industry does not stand still. Recent trends include the advancement of eco-friendly operations, improvements in the efficiency of fiber laser technology, and enhancements in smart automation systems that improve precision and reduce the need for human input.

Considering all of these crucial factors will help you select a laser engraving machine that meets your project specifications and will add value to your workflow for years to come.

Are Diode Lasers Suitable for Small Business Use?

The relatively low price of diode lasers, their small size, and their versatility have made widespread adoption of technology by small businesses easier. They are particularly useful in engraving and cutting delicate and thin wood, acrylic, plastic, leather, and similar materials, including crafting items, personalization gifts, or small-scale factory items.

Compared to CO2 and fiber lasers, lower-priced options such as diode lasers offer a wider range of benefits. A small operation or a startup with limited funding can purchase entry-level models that range from $200 to $1,000. Cost isn’t the only saving offered by these models. Electric power consumption is relatively low compared to other types of lasers, which saves on operational costs, and many designs tend to be user-friendly, requiring fundamental training, which further increases the level of savings for businesses with one or two operators.

Diode lasers are also very precise with detailed designs and can achieve engraving resolutions as high as and between 1,000 and 5,000 DPI, depending on the model used. However, These models should not be used for cutting thick materials or heavy-duty industrial tasks, for they contain a low power output of 3W to 20W.

From the perspective of small businesses trying to venture into custom goods, diode lasers provide a unique combination of cost-effectiveness, usability, and dependability, indicating that they will offer suitable returns on investment for laser engraving and marking work in low—to medium-production environments.

Efficiency Comparison of CO2 vs Fiber Lasers

When it comes to industrial applications, lasers, whether CO2 or fiber, need to be efficient, among other factors. A CO2 laser uses a carbon dioxide, nitrogen, and helium gas mixture, while a fiber laser uses a doped optical fiber as its lasing medium.

Power Efficiency: CO2 lasers are less energy-efficient than fiber lasers. The former operates between 10-15% efficiency while the latter consumes 25-30% of energy, allowing the fiber lasers to do more work at lower energy costs. In industrial settings where the input power needs to be sustained, the energy savings from greater fuel efficiency can result in lower expenditures.

Material Versatility: Non-metallic materials such as wood, plastics, and acrylic can easily be cut using CO2 lasers, which is why they are used in the signage and crafts industries. Marking and engraving metals, including reflective metals such as copper and aluminum, is easier with fiber lasers, which makes the devices useful in the industrial fabrication and manufacturing sectors.

Maintenance and Lifespan: Fiber lasers frequently need less maintenance because their solid-state structure does not contain moving components or mirrors. On the other hand, CO2 gas tube lasers, because of their gas reliance, often have more extraordinary maintenance expenses as parts might need to be replaced occasionally. Compared to CO2 lasers, fiber lasers have approximately 100,000 operational hours, about 80,000 more than the latter’s 20,000, demonstrating a significantly longer life span.

Speed and Precision: Compared to CO2 lasers, fiber lasers are faster and more precise, especially with fine-detail work. Their capability to focus beams into smaller points allows for clean and precise cuts. Though slower when working with metals, CO2 lasers still maintain unmatched edge quality when cutting non-metal materials.

Cost Implications: Businesses requiring high precision and laser cutting throughput will most likely benefit from fiber lasers despite the higher initial purchase cost. This is due to their significantly lower energy usage, maintenance, and increased lifespan, which provides value over time.

Deciding on a laser type still largely depends on a business’s specific requirements, including the materials being processed, production scale, and the budget allocated for both upfront costs and future operational spending. In this case, a CO2 laser would work better for businesses with lower precision requirements.

What Are the Applications of Diode, CO2, and Fiber Lasers?

Diode Lasers: These odd laser diodes have a range of applications—the use of which tends to be low-power—like scanning barcodes, medical procedures, and even communication via fiber optics. They are also helpful for engraving and marking soft metallic materials in manufacturing contexts.

CO2 Lasers: These types of lasers are also used for cutting, engraving, and welding non-metallic materials like plastics, wood, acrylic, glass, and leather. They’re especially useful for a wider array of industries, including fabrication, packaging, and signage.

Fiber Lasers: Among all types of lasers, fiber lasers are the most efficient in cutting, marking, and engraving. Due to the high demand for speed and precision in those fields, they’re the most common type of laser used in the automotive, electronics, and aerospace industries.

Common Uses of CO2 Laser Engravers

Laser engravers that employ CO2 technology are powerful tools that can be used for many purposes. These purposes include:

- Producing Signs: Creating professional signs by engraving and cutting precise details on materials such as wood or acrylic.

- Custom Designs: Personalize items by creating intricate leather, glass, and plastic designs.

- Packaging Prototyping: Constructing prototypes and layouts from paper, cardboard, or other similar materials.

- Artistic Work: Engraving, cutting, or designing wood, fabric, and other materials for creative purposes and decorative pieces.

- Industrial Work: Cutting and engraving non-metal parts used in production processes.

Such tools are necessary due to their unmatched precision and efficiency in sectors ranging from creative industries to manufacturing.

Exploring the Versatility of Fiber Lasers

Thus far, fiber lasers may achieve the precision and adaptability necessitated in various industries, as they are known to be an essential component due to the various applications they offer. Focused on metal cutting, engraving, and marking, fiber lasers fulfill the requirements of aerospace, automotive, cosplay jewelry, electronics, and other industries that demand high reliability.

Fiber lasers are utilized in a range of metals, such as titanium, brass, stainless steel, aluminum, and other alloys. This reduces energy expenditure while increasing operational accuracy due to the high-quality beams emitted and energy efficiency inherent in the devices. Compared to other systems, fiber lasers can operate 2-5 times higher within the same threshold with thin materials, further enhancing manufacturing industry productivity.

Empirical fiber lasers claim minimal maintenance for up to 100,000 working hours while offering longevity and dependability. Moreover, with the addition of air cooling systems, the devices obtain compact sizes, increasing their integration capabilities into other production lines, which ensures optimizing space usage.

Fiber laser technology opens new possibilities for complex micro-marking and engraving data codes onto metal pieces, which is essential for industries like electronics and medical devices. Because of these demands on precision and efficiency, modern material processing solutions continue to utilize fiber lasers.

Where to Use Diode Laser Technology

Surgical procedures, dermatology, and corrective eye surgeries are increasingly performed using diode lasers. At the same time, other fields of medicine also benefit from its enormous advantages of compact design and varying wavelengths. These features significantly improve patient outcomes by making them amenable to less invasive surgeries and treatment options.

The telecommunications industry also heavily relies on diode lasers for fiber-optic data transfer. These compact devices are excellent data transporters because of their reliability in long-distance communication and high-speed data transmission due to their stable performance.

Another prominent application area is the automotive industry, which uses diode lasers for welding, brazing, and cutting thin metals. With the aid of diode lasers, manufacturers can achieve clean joints and cuts that are precision-engineered to aid in the lightweight design of vehicles and boost their fuel efficiency. אונז

The compact design of diode lasers, along with their multifunctional usability and high degree of efficiency, is enabling them to be widely adopted across industries. This global acceptance closes the gap in industrial capabilities.

Energy-efficient diode laser systems used for precise plastic bonding and laser soldering bring even stronger advantages to the consumer and electronic goods manufacturing industries. As a result, precision and uniformity in the products are easily achieved.

Diode laser innovations have met the growing use of additive manufacturing technologies. Due to their high beam quality, diode lasers now have a place in material processing and 3D printing. This enables accurate construction of parts and prototypes. Industry prognoses indicate that with new high-power lasers and expanding automation across industries, the global diode laser market will experience considerable growth shortly.

Can CO2 and Diode Lasers Work Together?

Indeed, lasers of greenhouse gases CO2 and diode can be used together depending on the use-case scenario for a given task. The characteristics of these two lasers are complementary; while CO2 lasers cut and engrave non-metal objects like wood, glass, and plastic, diode lasers are better for more precise tasks such as marking, engraving, and some processes on metals. Using both lasers can increase the efficiency of processing materials and broaden the scope of raw materials utilized in manufacturing or industrial activities. For instance, some systems may employ CO2 lasers for engraving and diode lasers for precise, intricate, detailed markings, improving flexibility and competitiveness.

Understanding CO2 and Diode Compatibility

The compatibility of CO2 and diode lasers lies in combining features such as functionality and range of capabilities. CO2 lasers, with their typical wavelength of around 10.6 µm, can cut and engrave non-metallic materials like wood and acrylic due to their strong organic absorption. Conversely, diode lasers have longer wavelengths, often between 800 and 980 nm, permitting greater precision in marking or processing some metals when proper coating is used.

The recent development of hybrid laser systems has shown promise for integrating CO2 and diode technologies. For example, CO2 lasers can high-speed cut acrylic or wood while diode lasers engrave serial numbers or logos onto the finished pieces. Studies show that hybrid setups enhance operational efficiency by 30%, especially in electronics and packaging regions where precision and speed are critical.

To meet varying demands, manufacturers are progressively using dual-laser systems. Modern progress, like the automation of inter-laser synchronization software, enables switching between standby and active modes during production, minimizing energy consumption and idle time. The improvements demonstrated lower diodes and CO2 laser compliance versatility and practicality in new industrial systems.

Advantages of Using Multiple Laser Types

- Versatile Capabilities Throughout Materials

Combining CO2 and diode lasers has made it possible to process various materials, including metals, plastics, wood, and even textiles. For example, CO2 lasers are proficient at cutting non-metallic materials such as wood and acrylic, while diode lasers mark and engrave metals. This level of versatility allows manufacturers to meet various production needs with a single integrated system.

- Cost-Efficient and Maximally Productive

Having multiple laser types within one system could enhance production efficiency, reducing expenditure for various machines. In addition, shifting from one laser to another seamlessly streamlines changing set-up times, as no equipment reconfiguration is required. Studies claim that multi-laser systems across multiple processes significantly reduce operational costs by simplifying workflows and maximizing equipment usage.

- Maximal Accuracy and Precision

The strategic use of different laser types for a unique specific task helps increase precision manufacturably. For instance, diode lasers are best for highly detailed marking because they create razor-sharp borders, while CO2 lasers are proficient at cutting large surfaces accurately and cleanly. This is highly beneficial regarding material wastage and particularly helpful in high-precision industries like aerospace and electronics.

- Enhanced Productivity Through Automation

Modern laser systems have incorporated advanced automation technologies, like multi-software-enabled controls, that allow using several lasers in unison. These systems enhance productivity as multifaceted operations are completed in shorter durations. Such enhancements provide improved turnaround time and higher throughput without reducing quality.

- Sustainability Benefits

Innovations in multi-laser systems have also supported sustainability efforts. These systems are more energy efficient due to optimal energy usage and prevention of unnecessary work. Moreover, processing a broader range of recyclable materials is beneficial for sustainable manufacturing, supporting global sustainability goals.

Multiple types of lasers offer precision, efficiency, and sustainability, making them assets for industries. Such advancements continue to transform manufacturing worldwide.

Reference Sources

-

Study: “An Overview Study on the Laser Technology and Applications in the Mechanical and Machine Manufacturing Industry”1

- Key Findings: This study highlights the versatility of laser technologies in metal processing, emphasizing their precision, speed, and ability to handle complex designs. CO2 lasers are noted for their high power and efficiency in cutting and engraving, while diode lasers are praised for their compactness and cost-effectiveness. Fiber lasers excel in precision and are particularly effective for intricate designs and high-speed operations.

- Methodology: The paper provides a comprehensive review of laser technologies, detailing their principles, applications, and advantages in the mechanical industry. It also discusses the integration of lasers in Industry 4.0 for enhanced manufacturing processes.

-

Study: “Direct Diode Lasers for Industrial Laser Cutting: A Performance Comparison with Conventional Fiber and CO2 Technologies”3

- Key Findings: This research compares the performance of direct diode lasers (DDL) with CO2 and fiber lasers. While DDLs show potential for reducing operational costs, their beam quality is currently inferior to CO2 and fiber lasers. However, DDLs achieve industrially relevant cutting speeds with acceptable surface quality, making them a viable option for specific applications.

- Methodology: The study employs experimental tests on steel and aluminum using a Design of Experiments approach. It also includes an analytical model to predict and explain performance variations based on laser absorption in metals.

- Top Co2 Laser Engraving Cutting Machine Manufacturer And Supplier In China

Frequently Asked Questions (FAQs)

Q: What is the main difference between a diode laser engraver and a CO2 laser?

A: The primary difference between a diode laser engraver and a CO2 laser is their technology and application. Diode lasers are generally less powerful and suitable for marking on softer materials. In contrast, CO2 lasers are more versatile and can engrave and cut a broader range of materials, including wood, acrylic, and metals.

Q: When should I choose a diode laser engraver over a CO2 laser?

A: You might choose a diode laser engraver when working with softer materials such as wood or plastic, which requires a more affordable option. Diode lasers are also compact and portable, ideal for hobbyists and minor projects.

Q: How do I decide between a CO2 laser and a fiber laser for metal engraving?

A: When deciding between CO2 laser and fiber laser for metal engraving, consider the types of metal you will be working with. Fiber lasers are generally more powerful and efficient for marking metals and fragile materials. CO2 lasers can engrave metal with special coatings but are less effective on bare metals.

Q: What are the advantages of fiber laser engraving machines over diode lasers?

A: Fiber laser engraving machines offer a higher engraving speed and better precision than diode lasers. They are also more effective at marking various metals, including those challenging to engrave with diode technology.

Q: Can I use a diode laser engraver for laser marking on metals?

A: While diode laser engravers can mark on metals, they are generally less effective than fiber lasers or CO2 lasers. For better results on metal surfaces, especially for industrial applications, consider using a fiber laser or a higher-powered CO2 machine.

Q: What types of laser engravers are available for industrial applications?

A: The foremost laser engravers available for industrial applications include CO2, fiber, and solid-state lasers. Each type has its strengths; fiber lasers are particularly effective for metal marking, while CO2 lasers excel in cutting and engraving non-metal materials.

Q: What should I consider when buying a laser for metal engraving?

A: When buying a laser for metal engraving, consider factors such as the type of material you will work with, the engraving speed required, the power of the laser, and whether it is compatible with diode lasers or fiber lasers. Additionally, assess your budget and the specific features of the laser marking machine.

Q: What are the cost and maintenance differences between fiber and CO2 lasers?

A: Fiber lasers are generally more expensive than CO2 lasers but require less maintenance due to their solid-state technology. CO2 lasers, while less costly upfront, may require more frequent maintenance and replacement of parts like CO2 molecules.

Q: Why are fiber lasers more potent than CO2 lasers for specific applications?

A: Fiber lasers are considered more potent than CO2 lasers for specific applications because they can deliver higher energy density, allowing deeper penetration and faster engraving on metals. This makes fiber lasers a preferred choice for industrial metal marking tasks.